|

|

|

|

|

#1 |

|

Senior Member

Join Date: Jul 2010

Location: Dandridge, Tn. USA

Posts: 2,226

|

Re: Make it handle

The idea of swapping arms has bee tossed around. The 1 3/4" move back on the upper ball joint would add about 9 deg of caster. - may be too much added to the stock 2 deg. Also, the arm is tilted at the ball joint, and swapping sides makes the ball joint tip backwards, I haven't tried it, but i think it may bind, or be right at the edge. Also, just moving the top back will also move the front centerline back. The smart way is to move both arms. Bottom forward 3/4", top back 1/2", would be the ticket.

Bad ass pict!!

__________________

GoodGuys 2012 Pro-Truck Champion  2012 Truckin' Throwdown Champion GoodGuys 2011 National Champion  2011 Truckin' Throwdown Champion GoodGuys 2010 National Champion  Proud to put our products up against all others! |

|

|

|

|

|

#2 |

|

Registered User

Join Date: Jun 2011

Location: Richmond,Va

Posts: 2,934

|

Re: Make it handle

I haven't messed with my truck because I've been busy and I had to take it home because they are doing construction at my work. I havent finished aligning my truck yet (except for toe). Maybe after Tgiving I'll swap the upper A arms, put it on the rack and see what happens.

__________________

Nick Carter 1967 C10 Short bed Fleetside Project Cheap Thrills! 2WD C10 Modern/Performance Alignments Easiest Alignment Ever! |

|

|

|

|

|

#3 | |

|

Registered User

Join Date: Jan 2011

Location: Mount Airy, NC

Posts: 132

|

Re: Make it handle

Quote:

Thanks

__________________

Jack Byrd '70 Chev Custom SWB(new to me), 307CID(added Weiand Stealth, headers and Edelbrock Performer carb, up to 17 MPG now), 700R4 '76 Airstream Argosy MH(want a longer one), 454CID, TH400 |

|

|

|

|

|

|

#4 | |

|

Registered User

Join Date: Mar 2005

Location: apple valley, ca

Posts: 2,670

|

Re: Make it handle

Quote:

__________________

Check out my latest endeavor: https://roundsixpod.com My build threads: '55 Chevy: http://67-72chevytrucks.com/vboard/s...d.php?t=247512 '64 C-20: http://67-72chevytrucks.com/vboard/s...d.php?t=446527 |

|

|

|

|

|

|

#5 |

|

Senior Member

Join Date: Jul 2010

Location: Dandridge, Tn. USA

Posts: 2,226

|

Re: Make it handle

On 63-87 C-10's, this is pretty easy. For the lower arms, remove the arm, and drill a new index hole in the cross shaft. I usually rotate the shaft 90 deg., then drill a new hole 3/4" back. You may need to grind a small amount off of the rear lip of the crossmember (more comon on 73-87) so that the bushing clears fine. Then bolt the arm back on. For the uppers, knock all the rivits out, unbolt the upper A-arm mount and slide it back. Weld it to the crossmember, and drill out the mount to fit the frame. Use grade #8 bolts and washers to bolt it back to the frame.

__________________

GoodGuys 2012 Pro-Truck Champion  2012 Truckin' Throwdown Champion GoodGuys 2011 National Champion  2011 Truckin' Throwdown Champion GoodGuys 2010 National Champion  Proud to put our products up against all others! |

|

|

|

|

|

#6 | |

|

Registered User

Join Date: Apr 2001

Location: DALLAS,TX

Posts: 22,031

|

Re: Make it handle

Quote:

__________________

67SWB-B.B.RetroRod 64SWB-Recycle 89CCDually-Driver/Tow Truck 99CCSWB Driver All Fleetsides @rattlecankustoms in IG Building a small, high rpm engine with the perfect bore, stroke and rod ratio is very impressive. It's like a highly skilled Morrocan sword fighter with a Damascus Steel Scimitar..... Cubic inches is like Indiana Jones with a cheap pistol. |

|

|

|

|

|

|

#7 | |

|

Registered User

Join Date: Oct 2008

Location: Parsons, KS

Posts: 652

|

Re: Make it handle

Quote:

Hey Rob, I am thinking of doing this to another crossmember I have, and was thinking of sectioning the upper A-arm mount to drop the mounting points while I am at it. Good idea? How much should I drop the mounting location?

