|

|

|

#76 |

|

Registered User

Join Date: May 2008

Location: Alta Loma, Ca.

Posts: 930

|

Re: The Story Of A Suburban (Lots Of Pics)

Are you going to keep those front springs? I see they have wear buttons on the ends, but thickness of the material and the fact that with 3 leafs the weight of the engine did not sag it much, means those springs are pretty stiff. (whew, run on sentence) It seems to me that a lot of flex/force would be transferred to the chassis with those springs. Have you seen the conversion were they use Chevy 1/2 ton 52 inch back springs on the front? They move the front mount forward about 2 inches. This would give you a little more clearence for the Dana 60 and allow more spring flex than your lift springs would allow. It should save the chassis. The only reason I bring this up is I had a lift on my 1976 3/4 ton that only had 2 leafs. I swapped them out for another companies multi leaf spring with thinner leaf material and the ride was improved dramatically.

How much lighter is the 4 cylinder Cummins? I have heard they weigh about 800 lbs, which is not too much heavier than a complete big block, correct? I enjoy reading this thread because you have been very creative in making things work. This is a credit to your skills and thought process as a mechanic and fabricator. |

|

|

|

|

|

#77 | ||

|

I had a V-8

Join Date: May 2003

Location: Phoenix AZ

Posts: 1,116

|

Re: The Story Of A Suburban (Lots Of Pics)

For the foreseeable future, the front springs will remain. I have spent (and need to spend) so much money on this project that, at this point, I can not justify replacing new parts with new parts.

Quote:

Quote:

Thank you. I try to think things through before I start on a particular aspect of a project so that I do not have to go back and re-do something I just did. While this sounds good, it does not always work out as planned, but by reducing the amount of "re-do's" it helps keep morale up and forward progress happening.

__________________

1972 K20 Suburban, 5.9L Cummins, Banks Power Pack, NV4500HD, NP205, H.A.D., D60/14FF ARB Link To Build: HERE. |

||

|

|

|

|

|

#78 |

|

Registered User

Join Date: Mar 2007

Location: Ben Wheeler,Texas

Posts: 992

|

Re: The Story Of A Suburban (Lots Of Pics)

Love the build, can't wait to see it finished.

__________________

05 2500HD 6.0 excab 69 LWB-Gone but not forgotten! 68 Dodge Charger 383/727 69 Dodge Charger-440/4spd |

|

|

|

|

|

#79 |

|

I had a V-8

Join Date: May 2003

Location: Phoenix AZ

Posts: 1,116

|

Re: The Story Of A Suburban (Lots Of Pics)

Thanks, me too!! (the can't wait to see it done part)

So, I have some big items to fit in small spaces. I have a large coolant reservoir ('91 V3500) that needs to find a place to call its own. I tried fitting it on the passenger fenderwell where they normally live. It fit like crap. Not one of the three little feet hanging off of it touch the inner fenderwell in a way that it can be mounted because the feet are used soley for locating it--not supporting the weight of it. The weight, by design, is supported by the tank sitting on the fenderwell. This does not work for me because my fenderwell is the wrong shape. I located a fenderwell to cut up and mount the portion of the top where the tank would sit to my fenderwell. Not ideal, but it should work. Then my air filter and associated plumbing components arrive. Good gawd they are huge. I wanted to use a paper filter, but I ended up going with an AFE Pro-Guard 7 filter. It has the best fine dust particle filtration of any washable filter on the market (almost as good as dry paper). All of the other filters I researched measured their filter performance in LARGE dust particles--not good in dry, dusty AZ. Anyways, back to the story. The filter ironically fits an 02-03 Cummins. It has a 4" inlet nipple and uses a clamp to secure it to whatever it mounts to. That will do just super. Well, the dimensions I read on their site look ALOT smaller than actually looking at the part in person. I got some 4" elbows (2-45* and 1-90*) figuring I could make some combination of them work for me. Those looked alot larger in real-life too. None of this is going to work. There is no way to get the filter into the only space it can fit and plumb it to the turbo. It was suggested by a friend to put the filter on the driver side. I did not like the sound of it, and did not like the mental image that my mind created of it, but desperate times call for blah, blah, blah... I ended up entertaining the thought enough to see what would be required to get it over there. The thought did not last long because I would have to place a 45* elbow directly on top of the intake plenum or intercooler pipe. The problem was that there was not enough hool clearance for the elbow to sit up there. Uuuuugh!! What the hell am I going to do?? Is it too late to go back to a big block?? I found something else to work on (don't remember what) and went on about my business. A few days later I went out for a few minutes and decided to cut up some short sections of 4" pipe to connect the elbows. I cut the pipe, de-burred it and started fubling around with trying to make something usable out of them. I ended up with something that looked like it might work, but the coolant puke tank was not going to work. Uuuuugh. Wait!! What about moving the tank to the drivers side. I took it over to the drivers side, set it 90* clockwise from how it would sit on the passenger fender and almost fell over laughing when I saw that two of the three feet actually fit the fenderwell at the correct angle!! No-way!! But it gets better--no, really!! The third foot needs a flat spot to mount to. I looked down through the hole only to see the only flat spot on the whole fenderwell sitting DIRECTLY UNDER THE FOOT!! No!! This can't be possible!! Oh, but it was!! The only fab work required was to make a spacer about .375" to fill the space between the flat foot and the flat spot on the fenderwell and drill three holes!! There were clearance issues with the hood hinge, but I'll let the pics show that. Here is what I came up with for the air filter and plumbing: (it still needs a support bracket and clamps on it) It actually clears the alternator by a fuzz and will have a fair bit of clearance to the fenderwell when a support bracket is installed.  Puke tank mounted to drivers fenderwell: (notice how the hose nipple points in a nice downward angle that matches the shape of the fenderwell also the pic makes the tank look like it is mounted at a goofy angle when it is actually quite level)  Now, the hood hinges on these trucks are monsterous pieces of iron. The throw of the hinges is measured in feet. A clearance issue is going to result. Look back at the previous pic and notice the back side of the tank kind of zigs then zags. This is a notch in the top of the tank (the notch does not go all the way down to the base of the tank). Believe it or not, the hood hinge uses this notch for clearance!! The pic shows it, but I still do not believe it.  So there you have it. A bunch of big stuff making a big, cavernous engine compartment seem positively tiny. Oh, by the way, I'm getting closer.....

