|

|

|

#951 |

|

Senior Member

Join Date: Mar 2011

Location: West Plains, Missouri

Posts: 7,559

|

Re: 55 Wagon Progress

Nice...Jim

__________________

my build thread: http://67-72chevytrucks.com/vboard/s...d.php?t=459839 Jimbo's long bed step build:http://67-72chevytrucks.com/vboard/s...t=464626<br /> |

|

|

|

|

|

#952 |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,647

|

Re: 55 Wagon Progress

Some days I can't leave well enough alone. I thought I'd see how stout my fancy hinges were before we get too far along in the upholstery stage of the console. I guess I had a gut feeling on these, but some slight side to side deflection rendered the hinges loosened, and the swage of the semi-tubular rivets showed some cracks...

We're a bit too far down this rabbit hole to change directions again, so I checked my inventory of semi-tubular rivets and found these HD items. These are used in securing latches and hinges to the HD saddle bags and tour packs. When I paint the Harleys, I break these things down to nothing to get fresh paint everywhere, then reinstall the hardware with new rivets. These are stainless and have shown in the past to be rather robust, so we'll drill out all the off shore rivets and install these.. Comparison... One set done, one to go..

__________________

Robert |

|

|

|

|

|

#953 |

|

Post Whore

Join Date: May 2015

Location: Alabama

Posts: 14,662

|

Re: 55 Wagon Progress

looks stout now!!! nice rivet tool

__________________

Mongo...aka Greg RIP Dad RIP Jesse 1981 C30 LQ9 NV4500..http://67-72chevytrucks.com/vboard/s...d.php?t=753598 Mongos AD- LS3 TR6060...http://67-72chevytrucks.com/vboard/s...34#post8522334 Columbus..the 1957 IH 4x4...http://67-72chevytrucks.com/vboard/s...63#post8082563 2023 Chevy Z71..daily driver |

|

|

|

|

|

#954 |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,647

|

Re: 55 Wagon Progress

Saturday morning Mike and I went to look at a 39 Ford that needs a complete new wiring harness. What a rats nest the under-dash was, with far too many splices. When people run wires with no regard to movement and function of things like the cowl vent handle or parking brake, when three separate wires are spliced to go from one point to another, you just shake your head. For me I guess it validates what I do in sharing the various tips and methods in this thread. If it helps one person to get some ideas to better improve their own build, or it keeps hack work like we saw Saturday from happening, then mission accomplished.

When we returned from that, I finished up the remaining hinge conversion, and Mike cut out some 18 GA cold rolled and made some bolting angles for some inner fenders we have planned in dressing up the blah engine compartment. Undoubtedly there will be some components bolted onto the original inner fenders and these "covers", and this bolting angle will allow us to remove them for access without having to remove fender bolts. Monday evening we had a departure, the upholstery has left the building! Well, most of it, we still have door panels, arm rests, etc, etc.... to address. Thanks Gary! Last night we cut out some bend sample strips to nail down our console lid insert, should get the final version cut out and fabricated Thursday night. Meanwhile, E and I worked on locating attachment holes on the mounting angles Mike had made. The original inner fenders were attached to the fender, and noticed we needed a mounting hole up front of our angles for better stability, so we added those holes and installed some rivnuts in the inner fenders. This will allow assembly without the need to hold washers and nuts on the opposite side. E gaining some rivnut installing skills.... This shows the side by side with the angles installed. https://www.youtube.com/watch?v=qePepMuDThE Thursday we'll get the attachment holes for the new inner inner fenders located, drilled, and rivnuts installed. Then these parts can get sent off for powder coating.

__________________

Robert |

|

|

|

|

|

#955 |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,647

|

Re: 55 Wagon Progress

E worked Thurday evening on drilling holes and installing rivet nuts for the inner inner fender mounts.

Oops, I think she chipped a nail.. Meanwhile, I fabricated the console lid insert... Today, Mike and I worked on the lower radiator mount. We tossed around various ideas, and settled on one that would keep the lower condensor mount a separate isolated part. We decided to use the same dies used to for the J-channel detail on the back of the 52 Chevy tailpan that we made up a couple years ago. Here the J-channel detail is added on a piece of 16 gauge cold rolled steel.. https://www.youtube.com/watch?v=52tz0CWvRHM Radiator test fit: https://www.youtube.com/watch?v=XEQFMLnb4z4 .

