|

|

|

|

|

#1 |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,647

|

Re: 55 Wagon Progress

Rick, my OCD must be off kilter, I can look at the straight and see 45* in it...

__________________

Robert |

|

|

|

|

|

#2 |

|

Senior Member

Join Date: Mar 2011

Location: West Plains, Missouri

Posts: 7,559

|

Re: 55 Wagon Progress

I like it on the 45 degree...Jim

__________________

my build thread: http://67-72chevytrucks.com/vboard/s...d.php?t=459839 Jimbo's long bed step build:http://67-72chevytrucks.com/vboard/s...t=464626<br /> |

|

|

|

|

|

#3 |

|

Post Whore

Join Date: May 2015

Location: Alabama

Posts: 14,662

|

Re: 55 Wagon Progress

45....

__________________

Mongo...aka Greg RIP Dad RIP Jesse 1981 C30 LQ9 NV4500..http://67-72chevytrucks.com/vboard/s...d.php?t=753598 Mongos AD- LS3 TR6060...http://67-72chevytrucks.com/vboard/s...34#post8522334 Columbus..the 1957 IH 4x4...http://67-72chevytrucks.com/vboard/s...63#post8082563 2023 Chevy Z71..daily driver |

|

|

|

|

|

#4 |

|

Registered User

Join Date: Jul 2015

Location: Turner Or

Posts: 40

|

Re: 55 Wagon Progress

I like the 45 as well

|

|

|

|

|

|

#5 |

|

Registered User

Join Date: Feb 2018

Location: covina, cal/windsor, on

Posts: 39

|

Re: 55 Wagon Progress

45

|

|

|

|

|

|

#6 |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,647

|

Re: 55 Wagon Progress

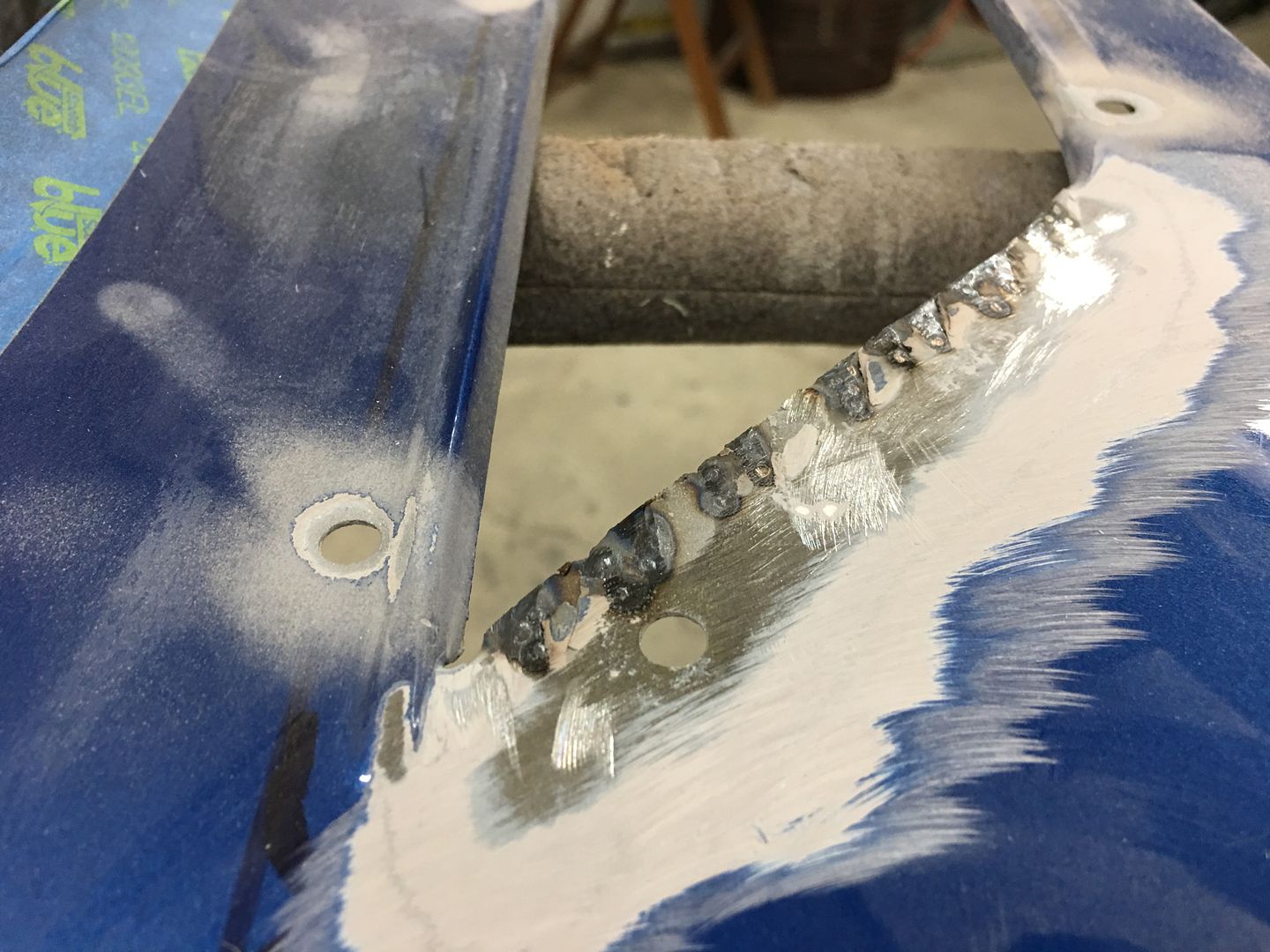

Thanks to all for their input on the speaker grilles, the owner has decided on the 45* rotation. Our other choice to ponder was whether to use chrome, polished, or brushed finish. We clamped some of the rings in the lathe and gave it a brushed finish, others were polished so we can compare..

