|

|

|

#1 |

|

Senior Enthusiast

Join Date: Feb 2007

Location: Spokane Valley, WA

Posts: 8,356

|

Markeb01 Build Thread

This is a test of Flickr Photo Host:

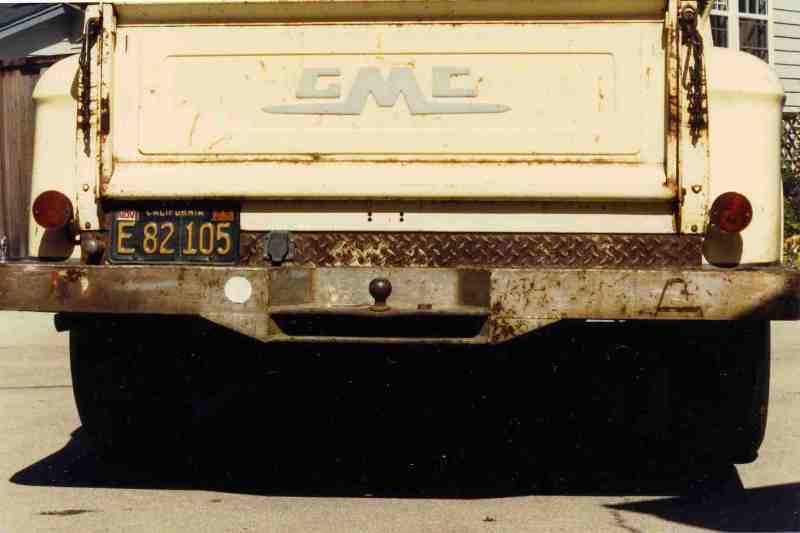

0001 by markeb01, on Flickr Our truck is semi-finished, so Iím posting a history of the transition from where it started to how it looks currently. A lot of the pictures are boring but Iím going to post many of the disassembly shots in case someone might find the details interesting for their own project. Weíve owned the truck for nearly 20 years so it may take a while to get everything uploaded. The truck was originally sold by Kimball Motors Company in San Luis Obispo, California to a retired gentleman. Base price was $2,112.45, with a discount of $800 trade in for his 1954 GMC. The only options were a Bardin bumper, West Coast style mirrors, and front and rear turns signals (separate line items). A camper shell was soon added and remained in place until his passing in the late 1980ís. Some time in the 1960ís he hit a deer, damaging the grille, grille support, and hood. The bent grille parts were replaced, while the hood was simply repaired. A nephew living in Alameda, California inherited the truck, and kept it for about 3 years. He replaced the 3 speed column shift transmission with a 4 speed SM-420 before losing interest and putting it up for sale. The truck became a birthday present from my wife in April 1992. Hereís what it looked like when we first got it home, minus the passenger side mirror I had already removed. Other than the transmission swap it was fundamentally dead stock with one remaining hubcap and a few dents and dings:    The wheels and tires were given to a friend for his 54 Chevy Ĺ ton and the fender emblems went to GMC Jolly. Hereís the worst of the body damage:    The first upgrade was a new set of wheels. 15x6 disc brake wheels up front with 15x8ís in the rear.   And a $5 set of 54 Chevy hubcaps, just because I liked 54 Chevys.

Last edited by markeb01; 07-24-2013 at 12:26 AM. |

|

|

|

| Bookmarks |

|

|