|

|

|

|

|

#1 |

|

Registered User

Join Date: Dec 2015

Location: Beaver Falls, Pa

Posts: 168

|

Re: 55 Wagon Progress

Robert, Let me start with: WOW, just WOW! As an autobody craftsman for over 30 years, I can sure appreciate the level of workmanship!

I'd like to mention something that came to me while looking at the photos of the sign you guys are working on. A little late to the party, but it may still be of value at some point. I realize that metal glue is not something a person at your level of skills would commonly use, however in the case of that sign...it would be THE way to go! I prefer the Fusor 208 for things like that. Everywhere the gaps are where sheetmetal is attached to the beaded area & where you put the plug welds on the overlapping areas...that would be MUCH easier with glue & because it is a solid attachment it is far superior, doesn't create heat damage & nothing to grind, ect. The uniform nature of the seam makes it where with a bit of care with a finger or a bodyfiller spreader ground to a rounded corner...a near perfect "rolled edge" transition can be made rather easy while sealing it all up. I can only say: "Please discus what Im suggesting with your paint/material jobber & give it a try!" Its not a "cure-all", but it has its place & that sign is a PERFECT example! Take Care, Lorne |

|

|

|

|

|

#2 |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,647

|

Re: 55 Wagon Progress

Thanks for the comments guys! Lorne, appreciate the insight, but like you said, I'm a bit far along on the sign at this point. The two "permanent" sides are welded, the opposite sides will be a screw and rivnut assembly to allow removal of one side for access to the electrics.. Have to keep that option open for the next project like that..

Thanks!!

__________________

Robert Last edited by MP&C; 09-24-2019 at 07:43 AM. |

|

|

|

|

|

#3 |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,647

|

Re: 55 Wagon Progress

Here's some of the forming process of our A-Pillar fabrication that I missed the other day. Did a couple time lapse videos, first shows the shrinking of the corner. The Vise Grip tucking tool, torch, and hammer is used to get the corner to come down about a 20* angle, then the two flanges were folded, which gives us one big tuck. At that point wide VEE is heated up and the high spots of the flange corner is hammered back into itself. Repeat for the next high spot, until the corner is folded where you want it.

https://www.youtube.com/watch?v=jH6lybdj94A Here's the corner shrink complete...  Then the barrel end hammer is used to make the joggle creases by using an upper die from our press brake as a post dolly. That’s the basic process. https://www.youtube.com/watch?v=-ZBpjeUw6us If you find the time lapse too fast, you can change playback speed on YouTube to slow things down a bit.. . .

__________________

Robert |

|

|

|

|

|

#4 |

|

Post Whore

Join Date: May 2015

Location: Alabama

Posts: 14,663

|

Re: 55 Wagon Progress

Robert,,,yall gonna have to quit mixing redbull and 5hr energys..haha...thats a neat process though

__________________

Mongo...aka Greg RIP Dad RIP Jesse 1981 C30 LQ9 NV4500..http://67-72chevytrucks.com/vboard/s...d.php?t=753598 Mongos AD- LS3 TR6060...http://67-72chevytrucks.com/vboard/s...34#post8522334 Columbus..the 1957 IH 4x4...http://67-72chevytrucks.com/vboard/s...63#post8082563 2023 Chevy Z71..daily driver |

|

|

|

|

|

#5 |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,647

|

Re: 55 Wagon Progress

I may need a few more....

