|

|

|

|

|

#1 |

|

Registered User

Join Date: May 2015

Location: texas

Posts: 253

|

Re: 55 Wagon Progress

amazing, beautiful, craftsmanship, more and more......

in awe. wish you or i was/were closer. i would love to learn from you.

__________________

Black 93 CCLB 3500 6.5 diesel, GV OD, TCI Ez-TCU controlled 4L80E, back on road 10/25/16 after sitting 4 years. 96 ECLB 2500, 6.5 diesel, auto, gone. |

|

|

|

|

|

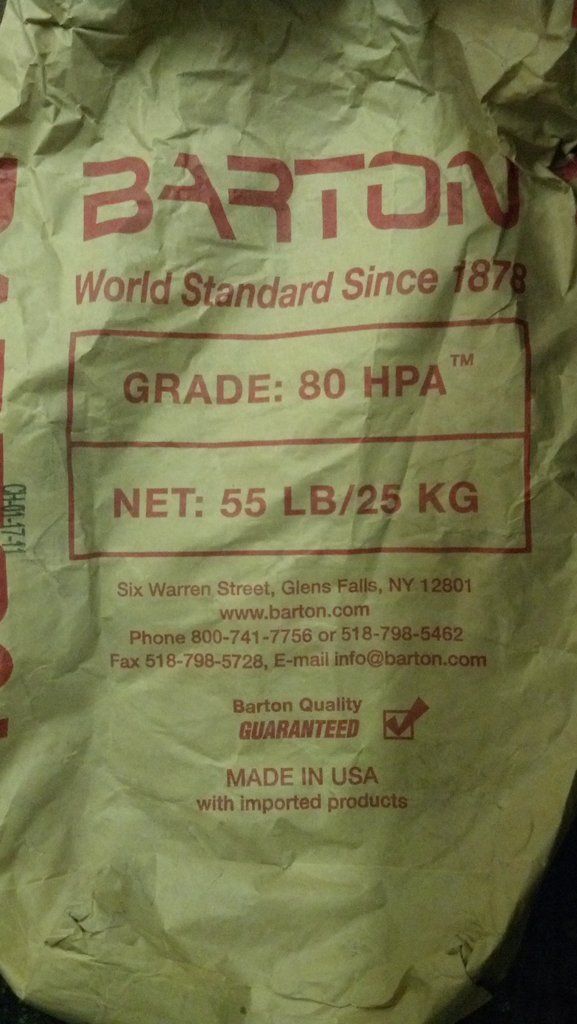

#2 |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,647

|

Re: 55 Wagon Progress

Thanks!

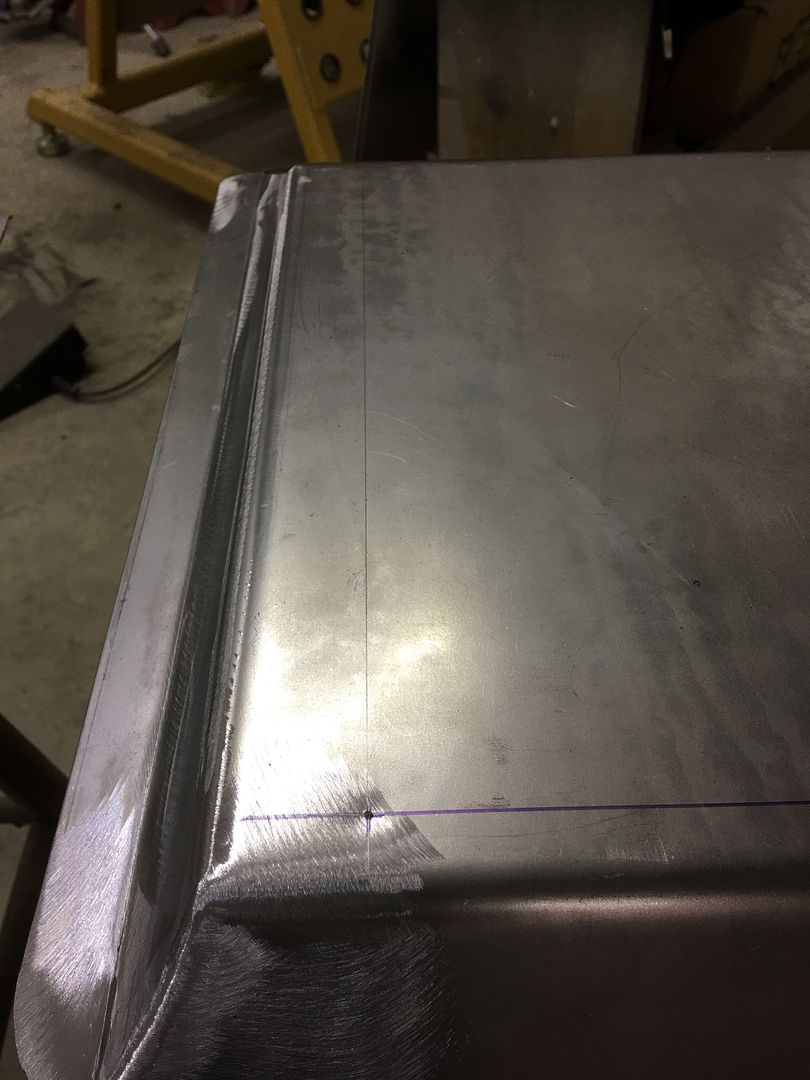

When we fabricated the quarter panel baffles we trimmed the upper profile to leave about a 1/16" gap, so that any possible body flex would be less likely to rub paint..  Plus, it gives a good anchor for the seam sealer....  Then we used masking tape to mark off the edges of the flange so we could transpose these to the wheel well for drilling plug weld holes...    Next, we have another yellow vehicle to work on. A new driver at a local high school missed seeing the bright yellow oversized vehicle as it passed, and backed into the side of it..  New filler panel was made out of 18 gauge steel, ready for some SPI epoxy..

__________________

Robert |

|

|

|

|

|

#3 |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,647

|

Re: 55 Wagon Progress

Fitting up the one piece wheel well into the passenger side quarter. Once fitted, the edge is marked with tape, wheel well removed, and the width available beneath for plug welds is noted. Then holes are punched in the wheel well to match, and it gets refitted. We started at the front so we could use vise grips to clamp, and worked progressively toward the back.

