|

|

|

|

|

#1 |

|

Always a work in progress

Join Date: Jun 2007

Location: Harker Heights, TX

Posts: 1,599

|

Re: 4L80E & TH400 Tech.

Ok I need some converter suggestions:

73 C10 5.3 w/243 heads shaved .025 to keep stock compression ratio Lunati 60510 Cam 212/218 @ .050 262/268 duration Lobe Sep 113 531/531 lift 3.90 rear gears 28" tall tire 98 4l80e stock 97k miles

__________________

USMC Retired Never trust a man who can't laugh at his own fart! 2010 Silverado Crew Cab 73 SWB 5.3/4l80e Build Thread: http://67-72chevytrucks.com/vboard/s...d.php?t=695168 Last edited by softballnrd27; 03-24-2016 at 12:37 PM. |

|

|

|

|

|

#2 |

|

Senior Member

Join Date: May 2009

Location: Fort Worth, TX

Posts: 6,370

|

Re: 4L80E & TH400 Tech.

Give Chris at Circle D Specialties a call. Their in Houston.

|

|

|

|

|

|

#3 |

|

Registered User

Join Date: Nov 2010

Location: Alabama

Posts: 740

|

Re: 4L80E & TH400 Tech.

Thanks for your input. Do you recommend starting with a 2wd trans for adapting the NP205?

|

|

|

|

|

|

#4 | |

|

Senior Member

Join Date: May 2009

Location: Fort Worth, TX

Posts: 6,370

|

Re: 4L80E & TH400 Tech.

Quote:

4wd Output shaft are cast & machined as 2wd shafts, Then are cut off for 4wd applications. TH400 Adaptors do not fit 4L80E's without machining the "Register" down a little. |

|

|

|

|

|

|

#5 |

|

Registered User

Join Date: Nov 2010

Location: Alabama

Posts: 740

|

Re: 4L80E & TH400 Tech.

Great thanks.

Has anyone tried a vss pulse generator like this and had good results? http://www.dakotadigital.com/index.c...109/prd109.htm |

|

|

|

|

|

#6 |

|

Always a work in progress

Join Date: Jun 2007

Location: Harker Heights, TX

Posts: 1,599

|

Re: 4L80E & TH400 Tech.

Clinebarger-

I'm prepping for the worst with the 4l80e I got and would like to know that if the trans needed a rebuild, is it feasible just to get a basic rebuild kit with all the parts you suggest and later(way later) on down the road when I do start making more power can I just upgrade the hard parts without a new rebuild kit? Billet shaft and stuff like that

__________________

USMC Retired Never trust a man who can't laugh at his own fart! 2010 Silverado Crew Cab 73 SWB 5.3/4l80e Build Thread: http://67-72chevytrucks.com/vboard/s...d.php?t=695168 |

|

|

|

|

|

#7 |

|

Senior Member

Join Date: May 2009

Location: Fort Worth, TX

Posts: 6,370

|

Re: 4L80E & TH400 Tech.

You will need a basic Seal Kit or Buy individual seals from GM.

For example....If you pull the Pump out to replace the Input Shaft, You will need the Pump to Case paper gasket & all 4 Sealing Rings on the Shaft itself. If I were you....I would do the SpiroLock Intermediate Snap Ring & Billet Forward Hub now so you don't have to pull the Valve Body, O/D Housing Bolt, O/D Housing, Forward & Direct Drums to install the Snap Ring & Forward Hub. These 2 items only add $200 to the build. Then you just have to pull the Pump, & O/D Carrier/Overrun Housing to replace the Input Shaft later on (Don't even have to remove the Pan) |

|

|

|

|

|

#8 |

|

Registered User

Join Date: Oct 2012

Location: Detroit

Posts: 748

|

Re: 4L80E & TH400 Tech.

Chris,

Just wanted to thanks for all your help and info from this thread on my rebuild. Trans is done and ready to go back in the truck.

__________________

Brandon Instagram: DRVFSTR Current Project: Beatrix - 1967 SWB LQ4/78mm Turbo/4L80e/ on bags Build thread: http://67-72chevytrucks.com/vboard/s...d.php?t=634691 |

|

|

|

|

|

#9 |

|

Senior Member

Join Date: May 2009

Location: Fort Worth, TX

Posts: 6,370

|

Re: 4L80E & TH400 Tech.

Your welcome, Let us know how is shifts.

|

|

|

|

|

|

#10 |

|

I'm just glad to be here!

Join Date: Jan 2008

Location: Longview, TX

Posts: 4,788

|

Re: 4L80E & TH400 Tech.

