|

|

|

|

|

#1 |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,647

|

Re: 55 Wagon Progress

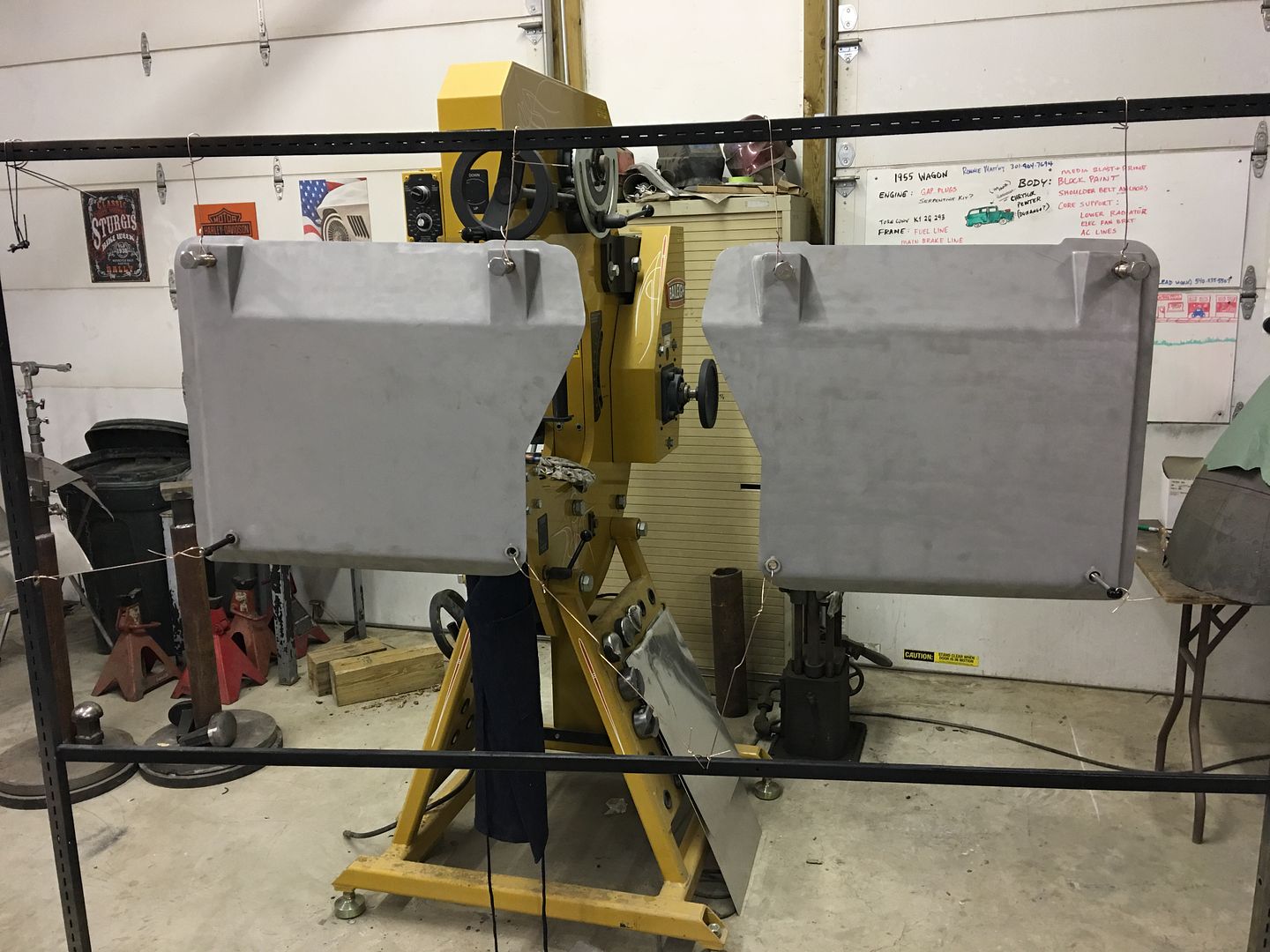

This weekend we got the three hex nuts welded underneath seat bracket number two, fourth hole is a bolt through......

1/4" tall spacers fabricated to make the seat tracks level, then tacked in place on the front holes..    Prepped and hung up for epoxy primer...  OEM seat bracket holes in the floor pans open to the inside of floor crossmembers. Rather than weld them closed and warp the floor pan, we opted for these fancy hole plugs.    SPI epoxy primer applied...   When it's 39* outside and the paint booth is sucking the heat out of the building, this is how you keep the temps up to a balmy 75* in the paint booth..  We'll let the seat brackets cure for a few days and then get started on plug welding them in place..