We did have a few plug welds that were contaminated from the epoxy primer, so we'll grind everything smooth, fix those areas, redress the welds and finish any bare areas with epoxy primer. One step closer to the Line-x coating on the underside... Here we are all tacked in place: https://www.youtube.com/watch?v=GuCIhFYUMXY .

__________________

Robert |

|

|

|

|

|

#4 |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,647

|

Re: 55 Wagon Progress

All plug welds completed and dressed. Now for the other side and we'll epoxy prime again..

__________________

Robert |

|

|

|

|

|

#5 |

|

Registered User

Join Date: May 2015

Location: texas

Posts: 253

|

Re: 55 Wagon Progress

that thing is looking jam up and jelly tight.

__________________

Black 93 CCLB 3500 6.5 diesel, GV OD, TCI Ez-TCU controlled 4L80E, back on road 10/25/16 after sitting 4 years. 96 ECLB 2500, 6.5 diesel, auto, gone. |

|

|

|

|

|

#6 |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,647

|

Re: 55 Wagon Progress

Thanks!

Tonight we worked on getting the driver's side wheel well installed. To help eliminate the contamination issue from the close proximity of the primer, we used these piloted burnishing brushes to remove the paint around the plug weld holes on both front and back sides...  That did the trick, no volcanoes this time...     Next we'll need to dress these welds and epoxy prime the bare spots. In the meantime, a test fit of the bucket seats. We're going to need to make some adapter brackets to weld to the floor, I don't think the wood one is going to fly...

__________________

Robert |

|

|

|

|

|

#7 |

|

Registered User

Join Date: Dec 2011

Location: Morris, Alabama

Posts: 184

|

Re: 55 Wagon Progress

That burnishing brush is the ticket! I've never seen one before but that is a great idea and makes a much nicer area than the 2" roloc I've always used.