__________________

74 GMC SWB Project "Sin-thia" Static Dropped 8"f/10"r http://67-72chevytrucks.com/vboard/s...d.php?t=460030  97 GMC reg cab short bed, 4.3V6 / 5spd, daily driver 220,000 miles, all stock for now |

|

|

|

|

|

|

#8 |

|

Senior Member

Join Date: Jul 2010

Location: Dandridge, Tn. USA

Posts: 2,226

|

Re: Make it handle

there is a slight change, but it actually reduces some of the factory bump-steer. More than the front/back position, when you 'tip' the spindle back to gain caster, it raises the steering arm slightly, and this also helps the factory steering geometry a bit.

__________________

GoodGuys 2012 Pro-Truck Champion  2012 Truckin' Throwdown Champion GoodGuys 2011 National Champion  2011 Truckin' Throwdown Champion GoodGuys 2010 National Champion  Proud to put our products up against all others! |

|

|

|

|

|

#9 |

|

Registered User

Join Date: Apr 2001

Location: DALLAS,TX

Posts: 22,031

|

Re: Make it handle

This is where my thoughts were going.... slight improvement on the bump-steer.

__________________

67SWB-B.B.RetroRod 64SWB-Recycle 89CCDually-Driver/Tow Truck 99CCSWB Driver All Fleetsides @rattlecankustoms in IG Building a small, high rpm engine with the perfect bore, stroke and rod ratio is very impressive. It's like a highly skilled Morrocan sword fighter with a Damascus Steel Scimitar..... Cubic inches is like Indiana Jones with a cheap pistol. |

|

|

|

|

|

#10 |

|

Registered User

Join Date: May 2011

Location: Anderson SC

Posts: 3,898

|

Re: Make it handle

I've skimmed over most the thread and there's a ton of great info here!! As much info there is on the suspension though, I didn't see as much discussion about modifications to the frame to decrease torsional flex/twisting. Having a rigid structure that the suspension is bolted to will help tremendously to get the suspension to work as it should instead of the frame twisting and absorbing the cornering loads, and tweaking the relative suspension mounting points front to rear- altering the four wheel alignment.

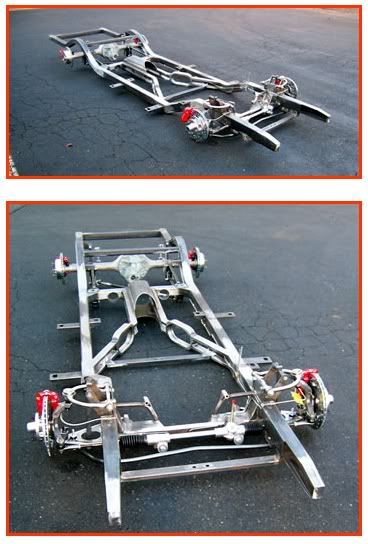

Since so many of us have stock frames, could we talk some about what could be done to the original frames to increase their rigidity? I'm going to be boxing the frame on my '66 C10 and would like to add an X member while I've got the body off. I started a topic on this but thought this would be a good place for discussion also. If it would be more appropriate to use a separate topic, the one I started is here: http://67-72chevytrucks.com/vboard/s...d.php?t=495785 My biggest questions at this point are: What would be a good design for an X member? I've seen a few that seemingly didn't have much bracing that would transfer twisting forces from side to side, instead it looked like the center cross supports themselves would flex/twist easily. I've also seen one with about a 1.5 foot long round tube center support design that looked really strong, since round tubing doesn't like to twist. Your thoughts on this? Do I need to fully box the frame rails front to rear, or do I need to leave some area open around the crossmembers to allow some flex so the frame doesn't crack? Or is that a myth? Here's where I'm at now, making patterns for boxing the frame. The first pic show how much flex there is with just one rear bag aired up. I'm planning on boxing all the way up to the steering box up front, and back past the C notchs in the rear. Also planning on welding the crossmember rivets.   And here's the pics I found of an X member with a tubular center design.

__________________

Project Goldilocks '66 C10 Short Fleet BBW Build '65 C10 Highly Detailed Stock Restoration Thread '78 Camaro Targa Roof Build '55 International Metal/Body/Paint Work '66 F100 Full Rotisserie Restoration '40 Packard 120 Convertible Coupe Restoration How To Restore and Detail an Original Gauge Cluster How To Detail Sand Body Panels, Edges, Corners, Etc |

|

|

|

|

|

#11 | |

|

Registered User

Join Date: Dec 2010

Location: Elbert county, CO

Posts: 249

|

Re: Make it handle

Quote:

I think i read, on this thread actually, that your supposed to box fully, but only run 2" beads of weld, then leave 2" open alternating between. This keeps some flex there to prevent cracking in the areas of high stress. Someone correct me if im wrong.  Id like to see how much flex you have after boxing the frame. Maybe a comparison photo once completed? Im not building an all out track machine like some of the guys here, but rather, a rat rod. Im using a 68 C10 frame that i zeed under the cab. I have bags in the same location as you and have a bunch of flex. Im kinda thinking that having the zee will lower the truck CG but then again, i know nothing about this science other then what ive read on this thread over the past 3 days  Im hoping that boxing will tighten this truck up and make it handle better. Im also thinking of adding an X section on the lowest part of the zee to tie at all together. I know this frame does NOT want to flip over. I had it all stripped down to flip upside down to do some work and it took everything i had to keep it from righting itself while it was on its side. |

|

|

|

|

|

|

#12 |

|

56 - autocross

Join Date: Apr 2010

Location: Camarillo, Ca

Posts: 1,121

|

Re: Make it handle

We kind of went a little overboard. We have three jackstands under the frame and it stays level in every direction.

|

|

|

|

|

|

#13 |

|

Senior Member

Join Date: Jul 2010

Location: Dandridge, Tn. USA

Posts: 2,226

|

Re: Make it handle

This is a good topic. I am asked all the time, " How much stiffer is it ? " How do you quantify that, there is no 'industry standard' for testing old or modified chassis. Here's what we do. Place three stands under the chassis, Two in the front, under the frame rails, just in front of the IFS crossmember/front CL. One in the back appx 10" fronm the rear of the rail. It helps over time to be consistent. The front needs to be stabilized, we use hooks in the floor, a pallet over the top, and a few hunder pounds over the front CL will work. The chassis should be level. Measure from the end of the un-suported rail to the floor. Next, place apxx 200 lbs (it would be nice if everybody used the same weight) on the end ov the un-suported rail, and measure the 'sag'. Do all of your chassis work, and re-check to see where your at.

__________________

GoodGuys 2012 Pro-Truck Champion  2012 Truckin' Throwdown Champion GoodGuys 2011 National Champion  2011 Truckin' Throwdown Champion GoodGuys 2010 National Champion  Proud to put our products up against all others! |

|

|

|

|

|

#14 | |

|

Registered User

Join Date: May 2011

Location: Anderson SC

Posts: 3,898

|

Re: Make it handle

Quote:

This guy's Cobra frame takes 11,122 ft-lb to make it twist one degree.  I'll bolt my front crossmember back in and set the frame up the same way, but I think even without adding any weight the frame will sag under it's own weight at least a few degrees, so it will be hard to get a baseline this way. I guess I could use that as the baseline, and then add weight to get it to twist one more degree. Rob's way will work great to get a baseline of how much it twist now vs after bracing it, but doesn't tell how much force it takes to twist the frame a given amount.

__________________

Project Goldilocks '66 C10 Short Fleet BBW Build '65 C10 Highly Detailed Stock Restoration Thread '78 Camaro Targa Roof Build '55 International Metal/Body/Paint Work '66 F100 Full Rotisserie Restoration '40 Packard 120 Convertible Coupe Restoration How To Restore and Detail an Original Gauge Cluster How To Detail Sand Body Panels, Edges, Corners, Etc |

|

|

|

|

|

|

#15 |

|

Senior Member

Join Date: Jul 2010

Location: Dandridge, Tn. USA

Posts: 2,226

|

Re: Make it handle

When it comes to actual boxing/bracing, remember that material thicknes is second to structural design. Triangles are stronger than squares. If you box the frame, 1/8" is fine, 3/16" is OK too. I do weld the full plate. Gaps lead to cracks. I don't usually box the intire frame. If you build a good center section/X-member, boxing under the cab is of little use.

__________________

GoodGuys 2012 Pro-Truck Champion  2012 Truckin' Throwdown Champion GoodGuys 2011 National Champion  2011 Truckin' Throwdown Champion GoodGuys 2010 National Champion  Proud to put our products up against all others! |

|

|

|

|

|

#16 |

|

Registered User

Join Date: Jun 2011

Location: Richmond,Va

Posts: 2,934

|

Re: Make it handle

FWIW, The industrial term is "Torsional Rigidity". I'm at work right now so I don't have extra time to add more info, sorry.