__________________

Robert |

|

|

|

|

|

#2 |

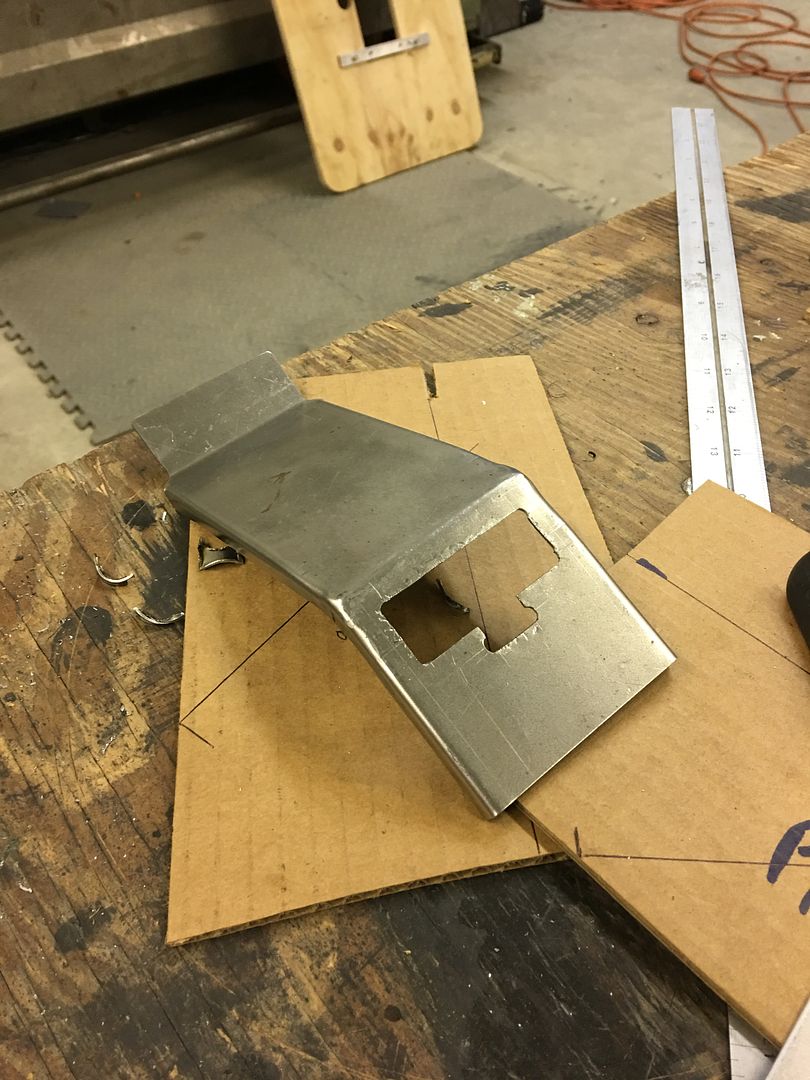

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,647

|

Re: 55 Wagon Progress

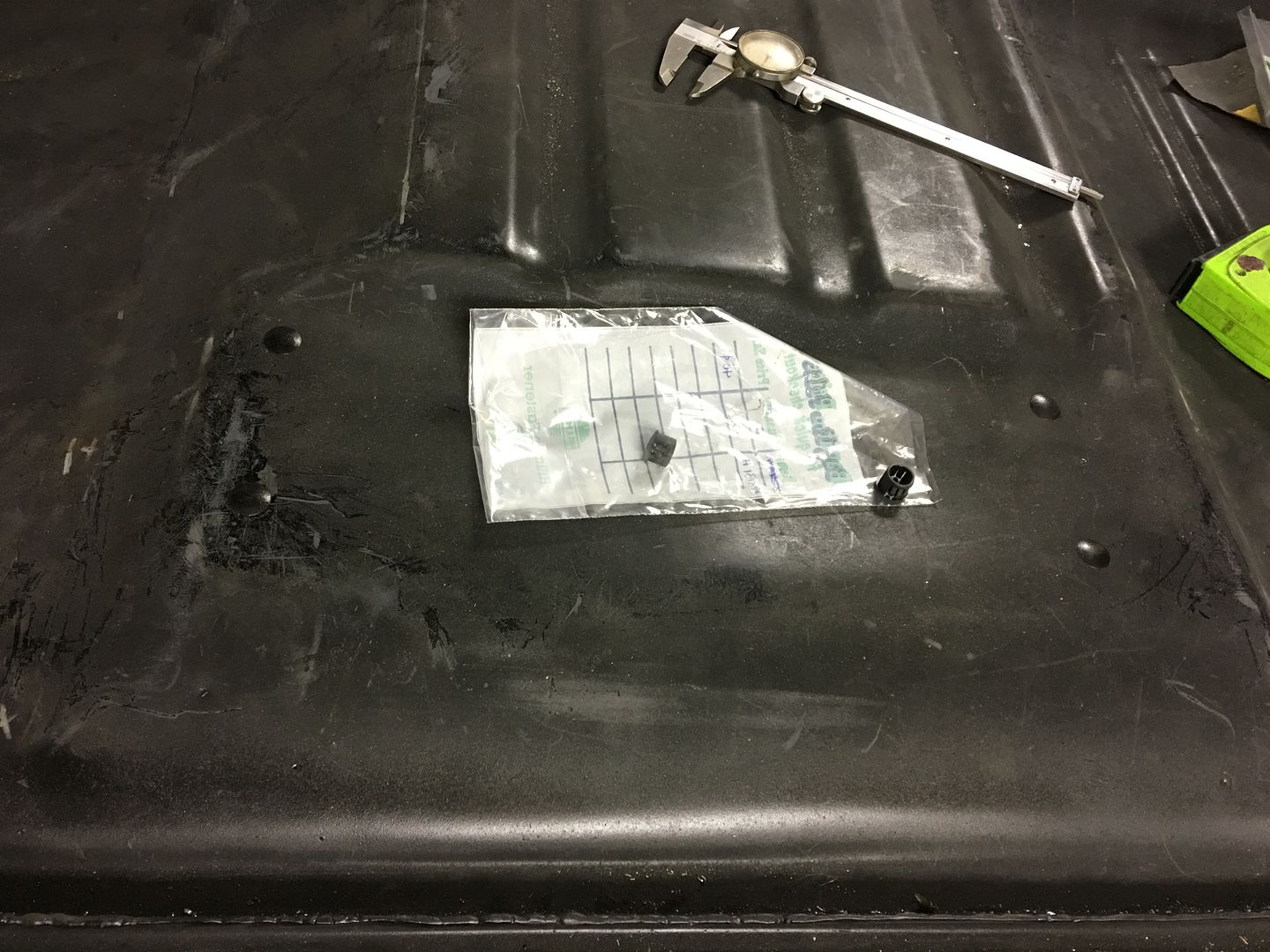

Got started on drilling plug weld holes this evening, here laying out the hole patterns to align with the floor crossmember where possible...

Once drilled to match our piloted burnishing brush, the paint surrounding the plug weld gets cleaned to prevent weld contamination.. https://www.youtube.com/watch?v=ELG55mmG2I0