__________________

1972 K20 Suburban, 5.9L Cummins, Banks Power Pack, NV4500HD, NP205, H.A.D., D60/14FF ARB Link To Build: HERE. |

|

|

|

|

|

#80 |

|

Registered User

Join Date: Dec 2008

Location: K.C. Missouri

Posts: 1,024

|

Re: The Story Of A Suburban (Lots Of Pics)

The problem was that there was not enough hool clearance for the elbow to sit up there. Uuuuugh!! What the hell am I going to do?? Is it too late to go back to a big block??

I will do you a favor and trade you my big block truck, just to make life easy on you of course !!!!  Very nice work, and can't wait til my,...... I mean your new old truck is whining with that banks on top!!! should run well, I loved my turbo diesels, I made the mistake of buying 502/Allison trans 2001 HD after my last diesel was stolen. |

|

|

|

|

|

#81 |

|

I had a V-8

Join Date: May 2003

Location: Phoenix AZ

Posts: 1,116

|

Re: The Story Of A Suburban (Lots Of Pics)

I have been getting several requests/demands for an update, so here it goes. I have been working on the wiring lately and it is about as exciting as watching paint drying on grass that is growing. That, and, I make very slow progress so taking pics just drags out the process, but I did take a few, so here they are:

I guess I should give a bit of background on how I wire my vehicles. I use factory terminals, connectors, crimping tools, wire (thermal cross-linked polyethylene jacketed) and the factory high-temp loom when I build a harness. When I am done I require it to have the appearance, durability, longevity, and servicability of a factory wiring harness. This is no easy feat. All of the equipment listed is expensive and most is not readily available. If I run out of loom for example, I can not run down to the local parts store and pick some up. Some terminals and even a couple connectors are available, but that is about it. I started this strange obsession years ago when I put an injected 5.7L in my '71 Nova. I wanted to replace the engine control harness due to age, but I couldn't bring myself to pay the rediculous amount of money that they cost, just to cut it up and throw most of it away. At that point I started accumulating the factory terminals and connectors. Somewhere along the way I felt rich and bought three factory crimping tools for about $125.00 each. As time went by, I found more and more terminals and now I have three bin drawers full (way over-stuffed would be a much more accurate term) of the oe terminals with several boxes of factory connectors both Weather Pack and non-sealed (56 &59 series). I have one bin drawer of typical generic terminals (mostly ring terminals) that rarely get used. When I do use them, I pull the plastic off the end, then crimp, solder and apply heat shrink to seal them. Ok, now that boredom has completely set-in, here is a few pics. I needed a different temp switch for the cold start timing advance, so I ordered one from Cummins. The switch was different than the one that I had, so it required the use of a new harness. It wasn't terribly priced (about $25.00).  The problem is I was going to have to cut up half of it to make it work with my setup. I did some checking with my suppliers and found the correct connector body. The connector body uses pull-to-seat terminals (put the wire through the connector body, crimp the terminal on the wire then pull it back into the connector to lock the terminal in place) and I was out of this particular series (fairly common--just forgot to re-order when I used the last one). If I cut up the Cummins harness, I still needed the terminals because I do not splice wires. I remove the terminal from the connector and run my own wire into it. I got the connector body and a pack of 20 terminals for about $7.00.  Being this motor was originally in a Dodge, there were several Dodge connectors on it. I was able to convert all but one to GM connectors. The only one that I could not convert was the connector for the fuel heater. Refusing to splice wires, I searched for and found some oe Dodge terminals.  The story goes on and on, but here is a pic of the fan relays and fuses. I had a time figuring out a place to put them, so I put them on the inside of the fender next to the battery. It keeps them out of the way, but yet they can still be accessed if necessary. The jumbled mess of wire in the core support was not finished yet.  I decided to replace the lift pump with a better unit. It looks like the one off of a P-pump motor, but it is different--to the tune of double the money :eek1:. The P-pump lift pump puts out too much pressure to use on my motor. This new pump keeps pressure and volume up at high engine loads where the original design falters.  So there you have it. Not much to look at, but it sure is nice to have most of it done. I have to take a couple pics of a few things in the interior that I did. With this stuff done, I'm very close to starting functional electrical tests.