__________________

Robert |

|

|

|

|

|

#956 |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,647

|

Re: 55 Wagon Progress

Another part we're adding due to the length of this car is a second interior light. We chose to go with the original version, so here's a factory mount, spot welds ground out from the back side of the included section of roof crossmember. Then it will get media blasted, epoxy primed, and plug welded in place.

We got the baffle/lower radiator mount plug welded in place... ...and the rubber edge trim for our lower radiator mount added.. The "final" version will include weather strip adhesive to keep it locked in place on the radiator. Needs to be pressed in a little more but this is the idea... Side baffles for the core support were trimmed on the inside (for our larger opening) , new mounting slots added, and access holes opened up.. Lower radiator hose clearance to the battery support bracket...

__________________

Robert |

|

|

|

|

|

#957 |

|

Senior Member

Join Date: Mar 2011

Location: West Plains, Missouri

Posts: 7,559

|

Re: 55 Wagon Progress

Robert, looking good...Jim

__________________

my build thread: http://67-72chevytrucks.com/vboard/s...d.php?t=459839 Jimbo's long bed step build:http://67-72chevytrucks.com/vboard/s...t=464626<br /> |

|

|

|

|

|

#958 |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,647

|

Re: 55 Wagon Progress

Thanks Jim!

I have a couple radius bends to do on the AC condenser bracket, so a piece of 1/2" 4130 was added to the Magnetic Brake die.. This will help keep things from moving, and it is welded on what is usually the back side, so no interference otherwise... This will be the mounting flange to the radiator.. 1" rod is used to form the radius on the side "covers" A test fit before we cut out the gaping hole for air flow.... https://www.youtube.com/watch?v=YbIW...ature=youtu.be The center hole is cut out and a flange tipped for wrapping a 3/16" rod for wire edge. This should add plenty of strength, if the 16 GA wasn't enough.. Our anvil we made up for stretching the metal in the corners for tipping.. Where we left off....to be continued.. .

__________________

Robert |

|

|

|

|

|

#959 |

|

Post Whore

Join Date: May 2015

Location: Alabama

Posts: 14,662

|

Re: 55 Wagon Progress

Man that's slick....looks awesome ...

__________________

Mongo...aka Greg RIP Dad RIP Jesse 1981 C30 LQ9 NV4500..http://67-72chevytrucks.com/vboard/s...d.php?t=753598 Mongos AD- LS3 TR6060...http://67-72chevytrucks.com/vboard/s...34#post8522334 Columbus..the 1957 IH 4x4...http://67-72chevytrucks.com/vboard/s...63#post8082563 2023 Chevy Z71..daily driver |

|

|

|

|

|

#960 |

|

Senior Member

Join Date: Mar 2011

Location: West Plains, Missouri

Posts: 7,559

|

Re: 55 Wagon Progress

Very nice...Jim

__________________

my build thread: http://67-72chevytrucks.com/vboard/s...d.php?t=459839 Jimbo's long bed step build:http://67-72chevytrucks.com/vboard/s...t=464626<br /> |

|

|

|

|

|

#961 |

|

Registered User

Join Date: Apr 2003

Location: Indep, MO

Posts: 5,893

|

Re: 55 Wagon Progress

Awesome work as always!

__________________

Boppa's Old Yeller Truck Build, Old Yeller's New Heart! Project Buzz Bomb Flyin' Low! |

|

|

|

|

|

#962 |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,647

|

Re: 55 Wagon Progress

Thanks for checking out the progress fellas!

Wire edged the opening this morning.. https://www.youtube.com/watch?v=w8Ay...ature=youtu.be

__________________

Robert |

|

|

|

|

|

#963 |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,647

|

Re: 55 Wagon Progress

Happy Thanksgiving everyone!

Had a request to show how the inside corners were tipped for wire edging the AC condenser opening. Here's a video (with poor audio.. iPhone seems to want to do a noise cancelling) that shows stretching the inner corners. I do spend a bit more time and accuracy on the real part, this was a quick, down and dirty demonstration.  https://www.youtube.com/watch?v=bkfr...ature=youtu.be We drilled out mounting hole pattern in the AC condenser to the radiator, and added AVK style rivet nuts to the radiator cross bars to secure.. Installed, this will be the profile of the upper mounting bracket (about 24+ inches wide), that will share the AC condenser upper mounting screws. Not sure if we want to do this in polished stainless or paint. Thoughts? The upper bracket will be attached to the core support also using rivet nuts, mainly from the back side to hide some of the hardware..