__________________

Robert |

|

|

|

|

|

#3 |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,647

|

Re: 55 Wagon Progress

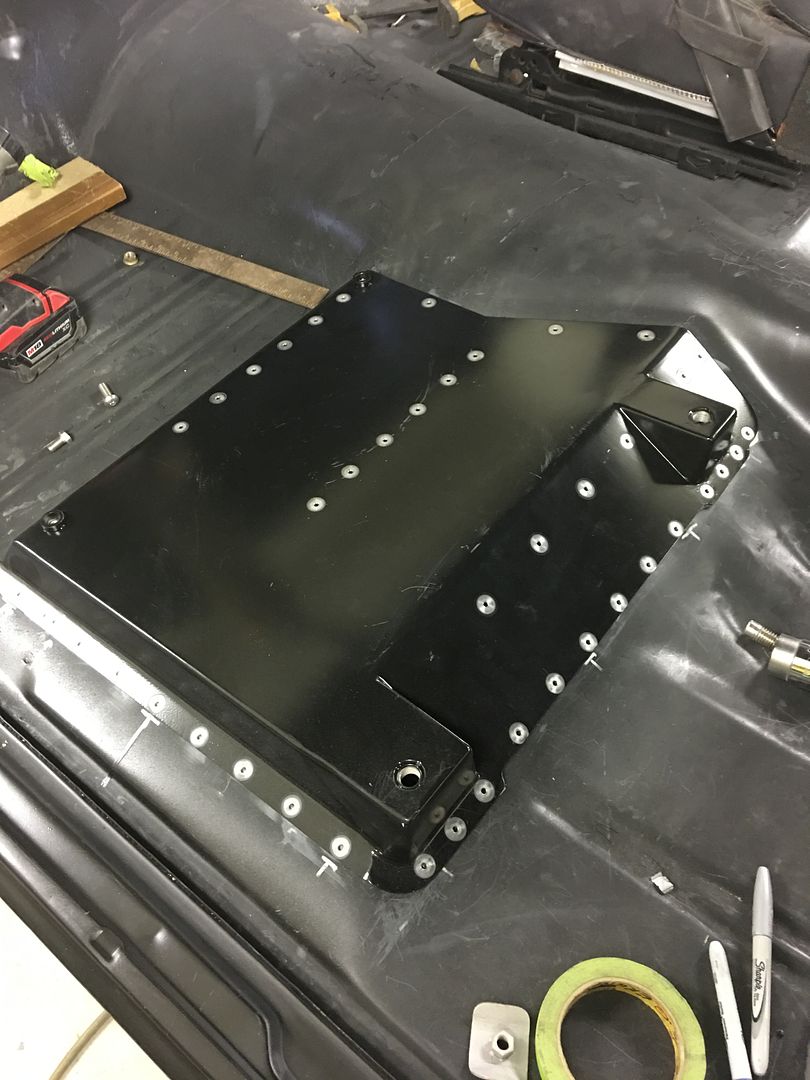

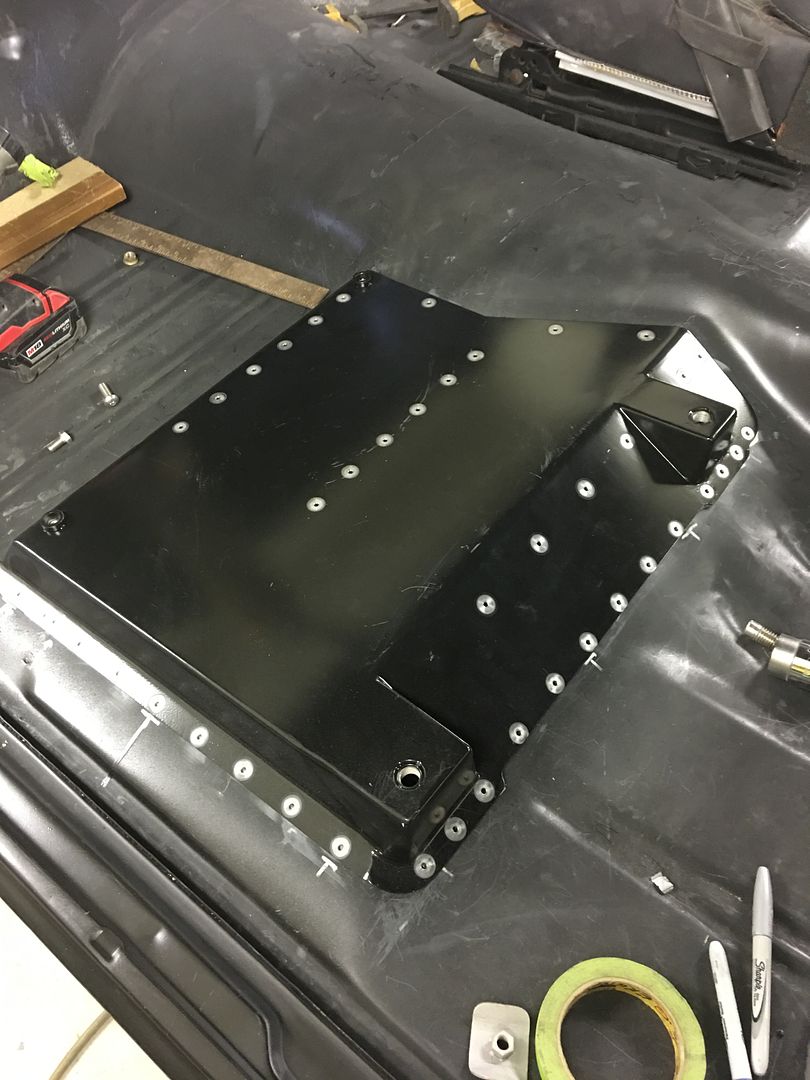

Getting some seat brackets welded in...

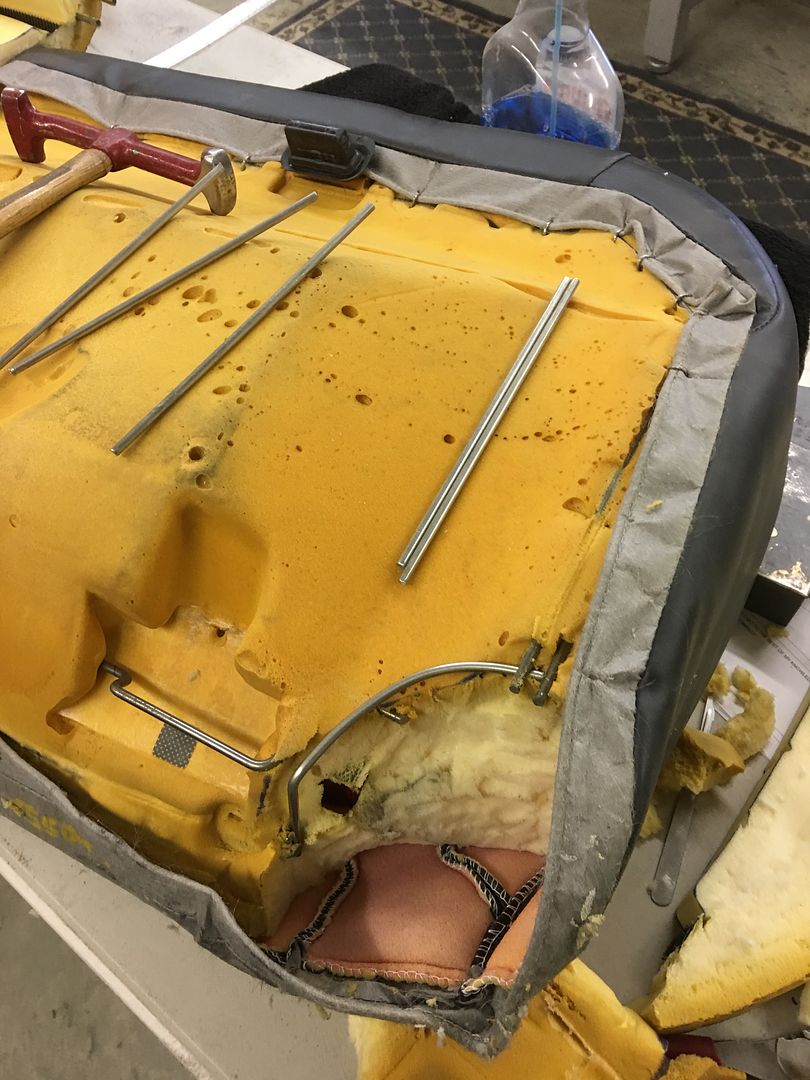

Plug welding... https://www.youtube.com/watch?v=VofyZCliZRg  But before we get all the front seats in and make it harder to access the back, lets get the seat riser plug welded in for the back seat...  Next, our rear seat that came with the buckets was slightly oversize for our widened wheel wells. Some quick measurements showed we need to lose about 2" in width..   Then the rear corners needed relieving for the wheel tubs.....    Some 3/16 diameter stainless rod was used to reconnect the pieces in the new rear corners  Some fire prevention for the foam..    With both sides fitting individually, time to join our sides back together...   Video of the surgery results.... https://www.youtube.com/watch?v=0ingFICYYws With the overlap of material trimmed, this part is looking pretty good!