__________________

1972 K20 Suburban, 5.9L Cummins, Banks Power Pack, NV4500HD, NP205, H.A.D., D60/14FF ARB Link To Build: HERE. Last edited by mosesburb; 03-25-2009 at 04:48 AM. |

|

|

|

|

|

#82 |

|

I had a V-8

Join Date: May 2003

Location: Phoenix AZ

Posts: 1,116

|

Re: The Story Of A Suburban (Lots Of Pics)

Since this project has taken longer than expected, I decided I had better put an A/C compressor on it now rather than wait. I am glad I decided to do it this way as I did not realize how much work it was going to take.

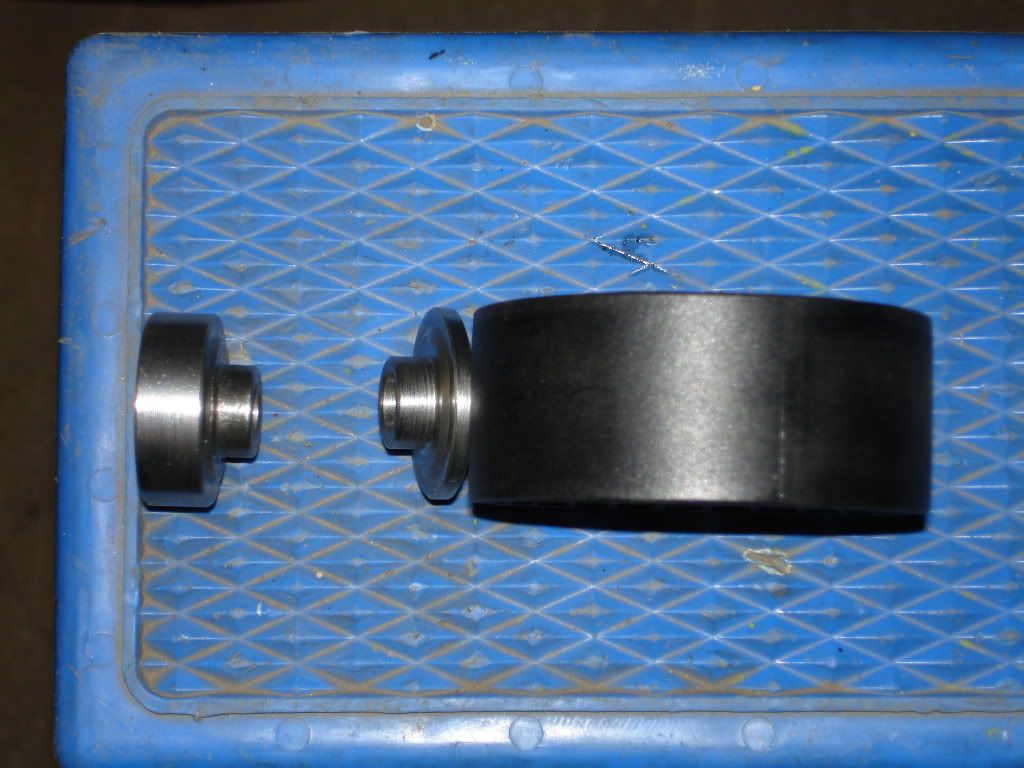

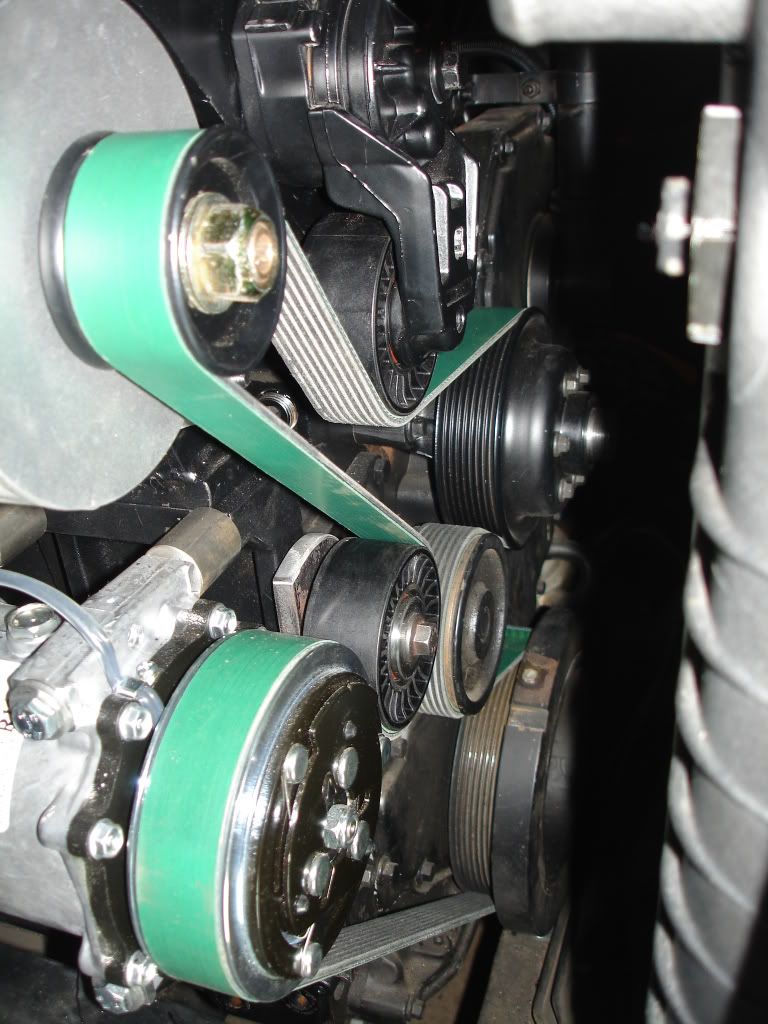

I went shopping through an A/C parts book and found a compressor off of a Sterling class 8 Tractor that looked like it would work great. I got it and installed it then instantly came to the realization that most of the work I spent on the accessory drive belt and lower hose was going to have to be re-done. Swell. The location of the compressor, directly under the alternator, created a situation that would have the belt coming off of the alternator and just barely glancing off of the compressor clutch. This would result in the belt screaming when the compressor engages. Not good. The problem is, there is not enough backside idler pullies in the system to re-route the belt and keep enough wrap on other vital components. I needed to add another backside idler, but there is no room to do it--none. I got an idea to try moving the compressor away from the engine. This worked rather well. It gave me some room to work with, but it also put the fittings for the compressor into the intercooler tube. I can deal with the intercooler tube later, but I need the clearance for a pulley now. I had Russ machine me up four 1.25" spacers for the compressor to make the room for the new pulley. I used the same pulley that is used on the tensioner to keep things simpler. I fabbed up a bracket to mount the pulley, but there were a couple problems with it. The major problem was the tensioner could swing down and make contact with it. First bracket fail:  The back of the holes it mounts to can kind of be seen it this pic. They are the shiny ones on the back of the front face. The lower set of holes have bolts in them:  It kind of sucked that this did not work as it was fairly quick to make and it looked good, but oh well. So I got to messing around with pulley location and