|

|

|

|

|

|

#8 |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,647

|

Re: 55 Wagon Progress

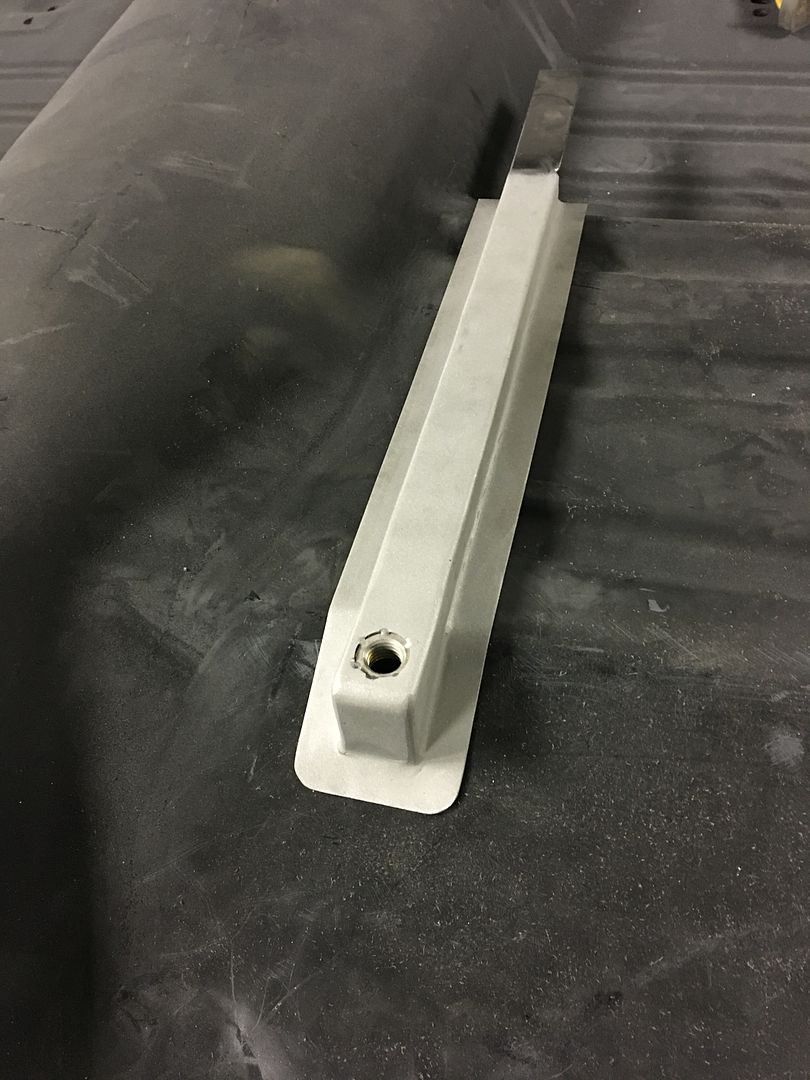

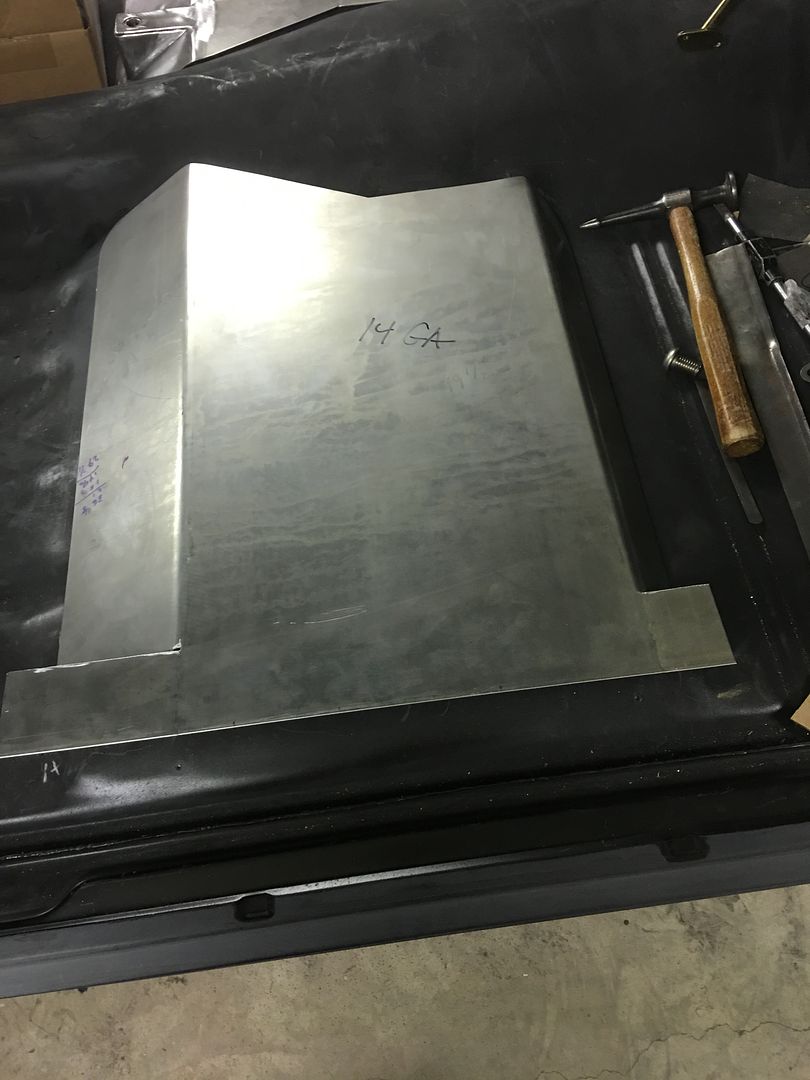

Here's the path we took on the seat risers....it's been a while now that GM has used wood in the vehicle, no sense in us bucking that trend! Started by fabbing up some 14 gauge steel into a hat section and left some longer ears on the ends to fold down and close the ends off..

Stainless hex nut welded inside for the seat frame hardware..  Missed getting these pics on the other end, but cardboard templates were transposed to steel fillers, cut out and welded in place, along with the flanges around the perimeter.   We plan on finishing the inner risers up this evening and leveling the seats across for sizing the height of the outer risers. Finished up the plug welds on the driver's wheel well. We'll get a few more parts prepped for epoxy and address those bare spots at the same time.