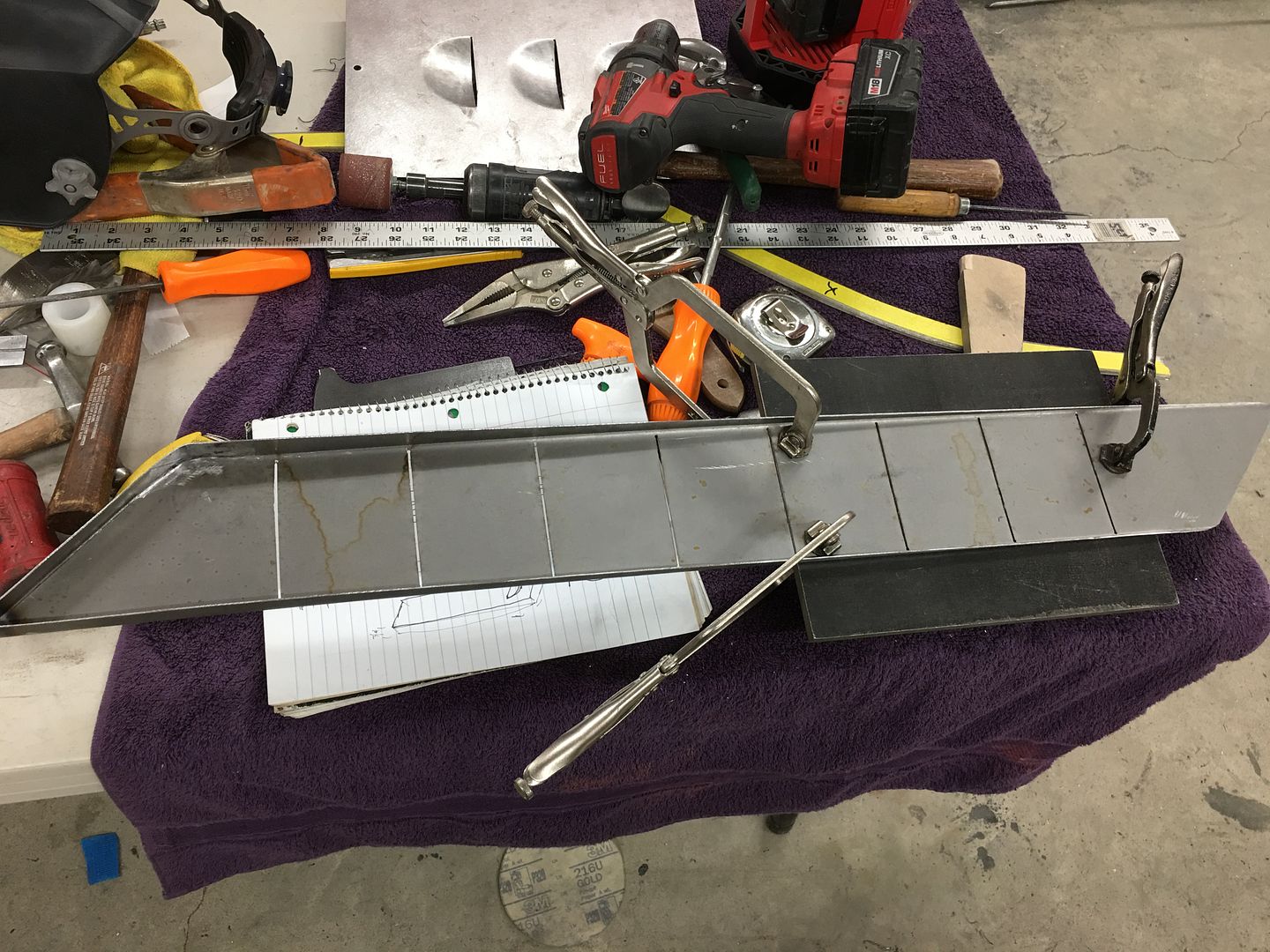

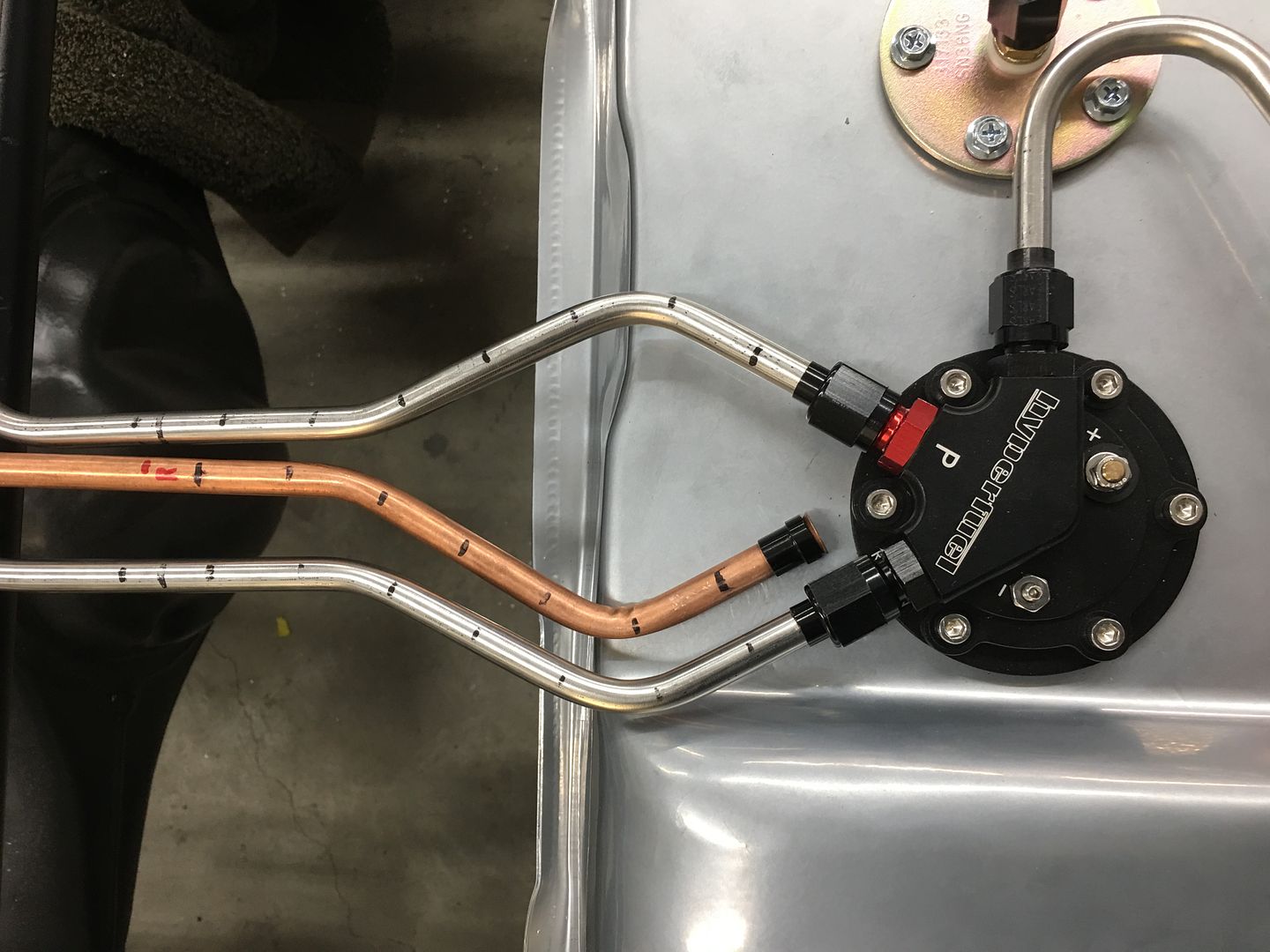

Here it was decided to go with the polished over brushed, and for ease of maintenance, we opted for chrome plating. So all the holes were drilled, counterbored, and transferred to their respective mounting location. The tweeter trim rings will be held in place with 6-32 hardware, the mids use 8-32, and the sub uses 10-32. Rivet nuts were installed where needed..      With the trim rings ready to send for plating, we turned our attention to the fuel lines, where we wanted a direct run all the way to the tank. Our bending efforts found Mike in a bit of a stretch..  The fuel line passes behind the body mount, we have a heat deflector in place where it passes over the tail pipe, and then it will connect directly to the tank. They will be secured with adel clamps fastened to the floor braces from underneath. Return line in place, supply line to go: https://www.youtube.com/watch?v=ZbUxujdz2PU .

__________________

Robert |

|

|

|

|

|

#7 |

|

Post Whore

Join Date: May 2015

Location: Alabama

Posts: 14,662

|

Re: 55 Wagon Progress

chrome rings sure will look good...but im kinda liking the brushed look myself...and after the quote I got to rechrome some mirrors I probably would go brushed

__________________

Mongo...aka Greg RIP Dad RIP Jesse 1981 C30 LQ9 NV4500..http://67-72chevytrucks.com/vboard/s...d.php?t=753598 Mongos AD- LS3 TR6060...http://67-72chevytrucks.com/vboard/s...34#post8522334 Columbus..the 1957 IH 4x4...http://67-72chevytrucks.com/vboard/s...63#post8082563 2023 Chevy Z71..daily driver |