__________________

Robert Last edited by MP&C; 11-23-2018 at 12:32 PM. |

|

|

|

|

|

#964 |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,647

|

Re: 55 Wagon Progress

So this weekend I worked on the "new" dolly to remove some of the rust..

Started with the media blaster to remove all the rust and scale... Next, the pits were removed using 60 grit roloc sanding discs, followed by brown, red, and then blue scotchbrite discs. Then some media blasting to give a good finish.. Lastly, some 320 on the DA to remove scratches from the dolly face, and a trip to the pedestal buffer with some thick gloves. All that fun aside, back on radiator mounts. The upper will be a combination mount and also cover for the top of the core support. This will be 44" long, so to help the magnetic brake make some more crisp bends we'll thin the bend lines in the Lennox using a tipping die. the 44" length on the panel is a bit long for my 48" linear slide, so another section is added to give us 96" to play with. Just clears the Pexto shear.. Motion picture of the process: https://www.youtube.com/watch?v=rCxakebyQzs Bend lines in place .... ….and we left off there for some turkey dinner. Should get it trimmed on the sides and folded up this Tuesday night.

__________________

Robert |

|

|

|

|

|

#965 |

|

Post Whore

Join Date: May 2015

Location: Alabama

Posts: 14,662

|

Re: 55 Wagon Progress

That dolley turned out really nice!!

__________________

Mongo...aka Greg RIP Dad RIP Jesse 1981 C30 LQ9 NV4500..http://67-72chevytrucks.com/vboard/s...d.php?t=753598 Mongos AD- LS3 TR6060...http://67-72chevytrucks.com/vboard/s...34#post8522334 Columbus..the 1957 IH 4x4...http://67-72chevytrucks.com/vboard/s...63#post8082563 2023 Chevy Z71..daily driver |

|

|

|

|

|

#966 |

|

Registered User

Join Date: May 2010

Location: Lawrenceville, Ga

Posts: 2,646

|

Re: 55 Wagon Progress

|

|

|

|

|

|

#967 |

|

Senior Member

Join Date: Mar 2011

Location: West Plains, Missouri

Posts: 7,559

|

Re: 55 Wagon Progress

Most people would have thrown it away, not you, very nice save...Jim

__________________

my build thread: http://67-72chevytrucks.com/vboard/s...d.php?t=459839 Jimbo's long bed step build:http://67-72chevytrucks.com/vboard/s...t=464626<br /> |

|

|

|

|

|

#968 |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,647

|

Re: 55 Wagon Progress

Thanks guys!

Our 18 Gauge upper radiator mount / core support cover is cut out and bent to fit. Still needs some minor trimming around the radiator top and then we’ll make some threaded spotters to mark our rivet-nut holes. https://www.youtube.com/watch?v=5ZbACO-IHY4 .

__________________

Robert |

|

|

|

|

|

#969 |

|

Senior Member

Join Date: Mar 2011

Location: West Plains, Missouri

Posts: 7,559

|

Re: 55 Wagon Progress

very nice...Jim

__________________

my build thread: http://67-72chevytrucks.com/vboard/s...d.php?t=459839 Jimbo's long bed step build:http://67-72chevytrucks.com/vboard/s...t=464626<br /> |

|

|

|

|

|

#970 |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,647

|

Re: 55 Wagon Progress

Thanks for checking out the progress Jim!

Well as normal, one change leads to one or more others. We thought we'd test fit to check out the clearance for the hood latch striker out in front of the AC condenser. I missed getting a picture of our attempt, but here's a view of the original from the service manual. No way the original latch striker will work with the AC condenser that far forward. So we filled in the rear bolt hole and bent the latch striker as close as we could to the latch hole, which gave us 1-1/2” more room. The support structure would no longer have the rear bolt hole in the same location, and we needed to slim it down to the same width as the modified striker... Next, the rear bolt for the striker will need to be horizontal now, so a stud is fabricated and welded in place, and the support bracket modified for this bolting arrangement as well. Media blasted.... test fit.... https://www.youtube.com/watch?v=d5iE1T77WHQ .......and on to the next hurdle

__________________

Robert |

|

|

|

|

|

#971 |

|

Senior Member

Join Date: Mar 2011

Location: West Plains, Missouri

Posts: 7,559

|

Re: 55 Wagon Progress

Great work Robert, most people (including myself), will think it's stock...Jim

__________________

my build thread: http://67-72chevytrucks.com/vboard/s...d.php?t=459839 Jimbo's long bed step build:http://67-72chevytrucks.com/vboard/s...t=464626<br /> |

|

|

|

|

|

#972 |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,647

|

Re: 55 Wagon Progress

Thanks Jim, the subtlety we were looking for..