Chris

I have more of a programming question than a mechanical rebuild question for the 4l80e. The set up is a 5.3 running off a 2000 Silverado PCM. We did a segment swap to change from a 4l60e to the 4l80e. Followed the wiring changes needed as found on LT1Swap.com. The truck idles fine in park or neutral, but stumbles and dies when you put it in gear. From past experience with a TH350 doing this, it would lead me to believe the convertor is to tight and loading up the engine. Before going to that point and swapping convertors, we have some other thoughts/questions. When we shift the trans to drive or reverse, the notice the O2 sensors nearly stop working and then it dies. If we add 1-2% throttle, we can keep it running. How does the electronics of the trans interface with the PCM? Does shifting it to drive electronically effect some part of the tune for the engine? If so, what parts should I look at? Thanks!

__________________

Karl  1965 Chevy Stepside(Grandpa's Old Blue) and (July 2015 Shop Build!)(2020, the Saga Continues) http://67-72chevytrucks.com/vboard/s...d.php?t=372424 The LST Challenge: http://67-72chevytrucks.com/vboard/s...=1#post7812257 Korbin's 1st Square: "Sunburn" http://67-72chevytrucks.com/vboard/s...d.php?t=418618 1985 GMC Sierra: "White Trash", Korbin's 2nd now... http://67-72chevytrucks.com/vboard/s...d.php?t=632305 Henry - 1984 Chevrolet, Owen's 1st Square |

|

|

|

|

|

#11 |

|

Registered User

Join Date: Oct 2012

Location: Detroit

Posts: 748

|

Re: 4L80E & TH400 Tech.

More like how it holds up to my abuse and the twin turbos

__________________

Brandon Instagram: DRVFSTR Current Project: Beatrix - 1967 SWB LQ4/78mm Turbo/4L80e/ on bags Build thread: http://67-72chevytrucks.com/vboard/s...d.php?t=634691 |

|

|

|

|

|

#12 | |

|

Senior Member

Join Date: May 2009

Location: Fort Worth, TX

Posts: 6,370

|

Re: 4L80E & TH400 Tech.

Quote:

Is you IAC motor working?, A stuck IAC will cause this issue because it cannot adjust for load. Converter Clutch Drag is VERY common on high mileage 4L80E's because the lack of "Lube to Line" bypass on stock units, Is this a rebuilt unit? This usually rears its ugly head when the unit is Hot/At operating temp. I'm not a Tuner, I wish I was!! Boosted C10, BrewCity, or Hart Rod will know more about that. I take that back....I don't wish I was, My plate is full enough Pressure Rise, Pressure Rise, Pressure Rise

|

|

|

|

|

|

|

#13 |

|

Registered User

Join Date: Aug 2004

Location: phoenix az

Posts: 105

|

Re: 4L80E & TH400 Tech.

Is there any advantage of using 6 over 5 disc direct drum? I know 6 will hold more lbs but is it worth the trouble. I'm using a 4L80E 34 sprag direct drum. I need to buy a aluminum piston the 2 sources I found said they could machine it to work with 6 disc or 5. It was my understanding that the 4L80E direct Drum has enough room for 6 disc if you remove the wavy and replace with steels.

|

|

|

|

|

|

#14 | |

|

Senior Member

Join Date: May 2009

Location: Fort Worth, TX

Posts: 6,370

|

Re: 4L80E & TH400 Tech.

Quote:

There was a few TH400's that came Factory with 6 Frictions in the Direct Drum (Behind 500 Cadillac's mostly), The 4L80E drum is machined to the same depth. Technically it has room for the Wave & 6 Frictions, Depending on the Machined Height of the Piston. What you DO NOT want too do is use a late 4L80E wave plate with a Piston machined for 6 Frictions & a Wave Plate, The 4L80E Wave is super thin & can get logged under the "Lip" in the Drum & burn the Directs down, Break the Piston etc. It is fine to run no Wave in the Directs......BUT, Along with Blocking the 3rd Accumulator, Can cause a overly harsh 3rd Apply. More Direct Clutch/Drum info.... Sometimes, You can Omit the Wave, Stack the Directs with 6 Forward .077" Steels & 6 .080" Frictions with a 5-Friction Piston, It's a rare occurrence this stacks-up with the correct clearance (.010" per friction), Got to watch what you read on the internet....Just because it works on one Drum/Piston/Backing Plate combination, Does Not mean it will work for you! As I touched on in our PM exchange....You NEED a Bleed Checkball in the Drum OR the Piston....But NOT both, Aluminum Pistons come in BOTH configurations! All 34 Element 4L80E Direct Drums have the Bleed in the Drum. If you or others get a Piston with a Bleed Capsule.......It's a easy fix with a 1/4-28 Set-Screw. Drill out the 2 tangs holding the Checkball in place, Remove the Checkball, Drill the hole all the way through with a 7/32" Drill Bit, Tap the hole with a 1/4-28 Tap.....NOT all the way trough!! You have to leave material for the Set-Screw too seat against, After you get the depth set right, Loctite the Set-Screw in & let sit overnight. Aluminum Direct Piston with a Bleed Checkball, & the 1/4-28 Set-Screw.  The Same piston from the top, The deep spring pockets, The fact they can be machined, & They are very Stout are the reasons to use the Aluminum Direct Piston in any H/P TH400 or 4L80E build using High Rate return springs. The Yellow circle is the Bleed, Between the 2 arrows is the material that gets machined for Piston/Clutch height.  This is a Stamped Steel TH400 Direct Piston with a Insert too control height, DO NOT use this Piston, They work OK on stock builds, Put Pressure to them & they can & will Fail!  4L80E Molded Stamped Steel Piston, Not suitable for High Rate Springs.