__________________

Robert |

|

|

|

|

|

#9 |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,647

|

Re: 55 Wagon Progress

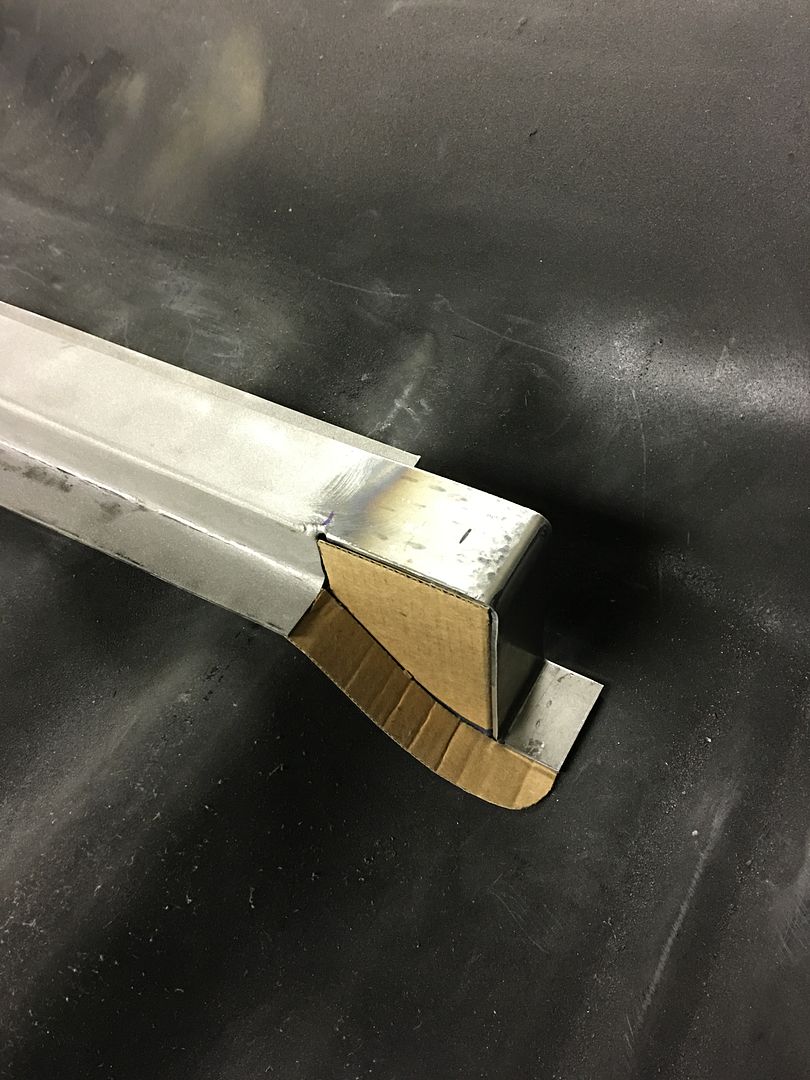

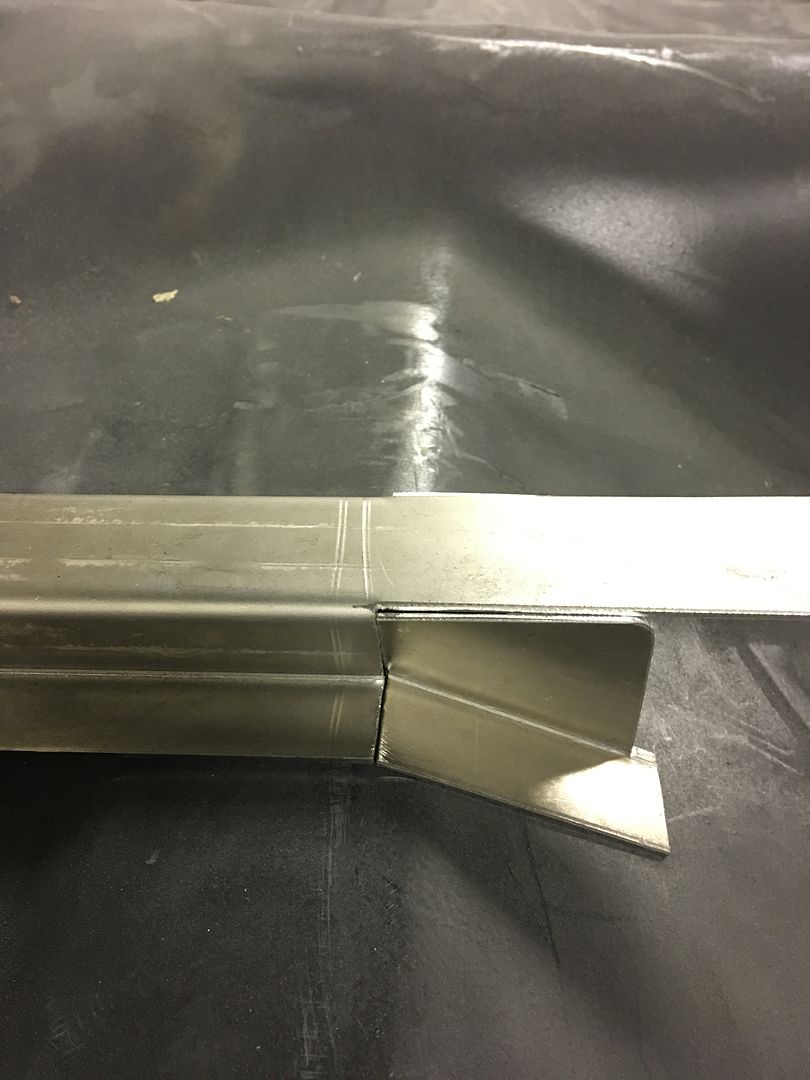

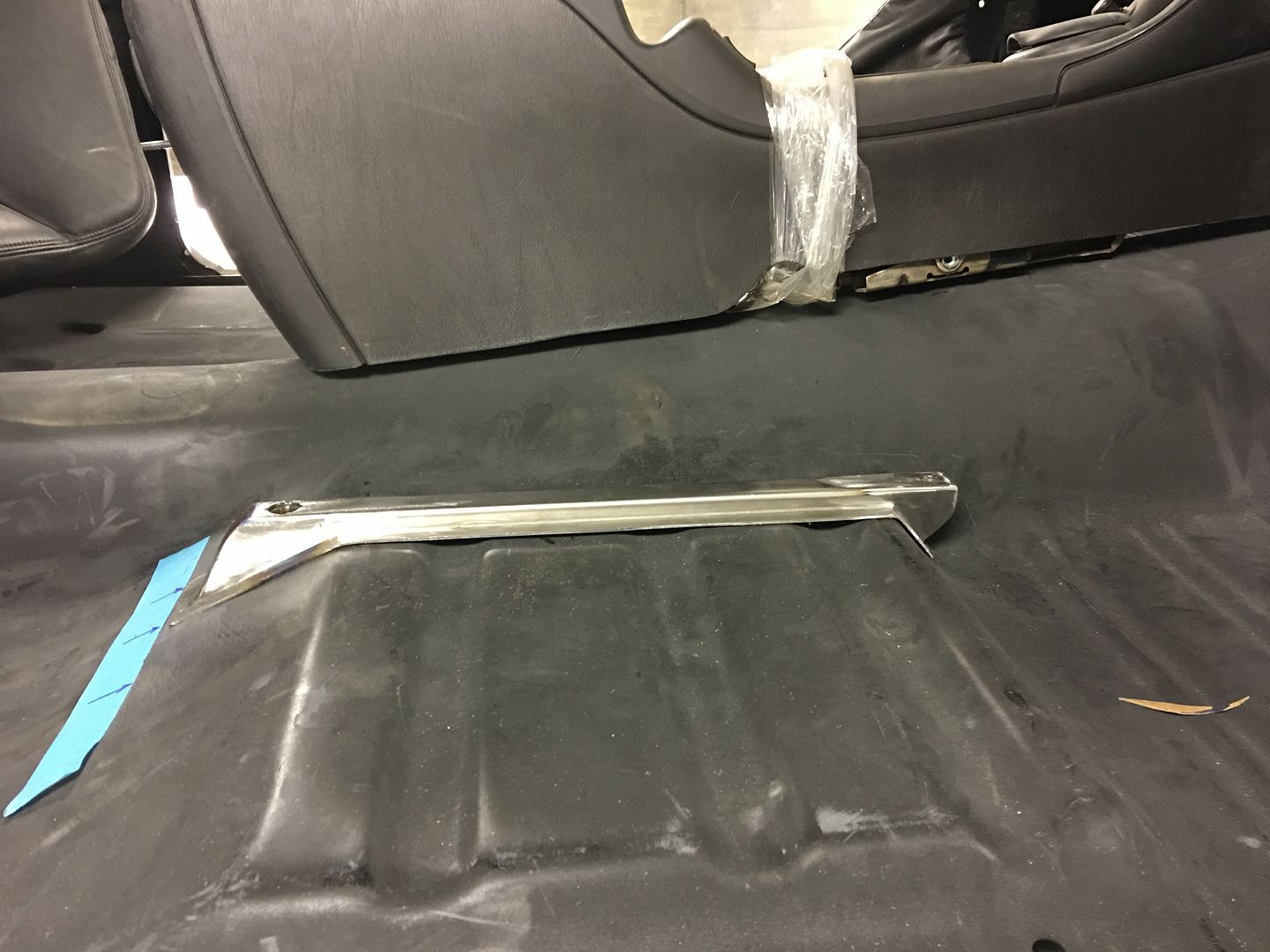

Seat riser bracket number two fabrication, got more detail pictures this time..

Used the Tipping die in the Lennox to thin out the crease line, makes for a more crisp bend, especially given the 14 gauge steel we're using...    After bending in the Diacro manual press brake using the gooseneck die...  Fitting and trimming the end transitions while matched to the floor...  Ready for the TIG

__________________

Robert |

|

|

|

|

|

#10 |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,647

|

Re: 55 Wagon Progress

OK, so sometimes you take another look and think yeah, we can do better than that. Today the passenger bucket seat was test fit onto our riser. It could be brought a bit tighter to the floor.

Next, looking at the cross member, the rear flange (red arrows) didn't match up to the rear flange of our riser.  The blue tape shows the rear flange of the cross member below...  Here's our updated riser, half as tall, and once trimmed the flange will match to above the cross member..

__________________

Robert |

|

|

|

|

|

#11 |

|

Registered User

Join Date: Apr 2011

Location: .