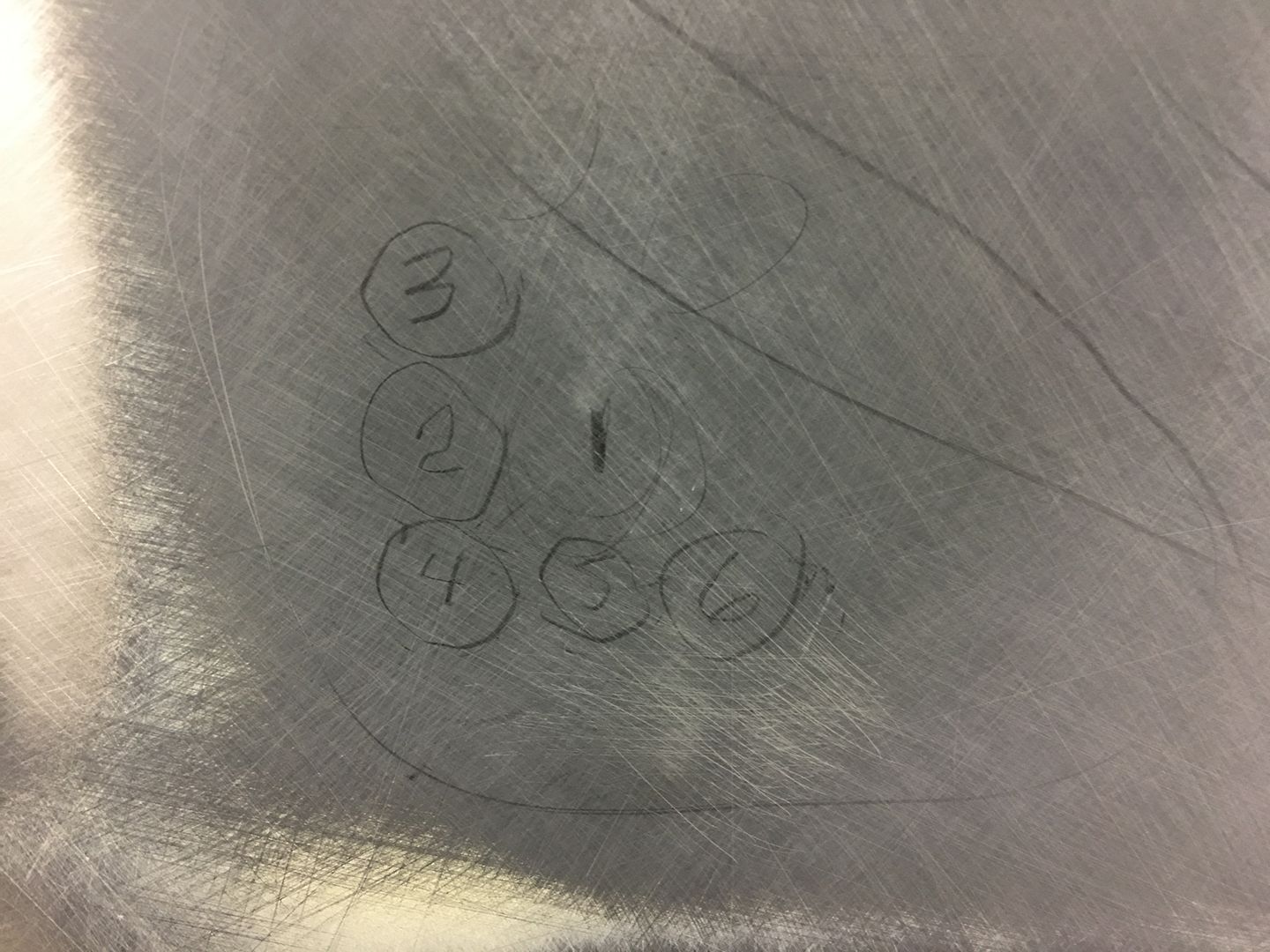

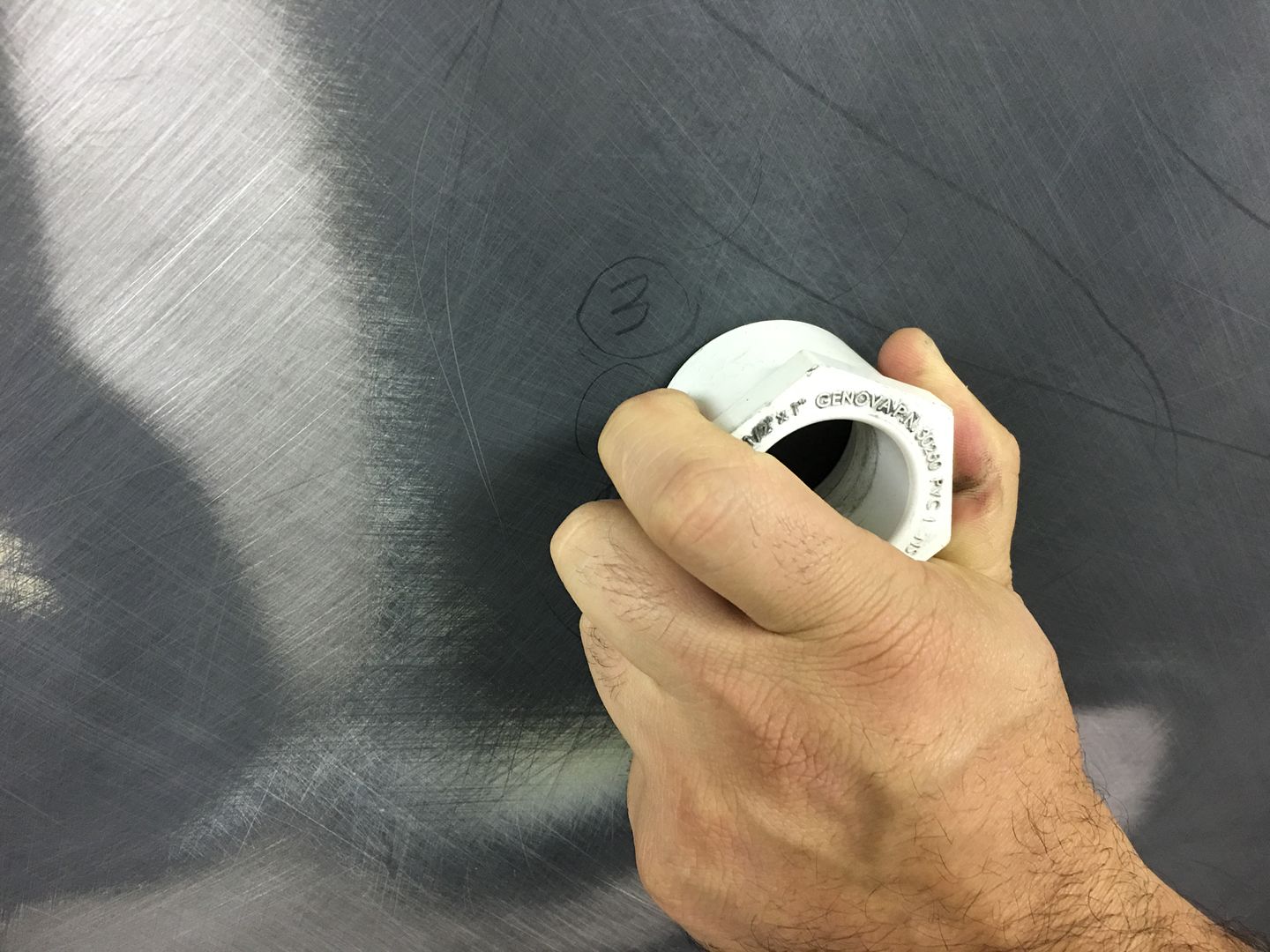

I took delivery the other day on a set of slide tracks so we used the opportunity to get the Arbor Press metalshaping dies from Pat Brubaker mounted under the table for better use of space. We used the Diacro press brake to bend some 1/8" aluminum for making some angle brackets for mounting. For those with a Diacro manual press brake, be aware the factory cast parts may not be 100% compatible with cheater bars. This happened a few months back, and our billet steel replacement is holding up much better, still has yet to transfer the problem farther down the line, knock on wood. E got the holes drilled out in the brackets, and I assembled the pieces.. This is much better.. a good start to cleaning off the table.. https://www.youtube.com/watch?v=i65pvDZGzio A demo of the process of using the arbor press.... https://www.youtube.com/watch?v=MUQghpUVohU .....and then today, Mike and I worked on blocking and straightening out the roof to get it a bit closer for painting. We did find a stretched spot in the roof, and chased it around a few times in using the body hammer and shot bag. No matter what we did, it tended to still have an up and down wave, so too much metal. The roof has been covered in SPI Epoxy for a while and I had no intention of removing the epoxy, so we opted for the donut dolly (this one home made) as it would leave the paint intact over using a torch.... Part of the difficulty in using the donut dolly is insuring the hammer aligns with the dolly for the most effective shrink. So we employed our magnet trick seen here: https://www.youtube.com/watch?v=Ubq89aPMJjY .......once the trouble areas needing a bump outward