|

|

|

#1001 |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,647

|

Re: 55 Wagon Progress

Thanks guys!

Some progress, doesn't look like much until you look at the floor...   Sometimes these louvers can be a challenge to sand.  In the spirit of "everything's a tool", a strip of 18 ga steel and a wrap of PSA paper does a good job of getting in the tight spaces.   Another shot of the scrap pile before I clean it up, this is what went into fabricating the escutcheons..  And now for the reason we didn't post earlier this week, had to make a speed run for Taco Tuesday.. even saw a full rainbow in the process.  https://www.youtube.com/watch?v=jWrIkyuUBTs Back in the shop this weekend, but we had a distraction in another Meco torch that showed up for sale not three miles away. So needless to say about the only thing accomplished was more welding practice!!   https://www.youtube.com/watch?v=O9Wf1AbzP3c After planishing... https://www.youtube.com/watch?v=BDy82sixbjQ .

__________________

Robert |

|

|

|

|

|

#1002 |

|

Post Whore

Join Date: May 2015

Location: Alabama

Posts: 14,663

|

Re: 55 Wagon Progress

Nice score Robert....a rainbow and a meco.......

__________________

Mongo...aka Greg RIP Dad RIP Jesse 1981 C30 LQ9 NV4500..http://67-72chevytrucks.com/vboard/s...d.php?t=753598 Mongos AD- LS3 TR6060...http://67-72chevytrucks.com/vboard/s...34#post8522334 Columbus..the 1957 IH 4x4...http://67-72chevytrucks.com/vboard/s...63#post8082563 2023 Chevy Z71..daily driver |

|

|

|

|

|

#1003 |

|

Registered User

Join Date: Dec 2012

Location: Pendleton, Indiana

Posts: 235

|

Re: 55 Wagon Progress

Nice find, I'm looking at getting a Meco. Ihaven't done any gas welding since welding school some 20+ years ago. Just curious what does your tank cart look like and tank sizes? Too small and all you get done going and getting them refilled, but i'm limited by space so can't too large and wife say I'm adding on.

LOL Rick |

|

|

|

|

|

#1004 |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,647

|

Re: 55 Wagon Progress

Rick, the O2 bottle is just over 3’ tall, the handle on the cart about 42”

__________________

Robert |

|

|

|

|

|

#1005 |

|

Registered User

Join Date: Dec 2012

Location: Pendleton, Indiana

Posts: 235

|

Re: 55 Wagon Progress

Thanks Robert, not too big of a foot print, that I couldn't make room.

Rick |

|

|

|

|

|

#1006 |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,647

|

Re: 55 Wagon Progress

Glad to help Rick!