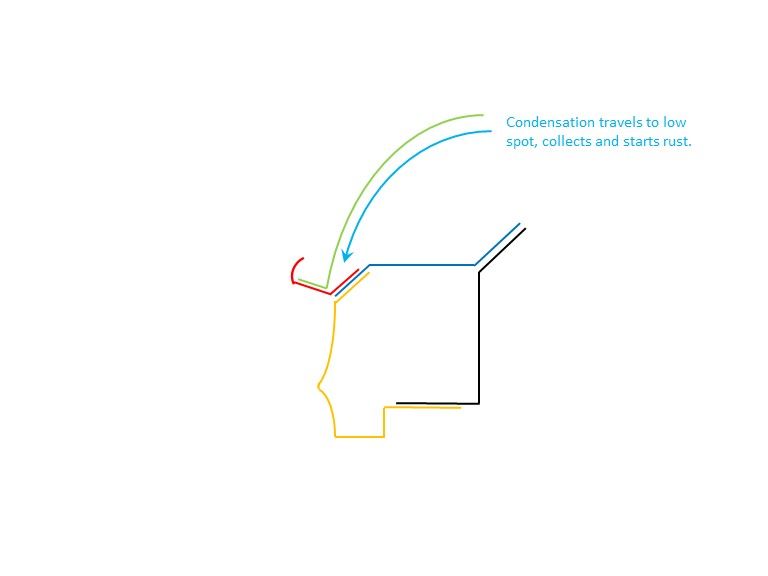

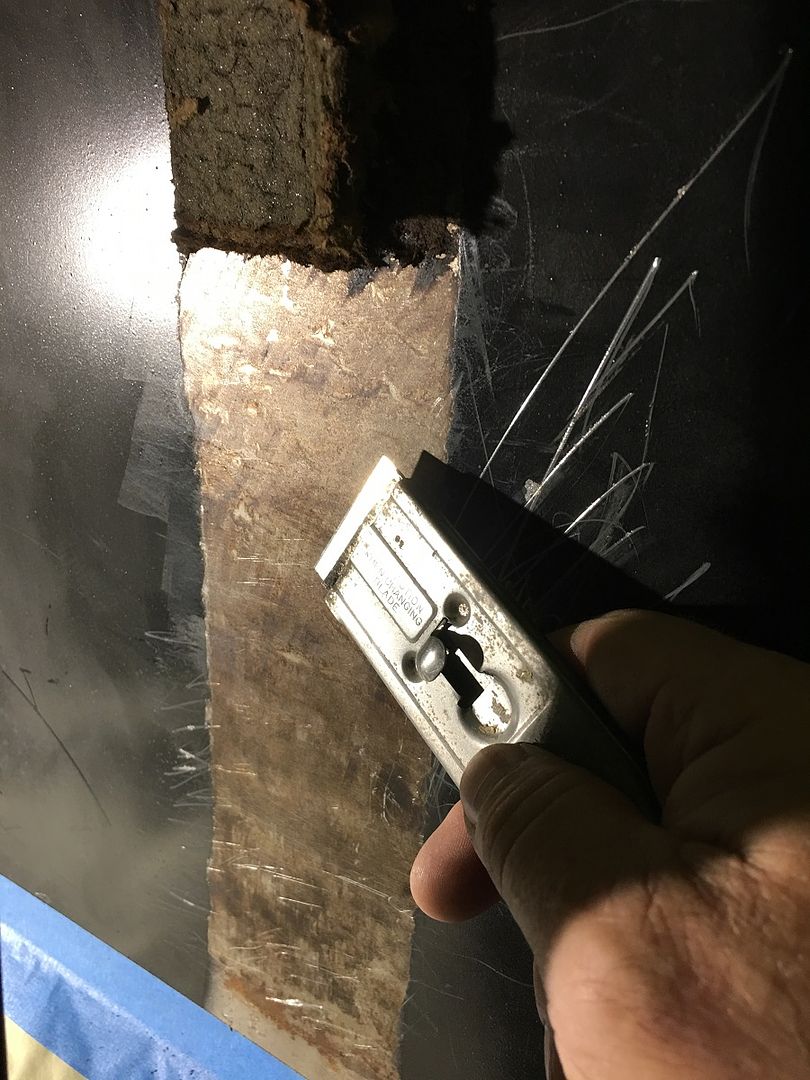

Today we worked on some rust prevention up inside the roof. This is between the roof skin and the perimeter structure just above the windows.  The car was rolled on it's side and SPI epoxy poured into the area, acid brush was used to cover everything we could..   Once the entire passenger side had been flooded around to the liftgate hinge, we rolled the car right side up again. It wasn't long that we had paint dripping on the top of the rocker panel.. It was running down inside the A Pillar and running out the bottom of the dogleg. This is a good indicator of exactly where the roof condensation runs to when it reaches the A Pillar, and why we had rust issues there.   Here's a picture of when we opened the roof for rust repair, showing what the condensation did for us..   So our primer is sealing the joint between the roof skin and the structure.. We found an opening above the windshield that would help us to flood the front seam....  We opened up an acid brush to form a funnel, and poured SPI Epoxy in the area..    A puddle out of the A Pillar dogleg shows we have good flow through the windshield...  To insure everything was covered above the windshield header, we joined two acid brushes for an extended reach over the header, and bent to match the roof skin profile....