were located (they were stretched inward), the magnet was placed directly over the spots and then we could trace the locations on the inside for proper hammer strike while the donut dolly was held over the corresponding location on the outside. This was about the best results I've had using the donut dolly. Here are a few of the shrink locations used to straighten out the roof and its waves...

__________________

Robert |

|

|

|

|

|

#973 |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,647

|

Re: 55 Wagon Progress

https://www.youtube.com/watch?v=pTp3yWKFTdk

Had a couple questions about the donut dolly. Basically this is just like off dolly but on steroids, as supporting the panel surrounding the hammer strike gives a much more effective capture and shrink of the dent. This also helps to explain why alignment of the hammer to the dolly is so critical, and why the magnet alignment trick I showed in the earlier post works so well to make your shrinking more effective. The dolly should always be placed on the concave side to be able to hammer into the dolly and bring the panel back straight. For a larger, more pronounced dent I’ll use a flat hammer, like the Snap-on BF603. If the panel is wavy but still somewhat flat, then I’ll use a crowned hammer such as the Snap-on BF618. Use caution with the crowned hammer to not hit hard enough to add a dent, ideally we want to hit so that the metal pushes slightly into the dolly but the springback would bring it back to flush. (This comes with experience) It’s at this point that the donut dolly is most effective. The video shown simulates using a flat faced hammer on a large radius/dent. This could be used to remove the dent altogether, or perhaps just reduce the sharpness of the radius, like the rear roof corner on a Model A. None of the tools we have will do everything, but I’ve found the donut dolly especially useful in shrinking where you don’t want to use heat (torch).