found that the pulley needs to be mounted almost directly over one the top mounting hole of my first bracket. I could use that hole to mount the pulley to but it is only 8mm 1.25. I do not want to go any smaller than 10mm 1.5. So I came up with a bracket that used the bottom hole on the upper mounting pad and the two holes on the lower mounting pad. This allowed me to put a bolt hole where I need it without having to bore out the casting. The only problem with using the upper and lower pads is that they are on two different planes. I measured them out to be off by .250". Easy enough, just weld a piece of 1/4" flat stock to the back of my idler bracket.   I called on Russ's 24/7 Machine Shop to make a couple pulley bushings for this. I had him basically duplicate the mounting bushing for a 4.3L (same as a 5.0L and 5.7L TBI) idler pulley, but making the base thicker so the pulley is spaced correctly for proper alignment. While he was at it I requested a "washer" for the front of the pulley. Once again, he delivered in first class style exactly what was needed.  So with all of this, I was able to mount everything up and see what works. After several(!!) attempts at finding the correct belt length, I finally found one. One thing I learned through this is that changing a belt on this is an absolute royal hemorrhaging pain in the ass (putting it very mildly). That being the case, I do not want to do it again. I decided to go with one of Gates' HD serpentine belts. These are going over 100K in the new Class 8 trucks that had been cooking off standard belts in 10-30K. I figure if it will go 100K on a Class 8 with EGR, it should last forever in my truck. The only issue I have with it is its nasty color. Now mind you my favorite color is green, but this just does not do it for me. Oh well, I will deal with the ugly color to not have to deal with changing it again anytime soon. In this pic the spacers for the compressor are visible and it shows the belt wrap on the compressor (well over 180*). There should be no issues with squeal on any component now. It looks like the belt is real close to touching between the new idler and the water pump pulley, but there is actually about 3/8" clearance between them.  So I found a compressor for a Peterbilt application that should work good. I just have to pick it up and get everything back together. I am getting farther away, but closer.....