__________________

Robert |

|

|

|

|

|

#6 |

|

Senior Member

Join Date: Mar 2011

Location: West Plains, Missouri

Posts: 7,559

|

Re: 55 Wagon Progress

Robert, that should take care of any problems, later down the road. Nice work as always...Jim

__________________

my build thread: http://67-72chevytrucks.com/vboard/s...d.php?t=459839 Jimbo's long bed step build:http://67-72chevytrucks.com/vboard/s...t=464626<br /> |

|

|

|

|

|

#7 |

|

Registered User

Join Date: Mar 2015

Location: Castle Rock, CO

Posts: 534

|

Re: 55 Wagon Progress

Unbelievable work!

I do have a question - if you want to get back in tight or mostly enclosed spaces where rust grows but either don’t have the skills or it just doesn’t make sense for a particular project, what do you think of using a product like Eastwood’s internal coating and rust encapsulation? https://www.eastwood.com/eastwood-in...z-aerosol.html For ex., I have an old Jeep pickup and i know there has to some level of rust in the rockers, pillars, inside roof edges, etc. with this product and their flex hose I can get in many spaces and spray them reasonably well and that has to be certainly better than nothing? Are there other better products or ways to deal with these areas? Thanks for allowing us to follow along! I have been encouraged to try some metal work I wouldn’t have if I didn’t see what you do.

__________________

Scott ______________ my '51 build: http://67-72chevytrucks.com/vboard/s...d.php?t=677979 |

|

|

|

|

|

#8 |

|

Post Whore

Join Date: May 2015

Location: Alabama

Posts: 14,663

|

Re: 55 Wagon Progress

cavity wax maybe?

__________________

Mongo...aka Greg RIP Dad RIP Jesse 1981 C30 LQ9 NV4500..http://67-72chevytrucks.com/vboard/s...d.php?t=753598 Mongos AD- LS3 TR6060...http://67-72chevytrucks.com/vboard/s...34#post8522334 Columbus..the 1957 IH 4x4...http://67-72chevytrucks.com/vboard/s...63#post8082563 2023 Chevy Z71..daily driver |

|

|

|

|

|

#9 |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,647

|

Re: 55 Wagon Progress

Scott, I’ve never used the Eastwood product to speak to how well it works. I would say if you think there are rust issues I would check into whether replacement rockers or other panels are needed. I try to encapsulate the rust in a trash can as I install new metal.

__________________

Robert |

|

|

|

|

|

#10 | |

|

Registered User

Join Date: Mar 2015

Location: Castle Rock, CO

Posts: 534

|

Re: 55 Wagon Progress

Quote:

I already bought several parts trucks or major sections and cut all the good metal out of them I could find. I will be trimming parts and replacing rusty sections where I can, as long as the rust doesn't spread further before I get there! Anyway, I'll just continue to watch you do your artistry and magic and try to dance that line between weenie work and something better!

__________________

Scott ______________ my '51 build: http://67-72chevytrucks.com/vboard/s...d.php?t=677979 |

|

|

|

|

|

|

#11 |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,647

|

Re: 55 Wagon Progress

Scott, we all started somewhere. Recognizing room for improvement will normally prompt one to improve skills as you learn.