|

|

|

|

|

#8 |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,647

|

Re: 55 Wagon Progress

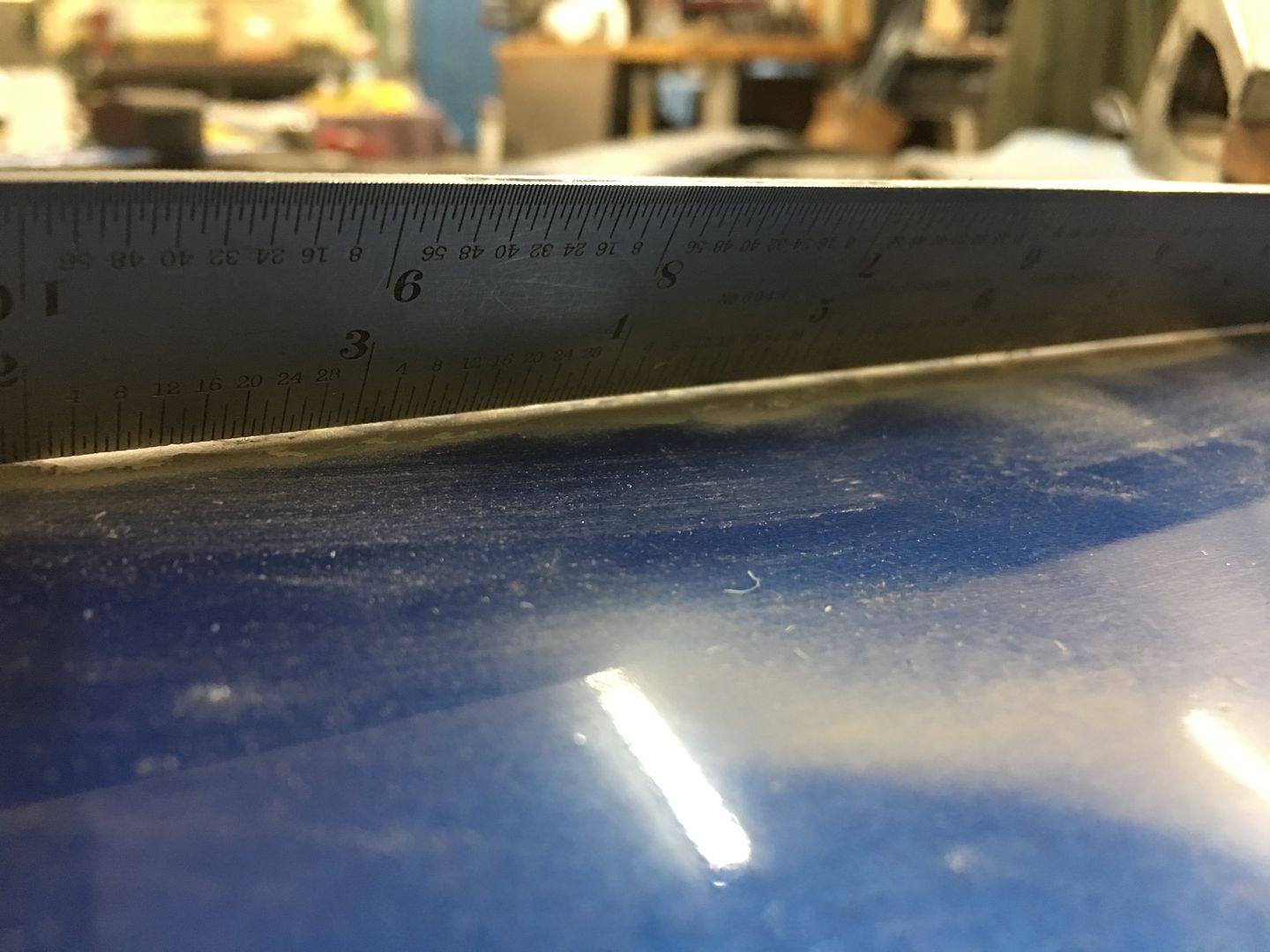

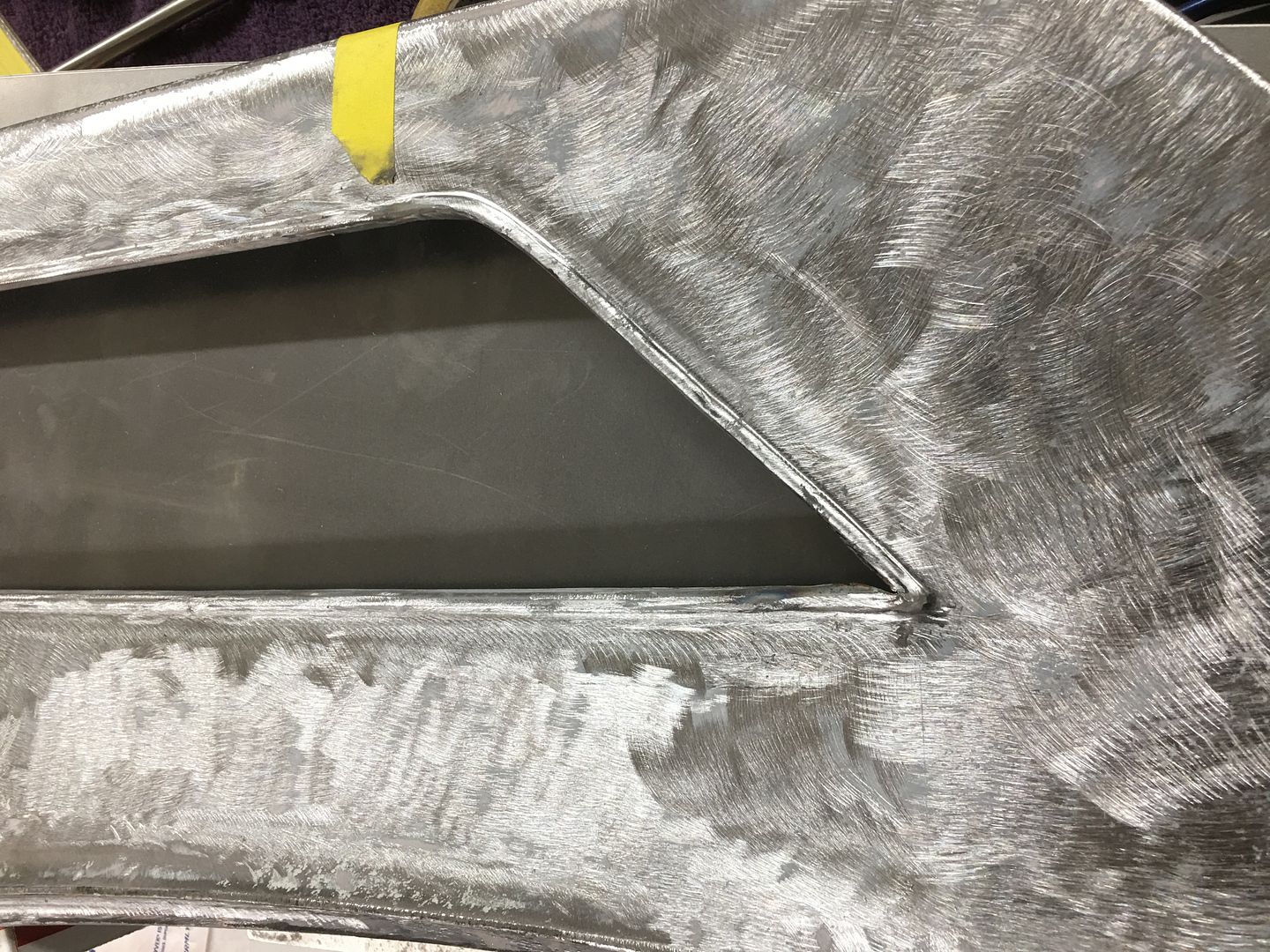

Had a slight distraction yesterday, a couple hood sides for a 37 Ford showed up. The owner wanted to remove the side "grille", and add a tapered recess pan with clamshell louvers. Here's what we started with...