__________________

1972 K20 Suburban, 5.9L Cummins, Banks Power Pack, NV4500HD, NP205, H.A.D., D60/14FF ARB Link To Build: HERE. |

|

|

|

|

|

#83 |

|

high-Tech Red Neck

Join Date: Feb 2008

Location: Livingston, MT/On my boat WA/BC/AK

Posts: 2,294

|

Re: The Story Of A Suburban (Lots Of Pics)

I tell you what man, it is a lot of work, but you are doing it right, and in the end, that is what will make the ole burb enjoyable to you when you can thumb your nose at the guy with a 55,000.00 excursion or escalade who is broke down on the side of the road, and you are out tooling on bye blowing a little black smoke their way.

I am pretty impressed with your install, I know when I get to putting the Cummins in my Dually I will be taking some very serious notes.

__________________

"He used to be a pretty nice feller, now he's a welder!" |

|

|

|

|

|

#84 |

|

I had a V-8

Join Date: May 2003

Location: Phoenix AZ

Posts: 1,116

|

Re: The Story Of A Suburban (Lots Of Pics)

Thanks man!!

I have gotten a few more things done lately. I figured out where my windshield washer reservoir needed to be located. I had some room left under the passenger battery tray, behind the headlight. I had a time trying to find a reservoir to fit in the allotted space and finally ended up with another '91 V3500 part. It fit the space great and met the requirements of having an integral electric pump. I got the reservoir and every other component, so I can get rid of the metal nozzles and go with wet arms. Just FYI, if anyone is thinking of trying this, the wiper arms from the later-body trucks are too long for these trucks.  In addition to three underdash/floor lamps, I also added a rear view mirror from a '93 S10. It has the two lamps that come on with the door jamb switches and stay on for 15 seconds or the key is turned to the run position (whichever comes first). I fished the wires up the "A" pillar and then across the panel above the windshield. I thought fishing wires up the "A" pillar was a ***** until I started fishing them across the panel above the windshield. Man, did that ever bring the suck. I finally succeeded and it is a pretty cool feature. The pic makes the wires look like they are hap-hazardly routed, but in real-life they look pretty clean.  I also figured out where my auxilliary (tach, EGT, and boost) gauges have to go. I wanted them in front of me, but with the way they did the defroster ducts, it would have left me with no defrost on my side. I had to put them to the right of the defrost duct, partially covering the speaker grille in the dash. Unfortuantely, I will not be able to run center speakers now, but oh well.  As of now, I have performed functional electrical tests and after taking care of a couple glitches, everything operates as intended. It's getting close, real close.....

__________________

1972 K20 Suburban, 5.9L Cummins, Banks Power Pack, NV4500HD, NP205, H.A.D., D60/14FF ARB Link To Build: HERE. |

|

|

|

|

|

#85 |

|

Registered User

Join Date: Dec 2008

Location: K.C. Missouri

Posts: 1,024

|

Re: The Story Of A Suburban (Lots Of Pics)

Where's the CB go?

|

|

|

|

|

|

#86 |

|

high-Tech Red Neck

Join Date: Feb 2008

Location: Livingston, MT/On my boat WA/BC/AK

Posts: 2,294

|

Re: The Story Of A Suburban (Lots Of Pics)

So now that you have done all this work to the truck, are you going to be getting it painted? And what color you have in mind if you do?

__________________

"He used to be a pretty nice feller, now he's a welder!" |

|

|

|

|

|

#87 |

|

high-Tech Red Neck

Join Date: Feb 2008

Location: Livingston, MT/On my boat WA/BC/AK

Posts: 2,294

|

Re: The Story Of A Suburban (Lots Of Pics)

__________________

"He used to be a pretty nice feller, now he's a welder!" |

|

|

|

|

|

#88 | |

|

I had a V-8

Join Date: May 2003

Location: Phoenix AZ

Posts: 1,116

|

Re: The Story Of A Suburban (Lots Of Pics)

Quote:

I have not decided yet. I hate body work with a passion, but I refuse to pay anybody to do it for me. I think I will try to drive the wheels off of this thing before I start any new projects on it.