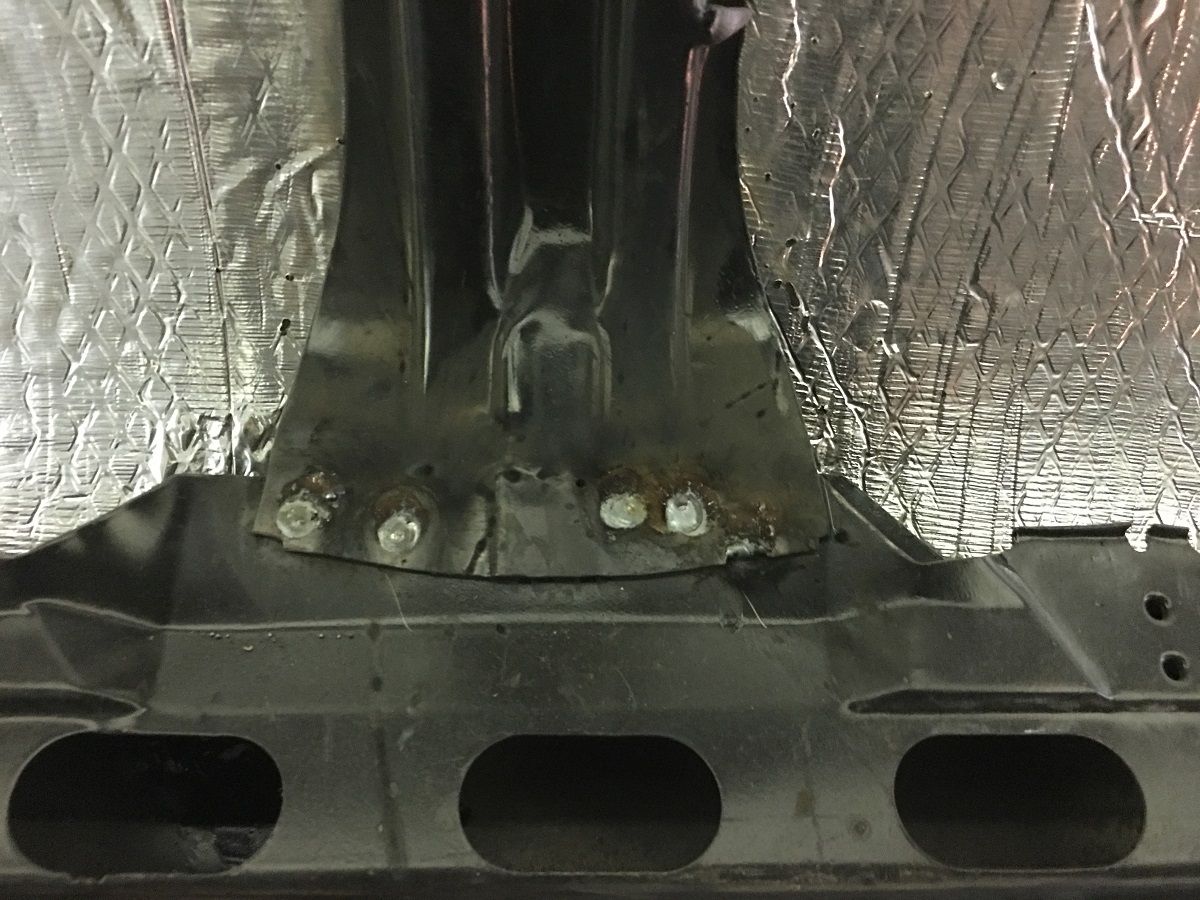

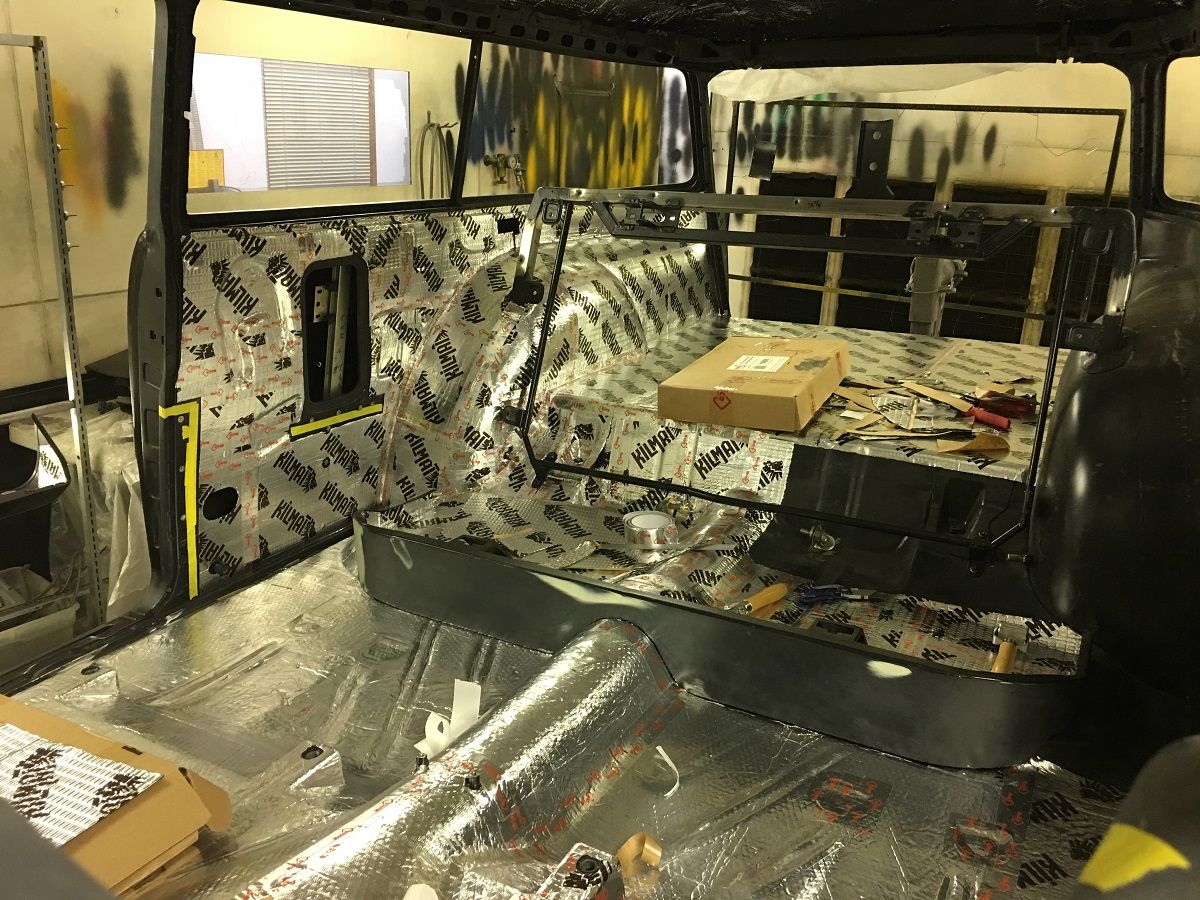

Progress this weekend, We had originally left the factory jute insulation under the roof supports, thinking we could just butt up to it with the new stuff. After installing the Noico inside the doors, I guess my OCD wasn't about to leave the old stuff in the roof. So the bottom edge of the roof supports were scribed on the driver's side for relocation purposes, de-spot welded, and pulled downward enough to scrape off the old jute..   https://www.youtube.com/watch?v=ZOj1...ature=youtu.be  The bare area is then scuffed with 80 grit and two coats of SPI epoxy primer applied.. After that sets up we applied the Noico sound deadening mat to the inside of the roof skin. Then the roof supports are aligned with our scribed marks and plug welded in place..    Mike has been plugging along on the Drummers Lounge sign, the arrow is close to done, it still needs fastening hardware added for the access panels, and holes added for the lights..

__________________

Robert Last edited by MP&C; 10-06-2019 at 10:56 PM. |

|

|

|

|

|

#12 |

|

Senior Member

Join Date: Mar 2011

Location: West Plains, Missouri

Posts: 7,559

|

Re: 55 Wagon Progress

Robert, hope you don't get tired of me saying the same thing over and over "Great work as always"...Jim

__________________

my build thread: http://67-72chevytrucks.com/vboard/s...d.php?t=459839 Jimbo's long bed step build:http://67-72chevytrucks.com/vboard/s...t=464626<br /> |

|

|

|

|

|

#13 |

|

Registered User

Join Date: Jan 2003

Location: Safford,AZ

Posts: 3,612

|

Re: 55 Wagon Progress

Drummers sign getting neon?

|

|

|

|

|

|

#14 |

|

Post Whore

Join Date: May 2015

Location: Alabama

Posts: 14,663

|

Re: 55 Wagon Progress

(Robert, hope you don't get tired of me saying the same thing over and over "Great work as always"...Jim )

cant agree enough!!!!!