Posts: 3,104

|

Re: 55 Wagon Progress

That is cool,

Make a more awesomer' bracket after making an awesome seat bracket and it fits the underside better. Totally in aw |

|

|

|

|

|

#12 |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,647

|

Re: 55 Wagon Progress

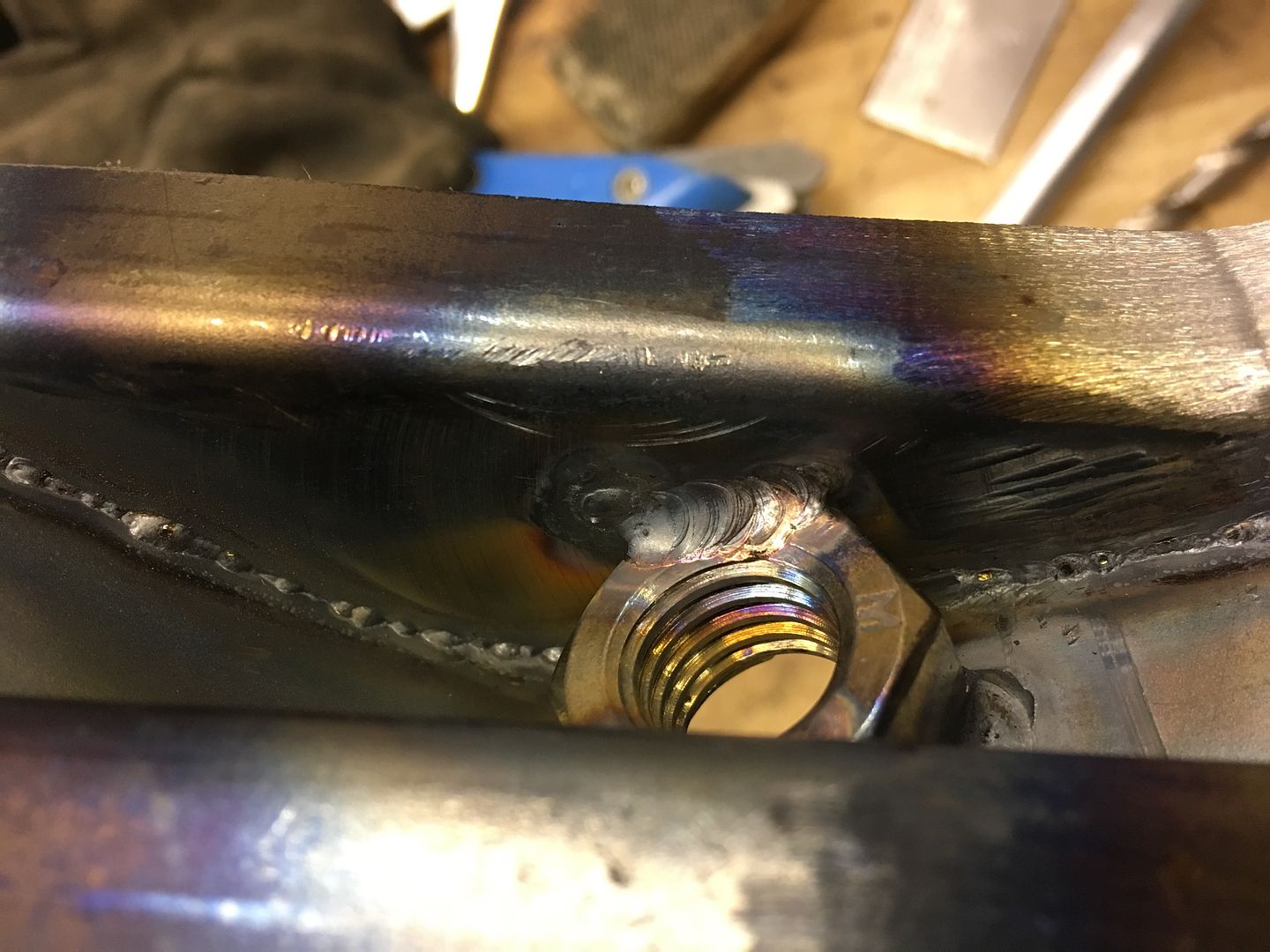

Thanks Bomp!

More details on the seat risers, here the 5/8-11 hex nut is welded inside. The tacks at the top are merely to hold it centered within the hole to maintain our correct C-C hole spacing. It gets welded inside as well to keep things anchored in place.    The 5/8 hardware was chosen as the factory seat bracket on these 2002 Monte Carlo seats had a hole that large existing already. The front of the seat bracket actually had another bracket underneath that was held in place with a solid rivet. We drilled out the rivet to remove the obstacle (so the rail was flat across the bottom), and opened the hole up for 3/8 hardware. Test fit....     Still need to fill in the flange corners on the front and this one will be ready for SPI epoxy primer to coat all the surfaces before it gets welded in place..