Some cutoff wheel action later....  In an attempt to keep as much metal on the ends as possible, we opted to flatten the sad remains of the horizontal fins. This involved some shrinking via the heating tip in the dent puller..   Looks like someone has spilled bondo all over this panel. Funny the inside didn't look all that mangled to warrant the amount we found.. Must be a TV car.. The shrinking efforts flattened out the ends fairly well...   I filled in the previous trim holes with 18 Ga plugs and TIG fusion while the owner worked away at removing the bondo so we could see what we had to work with...     Next, we had to fold a flange in the front and extend the factory bead around the opening down the front where we had flattened the panel. Some of the existing bead profiles had seen better days in the past 80 plus years, so I checked a set of joggle dies I had made for drip rail as it looked close...   New flange folded at the front, bead added using the Lennox, original beads touched up ...    Tapered pan fabricated.....  Louver layout   Welded in place..  He is having some art deco style trim pieces made to accent the louvers down the center, topped by 62 Impala fender trim. We didn't have those, so here it is with alternate SS fuel line for your viewing pleasure...

__________________

Robert |

|

|

|

|

|

#9 |

|

Post Whore

Join Date: May 2015

Location: Alabama

Posts: 14,662

|

Re: 55 Wagon Progress

That's cool...would like to see the finished product.....

__________________

Mongo...aka Greg RIP Dad RIP Jesse 1981 C30 LQ9 NV4500..http://67-72chevytrucks.com/vboard/s...d.php?t=753598 Mongos AD- LS3 TR6060...http://67-72chevytrucks.com/vboard/s...34#post8522334 Columbus..the 1957 IH 4x4...http://67-72chevytrucks.com/vboard/s...63#post8082563 2023 Chevy Z71..daily driver |

|

|

|

|

|

#10 |

|

Senior Member

Join Date: Mar 2011

Location: West Plains, Missouri

Posts: 7,559

|

Re: 55 Wagon Progress

Robert, very nice, really changed the look of side panel...Jim

__________________

my build thread: http://67-72chevytrucks.com/vboard/s...d.php?t=459839 Jimbo's long bed step build:http://67-72chevytrucks.com/vboard/s...t=464626<br /> |

|

|

|

|

|

#11 |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,647

|

Re: 55 Wagon Progress

Thanks for checking out the progress guys!

Well the owner sent me a "concept photo" complete with cardboard cutout... The piece of cardboard against the hood side will be chrome plated, the next will be a contrasting color to the car, and topped off with the Impala fender trim..

__________________

Robert Last edited by MP&C; 02-24-2019 at 02:37 AM. |

|

|

|

|

|

#12 |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,647

|

Re: 55 Wagon Progress

More progress on the fuel lines, with both lines now routed, we opted for glue lined heat shrink as an abrasion resistant covering where it passes closely to the body, and regular heat shrink to keep the two together.