__________________

1972 K20 Suburban, 5.9L Cummins, Banks Power Pack, NV4500HD, NP205, H.A.D., D60/14FF ARB Link To Build: HERE. |

|

|

|

|

|

|

#89 |

|

I'm a poor spectator

Join Date: Aug 2006

Location: San Antonio, Tx

Posts: 2,287

|

Re: The Story Of A Suburban (Lots Of Pics)

Just got caught up on your project, nice.

__________________

2006 Jeep Unlimited IMPACT ORANGE 1993 Chevy 2500 4x4 ExCab LWB 454/NV4500 Tow rig  1977 Ford F100 2x4 LWB 1st truck I owned, still have it!!!  1979 Ford F150 4x4 SWB Built Ford Tough!!!  1971 Chevy Blazer 350 / SM465 / NP205 UNDER CONSTRUCTION Soon to have a LQ4 6.0!!! |

|

|

|

|

|

#90 |

|

Registered User

Join Date: Dec 2004

Location: Northern AZ

Posts: 7,271

|

Re: The Story Of A Suburban (Lots Of Pics)

Hurry up and get it done, I need my Burb back!! Just kiddin' this is the Burb I have wanted to build and next weekend I take one step closer to doing that as I am picking up a nice 2wd Burb while I am down there. I'll hopefully get to meet up w/ya and get to see this in person and pick up the the intake and shroud!

PM me? |

|

|

|

|

|

#91 |

|

Registered User

Join Date: Jul 2005

Location: Kernersville, NC

Posts: 599

|

Re: The Story Of A Suburban (Lots Of Pics)

sat here and read the whole thing. one heck of a build. looks like your doin a dang good job. cant wait to see some videos of this thing once ya get done. chris.

__________________

its a work in progess. 71 c-10 lwb, in the middle of frame off restoration. 69 c-10 swb, drag truck, 406 sbc, balanced, comp 292 cam, ported, polished, gasket matched, and bowl blended pro comp 210cc heads, 2.02/1.60 ferrea valves,1.6 roller rockers, re curved hei with msd 6al box, 2-step rev limter, accel 300+ wires, ported victor jr intake, holley 750 double pumper carb, dynomax 1 5/8 headers, 4 spd munci m-20 with super case and iron midplate, mr. gasket vertigate shifter, 5.38 pro gears with full spool, 33 spline moser axles and c-clip elimators, line-loc, 5 gal fuel cell, holley blue pump.   7.807 @ 88.37mph 1.60 60FT 80 g-20 van, tow rig, cammed 305, th350, 10 bolt 88 jeep wrangler, dd, 258, ax-15 swap, 4.5" lift, 33x12.50's, lockers, 3.55's |

|

|

|

|

|

#92 |

|

Engine n00b

Join Date: Feb 2008

Location: Austin

Posts: 1,031

|

Re: The Story Of A Suburban (Lots Of Pics)

great thread - subscribing.

|

|

|

|

|

|

#93 | ||

|

I had a V-8

Join Date: May 2003

Location: Phoenix AZ

Posts: 1,116

|

Re: The Story Of A Suburban (Lots Of Pics)

Quote:

Holy cow!! You must have brought a sandwich!! Quote:

Thanks!! Well, no new pics to show, but there is news here. I got it running last week!! I bled the injectors and tried cranking for oil pressure to no avail, so I turned the fuel on and it lit up like it had run yesterday--oil pressure came right up after it started. Sounds *****in'!! Of course, that may have something to do with only having 12" of pipe hanging off of the turbo, but I'm diggin it nonetheless. My neighbors now have a complete understanding of what I have been doing under the hood of this thing for the past year now, hehehe. I let it run for awhile, doing functional tests on components and everything seems cool. The only problems I had were a leaking coolant reservoir (new GM part) and no power steering/braking assist. I chased that monkey for about a week and a half until I finally found the problem in the pump. I got that straightened out and everything works great. I got the NP205 torn down and cleaned up with the guts ready to go into my housing and started working on my NV4500 also. Everything looks good, just need to clean the parts and get it together. I'm looking forward to driving this thing now!! So everything is going well until I was at my Mom's house last weekend doing some electrical work for her and managed to put myself out of comission for awhile.  The white diagonal line near the top of the thumb is NOT supposed to be there. I was cutting a piece of conduit with my 28V Sawzall (nowhere near as smooth as my corded Super Sawzall) and the material pinched the blade and was moving with the blade. Well, sometime in there my thumb somehow managed to get between the material and the shoe on the Sawzall and BANG, BANG, BANG, BANG, BANG, BANG, BANG, BANG, etc. I ended up with a purple fingernail and lost a dime sized chunk of skin on the fingerprint side. Now, I'm no stranger to the Band-Aid box (I carry my own stash at all times), but this had to rank in the top one or two most painful injuries in recent memory. I waited a couple days and went and got it checked out because it was hurting well below the injured area. Doc couldn't explain why it hurt where it hurt, but informed me that I had done more damage that I initially thought. Swell. Now I get to sit home and do basically nothing. No work (not good), no work in the shop, nothing. Grrr. I'm really close, but I can't do a damn thing about it....