__________________

Robert |

|

|

|

|

|

#13 |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,647

|

Re: 55 Wagon Progress

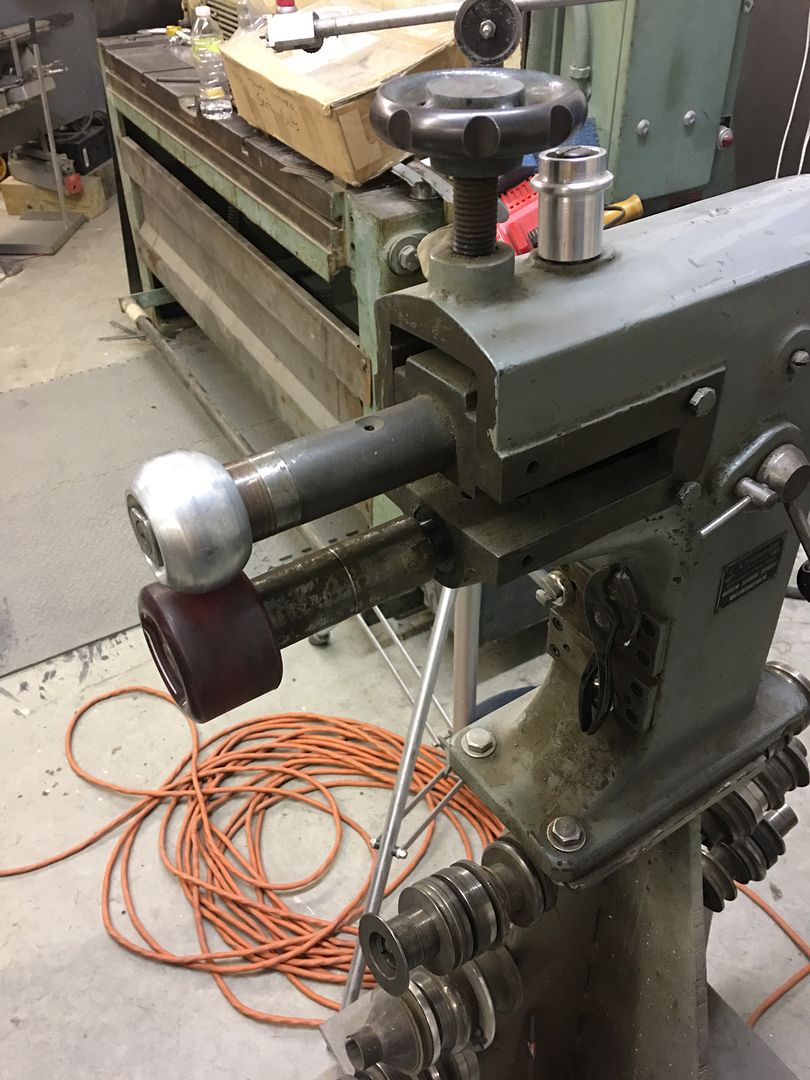

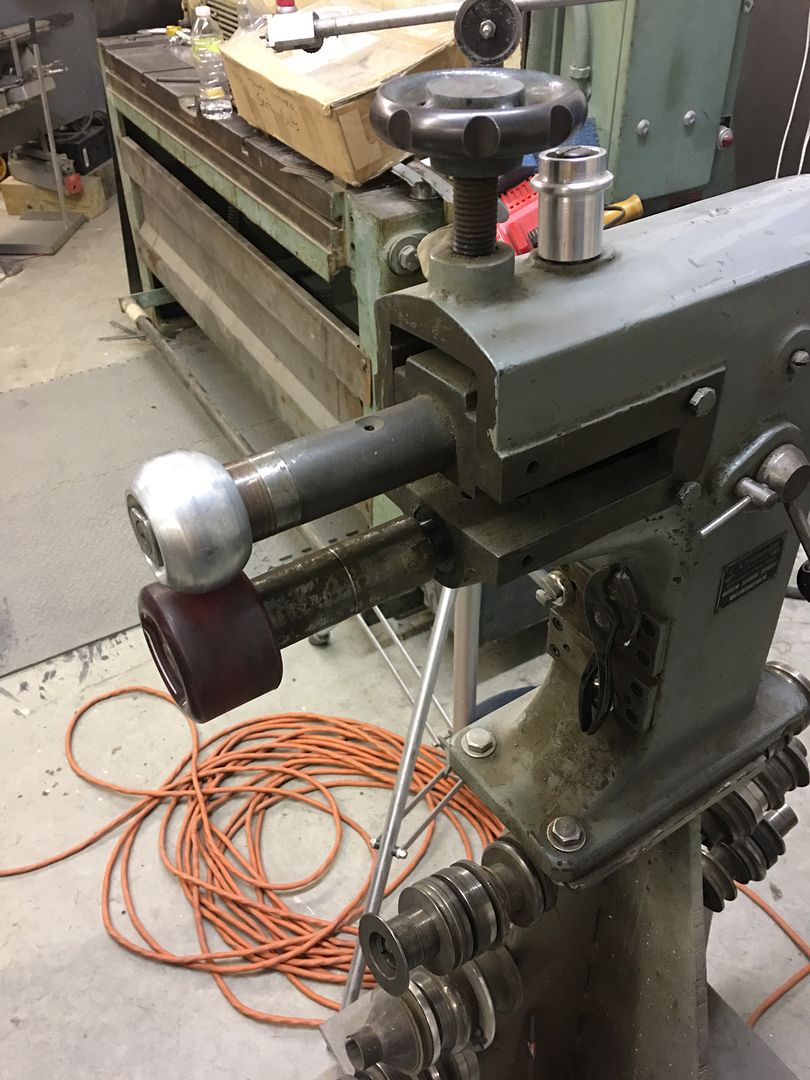

Moving on to the outer risers, these ones will be a bit taller due to the recess where the original seat frames bolted. We started out with using the tipping die in the Lennox to thin the 14 gauge cold rolled steel at the bend line for a more crisp bend.

https://www.youtube.com/watch?v=OKFZqnHb9eY Next, after making the inside bends, the Fasti-werks bead roller is used with a skate board wheel to add a radius to the outer "leg" of the riser.      Next time in the shop we'll get the ends closed up.....

__________________

Robert |

|

|

|

|

|

#14 |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,647

|

Re: 55 Wagon Progress

Moving on to closing up the ends of the outer seat riser... Quite a bit of stretch to get this corner to match up to the seat riser...

https://www.youtube.com/watch?v=wzorB_hwLZM Then the corner was Tig welded in place and another test fit with the bucket seat.. https://www.youtube.com/watch?v=kf-X5eHc5bE