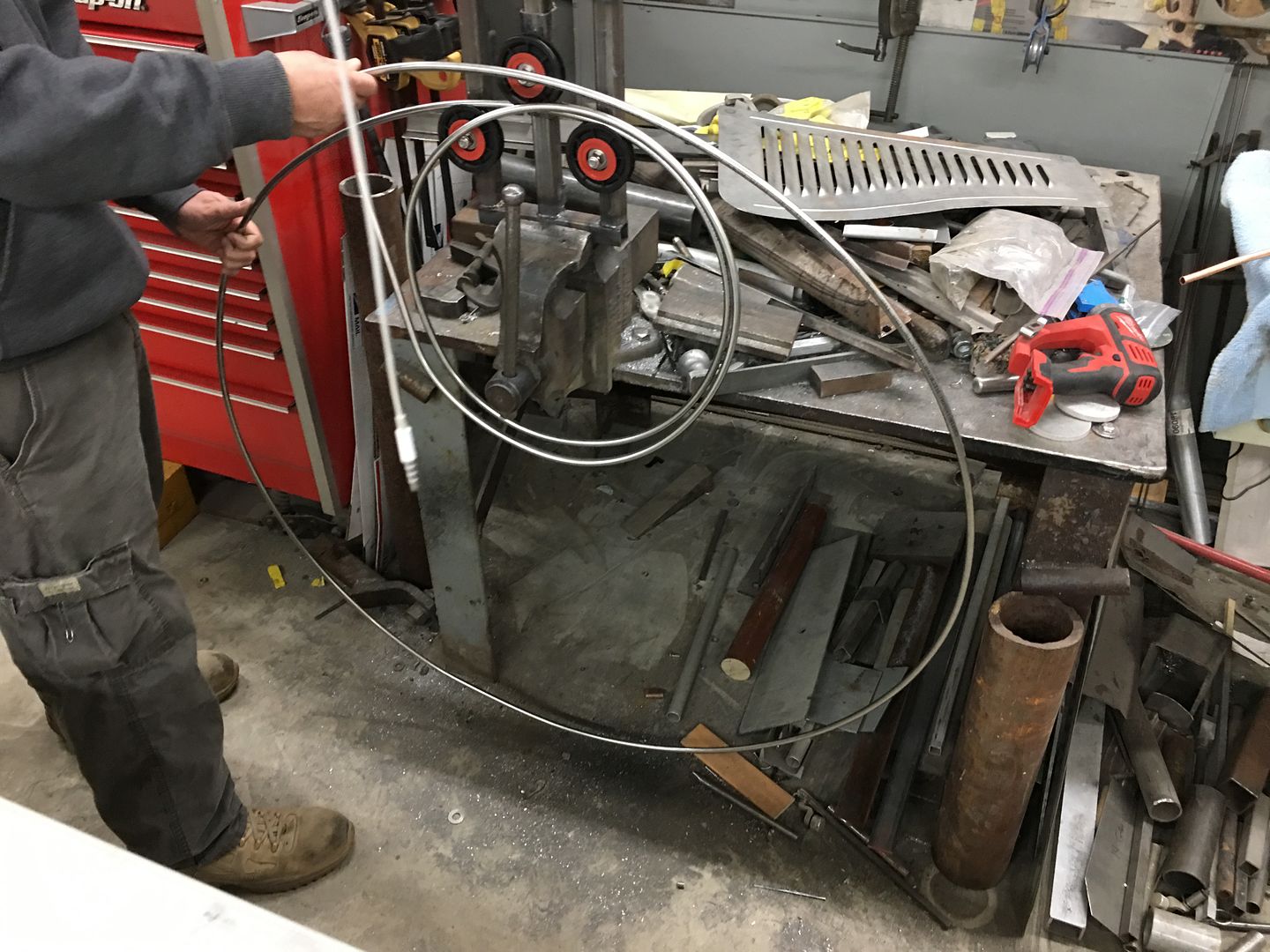

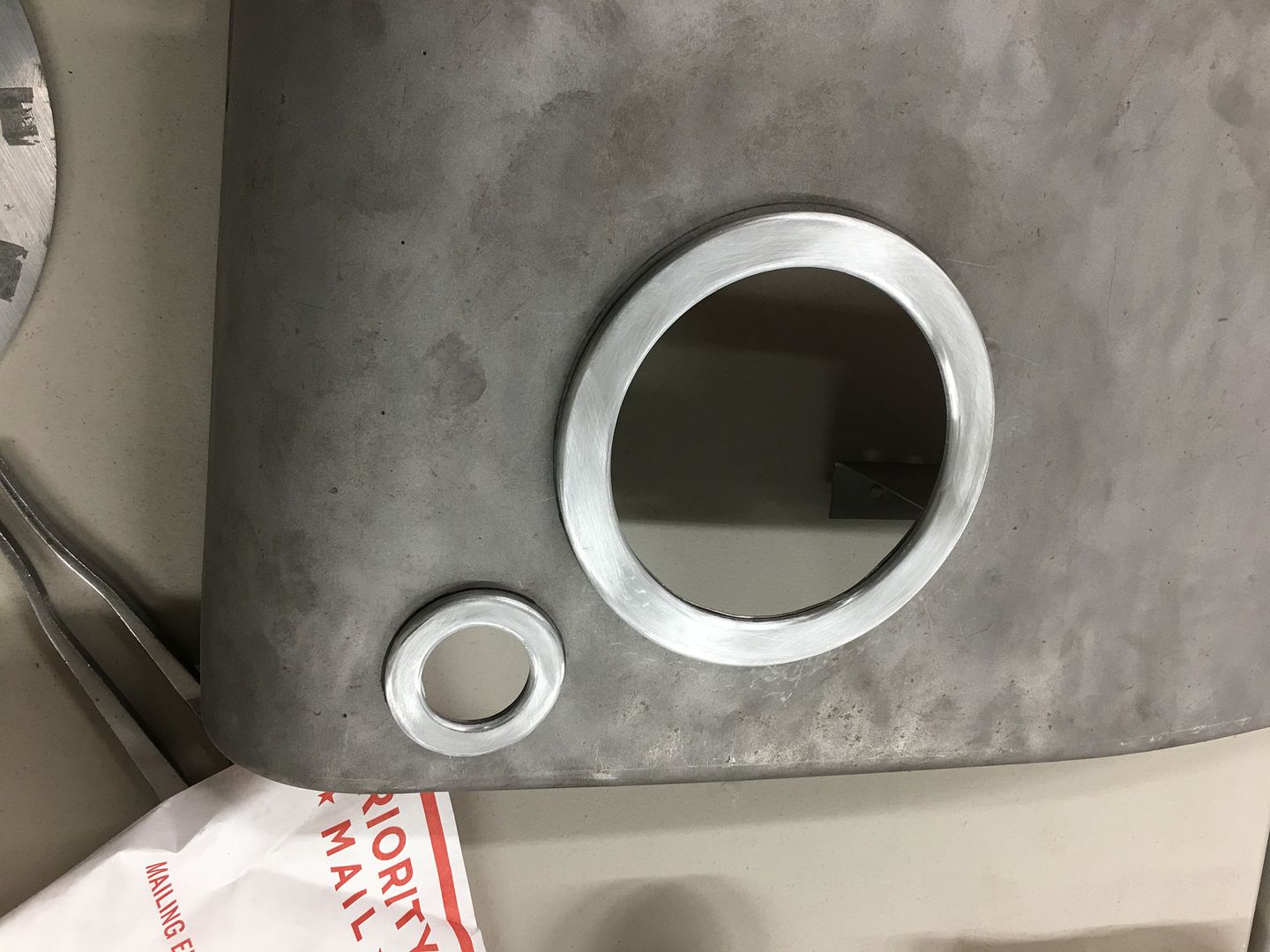

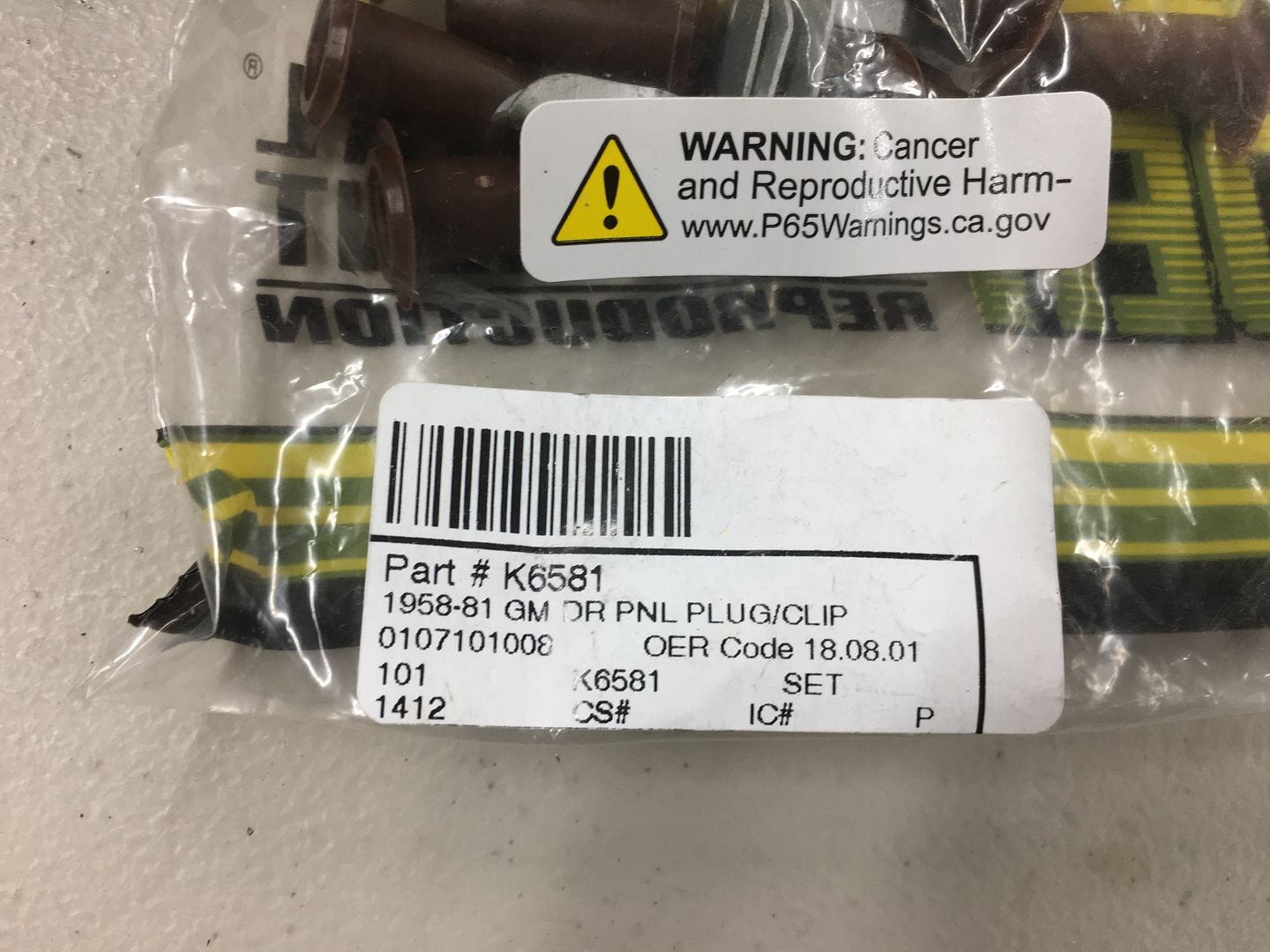

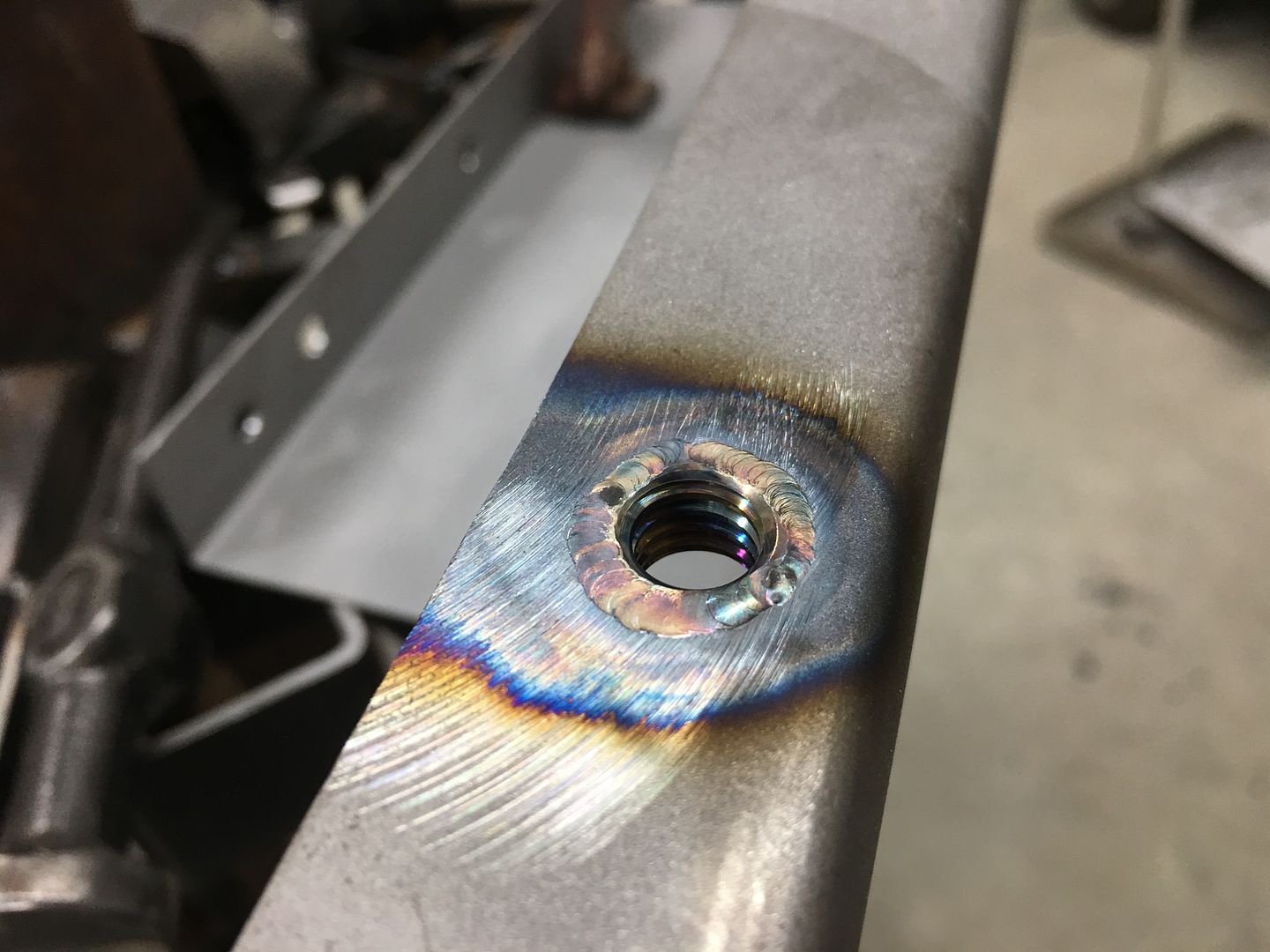

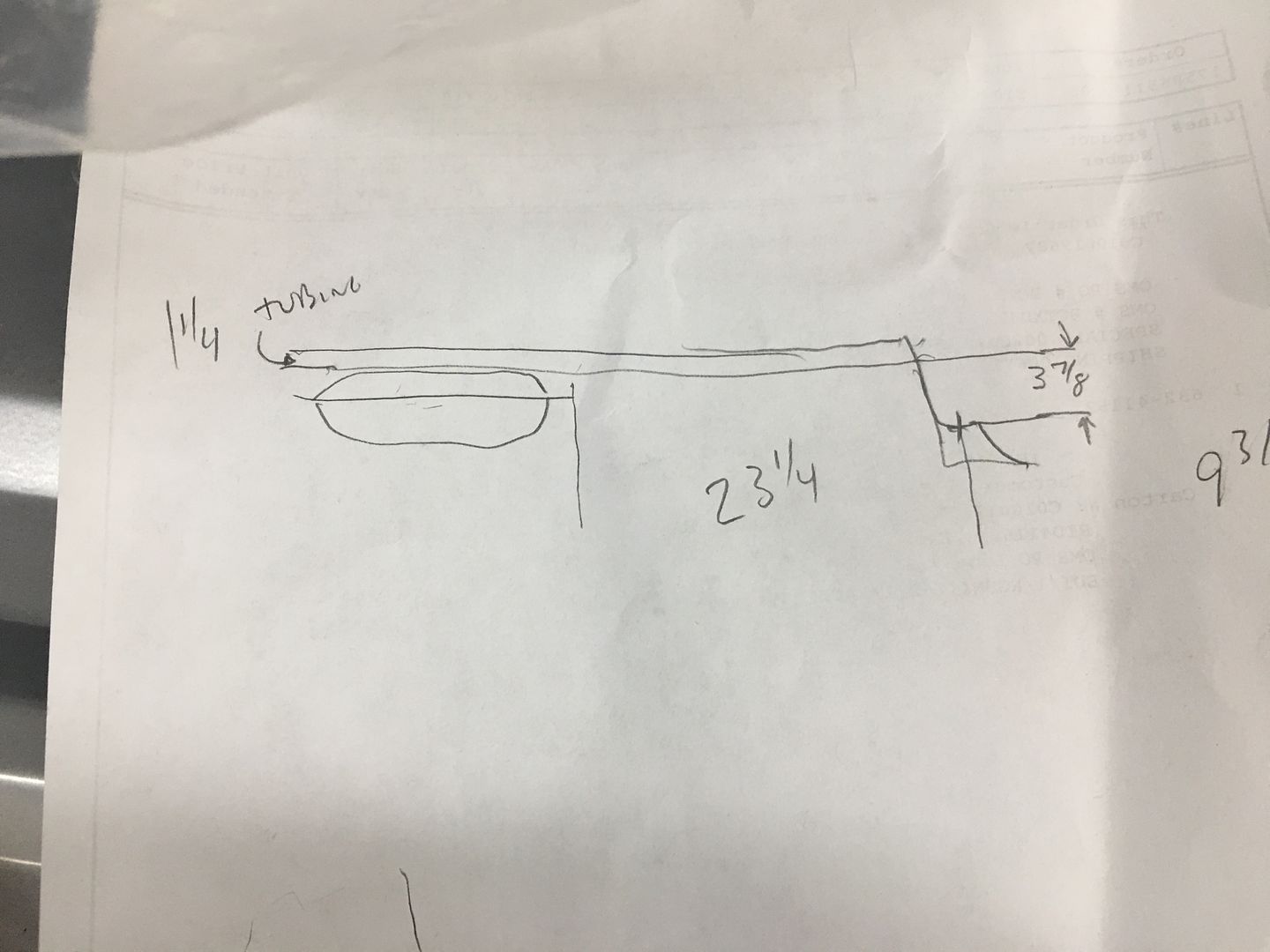

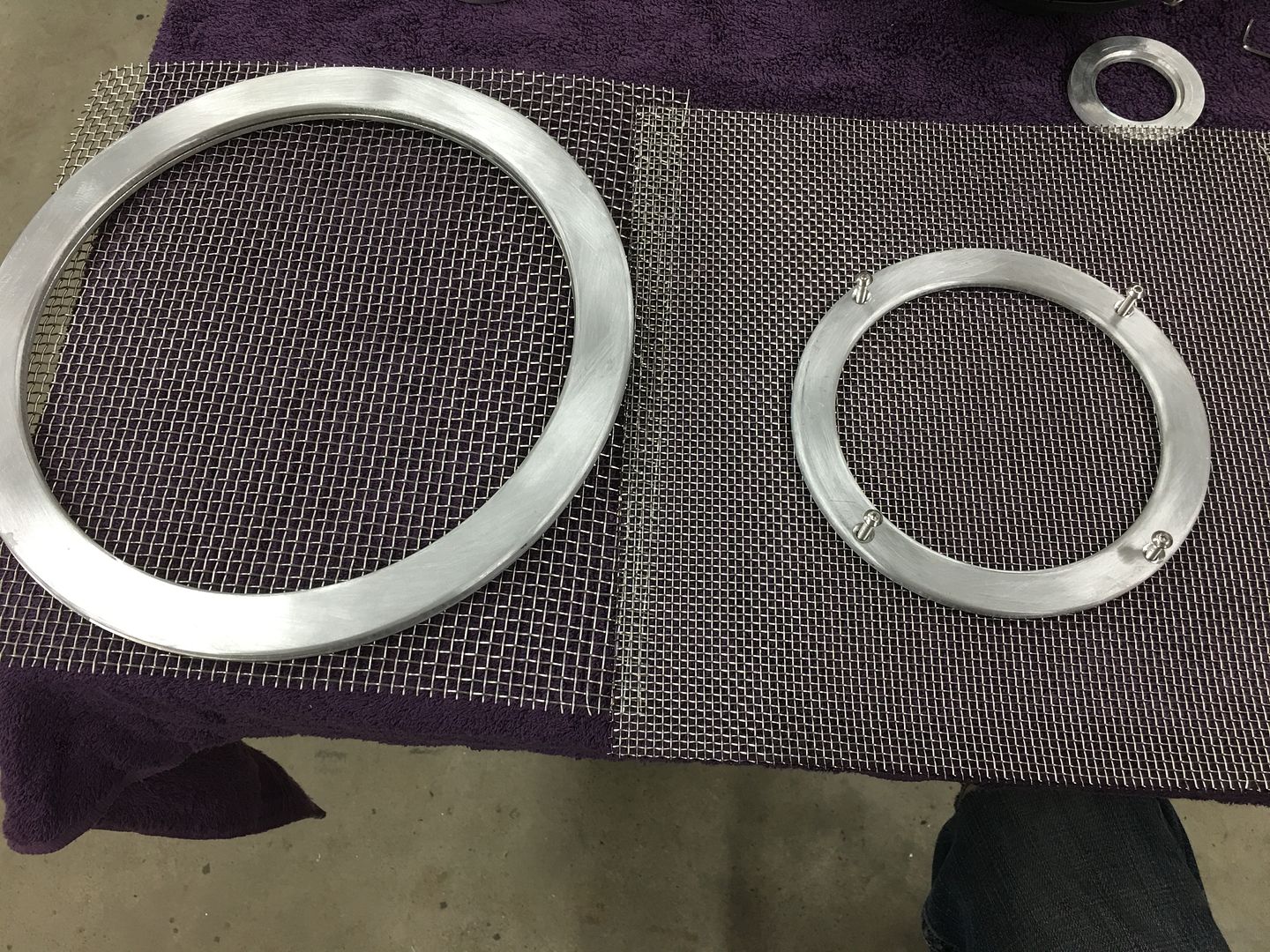

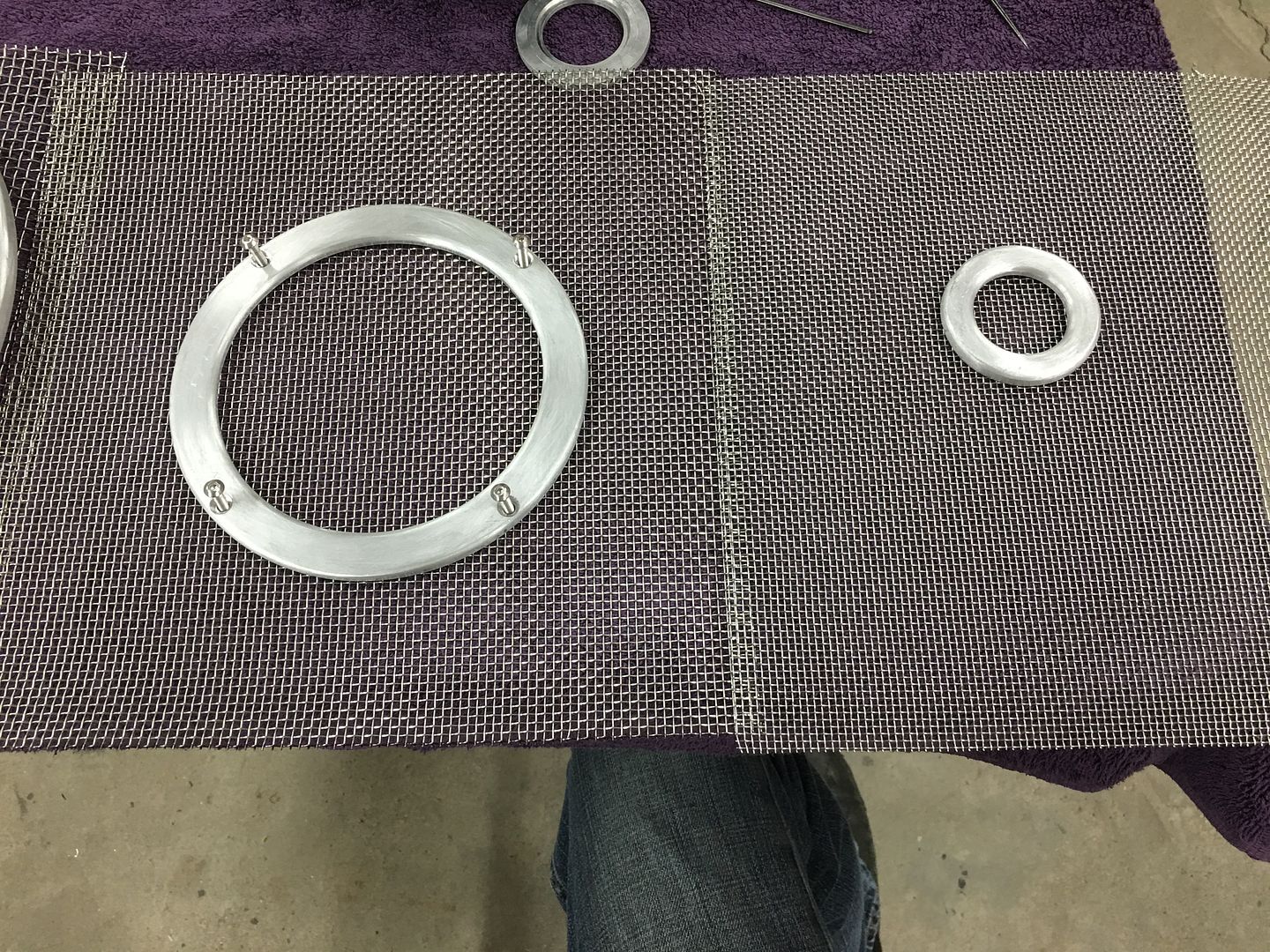

More progress on the wagon, we had ordered some 3/8 Stainless fuel line, which comes in a coil... so we needed to be able to straighten it out as I can see me "unbending" and getting it right.. So I placed an order with McMaster Carr for some pulleys designed for 3/8 rope and using 3/8 bolt hole in the bearing. Part number 59475K51.  A drive mechanism was made using 3/8-16 stainless all-thread, and the slider was cut and re-welded to better fit the 1" square tubing.   A better view all around of the design, we used three pulleys so this could also serve as a bender as well as straightener.. https://www.youtube.com/watch?v=TpgMekrEA3g Then Mike and I did a test run using copper tubing... https://www.youtube.com/watch?v=FumsneaLJlU Now onto the stainless....    