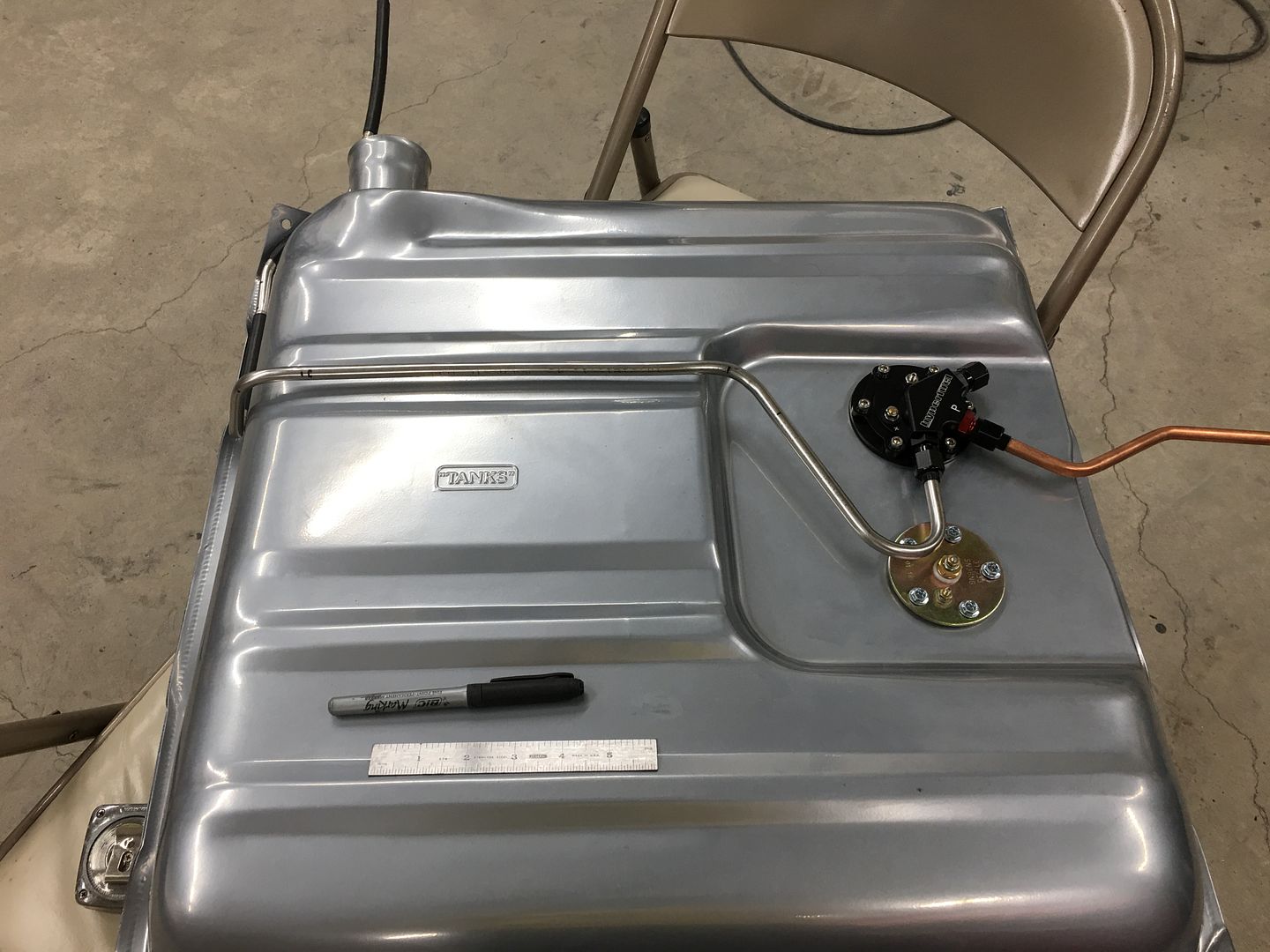

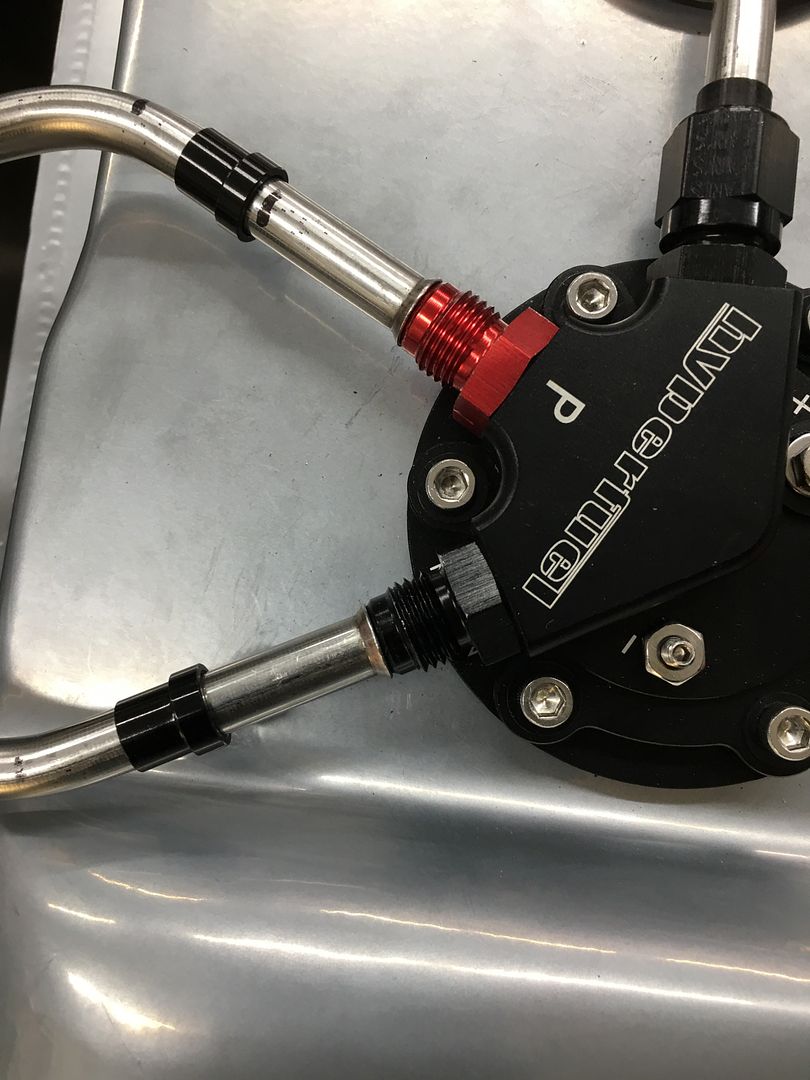

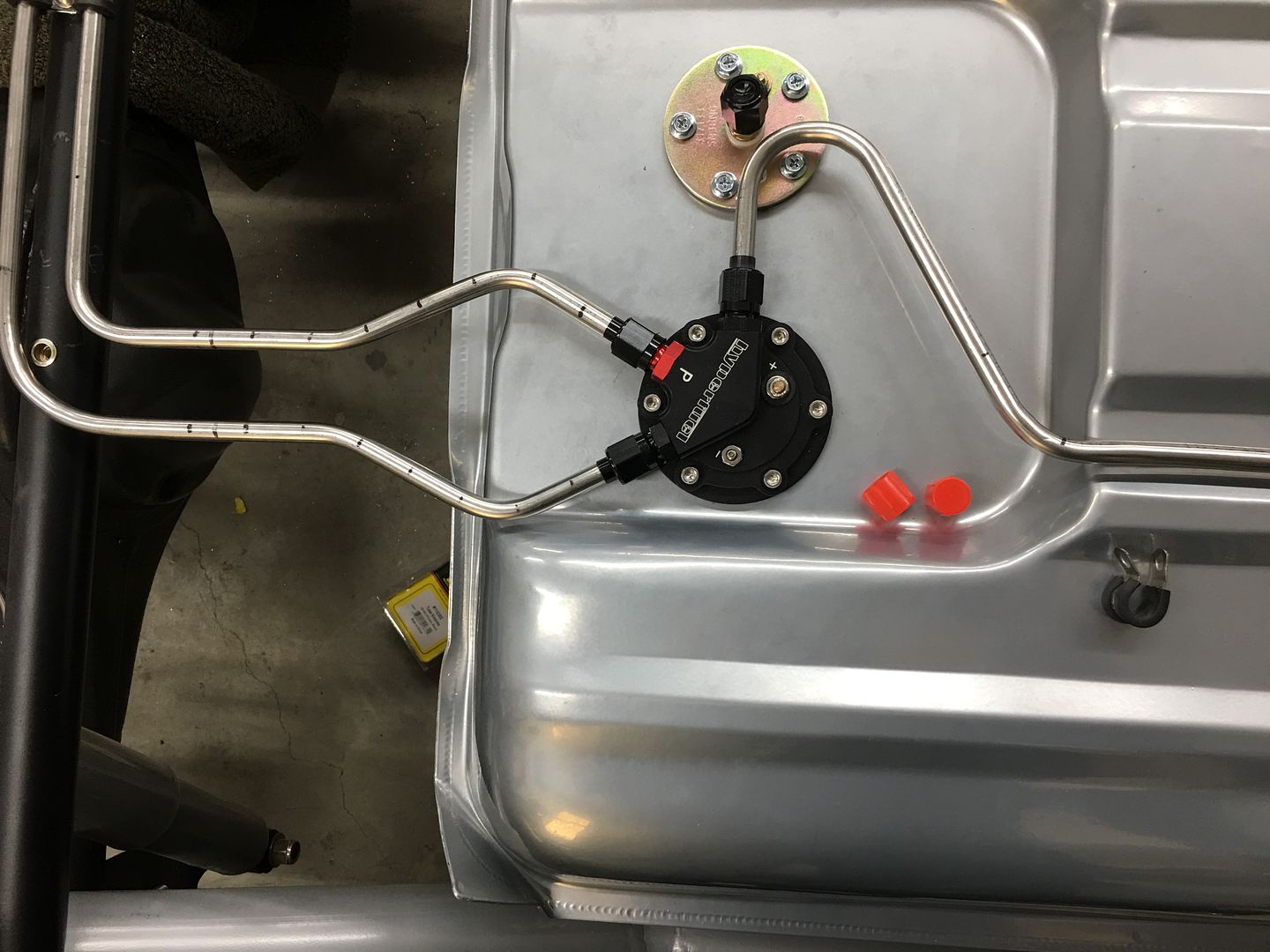

Mike installs an anchor point for adel clamps in the shock crossmember     Test bends at the fuel pump..     Next to add some AN fittings..

__________________

Robert |

|

|

|

|

|

#13 |

|

Senior Member

Join Date: Jul 2012

Location: Oblong, Illinois

Posts: 7,028

|

Re: 55 Wagon Progress

So many great ideas and excellent work you share. Greatly appreciated!

|

|

|

|

|

|

#14 |

|

low n' slo

Join Date: Mar 2009

Location: rosenberg, texas

Posts: 5,172

|

Re: 55 Wagon Progress

wow...you guys have some serious skill...and amazing attention to detail.

fun to watch!

__________________

67 1/2 ton Suburban - Project DRGNWGN. Build thread  -_--_--_ _________ _--_-_ -/____|__|__\__ ,.,,,.,.,,.,|_O _______ O_] |