__________________

Mongo...aka Greg RIP Dad RIP Jesse 1981 C30 LQ9 NV4500..http://67-72chevytrucks.com/vboard/s...d.php?t=753598 Mongos AD- LS3 TR6060...http://67-72chevytrucks.com/vboard/s...34#post8522334 Columbus..the 1957 IH 4x4...http://67-72chevytrucks.com/vboard/s...63#post8082563 2023 Chevy Z71..daily driver |

|

|

|

|

|

#15 | |

|

Registered User

Join Date: Dec 2011

Location: Mobile, Alabama

Posts: 996

|

Re: 55 Wagon Progress

Quote:

I totally agree as well. One day this project will be finished and fabrication school will be over for us until you hopefully start and document a new project. Like I said many many posts of yours ago......just because we are not commenting doesn't mean we are not watching. Keep it coming!!

__________________

My Build - http://67-72chevytrucks.com/vboard/s...d.php?t=515876 |

|

|

|

|

|

|

#16 |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,647

|

Re: 55 Wagon Progress

Thanks for following along fellas!

Today Mike sent time blocking out the epoxy on the sign parts and addressing any low areas. I continued working on sound deadening, have one inner quarter panel left to go..   https://www.youtube.com/watch?v=f-ByQZLYwRU

__________________

Robert |

|

|

|

|

|

#17 |

|

BlahBlahBlah

Join Date: Feb 2002

Location: Wa.

Posts: 19,995

|

Re: 55 Wagon Progress

I'm curious on an amazing build like this what are the expectations of the owner on the time line from start to finish? I've noticed on the high end car builders TV shows the time to build can run in to several years.

__________________

… … … … … … … … ... … … … … … … … … … … … |

|

|

|

|

|

#18 |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,647

|

Re: 55 Wagon Progress

She brought it to a part time shop (day job pays for family health insurance) so that comes with the distractions that go with it (and travel for the day job..) we're getting close to light at the end of the tunnel now..

Sign progress, Fine tuning of some of the parts....   …..and for mounting it on the steel pole, this "shoe" is made of 14 gauge cold rolled and formed using the Go Kart slick.. The "sleeve" will slide over the pole and a set screw will hold it in place..        All ready for a splash of paint... The sound mat is installed inside the wagon... https://www.youtube.com/watch?v=H0X0t0nT4t4 .