At this point we measured and cut the 20' piece in two so it would be more more manageable. Straightened....  Now we used the adjustable spline to get the curve of the frame for the proper bend on the stainless...   A strip of tape applied helps to lock the shape from moving, and the tubing is marked for the radius distance..  The tube is placed back in the new machine to add the radius to match our profile...    Adding some of the needed bends...  For some of the interior details, we took delivery of the speaker trim rings from my cousin JB, he did a nice job cutting these out for us... They still need holes drilled, stainless mesh cut to fit, and polishing...  ....and our Mopar door clips we were going to use for the rear arm rests turned out to be a bit brittle, most snapped off rather than pull back through the hole. So we ordered the similar GM version, keeping our fingers crossed...  Alas, in my typical Murphy strikes again mode, these were slightly smaller and/or the holes already located in the kick panels were slightly gaping.. We searched the entire shop for a MacGyver solution and found that a 3/8-16 hex nut did a good job of "capturing" the clip, but without the "not letting go" part that a hole in sheet metal provides if the clip rotates slightly while in the hole. So some 3/8 stainless nuts were machined so that they could be welded into the kick panel and yet have the thread grip flush at the surface.

__________________

Robert |

|

|

|

|

|

#1007 |

|

Post Whore

Join Date: May 2015

Location: Alabama

Posts: 14,663

|

Re: 55 Wagon Progress

nice job Robert....that tubing jig is a nice touch

__________________

Mongo...aka Greg RIP Dad RIP Jesse 1981 C30 LQ9 NV4500..http://67-72chevytrucks.com/vboard/s...d.php?t=753598 Mongos AD- LS3 TR6060...http://67-72chevytrucks.com/vboard/s...34#post8522334 Columbus..the 1957 IH 4x4...http://67-72chevytrucks.com/vboard/s...63#post8082563 2023 Chevy Z71..daily driver |

|

|

|

|

|

#1008 |

|

Registered User

Join Date: Dec 2011

Location: Morris, Alabama

Posts: 184

|

Re: 55 Wagon Progress

That tubing bender/straightener!