__________________

Robert |

|

|

|

|

|

#4 |

|

Senior Member

Join Date: Mar 2011

Location: West Plains, Missouri

Posts: 7,559

|

Re: 55 Wagon Progress

Robert, nice job, fits verywell...Jim

__________________

my build thread: http://67-72chevytrucks.com/vboard/s...d.php?t=459839 Jimbo's long bed step build:http://67-72chevytrucks.com/vboard/s...t=464626<br /> Last edited by oldman3; 03-12-2017 at 11:09 PM. |

|

|

|

|

|

#5 |

|

Senior Member

Join Date: Jan 2009

Location: Raleigh, NC

Posts: 444

|

Re: 55 Wagon Progress

Looks really nice, you do great work.

I appreciate your posts and videos. It gives some interesting insights on how the job should be done correctly.

__________________

1949/1954 with LS swap-yeah! http://s260.photobucket.com/albums/i...0/AD%20trucks/jumbled mess of unorganized photos |

|

|

|

|

|

#6 |

|

Registered User

Join Date: Apr 2011

Location: .

Posts: 3,104

|

Re: 55 Wagon Progress

So perfect only the knowing eye 'might' catch it.

Job well done Sir. |

|

|

|

|

|

#7 |

|

Registered User

Join Date: Apr 2003

Location: Indep, MO

Posts: 5,893

|

Re: 55 Wagon Progress

Fantastic work as always!

__________________

Boppa's Old Yeller Truck Build, Old Yeller's New Heart! Project Buzz Bomb Flyin' Low! |

|

|

|

|

|

#8 |

|

Senior Member

Join Date: Jul 2012

Location: Oblong, Illinois

Posts: 7,028

|

Re: 55 Wagon Progress

Yes, very nice work. Where did the piloted burnishing brush come from?

|

|

|

|

|

|

#9 |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,647

|

Re: 55 Wagon Progress

They came from McMaster Carr. Look up piloted end brushes. They have them in various pilot sizes and either 1/2 or 3/4 diam, we used 1/2..

Thanks for the comments guys! Posted via Mobile Device |

|

|

|

|

|

#10 |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,647

|

Re: 55 Wagon Progress

With the 55's rear seat bottom narrowed to fit the wheel tubs.....

....time to do the same for the seat back. First to blow it apart....  This had a multiple fold down, arm rest in the middle, non 55 looking arrangement. The arm rest will be first to go, and we'll attach the fold down sections together.. The frame is sectioned in the middle, a tube driven inside, and TIG welded around the perimeter..   Then the seat innards are trimmed accordingly to make a one piece back..   Then some 14 gauge strips are cut out to join the two sections together..          That should work, tomorrow we'll work on the new pivot brackets..

__________________

Robert |

|

|

|

|

|

#11 |

|

Senior Member

Join Date: Mar 2011

Location: West Plains, Missouri

Posts: 7,559

|

Re: 55 Wagon Progress

Wow, One heck of a nice job on the back parts of seat...Jim

__________________

my build thread: http://67-72chevytrucks.com/vboard/s...d.php?t=459839 Jimbo's long bed step build:http://67-72chevytrucks.com/vboard/s...t=464626<br /> Last edited by oldman3; 03-25-2017 at 11:05 PM. |

|

|

|

|

|

#12 |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,647

|

Re: 55 Wagon Progress

Thanks Jim!