__________________

Robert |

|

|

|

|

|

#19 |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,647

|

Re: 55 Wagon Progress

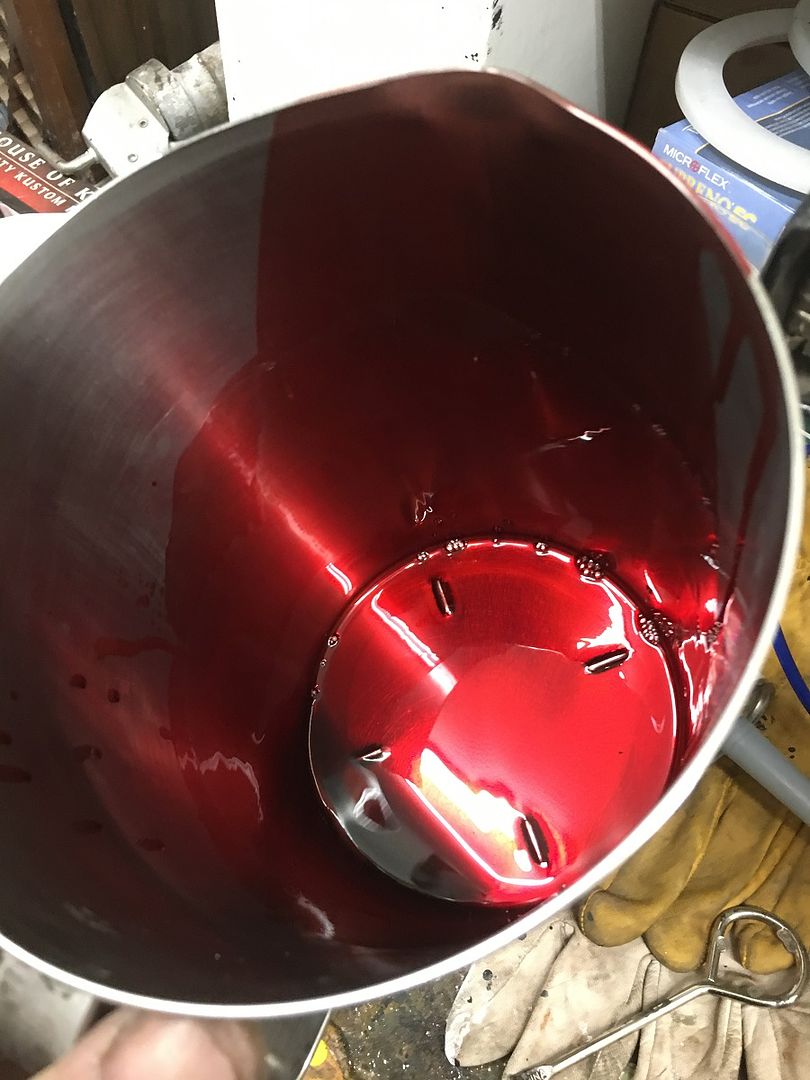

A couple coats of Epoxy last night to seal things up....

….and then a white face added to the lighted surfaces...   Then they were masked off for painting the silver....  and a bit of color for the "drum"    video: https://www.youtube.com/watch?v=lPbuYB1HTTo Now to see if Mike can get this assembled this week...

__________________

Robert |

|

|

|

|

|

#20 |

|

Post Whore

Join Date: May 2015

Location: Alabama

Posts: 14,663

|

Re: 55 Wagon Progress

Looking good ....as always

__________________

Mongo...aka Greg RIP Dad RIP Jesse 1981 C30 LQ9 NV4500..http://67-72chevytrucks.com/vboard/s...d.php?t=753598 Mongos AD- LS3 TR6060...http://67-72chevytrucks.com/vboard/s...34#post8522334 Columbus..the 1957 IH 4x4...http://67-72chevytrucks.com/vboard/s...63#post8082563 2023 Chevy Z71..daily driver |

|

|

|

|

|

#21 |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,647

|

Re: 55 Wagon Progress

Thanks Greg!

The sign was partially assembled today, and a test of the lights...   Lighting: https://www.youtube.com/watch?v=XSX80znqiAo .

__________________

Robert |

|

|

|

|

|

#22 |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,647

|

Re: 55 Wagon Progress

Well the Logo has just been added, and the sign has left the building. Mike did the majority of the work on this project, I'm real pleased with how it turned out. More importantly, so is the customer!!

video: https://www.youtube.com/watch?v=qewqepgfapc

__________________

Robert |

|

|

|

|

|

#23 |

|

Post Whore

Join Date: May 2015

Location: Alabama

Posts: 14,663

|

Re: 55 Wagon Progress

Looks great Robert!!....does it play the music also?....or is that the shop radio?

__________________

Mongo...aka Greg RIP Dad RIP Jesse 1981 C30 LQ9 NV4500..http://67-72chevytrucks.com/vboard/s...d.php?t=753598 Mongos AD- LS3 TR6060...http://67-72chevytrucks.com/vboard/s...34#post8522334 Columbus..the 1957 IH 4x4...http://67-72chevytrucks.com/vboard/s...63#post8082563 2023 Chevy Z71..daily driver |

|

|

|

|

|

#24 |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,647

|

Re: 55 Wagon Progress

That was music we played in the shop for the occasion..

You never know what's playing over here.. You never know what's playing over here..

__________________

Robert |

|

|

|

|

|

#25 |

|

Registered User

Join Date: Jan 2003

Location: Safford,AZ

Posts: 3,612

|

Re: 55 Wagon Progress

Nice work!!

|

|

|

|

|

| Bookmarks |

|

|