__________________

1972 K20 Suburban, 5.9L Cummins, Banks Power Pack, NV4500HD, NP205, H.A.D., D60/14FF ARB Link To Build: HERE. |

||

|

|

|

|

|

#94 |

|

Registered User

Join Date: Mar 2007

Location: Ben Wheeler,Texas

Posts: 992

|

Re: The Story Of A Suburban (Lots Of Pics)

Brings back memories of the finger between the trailer ball and tounge of the trailer and stupid me deciding "pull" was the best option at the time! Glad you got her breathing black smoke!

__________________

05 2500HD 6.0 excab 69 LWB-Gone but not forgotten! 68 Dodge Charger 383/727 69 Dodge Charger-440/4spd |

|

|

|

|

|

#95 |

|

Registered User

Join Date: Dec 2008

Location: K.C. Missouri

Posts: 1,024

|

Re: The Story Of A Suburban (Lots Of Pics)

Damn, That sucks!!! Sorry to hear it, glad to hear another Suburbans running though,

|

|

|

|

|

|

#96 |

|

Registered User

Join Date: Dec 2004

Location: Northern AZ

Posts: 7,271

|

Re: The Story Of A Suburban (Lots Of Pics)

Looks like I'll be there this weekend, so if you can handle the pain, I'd love to hear her run!!

|

|

|

|

|

|

#97 |

|

I had a V-8

Join Date: May 2003

Location: Phoenix AZ

Posts: 1,116

|

Re: The Story Of A Suburban (Lots Of Pics)

I have had a couple requests for information regarding my fuel tank installation and seeing as how I can't do much productive work with only one opposable thumb and all, I figured this was a good time to give a few details on the swap.

As was previously stated, I used a fuel tank from azblazer/K5NUTT's 79 K5. Now, we all realize that these tanks have the fuel fill pipe on the passenger side and our fill is on the driver's side. I remedied this by rotating the tank 180* front to back. The only problem I see with this is reduction of departure angle. This is something to consider, seeing as how Suburbans have an extremely horrible departure angle to start with. I decided to roll the dice and give it a shot anyways. That being said, if I were to do it again, I would take a good look at a similar vintage van. They had similar capacities and the fuel fill pipe is already on the driver's side. I am not sure if the dimensions work or not, but if they do and they have the taper at the rear, this may just be the hot ticket. Now, I stated "similar vintage". There is a reason for this. Our trucks use what is now considered a tiny 1-3/8" fill pipe. Most newer vehicles use 1-1/2" or larger fill pipe. Up to at least 1979, the fill pipe diameter was still 1-3/8". There are ways around this if you opt to use a later model tank (i.e. late model with fuel injection sending unit and internal baffeling for F/I). I have done it. It is not real fun, but it can be done. It involves welding a "bushing" onto the end of the existing fill pipe that matches the diameter of the fill pipe on the tank. One benefit to doing this is it gets you into a larger diameter hose which is easier to find. Gates now makes fuel fill hose with 45* and 90* bends, but they do not make it in 1-3/8". The nuts and bolts of the swap are pretty straightforward. In the back, I used a piece of 5/16" x 4" flat stock laid across and bolted to the top of the frame rails spaced up by a piece of 5/16 x 2" flat stock. In the front, I used a piece of 3/8" x 3" flat stock. This is what the top of the tank will be loaded against when installed. I used this strange combination of material to avoid using a channel type material to keep from running into interference with the body. After all was said and done, I realize this was not necessary as there was room to have support ribs, but what I made works, so there it stays. I made two crossmembers out of 2x2x.187 wall angle stock for the straps to mount to. For the straps, I used stock GM replacement straps for a '79 K5. They lend themselves well to adapting to a project like this because they have a hook on one end and a threaded stud on the other. For vibration isolation/abrasion resistance, I used 60lb roofing felt for the strap iinsulators and upper tank cushions. It works great and is readily available if you have recently replaced a roof. I guess some pics are in order. This is the rear upper mounting. The spcers under the plate can be seen.  This is the front upper mounting. It also illustrates the location of the front of the tank relative to the frame/body.  This is the forward crossmember for mounting the straps:  This is the rear crossmember:  So that shows the basic mounting of the tank. If I had it to do over, I would probably change a few things, but this is what I have for now. In my opinion, there are many advantages to doing this swap over a custom tank. One being cost. Finding a tank in a wrecking yard is cheap, the mounting steel is cheap, the straps from GM are not terribly cheap, but not too terribly expensive either. Another advantage is it is all GM. Go to the parts store and get a sending unit or a tank seal or a sending unit strainer etc--readily available cheap parts. The sending unit, whether you use an old tank or a fuel injection tank will be the same 0-90 ohm range as your original gauge--not some aftermarket only range that renders your oe gauge useless. I feel it is also a clean swap. The tank looks like it belongs in the truck. It is not an angular, welded unit. It is a clean, smooth, radiused unit. Maybe that's not worth much, but I think it keeps the clean look going on. So there you have it. This is how I did mine. I am sure there are many other ways to obtain the same end result, but I wanted to show how I did mine to hopefully answer some questions of give a visual or two on what one way to do it is. Man, typing with only one thumb in an interesting endeavour. It doesn't seem like it should make much difference, but it sure takes alot longer.