|

|

|

|

|

#15 |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,647

|

Re: 55 Wagon Progress

Thanks guys!

Hood side number two completed yesterday. The flanges of the tapered pan get some stretch treatment in the kick Erco to match the profile of the hood side..  For the questions about the cutting device, it is a long nose pneumatic cut off tool from Blue Point. For keeping the cut nice and perpendicular, and disc width, the long nose works better (for me anyhow) by having the long nose as a visual guide to keep it parallel to our centerline. I don't think I would have seen as good of results using the standard cut off tool.   Each slot has stop drill holes at the end, to help remove any cracking issue and also to better determine end of cut.   E helped out with the punching efforts...…   Panel gets tacked in and welded with the TIG...

__________________

Robert |

|

|

|

|

|

#16 |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,647

|

Re: 55 Wagon Progress

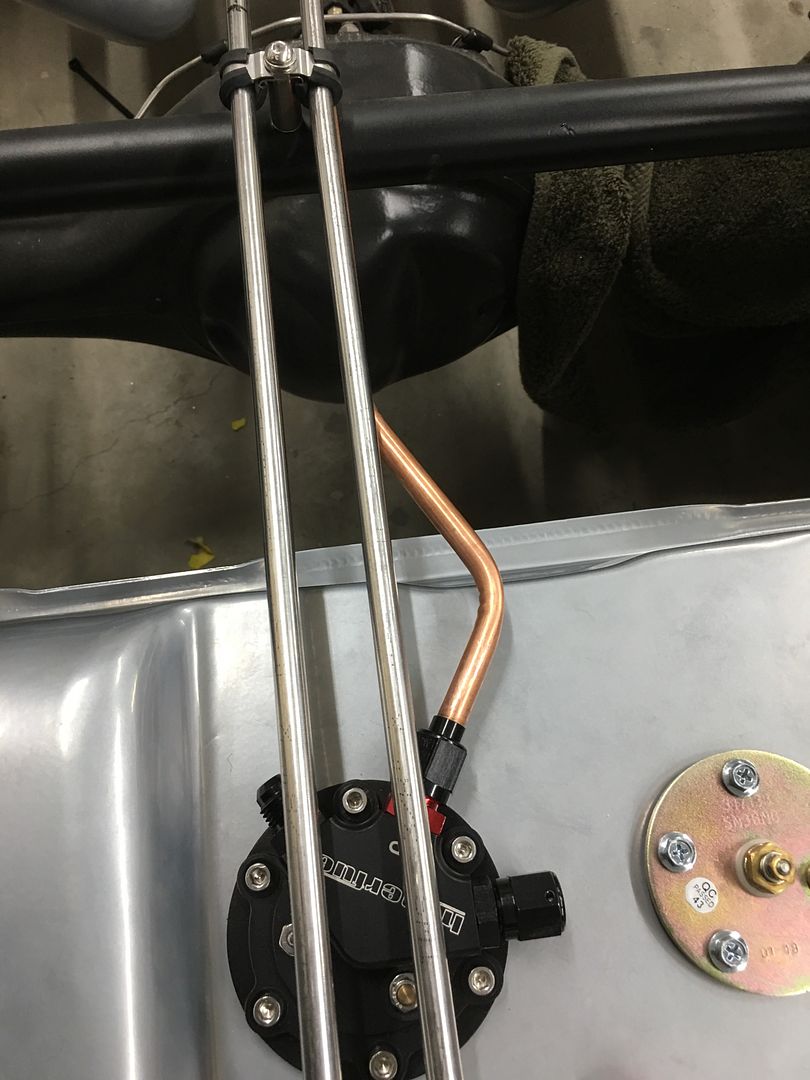

Our vent/check valve for the fuel tank will get mounted up behind the driver's tail light by the filler neck. We bent up a piece of stainless tubing last night for the vent line. The glue-lined heat shrink works well to provide a cushion/vibration dampener up against the tank.. For our stainless bends, we had also bought a roll of copper tubing to use for test bends. Inch increments were marked, bends made, and then these marked "starting points" could be transferred to the stainless for more accurate bends.....and less of a scrap pile.