__________________

Robert |

|

|

|

|

|

#974 |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,647

|

Re: 55 Wagon Progress

More progress on the wagon, we are adding a second interior light, so an original was sourced so they would match...

.....and media blasted, ready for primer..  Gary dropped off the rear seat so we could match drill holes into the side bolsters and install 5/16 rivet nuts for attachment..   And we found another low spot in the roof, likely due to media blasting the light bracket too close to the roof skin. We used the rare earth magnet trick to accurately locate the inside to outside for exact alignment of the hammer to the donut dolly..  outside, where we used the donut dolly to hammer into...   ....and the inside, where we use the crowned hammer.....   Using this method we were able to locate, layout, and bump all of the low spots to a consistent crown to match the surrounding panel, all in less than 5 minutes. In this case, a much better option than mixing and sanding filler. This video better shows the concept.. https://www.youtube.com/watch?v=HHHT...ature=youtu.be

__________________

Robert |

|

|

|

|

|

#975 |

|

Senior Member

Join Date: Mar 2011

Location: West Plains, Missouri

Posts: 7,559

|

Re: 55 Wagon Progress

Thanks for update...Jim

__________________

my build thread: http://67-72chevytrucks.com/vboard/s...d.php?t=459839 Jimbo's long bed step build:http://67-72chevytrucks.com/vboard/s...t=464626<br /> |

|

|

|

|

| Bookmarks |

|

|