|

|

|

|

|

|

|

#15 |

|

Registered User

Join Date: Aug 2004

Location: phoenix az

Posts: 105

|

Re: 4L80E & TH400 Tech.

Would it be okay to run the heavy duty return springs with 5 clutch disk setup and all the modifications you describe in this thread? No reason for me to use anything from the transgo 400-pro kit I bought Ill just return it to summit. Thanks for posting the pictures some good information there.

|

|

|

|

|

|

#16 | |

|

Senior Member

Join Date: May 2009

Location: Fort Worth, TX

Posts: 6,370

|

Re: 4L80E & TH400 Tech.

Quote:

I'm not a big fan of the Trans Go 400-Pro anyway......Mostly because the Multi Layer Separator Plate. That's how they Dual Feed the Directs without trans tear down. The Overkill Pressure Regulator Spring bumps pressure too much at Idle/No load. If you need to downshift into 1st at high speeds....I can walk you through that modification. But you will need to purchase the Return Springs, Boost Valve, & Intermediate Snap Ring separately. Return Springs http://www.ckperformance.com/View/HI...ELEASE-SPRINGS Boost Valve https://www.summitracing.com/parts/sox-400-lb1 Spirolock Intermediate Snap-Ring http://www.ckperformance.com/View/TH...UTCH-SNAP-RING If the budget allows, A Billet Direct Piston would be a nice addition & You can spec it out the way YOU want! http://www.ckperformance.com/View/BI...-CLUTCH-PISTON |

|

|

|

|

|

|

#17 |

|

Registered User

Join Date: Aug 2004

Location: phoenix az

Posts: 105

|

Re: 4L80E & TH400 Tech.

I would like to be able to manually shift down to 1st gear if possible. What do you think about this pressure regulator spring CK sells 185-190 PSI http://www.ckperformance.com/View/TH...GULATOR-SPRING Should I just leave the stock spring in the pump?

|

|

|

|

|

|

#18 |

|

Senior Member

Join Date: May 2009

Location: Fort Worth, TX

Posts: 6,370

|

Re: 4L80E & TH400 Tech.

I'll snag a Valve Body from work & go through the mod with you, Just keep in mind it will shift into 1st at ANY speed!!

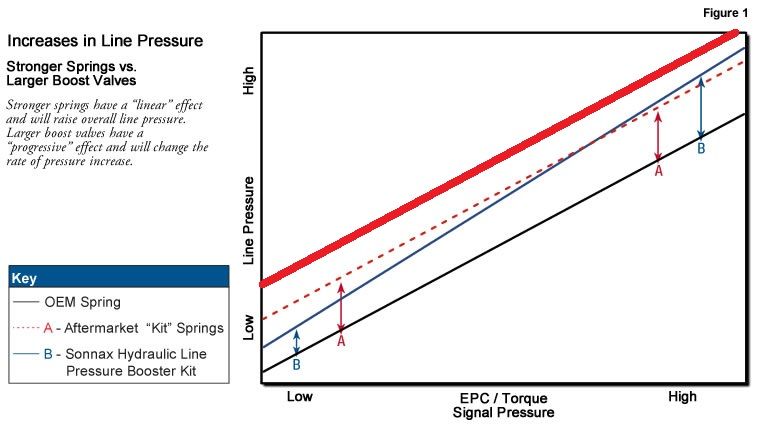

Higher Rate PR Springs boost pressure in a Linear fashion, The increase at full throttle/high load is fine, It's the increase at Idle/No load is the issue in a street vehicle with a sub 3000 stall converter as it will bang into gear. If your going too run a High Stall Converter......You won't feel it. Large Ratio Boost Valves boost pressure in a Progressive fashion, Good pressures a full throttle with No increase at Idle/no load conditions. **The Sonnax 400-LB1 does include a 10% stronger PR Spring, This is the increase in pressure at "No-Load/Torque Signal" in the Graph)** I added the Red Line to reflect about what the CK PR spring will do.