__________________

1972 K20 Suburban, 5.9L Cummins, Banks Power Pack, NV4500HD, NP205, H.A.D., D60/14FF ARB Link To Build: HERE. |

|

|

|

|

|

#98 |

|

I had a V-8

Join Date: May 2003

Location: Phoenix AZ

Posts: 1,116

|

Re: The Story Of A Suburban (Lots Of Pics)

So, technically I am released to go back to work tomorrow night. I figured I should take the structure off of my thumb and see what I can actually do with it. May as well do something on the Sub right??

I decide the project of the day will be bending up some 1-1/4" x .187" flat stock to serve as a support for the air filter/intake plumbing. Good thing to do with a questionable thumb I figure. So I get to bending the flat stock up and things are going pretty good. Every once in awhile I get a friendly reminder through my central nervous system that I have an injured thumb, but not as often as I thought I would. So I get the bracket made (had to use a Sawzall twice) and get it painted. In the mean time I clean up my "hose connectors" and prepare them for installation. Around now, my wife comes out and says she's going somewhere to meet up with one of her friends to shop, eat, something. So, I put some RTV that I got from the International Truck store in the ends of the tubes and install the connectors. I wanted to use this RTV because it has weapons grade strength--unbelievable stuff--it is like ten part epoxy or something. I get it in there and install the connectors and put clamps on. I put the filter on and the pre-filter cover also. I look at it, liking what I see, and decide I need to run the motor--just to make sure everything is good-to-go of course. Well, my boy likes to push the button on the remote starter under the hood and make the engine run, so I locate him in the front yard and invite him over to make it run. He comes over and hits the switch and it rattles to life with no effort at all. I set the manual throttle to 1200rpm and let it run. Well, the one thing i did not realize was that the front door on the house was open. The screen door was closed, but the inside door was wide open. I came in after it had been running for around 15min and whoa, my house had the heavenly aroma of pre-burned diesel fuel. Oh noez!! I have the silly suspicion that my wife is not going to have the same appreciation for the scent of the air inside the house as I do. Sooo, as I sit here typing this I have all the doors open with my cooler running in warp drive trying to clear the air before she gets home. I hope I am successful...... If I make no future posts here, you will know the answer.

__________________

1972 K20 Suburban, 5.9L Cummins, Banks Power Pack, NV4500HD, NP205, H.A.D., D60/14FF ARB Link To Build: HERE. |

|

|

|

|

|

#99 |

|

I had a V-8

Join Date: May 2003

Location: Phoenix AZ

Posts: 1,116

|

Re: The Story Of A Suburban (Lots Of Pics)

Well, I pulled it off. Got the house cleared out before she got home. I did tell her about it because I knew what was going to happen today. Sure enough, I hear my boy throwing me under the bus explaining what went on while she was away. He did take some undeserved blame in telling her that HE had forgotten to close the door, so good on him for that one.

Anyways, I realized that I had not posted any overview pics of the engine bay since I finished it up. So, without further delay, here are a couple:  And:

__________________

1972 K20 Suburban, 5.9L Cummins, Banks Power Pack, NV4500HD, NP205, H.A.D., D60/14FF ARB Link To Build: HERE. |

|

|

|

|

|

#100 |

|

PROJECT 7DEUCE

Join Date: Dec 2002

Location: GRANTS PASS OR

Posts: 21,608

|

Re: The Story Of A Suburban (Lots Of Pics)

It almost looks factory.. Job very well done..

__________________

GO BIG GREEN  GO DUCKS GO DUCKSMEMBER #6377 72 k-5 daily driver 6'' lift 35'' 350-350-205 slowly getting rust free. Project "7DEUCE" check out my build http://67-72chevytrucks.com/vboard/s...d.php?t=267665 Tim Powell..R.I.P EastSideLowlife..... R.I.P.. |

|

|

|

|

| Bookmarks |

|

|