__________________

Nick Carter 1967 C10 Short bed Fleetside Project Cheap Thrills! 2WD C10 Modern/Performance Alignments Easiest Alignment Ever! |

|

|

|

|

|

#17 | |

|

Registered User

Join Date: May 2011

Location: Anderson SC

Posts: 3,898

|

Re: Make it handle

Quote:

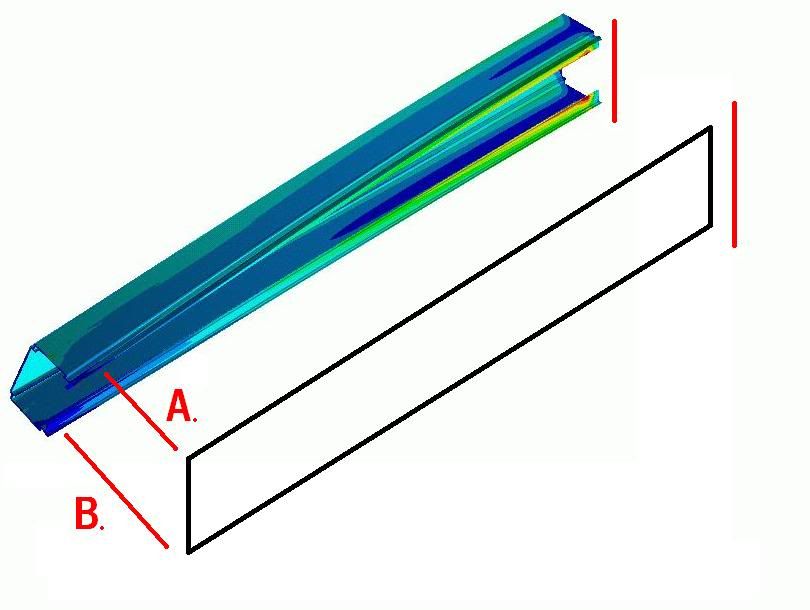

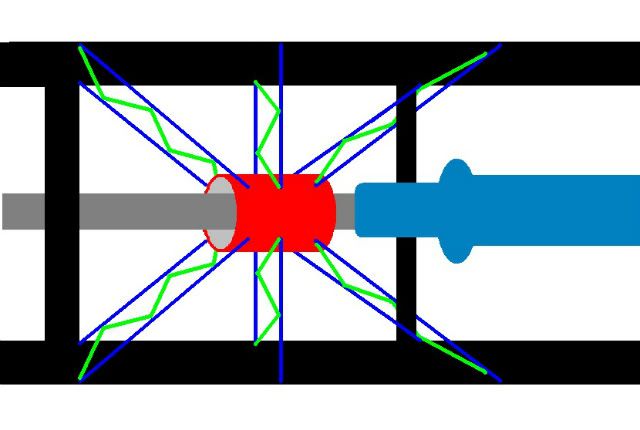

I'm planning on boxing the frame full length with 1/8" plate and adding a double (upper and lower level) X member with a large diameter round tube center section. The upper level X brace will weld to the upper flange of the frame rail, and the lower X brace will weld to the lower flange of the frame rail. I'll tie the upper and lower X members together with vertial triangulated bracing between the upper and lower X members. The solid round tube center section shouldn't allow any twisting front to rear, since round tube is very resistant to twisting down it's length. The reason I want a double layered X member is that the distance between the upper and lower sections of the frame C channels changes as the frame twist. An upper and lower X member will tie the top and bottom flanges of the C channel together and won't let the distance between them change. If I just made a single layer X member and welded it in the frame rails, it wouldn't hold the frame rails from spreading top-to-bottom. I made this drawing in paint to show how the distance between the frame rails change as they twist. Notice how distance "A" is shorter than distance "B". Just one brace in the center would still allow the frame to pivot around that one brace, no matter how strong the brace is. Upper and lower X members with triangulated vertical bracing in between should lock down the distance of the rails, keeping them from twisting.

__________________

Project Goldilocks '66 C10 Short Fleet BBW Build '65 C10 Highly Detailed Stock Restoration Thread '78 Camaro Targa Roof Build '55 International Metal/Body/Paint Work '66 F100 Full Rotisserie Restoration '40 Packard 120 Convertible Coupe Restoration How To Restore and Detail an Original Gauge Cluster How To Detail Sand Body Panels, Edges, Corners, Etc |

|

|

|

|

|

|

#18 |

|

Registered User

Join Date: May 2011

Location: Anderson SC

Posts: 3,898

|

Re: Make it handle

I drew up a rough sketch of my idea of a double layered X member using MS Paint. My paint skills suck but I wanted yall to see what's going on in my head and see if yall approve. Don't stare at it too long or you'll get disoriented and fall out of your chair.