So many great ideas throughout this thread, Robert. |

|

|

|

|

|

#1009 |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,647

|

Re: 55 Wagon Progress

Thanks guys!

Saturday we got the tank installed so we could get a good reading on where it locates in relation to the body mounts in front of the axle.  We also pulled a pattern from the body mount so we could bend the lines around it accurately.  Highly technical drawing showing our tank location...  Tank located per our drawing in relation to body mount..  The more I look at this, the less I wanted to use the braided lines between the hard line and the tank. I'm just not comfortable with another fitting in the vicinity of the tail pipes. So back up and punt, looks like we're getting new tubing and bending again. The last lines weren't long enough to make it back to the tank, so we'll chalk them up as practice pieces, learning curve, if you will... Here the Body mount pattern is bolted up, the lines will make a bend behind this body mount, travel across to the middle, and then toward the back where it will attach directly to the tank.  The lines will come close to the passenger tail pipe, so we'll add a heat shield. I visited a local motorcycle shop and picked up a donor...  trimmed to fit...    That should do. Next, we need to finish the kick panels for upholstery, which means mounting the speakers. The trim rings from cousin JB will need holes drilled to match the speakers. We have some button head allen screws we plan on using, but didn't really care for the surface mounted look...  This would look so much better with the details of counterbored holes. Alas, the pitfalls of working on Saturdays without a local source. What's a person to do but make their own. The extended die grinder almost fits the Aloris tool holder too well, like it was made to be. https://www.youtube.com/watch?v=q38H...ature=youtu.be A 120 grit roloc sanding disc does well to backface the cutting edge and we are in business..  Much better, all in the details..   ….and adding the tweeters to the kick panel...

__________________

Robert |

|

|

|

|

|

#1010 |

|

Senior Member

Join Date: Mar 2011

Location: West Plains, Missouri

Posts: 7,559

|

Re: 55 Wagon Progress

Very nice as always...Jim

__________________

my build thread: http://67-72chevytrucks.com/vboard/s...d.php?t=459839 Jimbo's long bed step build:http://67-72chevytrucks.com/vboard/s...t=464626<br /> |

|

|

|

|

|

#1011 |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,647

|

Re: 55 Wagon Progress

Thanks Jim!