|

|

|

|

|

|

#19 |

|

Registered User

Join Date: Aug 2004

Location: phoenix az

Posts: 105

|

Re: 4L80E & TH400 Tech.

Reading another wiki on modifications it was suggested one use only half heavy duty return springs and half stock springs in the direct drum? Do you have any thoughts on that I see you already discussed a .30 bleed hole with 5500RPM and higher applications. My assumption is more pressure is needed in the direct drum to over come the heavy duty springs.

|

|

|

|

|

|

#20 |

|

Senior Member

Join Date: May 2009

Location: Fort Worth, TX

Posts: 6,370

|

Re: 4L80E & TH400 Tech.

Did they mention a reason for Half High Rate & Half Stock return springs?

Because, I can't think of one..... I have ran full sets of high rate return springs in Stock Pressure TH400's with no issues, The springs will hold-off the Piston from moving 'til a little more pressure builds, Resulting in a later but Quicker shift. Buy later, I talking 100th's of a second. With used stock spring, They could have millions of cycles on them, I testing several sets on my Valve Spring Checker, Set right before coil bind....The weights were all over the place, Springs from CK, ATI, & Hughes are very uniform in weight, Trans Go spring are OK but have the most variance in weight out of the aftermarket springs I tested. You could use the Half & Half method & probably be OK as long as they are staggered (1 High Rate, 1 Stock, & so on) Builders have their own practices & beliefs, Some of this stuff can not be proven in a conventional way, We do one mod, Test the trans, Tear it down 100-300 passes later & assess the situation. The Bleed hole is a secondary guard from centrifugal apply at high RPM, & a faster release on "Detent" Downshift, & "Forced" Downshift. |

|

|

|

|

|

#21 |

|

Registered User

Join Date: Aug 2004

Location: phoenix az

Posts: 105

|

Re: 4L80E & TH400 Tech.

I read about using half stock and half heavy duty from this he doesn't say whyhttp://www.crankshaftcoalition.com/w...0_rebuild_tech

I assumed the best way would be to alternate between springs ill just go with all heavy duty |

|

|

|

|

|

#22 |

|

Registered User

Join Date: Nov 2015

Location: Ionia Michigan

Posts: 336

|

Re: 4L80E & TH400 Tech.

I have, amongst other vehicles, an 07 Trailblazer LT, with the 5.3.

I'm swaping the 5.3 for a 6.0, and would like to swap a 4l80 behind it. If I used a 2WD for a donor, would the VSS on it be able to communicate with my PCM with a segment swap or repinning the harness?

__________________

J.R. Link to Daryl's build, http://67-72chevytrucks.com/vboard/s...10#post8443010 Link to my Youtube channel with build info, https://www.youtube.com/thedrivewayengineer |

|

|

|

|

|

#23 |

|

Senior Member

Join Date: May 2009

Location: Fort Worth, TX

Posts: 6,370

|

Re: 4L80E & TH400 Tech.

Is this 2WD, 4WD, AWD??

|

|

|

|

|

|

#24 |

|

Registered User

Join Date: Nov 2015

Location: Ionia Michigan

Posts: 336

|

Re: 4L80E & TH400 Tech.

4wd, I currently have an NP 226, I would be swapping to a 241, or 261 depending on what is easier.

__________________

J.R. Link to Daryl's build, http://67-72chevytrucks.com/vboard/s...10#post8443010 Link to my Youtube channel with build info, https://www.youtube.com/thedrivewayengineer |

|

|

|

|

|

#25 |

|

Senior Member

Join Date: May 2009

Location: Fort Worth, TX

Posts: 6,370

|

Re: 4L80E & TH400 Tech.

Both NP241, NP261 have a VSS sensor, So no need for you to buy a 2wd unit. A 4wd unit & Adapter will fit both T-Cases.

We only use 2wd units when adapting a older T-case that doesn't have a Output VSS sensor. All GM Output VSS sensors create the same 40 Pulses Per Revolution A/C Sine Wave Signal. |

|

|

|

|

| Bookmarks |

|

|