__________________

Project Goldilocks '66 C10 Short Fleet BBW Build '65 C10 Highly Detailed Stock Restoration Thread '78 Camaro Targa Roof Build '55 International Metal/Body/Paint Work '66 F100 Full Rotisserie Restoration '40 Packard 120 Convertible Coupe Restoration How To Restore and Detail an Original Gauge Cluster How To Detail Sand Body Panels, Edges, Corners, Etc Last edited by theastronaut; 11-30-2011 at 04:39 PM. |

|

|

|

|

|

#19 |

|

Registered User

Join Date: Jan 2011

Location: Mount Airy, NC

Posts: 132

|

Re: Make it handle

Greetings folks, sorry to interrupt the discussion on frame boxing, but I think I discovered my level of ignorance today. I had the frame straightened on my '70 C10 last week and had it aligned today. Rob was wanting +8 caster, -1 camber and I was going to try 1/8 toe out. I asked the tech for max caster, -1 camber and 1/8 toe out. He was saying these dimensions were a combined number. Is this correct, and the trick is to balance it half per side? 4+4=8?

FYI-I don't know how it will be in the long run, but the 1/8 toe out seems to yield a better turn-in. It takes a set better now. Really want some more caster though. Thanks,

__________________

Jack Byrd '70 Chev Custom SWB(new to me), 307CID(added Weiand Stealth, headers and Edelbrock Performer carb, up to 17 MPG now), 700R4 '76 Airstream Argosy MH(want a longer one), 454CID, TH400 |

|

|

|

|

|

#20 | |

|

Registered User

Join Date: Nov 2011

Location: Cascadia, Wa

Posts: 28

|

Re: Make it handle

Quote:

If you are still stock...you will need some help / additional work to get to +8* caster because it is not possible unless you alter stock or go aftermarket to tilt the spindle... these include modifying / changing to different A arms modifying attachment points via rewelding and/or crossmember moving or replacement... I am considering the dropmember & move forward route currently...

__________________

'76 SB 350 400 |

|

|

|

|

|

|

#21 | |

|

Registered User

Join Date: Jan 2011

Location: Mount Airy, NC

Posts: 132

|

Re: Make it handle

Quote:

I'm looking at a crossmember mod also if Rob ever has time to check out the modification I came up with. Thanks again,

__________________

Jack Byrd '70 Chev Custom SWB(new to me), 307CID(added Weiand Stealth, headers and Edelbrock Performer carb, up to 17 MPG now), 700R4 '76 Airstream Argosy MH(want a longer one), 454CID, TH400 |

|

|

|

|

|

|

#22 | |

|

Registered User

Join Date: Nov 2011

Location: Cascadia, Wa

Posts: 28

|

Re: Make it handle

Quote:

http://www.aligncraft.com/terms/terms.html The two "issues" listed with increased positive caster listed here are increased road/impact "feel" (watch those pot holes) and less tolerance to unmatched alignment...neither one is a deal breaker for me. YMMV Rob and or others, I was wondering if there is a good target range for SLA scrub radius for autocross/road course...amazing how many factors come into play with tires, hubs, SAI, etc...!

__________________

'76 SB 350 400 |

|

|

|

|

|

|

#23 | |

|

Senior Member

Join Date: Jul 2010

Location: Dandridge, Tn. USA

Posts: 2,226

|

Re: Make it handle

Quote:

__________________

GoodGuys 2012 Pro-Truck Champion  2012 Truckin' Throwdown Champion GoodGuys 2011 National Champion  2011 Truckin' Throwdown Champion GoodGuys 2010 National Champion  Proud to put our products up against all others! |

|

|

|

|

|

|

#24 | |

|

Registered User

Join Date: Jun 2011

Location: Richmond,Va

Posts: 2,934

|

Re: Make it handle

Quote:

__________________

Nick Carter 1967 C10 Short bed Fleetside Project Cheap Thrills! 2WD C10 Modern/Performance Alignments Easiest Alignment Ever! |

|

|

|

|

|

|

#25 |

|

Senior Member

Join Date: Jul 2010

Location: Dandridge, Tn. USA

Posts: 2,226

|

Re: Make it handle

I have ta agree with DOC, stock front ends, or even stock dimension components will only get you about +4* caster. Even so, I'd bet your truck dives a lot better now.

A question for ya DOC, with 'normal' thought, I would say that really wide front tires will create a wander, I'm talking about 305 or bigger. Now, do you think that big caster numbers, 8* to 9*, would correct this? I'm considering larger front tires, more to the inside, -1* camber, with a 2.36" scrub radius.

__________________

GoodGuys 2012 Pro-Truck Champion  2012 Truckin' Throwdown Champion GoodGuys 2011 National Champion  2011 Truckin' Throwdown Champion GoodGuys 2010 National Champion  Proud to put our products up against all others! |

|

|

|

|

| Bookmarks |

|

|