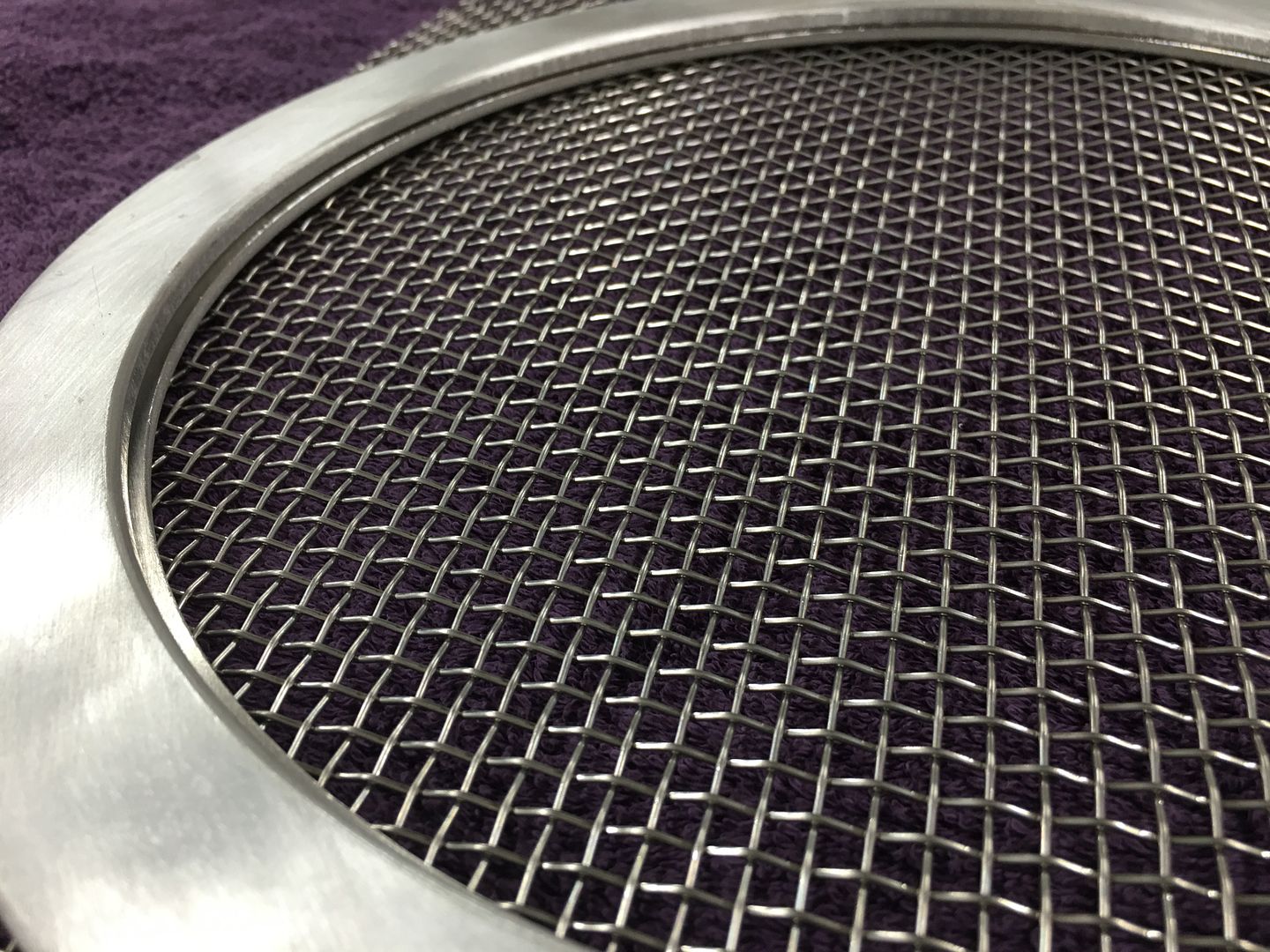

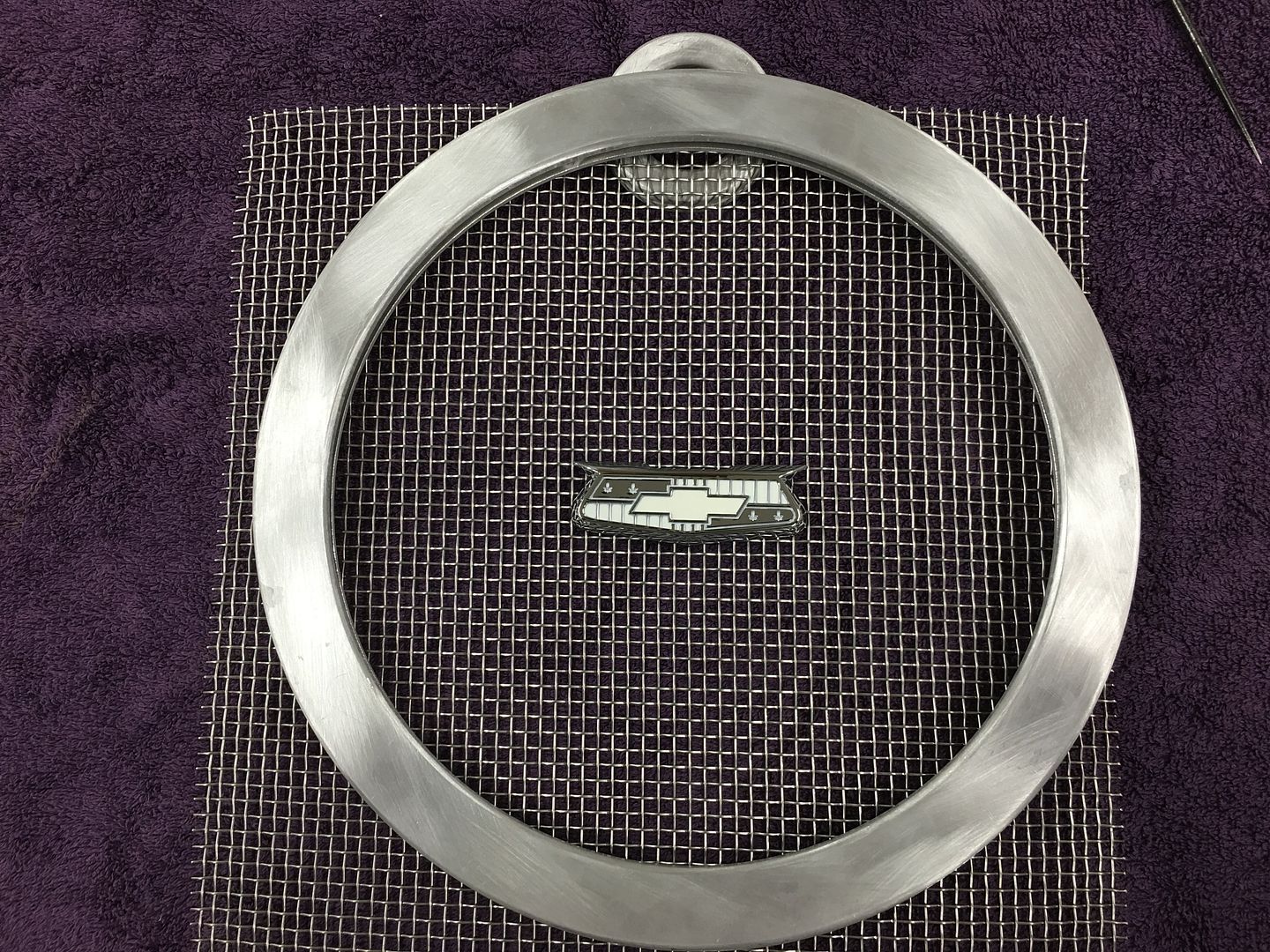

Took delivery yesterday of the 304 Stainless mesh for the speaker grills.  Just like we used different widths on the trim rings so they would be proportional to the diameter, with the mesh we used three different sizes as well..   For the bass speaker grill we are also adding a BelAir emblem. The mesh will be recessed for that so the emblem is flush, then the remaining mesh will be pressed outward so it is flush with the surface of the trim ring. (or so) Now for the unofficial poll, would you orient the mesh straight across/up and down, or at a 45 degree rotation?

__________________

Robert |

|

|

|

|

|

#1012 |

|

Senior Member

Join Date: Mar 2011

Location: West Plains, Missouri

Posts: 7,559

|

Re: 55 Wagon Progress

I like it on the 45 degree...Jim

__________________

my build thread: http://67-72chevytrucks.com/vboard/s...d.php?t=459839 Jimbo's long bed step build:http://67-72chevytrucks.com/vboard/s...t=464626<br /> |

|

|

|

|

|

#1013 |

|

Registered User

Join Date: Dec 2012

Location: Pendleton, Indiana

Posts: 235

|

Re: 55 Wagon Progress

Robert, I'm going with the 45 degree rotation, but I'm sure the people with OCD will opt for straight.

Rick |

|

|

|

|

|

#1014 |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,647

|

Re: 55 Wagon Progress

Rick, my OCD must be off kilter, I can look at the straight and see 45* in it...

__________________

Robert |

|

|

|

|

|

#1015 |

|

Post Whore

Join Date: May 2015

Location: Alabama

Posts: 14,663

|

Re: 55 Wagon Progress

45....

__________________

Mongo...aka Greg RIP Dad RIP Jesse 1981 C30 LQ9 NV4500..http://67-72chevytrucks.com/vboard/s...d.php?t=753598 Mongos AD- LS3 TR6060...http://67-72chevytrucks.com/vboard/s...34#post8522334 Columbus..the 1957 IH 4x4...http://67-72chevytrucks.com/vboard/s...63#post8082563 2023 Chevy Z71..daily driver |

|

|

|

|

|

#1016 |

|

Registered User

Join Date: Jul 2015

Location: Turner Or

Posts: 40

|

Re: 55 Wagon Progress

I like the 45 as well

|

|

|

|

|

|

#1017 |

|

Registered User

Join Date: Feb 2018

Location: covina, cal/windsor, on

Posts: 39

|

Re: 55 Wagon Progress

45

|

|

|

|

|

|

#1018 |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,647

|

Re: 55 Wagon Progress

Thanks to all for their input on the speaker grilles, the owner has decided on the 45* rotation. Our other choice to ponder was whether to use chrome, polished, or brushed finish. We clamped some of the rings in the lathe and gave it a brushed finish, others were polished so we can compare..

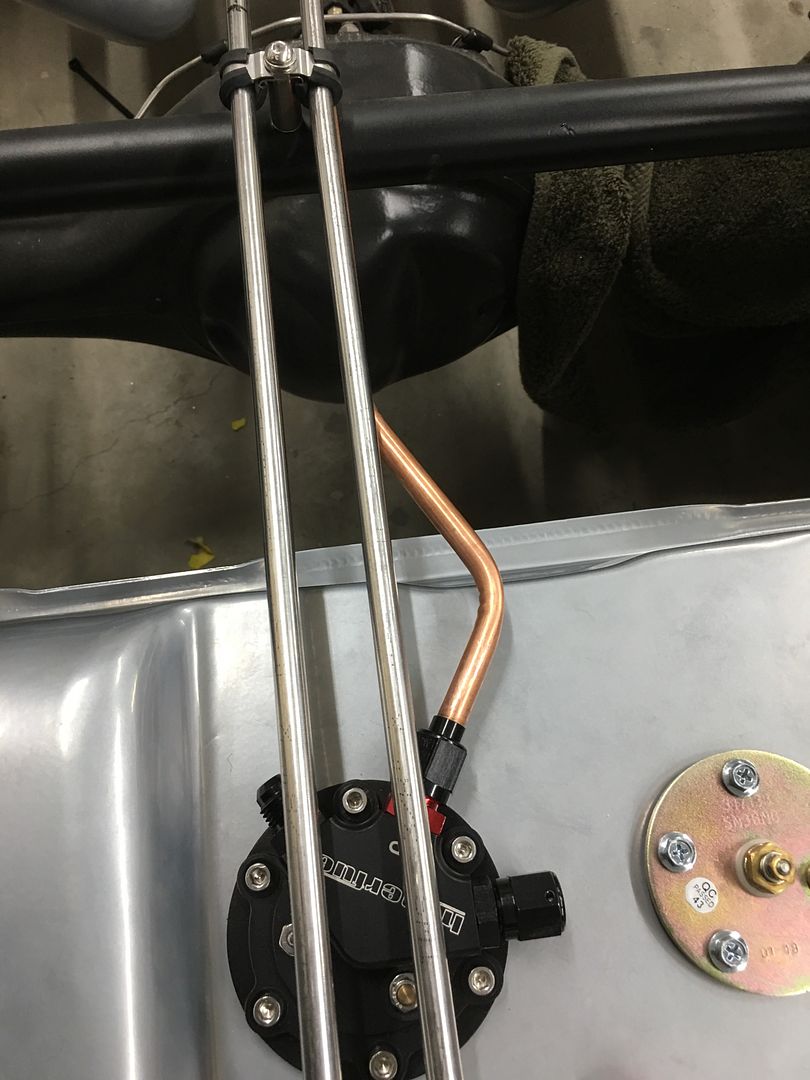

Here it was decided to go with the polished over brushed, and for ease of maintenance, we opted for chrome plating. So all the holes were drilled, counterbored, and transferred to their respective mounting location. The tweeter trim rings will be held in place with 6-32 hardware, the mids use 8-32, and the sub uses 10-32. Rivet nuts were installed where needed..      With the trim rings ready to send for plating, we turned our attention to the fuel lines, where we wanted a direct run all the way to the tank. Our bending efforts found Mike in a bit of a stretch..  The fuel line passes behind the body mount, we have a heat deflector in place where it passes over the tail pipe, and then it will connect directly to the tank. They will be secured with adel clamps fastened to the floor braces from underneath. Return line in place, supply line to go: https://www.youtube.com/watch?v=ZbUxujdz2PU .