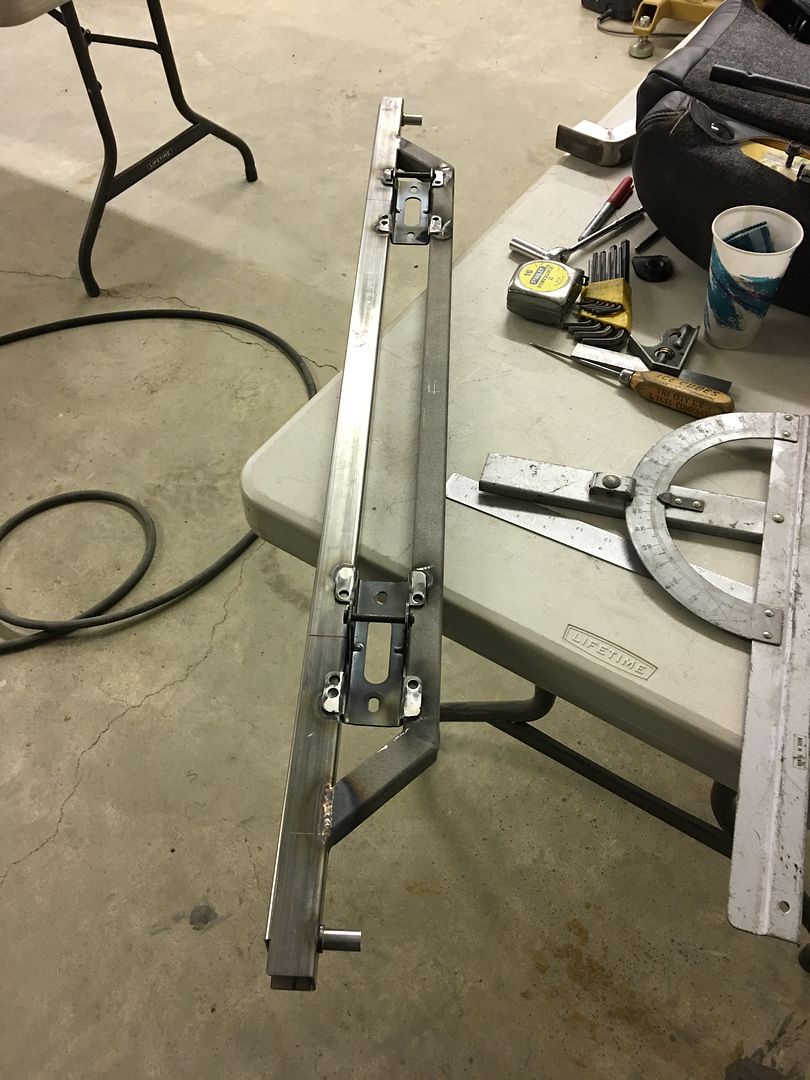

In removing the section of foam on the seat back we find the cushion has a wire around the arm rest void. As we are removing the arm rest altogether (when it gets reupholstered) we removed the wire..     The previous pivot for the seats had a tapered pin hex bolt that secured into a hex nut that was welded onto the pivot bracket, which can be seen here:  Due to our width constraints, we need to remove all that excess hardware.. So we chose to put the "securing nut" inside the seat, and use a simple pan head allen screw through the 12 gauge bracket.. Here's our Pivot "axle" inside the seat back..   Here's the test fit of our 12 gauge steel pivot bracket. Radius was used on the bends to match the tube. The tube was originally round, and the side uprights were flattened out using the MH19 hammer to buy us some more clearance between wheel tubs..  The bead shown on the bracket was done on the Lennox Nibbler. This should give us a bit of clearance on the edges to help prevent binding of the upholstery.  Bead turned out pretty well for 12 gauge steel! Some TIG welding to put the parts together:    Video of it in operation: https://www.youtube.com/watch?v=KCcpqbF1jUU One part down, next we'll tackle the brackets to the floor.

__________________

Robert |

|

|

|

|

|

#13 |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,647

|

Re: 55 Wagon Progress

Doesn't seem like much got done this weekend, but here's what we did..