__________________

Robert |

|

|

|

|

|

#15 |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,647

|

Re: 55 Wagon Progress

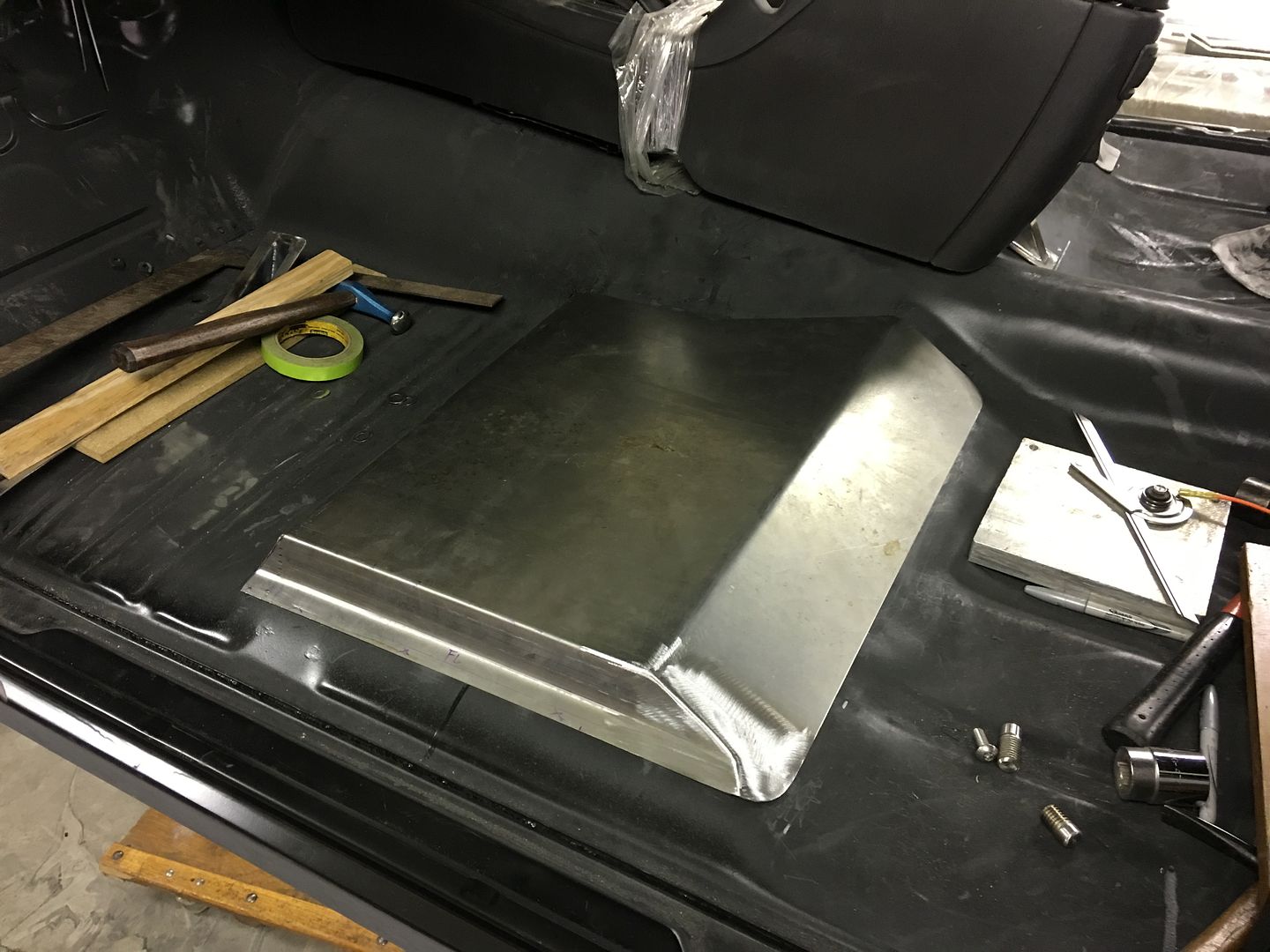

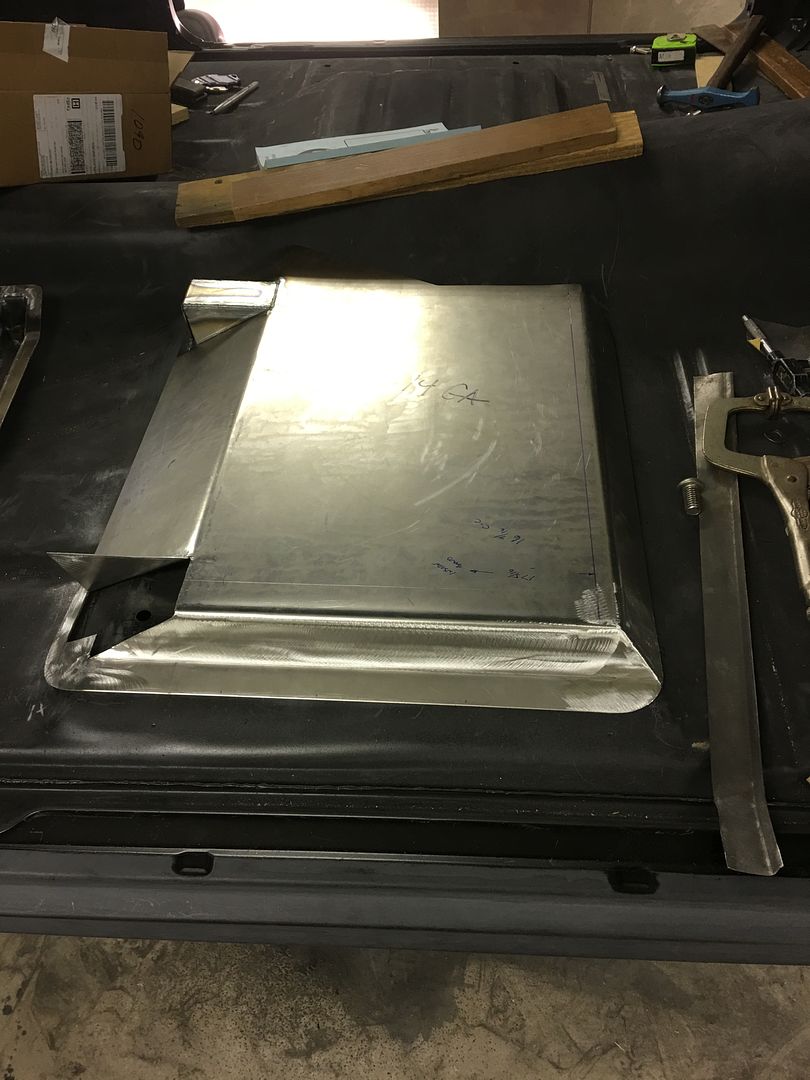

Well, let's back up and punt one more time. The owner of the 55 stopped by about a week ago and sat in the mocked up bucket seat. She said it sat too high, so our version 2 seat brackets were out. Cutting the floor pan was over-ruled (for recessing the brackets) so we opted for a 14 gauge flat seat pan directly on top of the floor, which also gave us a shape we could eliminate the "step" in the floor.

https://www.youtube.com/watch?v=JYklSvTtTTQ https://www.youtube.com/watch?v=CfWqQyOeXJo Next is to add the wedges to the rear ramp for attaching the rear of the track slides...

__________________

Robert |

|

|

|

|

|

#16 |

|

Registered User

Join Date: Dec 2011

Location: Mobile, Alabama

Posts: 996

|

Re: 55 Wagon Progress

The youtube videos are a nice touch. Thanks!

__________________

My Build - http://67-72chevytrucks.com/vboard/s...d.php?t=515876 |

|

|

|

|

|

#17 |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,647

|

Re: 55 Wagon Progress

Thanks!