__________________

Robert |

|

|

|

|

|

#1019 |

|

Post Whore

Join Date: May 2015

Location: Alabama

Posts: 14,663

|

Re: 55 Wagon Progress

chrome rings sure will look good...but im kinda liking the brushed look myself...and after the quote I got to rechrome some mirrors I probably would go brushed

__________________

Mongo...aka Greg RIP Dad RIP Jesse 1981 C30 LQ9 NV4500..http://67-72chevytrucks.com/vboard/s...d.php?t=753598 Mongos AD- LS3 TR6060...http://67-72chevytrucks.com/vboard/s...34#post8522334 Columbus..the 1957 IH 4x4...http://67-72chevytrucks.com/vboard/s...63#post8082563 2023 Chevy Z71..daily driver |

|

|

|

|

|

#1020 |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,647

|

Re: 55 Wagon Progress

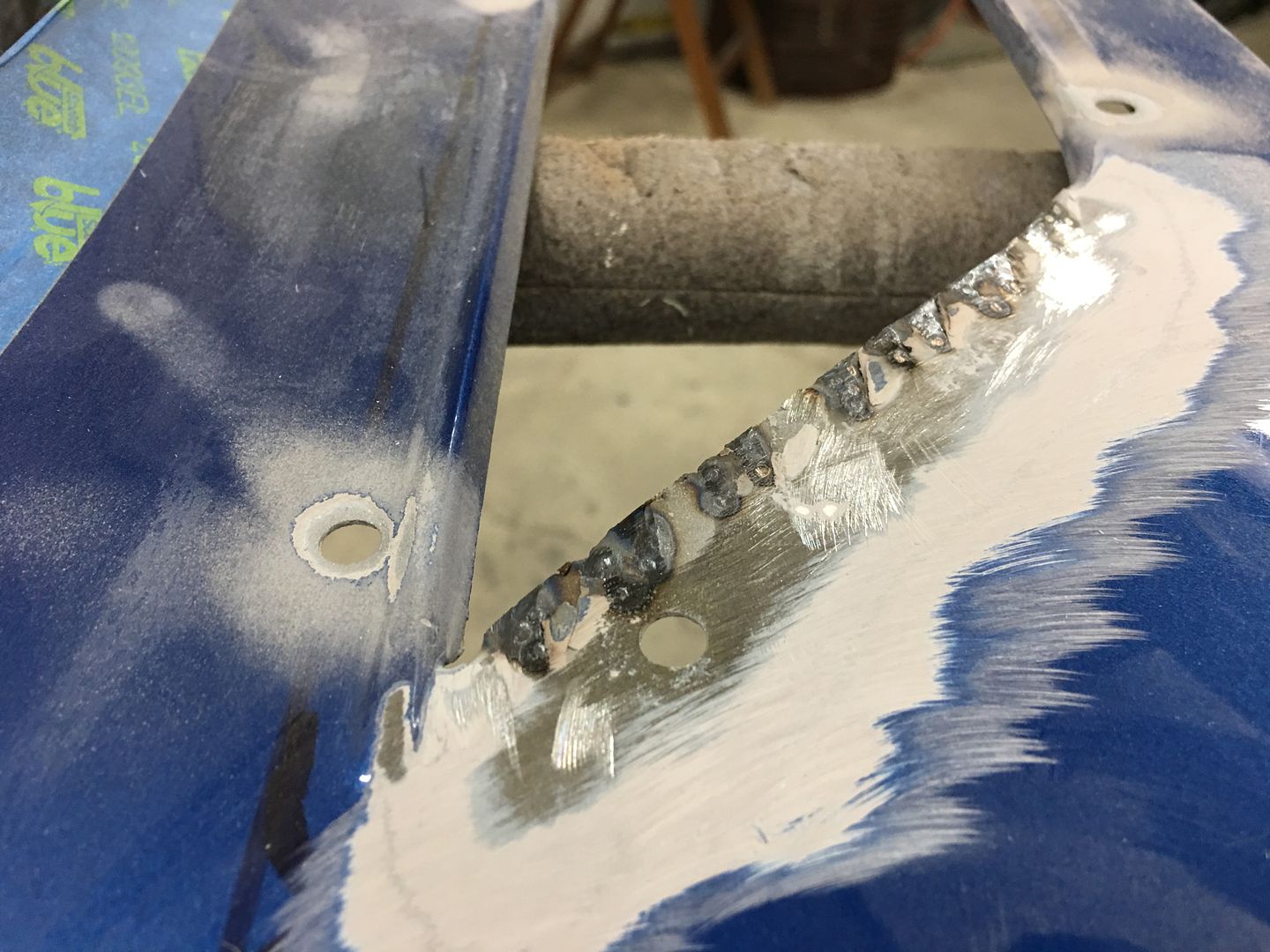

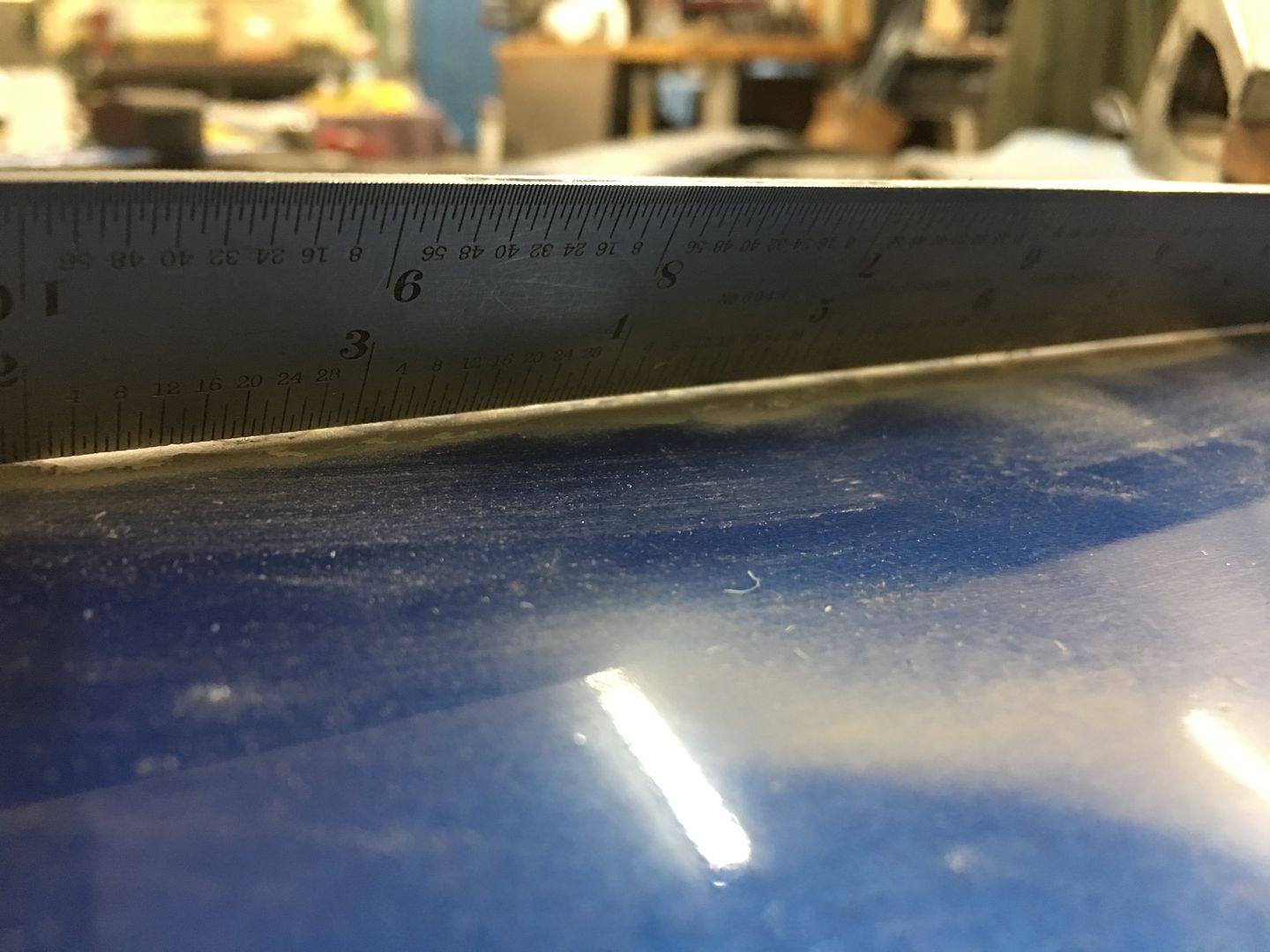

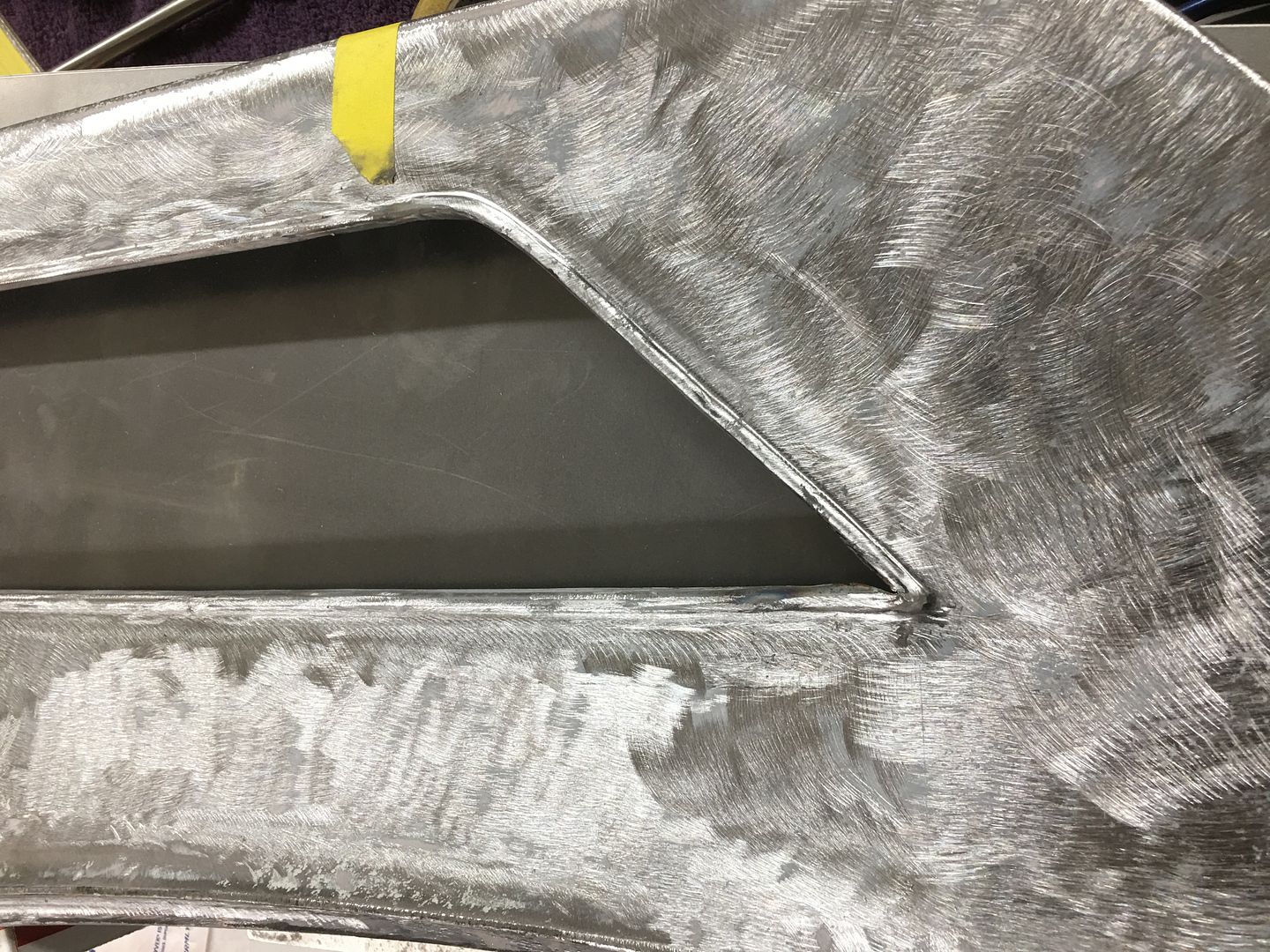

Had a slight distraction yesterday, a couple hood sides for a 37 Ford showed up. The owner wanted to remove the side "grille", and add a tapered recess pan with clamshell louvers. Here's what we started with...

Some cutoff wheel action later....  In an attempt to keep as much metal on the ends as possible, we opted to flatten the sad remains of the horizontal fins. This involved some shrinking via the heating tip in the dent puller..   Looks like someone has spilled bondo all over this panel. Funny the inside didn't look all that mangled to warrant the amount we found.. Must be a TV car.. The shrinking efforts flattened out the ends fairly well...   I filled in the previous trim holes with 18 Ga plugs and TIG fusion while the owner worked away at removing the bondo so we could see what we had to work with...     Next, we had to fold a flange in the front and extend the factory bead around the opening down the front where we had flattened the panel. Some of the existing bead profiles had seen better days in the past 80 plus years, so I checked a set of joggle dies I had made for drip rail as it looked close...   New flange folded at the front, bead added using the Lennox, original beads touched up ...    Tapered pan fabricated.....  Louver layout   Welded in place..  He is having some art deco style trim pieces made to accent the louvers down the center, topped by 62 Impala fender trim. We didn't have those, so here it is with alternate SS fuel line for your viewing pleasure...