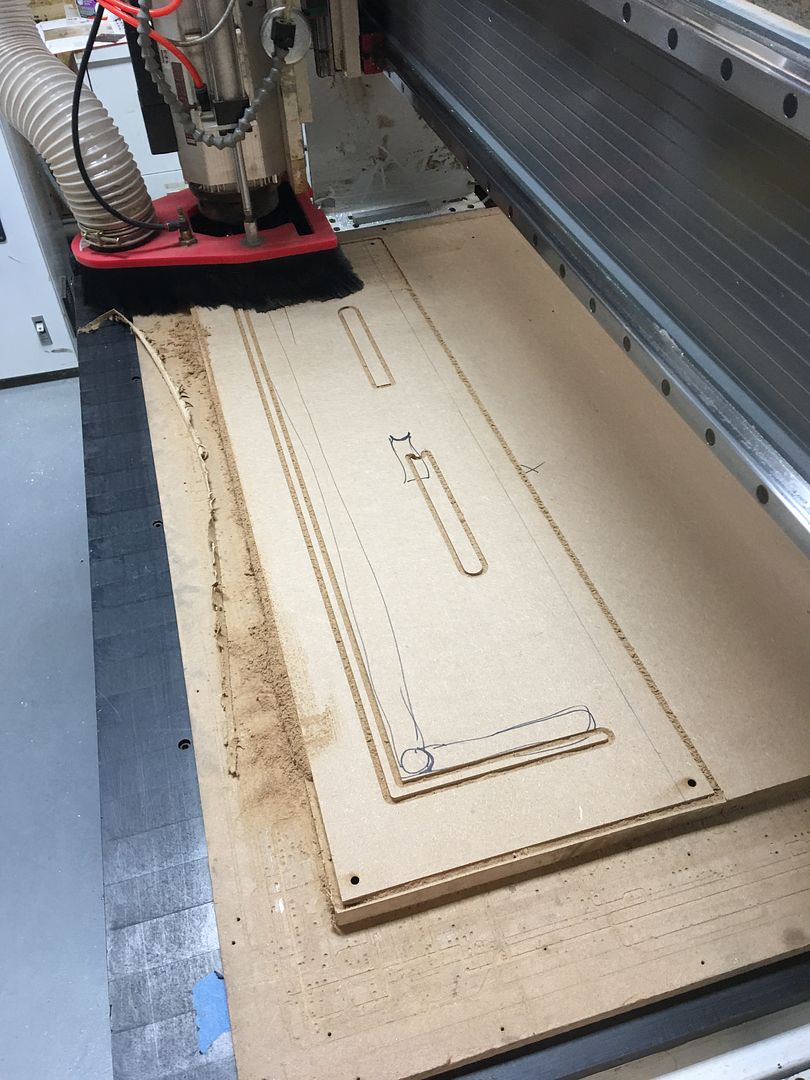

Stopped by the local CNC router facility to get some generic guides made for bead detail on the Lennox Nibbler...  Also had some blanks cut out over there to the right side. These were to form stops so we can adjust length of our pattern shorter as needed..   It has a snug fit like so:  Next was to turn up a new die with less crown than the other we've been using, just to have a different look, a flatter bead..    Setting up for some practice runs...   Here's a comparison between the new die and the fuller radius we've been using.. https://www.youtube.com/watch?v=HMi7...ature=youtu.be Thursday night headed over to Virginia, the 52 Chevy tail pan now resided in Fredericksburg and I needed to borrow the original and new one for the Coming Out car show in Charlotte Hall, being held Sunday (today). I had been dragging my feet about even going to the show, but the weather forecast promised beautiful weather, so I went ahead and reserved a vendor spot to show off our fabrication work. Friday night started gathering some samples to take and a put some pictures together for an album..  We still had all the original pieces for the lift gate repair, so that was a good sample.. Set up at the show, I figured parked next to the Ice Cream truck would be easier on my will power than the smell of three BBQ trucks on the other side...    Got these pictures right after we set up and before all the crowd showed up. Had a blast, talking metalshaping, rust repair, etc. for most of the day.. Got to meet Duallyjams and look at some of his stainless needing repairs.. The days over, I guess I've got to get back to work now...

__________________

Robert Last edited by MP&C; 04-06-2017 at 06:38 AM. |

|

|

|

|

|

#14 |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,647

|

Re: 55 Wagon Progress

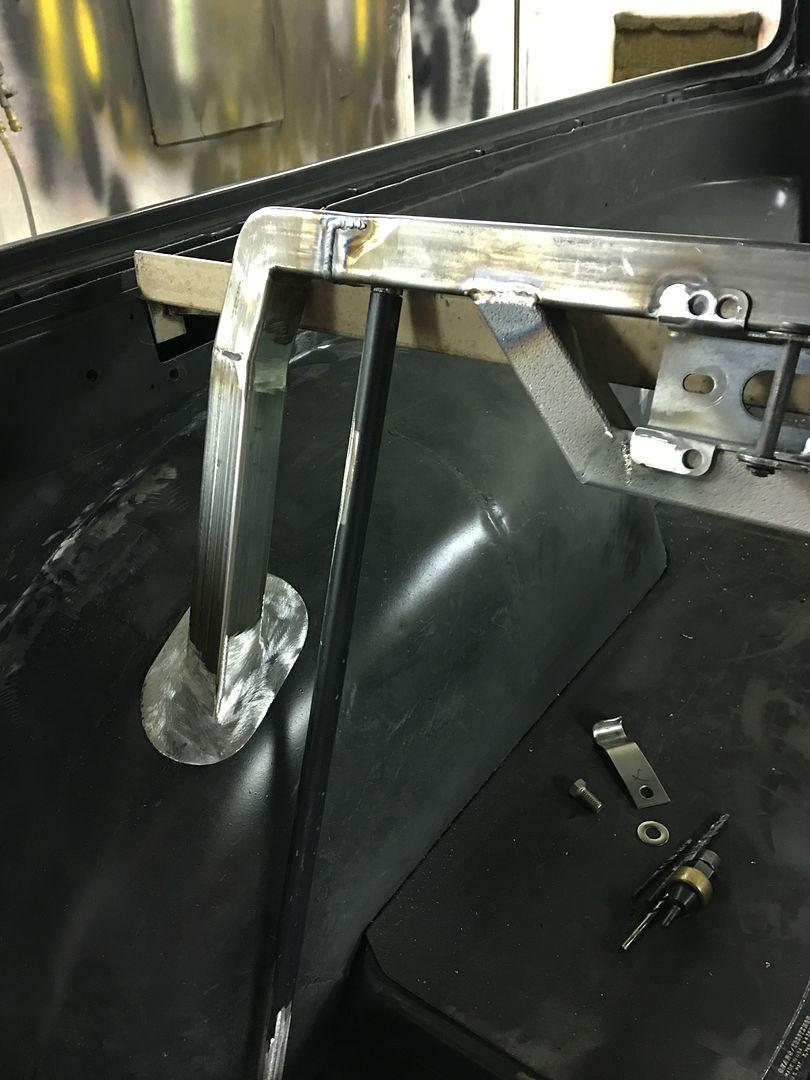

Back in the shop this evening, time to make some bolting brackets to hold the seat back frame to the floor..

Locating...   Brackets TIG welded on....  This shows it in place, we have about 1/4" clearance at the tight spots.... https://www.youtube.com/watch?v=jB5qRfP7IxY The cleco's were removed and 1/4-20 AVK rivet nuts installed in the floor... Missed that picture...   Next will be the top support....

__________________

Robert Last edited by MP&C; 04-05-2017 at 12:16 PM. |

|

|

|

|

|

#15 |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,647

|

Re: 55 Wagon Progress

Now for the top of the seat frame... We started with some 3/8-16 standoffs that are 5/8 diameter, and turn them to 1/2 diameter to fit inside the seat frame tube...