Final design on the bucket seat brackets... and owner approved today as well. One down, one to go.. This is made from 14 gauge cold rolled steel and puts the seat about as low as we can go without cutting the floor pan.. Video of the seat bracket: https://youtu.be/YF7LOe7eLTQ Seat test fitted:

__________________

Robert |

|

|

|

|

|

#18 |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,647

|

Re: 55 Wagon Progress

Don't think I showed this on the other side, but here's how we find the center of the bend for dimensioning the seat bracket..

Bent up and a test fit...  Relief cuts made for the next fold.....

__________________

Robert |

|

|

|

|

|

#19 |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,647

|

Re: 55 Wagon Progress

.....then rolled through the bead roller

and then the brake is used to fold the outer flange. Here, all welded in place...  The front hole pattern is laid out to match the drivers bracket, and then some perpendicular lines laid out for locating the rear risers...

__________________

Robert |

|

|

|

|

|

#20 |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,647

|

Re: 55 Wagon Progress

Got a new apprentice that started this past Saturday.. Her mom even thought it was a good idea!

She's getting the driver's seat bracket all prepped for SPI epoxy primer, while I worked on finishing the passenger bracket..

__________________

Robert |

|

|

|

|

|

#21 |

|

Registered User

Join Date: Apr 2011

Location: .

Posts: 3,104

|

Re: 55 Wagon Progress

Great seeing them young ones interested.

|

|

|

|

|

|

#22 |

|

Registered User

Join Date: Jan 2012

Location: Whitesboro, Texas

Posts: 932

|

Re: 55 Wagon Progress

What kind of media are you using in your blast cabinet?

__________________

Cheers - Wayne Our Shop Build - http://67-72chevytrucks.com/vboard/s...d.php?t=620966 '55 Wagon Build - http://67-72chevytrucks.com/vboard/s...d.php?t=689157 1971 Cheyenne Super Ochre/White LWB 350 Auto - my son's truck "Nancy" 1972 GMC K2500 Custom 4X4 Olive LWB 400 SB 4-speed -"Greenie" - Restoration to begin after the '55 Nothing sucks more than that moment during an argument when you realize you're wrong. |

|

|

|

|

|

#23 |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,647

|

Re: 55 Wagon Progress

It's actually made for water jet machines, get it from a local machine shop.. Also use the 80 grit garnet that tractor supply carries.

__________________

Robert |

|

|

|

|

|

#24 |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,647

|

Re: 55 Wagon Progress

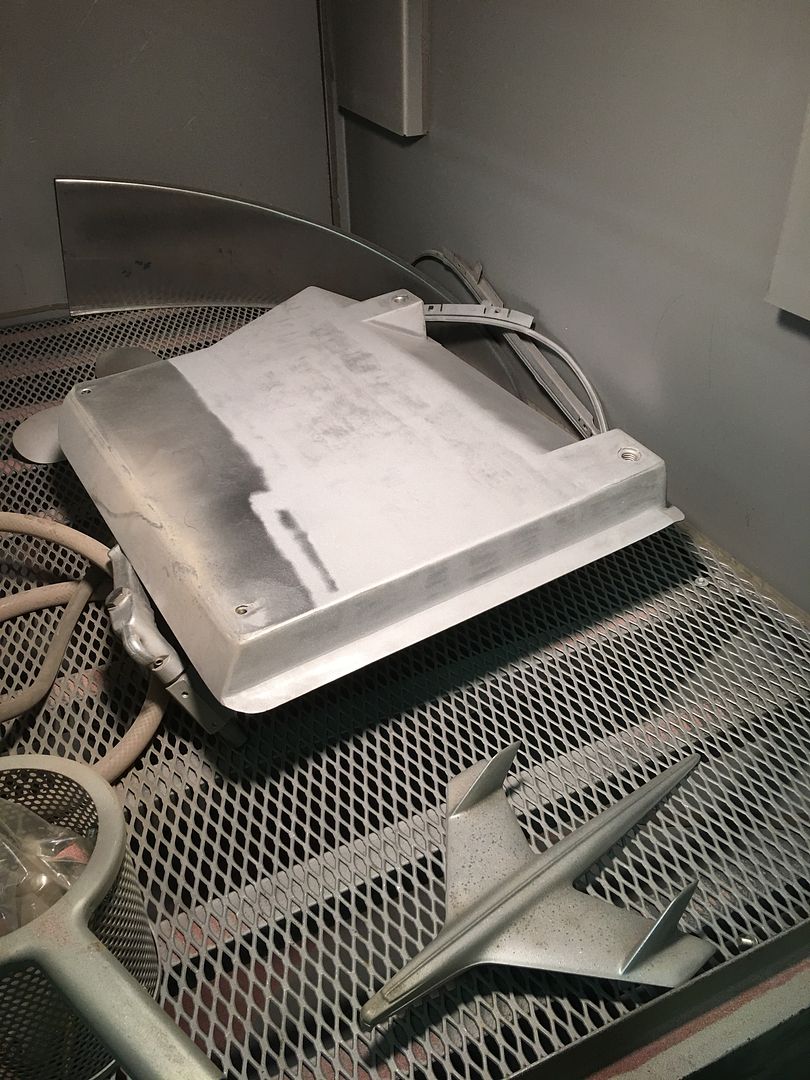

Sometimes you just need to screw off in the shop all day. So while the new hire continued with media blasting, I turned my attention to this "new" hoop for the Watervliet planishing hammer that just showed up.. This square version is somewhat rare, ie: hard to find, but I had a particular location in mind..

The Baileigh power hammer has some threaded holes on the left side for their own version of a planishing hammer mount, but I just didn't have the funds laying around for their version. So lets see what we can do with Old Faithful...   Drum sander does wonders in pipe fitment, and it sure was easier to TIG with a nice tight fit...       All we need now is paint and a pedal.. https://www.youtube.com/watch?v=_evAUjqr-5Q .

__________________

Robert |

|

|

|

|

|

#25 |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,647

|

Re: 55 Wagon Progress

Getting down to the nitty gritty on the seat brackets, number two is all but done, need to weld in three hex nuts and touch up some media blasting. Hoping for good weather this weekend so we can spray some epoxy primer on them and get these installed...

And the last two pipe clamps came in at Napa (installed with lock nuts), so we can now throw some air to the planishing hammer and try out the new fixture..

__________________

Robert |

|

|

|

|

| Bookmarks |

|

|