__________________

Robert |

|

|

|

|

|

#1021 |

|

Post Whore

Join Date: May 2015

Location: Alabama

Posts: 14,663

|

Re: 55 Wagon Progress

That's cool...would like to see the finished product.....

__________________

Mongo...aka Greg RIP Dad RIP Jesse 1981 C30 LQ9 NV4500..http://67-72chevytrucks.com/vboard/s...d.php?t=753598 Mongos AD- LS3 TR6060...http://67-72chevytrucks.com/vboard/s...34#post8522334 Columbus..the 1957 IH 4x4...http://67-72chevytrucks.com/vboard/s...63#post8082563 2023 Chevy Z71..daily driver |

|

|

|

|

|

#1022 |

|

Senior Member

Join Date: Mar 2011

Location: West Plains, Missouri

Posts: 7,559

|

Re: 55 Wagon Progress

Robert, very nice, really changed the look of side panel...Jim

__________________

my build thread: http://67-72chevytrucks.com/vboard/s...d.php?t=459839 Jimbo's long bed step build:http://67-72chevytrucks.com/vboard/s...t=464626<br /> |

|

|

|

|

|

#1023 |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,647

|

Re: 55 Wagon Progress

Thanks for checking out the progress guys!

Well the owner sent me a "concept photo" complete with cardboard cutout... The piece of cardboard against the hood side will be chrome plated, the next will be a contrasting color to the car, and topped off with the Impala fender trim..

__________________

Robert Last edited by MP&C; 02-24-2019 at 02:37 AM. |

|

|

|

|

|

#1024 |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,647

|

Re: 55 Wagon Progress

More progress on the fuel lines, with both lines now routed, we opted for glue lined heat shrink as an abrasion resistant covering where it passes closely to the body, and regular heat shrink to keep the two together.

Mike installs an anchor point for adel clamps in the shock crossmember     Test bends at the fuel pump..     Next to add some AN fittings..

__________________

Robert |

|

|

|

|

|

#1025 |

|

Senior Member

Join Date: Jul 2012

Location: Oblong, Illinois

Posts: 7,028

|

Re: 55 Wagon Progress

So many great ideas and excellent work you share. Greatly appreciated!

|

|

|

|

|

| Bookmarks |

|

|