Then holes are drilled in some 1.25 square tubing...   Tacked in place and a nut used for added insurance...    Seat latches plug welded in place...  Side pieces formed....      The side pieces will be trimmed, fitted, and welded to the wheel well...

__________________

Robert |

|

|

|

|

|

#16 |

|

Senior Member

Join Date: Mar 2011

Location: West Plains, Missouri

Posts: 7,559

|

Re: 55 Wagon Progress

Robert, you sure make some great pieces, love the attention to detail, that some may never see...Jim

__________________

my build thread: http://67-72chevytrucks.com/vboard/s...d.php?t=459839 Jimbo's long bed step build:http://67-72chevytrucks.com/vboard/s...t=464626<br /> |

|

|

|

|

|

#17 |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,647

|

Re: 55 Wagon Progress

Thanks Jim!

More work on the seat back bracket... Trimming the side pieces to match the wheel well...  Adding welding flange, hammered out of 16 gauge steel..   Test drive.... https://www.youtube.com/watch?v=mpFl01yHvKw Used the Roper Whitney hand punch to make our plug weld holes..     Next we'll close off the back area to contain the amp and bass speaker.

__________________

Robert |

|

|

|

|

|

#18 |

|

Registered User

Join Date: Dec 2011

Location: Mobile, Alabama

Posts: 996

|

Re: 55 Wagon Progress

The close up photos really do help! Thanks for posting.

__________________

My Build - http://67-72chevytrucks.com/vboard/s...d.php?t=515876 |

|

|

|

|

|

#19 |

|

Senior Member

Join Date: Jul 2012

Location: Oblong, Illinois

Posts: 7,028

|

Re: 55 Wagon Progress

Impressive work on the seat frame Robert. Appreciate the documented details ... thanks for sharing.

|

|

|

|

|

|

#20 |

|

Registered User

Join Date: May 2015

Location: texas

Posts: 253

|

Re: 55 Wagon Progress

looking great, as always.

__________________

Black 93 CCLB 3500 6.5 diesel, GV OD, TCI Ez-TCU controlled 4L80E, back on road 10/25/16 after sitting 4 years. 96 ECLB 2500, 6.5 diesel, auto, gone. |

|

|

|

|

|

#21 |

|

Registered User

Join Date: Apr 2003

Location: Indep, MO

Posts: 5,893

|

Re: 55 Wagon Progress

Wow! I'll be stealing that square tube rounding trick! Nice stuff!

__________________

Boppa's Old Yeller Truck Build, Old Yeller's New Heart! Project Buzz Bomb Flyin' Low! |

|

|

|

|

|

#22 |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,647

|

Re: 55 Wagon Progress

Thanks for all the comments

Had a short evening in the shop as I was busy packing the neon clock for shipment, so the remainder was spent working on some of the many final details of the rear seat. Here are the factory seat clips to hold the seat bottom in place.   In order to use these, let's do a sample and see if we cut a hole in some sheet metal that they'll fit into..     This looks like it will work, we'll get some 18 gauge strips made to hold these that 45 down to the floor, adding some bead details for strength..

__________________

Robert |

|

|

|

|

|

#23 |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,647

|

Re: 55 Wagon Progress

Time for some brackets for the rear seat bottom retainers. Cut out some 19 gauge...

Drilled some holes for an inside radius, and trimmed the corners for the floor pan flange..  Now to fold some flanges on the sides for strength, using the Diacro press brake and a 1/2" thick lower die. By adding some rare earth magnets to the back side to serve as a back stop, we get a perfect 1/4" flange...   Then some back and forth between the Erco kick shrinker and the press brake with a narrow die inside the folds.... and we have 45* bends on either end of our brackets...  Test fit.... and trimming the retainer hole...

__________________

Robert |

|

|

|

|

|

#24 |

|

Senior Member

Join Date: Mar 2011

Location: West Plains, Missouri

Posts: 7,559

|

Re: 55 Wagon Progress

Robert, when you make up your parts, it leaves my without any words to say, just over the top...Jim

__________________

my build thread: http://67-72chevytrucks.com/vboard/s...d.php?t=459839 Jimbo's long bed step build:http://67-72chevytrucks.com/vboard/s...t=464626<br /> |

|

|

|

|

|

#25 |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,647

|

Re: 55 Wagon Progress

Thanks Jim!

Had our new apprentice started today, while I cut out the hole in the second seat bracket, Mike got started on punching and drilling holes for plug welding the passenger bucket seat bracket...    After I got the bracket hole cut out, E media blasted the brackets and added some SPI epoxy using a brush. We mainly wanted to get the bottom side well covered as it will be inaccessible once welded in place..   First coat...  Two coats, that should hold us for under a seat...  Meanwhile I got out the John Deere rod bender to see if we could make up some anchors for the shoulder belt..  Bent with relief for a 1/2-13 lock nut..   Welded with short bursts and plenty of cooling between to keep the nylon lock intact..  test fit...   plug weld holes drilled and welded in place....   Mike finished up plug welding the seat bracket in place...

__________________

Robert |

|

|

|

|

| Bookmarks |

|

|