Video version.. https://www.youtube.com/watch?v=NE_3...ature=youtu.be .

__________________

Robert |

|

|

|

|

|

#17 |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,647

|

Re: 55 Wagon Progress

Well after about 12 years, the Lennox TE150 is leaving the building. When we did the 35 Chevy louvers for Cody Walls, it hinted then of it's limitations. Simply put, not enough throat capacity with some of the automotive panels.

I bought this from Northwest Airlines and picked it up from their then recently closed DC-9 maintenance facility at the Hartsfield Atlanta airport. They had shut down the operation and moved maintenance overseas. This and a 100 ton drop press was the last that remained in an otherwise vacant building. I've found another metalshaper that has a larger machine, but doesn't really use it for the capacity. So after negotiating the terms, he will be using this for the (mainly) motorcycle fabrications, where I will have more capacity for larger automotive panels.

__________________

Robert |

|

|

|

|

|

#18 |

|

Post Whore

Join Date: May 2015

Location: Alabama

Posts: 14,662

|

Re: 55 Wagon Progress

wow....that is one huge chunk of steel...

__________________

Mongo...aka Greg RIP Dad RIP Jesse 1981 C30 LQ9 NV4500..http://67-72chevytrucks.com/vboard/s...d.php?t=753598 Mongos AD- LS3 TR6060...http://67-72chevytrucks.com/vboard/s...34#post8522334 Columbus..the 1957 IH 4x4...http://67-72chevytrucks.com/vboard/s...63#post8082563 2023 Chevy Z71..daily driver |

|

|

|

|

|

#19 |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,647

|

Re: 55 Wagon Progress

Good thing I got a tilt bed trailer last year, it came in handy.. As well as borrowing some piano moving jacks..

With rain in the forecast for Friday, we loaded up the TE150 Thursday night and left it inside. All ready for the 2+ hour drive to it's new home on Saturday..  With our "trade-in" situated next to the newsed machine, you get a hint to the comparison in size. What you don't see is what is used on the inside. The TE150 uses 1/2" thick steel plate on the sides, the TE250 uses 1-1/4" thick steel plate. Quite a difference, and easily noticed when moving..   Winch helps with the uphill movement..  We made another stop and also picked up a small spinning lathe, a Model 18 DuaLathe, and a larger 3 phase converter. The motor size on the Lennox jumps from 1.5 hp to 5hp on the new one, and my present converter is a bit undersized for the occasion. All backed in the shop for the unloading ceremonies..   Some square pads were cut out of horse mat for mounting, and 3/4" anchors sunk into the concrete..  ….and let's not forget the requisite safety warning label..  Still need to wire in the three phase converter, but glad all the moving is complete.

__________________

Robert Last edited by MP&C; 03-10-2019 at 10:18 PM. |

|

|

|

|

|

#20 |

|

Registered User

Join Date: Oct 2014

Location: somewhere . . .

Posts: 969

|

Re: 55 Wagon Progress

cool bumper sticker ....

__________________

dont want to hear excuses, i want to hear solution(s) |

|

|

|

|

|

#21 |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,647

|

Re: 55 Wagon Progress

Finished up the fuel lines at the tank, bending and flaring..    test fit to the pump.....   Helpful hint of the day, copper line works well for trial runs...  Side stepped the area above the third member with the fuel line in case of extreme movement... the Adel clamps floating there will attach to the underside of the floor brace.

__________________

Robert |

|

|

|

|

|

#22 |

|

Senior Member

Join Date: Mar 2011

Location: West Plains, Missouri

Posts: 7,559

|

Re: 55 Wagon Progress

Looks great...Jim

__________________

my build thread: http://67-72chevytrucks.com/vboard/s...d.php?t=459839 Jimbo's long bed step build:http://67-72chevytrucks.com/vboard/s...t=464626<br /> |

|

|

|

|

|

#23 |

|

Registered User

Join Date: Jul 2012

Location: Rosenberg, Texas

Posts: 3,506

|

Re: 55 Wagon Progress

Nice work!

__________________

-Duane C/10 Club Texas member 1971 Chevy C10 "Brutus" SWB Fleetside 2016 6.0L (L96) 6L90E (driver/project) 1965 Pontiac GTO "Royal Goat" 400/TH400 w/AC (my baby) |

|

|

|

|

|

#24 |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,647

|

Re: 55 Wagon Progress

Well our progress on the wagon is hard to show, other than a pile of sanded paint residue on the floor.. So let's look at the sample louvers just completed, these are rotated 15 degrees..

The new 3 phase converter is wired in, and it sure is nice not having to swap plugs anymore.. this one has three outputs.

__________________

Robert |

|

|

|

|

|

#25 |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,647

|

Re: 55 Wagon Progress

Busy weekend! Saturday we got the power window mechanisms cut to length, and installed for the rear windows. We found some 1/4-20 x 1" standoffs about perfect for spacing the vertical part where it needed to be for locating the window track centered in the opening..

Lock nuts used to keep the spacer from spinning during attachment...  1/4-20 Rivnut added to secure the top..   Track is pretty well centered....  Also made a bracket for the Diacro No. 1A bender so we can use it in our universal stands..     Sunday was the Coming Out Car Show put on by the Southern Knights Rod and Custom Car Club. We got Brad to bring his car out for the event. It's like a magnet, he was answering questions all day. We had some metal fabrications on display, and I enjoyed talking to many people about their projects, welding processes, and our fabrication capabilities.       *photo credit Mike Tunney, Old Liners Car Club

__________________

Robert |

|

|

|

|

| Bookmarks |

|

|