|

|

|

|

|

#1 |

|

Senior Member

Join Date: Mar 2011

Location: West Plains, Missouri

Posts: 7,559

|

Re: 55 Wagon Progress

Very cool...Jim

__________________

my build thread: http://67-72chevytrucks.com/vboard/s...d.php?t=459839 Jimbo's long bed step build:http://67-72chevytrucks.com/vboard/s...t=464626<br /> |

|

|

|

|

|

#2 |

|

BlahBlahBlah

Join Date: Feb 2002

Location: Wa.

Posts: 19,992

|

Re: 55 Wagon Progress

I don't think there is anything you cant make out of metal. The sign is amazing!

__________________

… … … … … … … … ... … … … … … … … … … … … |

|

|

|

|

|

#3 |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,647

|

Re: 55 Wagon Progress

Thanks guys!!

Time for a long overdue update. I've had too much travel for the day job since the first of the year. Case in point, we've had more than one Taco Tuesday at the Sand Bar in Cocoa Beach...  Since completing the Drum Sign, Mike has been removing dings from the wagon's stainless trim. Here Vince and I test fit the side spears..   We've done some stainless repair before using small hammers and handmade punches to match the rear side of the profile, but during the last metalshaping workshop I attended at Will Cronkrite's shop in SC, I picked up a stainless dent/ding removal fixture that he had made up.. The blue sleeve at the top works on the premise of a slide hammer, with the force applied controlled by the operator. The die at the bottom (punch) is removable to allow a wide variety of specialized punches to fit the application.   This tool allows more controlled manipulation, especially to those of us that don't do this type of repair every day... and it's been Duallyjams tested and approved! Here's one of the purpose built punches made for the trim...  Here's some of our efforts in polishing out the trim after ding removal, filing, and about 6 steps of progressively finer grits of w/d and trizact….  Reflection....  We also were test fitting the dash trim that the owner had picked up. I know, billet is a bit played out, but let's see what works here...  In fitting the corner pieces, the rear point of the trim does not match the unequal radius of the recess in the dash. Then when the middle (concave) radius is pushed into the recess, the rear "point" drops down out of the recess. So the underlying message here it the fit of these parts is piss poor at best.  So we are not going to use these, but opting for something in a stainless trim.. final design TBD... Lastly, all the travel I've had for the day job really interferes with long term efforts, paintwork in particular. So in the interest of keeping progress moving forward, we have farmed out the paintwork to Brandon and Richard Glymph at Absolute Rod and Custom Paint. So last weekend the body and various parts were delivered to their shop in Annapolis..  So we should be doing assembly here in the near future!!

__________________

Robert |

|

|

|

|

|

#4 |

|

Post Whore

Join Date: May 2015

Location: Alabama

Posts: 14,662

|

Re: 55 Wagon Progress

cant wait..!!!

__________________

Mongo...aka Greg RIP Dad RIP Jesse 1981 C30 LQ9 NV4500..http://67-72chevytrucks.com/vboard/s...d.php?t=753598 Mongos AD- LS3 TR6060...http://67-72chevytrucks.com/vboard/s...34#post8522334 Columbus..the 1957 IH 4x4...http://67-72chevytrucks.com/vboard/s...63#post8082563 2023 Chevy Z71..daily driver |

|

|

|

|

|

#5 |

|

Senior Member

Join Date: Mar 2011

Location: West Plains, Missouri

Posts: 7,559

|

Re: 55 Wagon Progress

Robert, work done to the trim is amazing. Look forward to the next update...Jim

__________________

my build thread: http://67-72chevytrucks.com/vboard/s...d.php?t=459839 Jimbo's long bed step build:http://67-72chevytrucks.com/vboard/s...t=464626<br /> |

|

|

|

|

|

#6 |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,647

|

Re: 55 Wagon Progress

Thanks guys!

I had a request to show more detail on the trim tool we've been using, so thought I'd share it here as well. The gentleman that made it for me advised the other day (as I had requests to see if he had more available) that he is long since retired, and anyone is more than welcome to use the details shown to make their own. https://www.youtube.com/watch?v=Njw3X8dDRko .

__________________

Robert |

|

|

|

|

|

#7 |

|

Post Whore

Join Date: May 2015

Location: Alabama

Posts: 14,662

|

Re: 55 Wagon Progress

That's a nice setup Robert...I see there is a punch side..is there also a cavity side to fit what your working on..?

__________________

Mongo...aka Greg RIP Dad RIP Jesse 1981 C30 LQ9 NV4500..http://67-72chevytrucks.com/vboard/s...d.php?t=753598 Mongos AD- LS3 TR6060...http://67-72chevytrucks.com/vboard/s...34#post8522334 Columbus..the 1957 IH 4x4...http://67-72chevytrucks.com/vboard/s...63#post8082563 2023 Chevy Z71..daily driver |

|

|

|

|

|

#8 |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,647

|

Re: 55 Wagon Progress

It's just the flat plate on the bottom. If you need a special shape or cradle to support the stainless trim it would have to be made per requirement. Although if you look in the video I have a piece of rubber that normally sits on the bottom, it's the reddish looking circle laying behind the tool on the table..

__________________

Robert |

|

|

|

|

|

#9 |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,647

|

Re: 55 Wagon Progress

Not many pictures to show on our wagon progress, the body has been blocked out and Brandon is getting some touch ups done to get ready for one final epoxy sprayout..

Vince has been given the thankless task of media blasting some of the remaining bare steel components so we can get some painting done of piece parts on this end. The condenser mount was media blasted, epoxy used to seal the wired edge, and some Evercoat 416 added and sanded smooth to form a slight radius fillet to finish it off.. We should be priming this coming week..

__________________

Robert |

|

|

|

|

|

#10 |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,647

|

Re: 55 Wagon Progress

Vince has been getting all the core support parts prepped this past week, so last night was paint night, time for some epoxy primer..

After epoxy:    Even got some epoxy on the low-rider wagon's rear axles.

__________________

Robert |

|

|

|

|

|

#11 |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,647

|

Re: 55 Wagon Progress

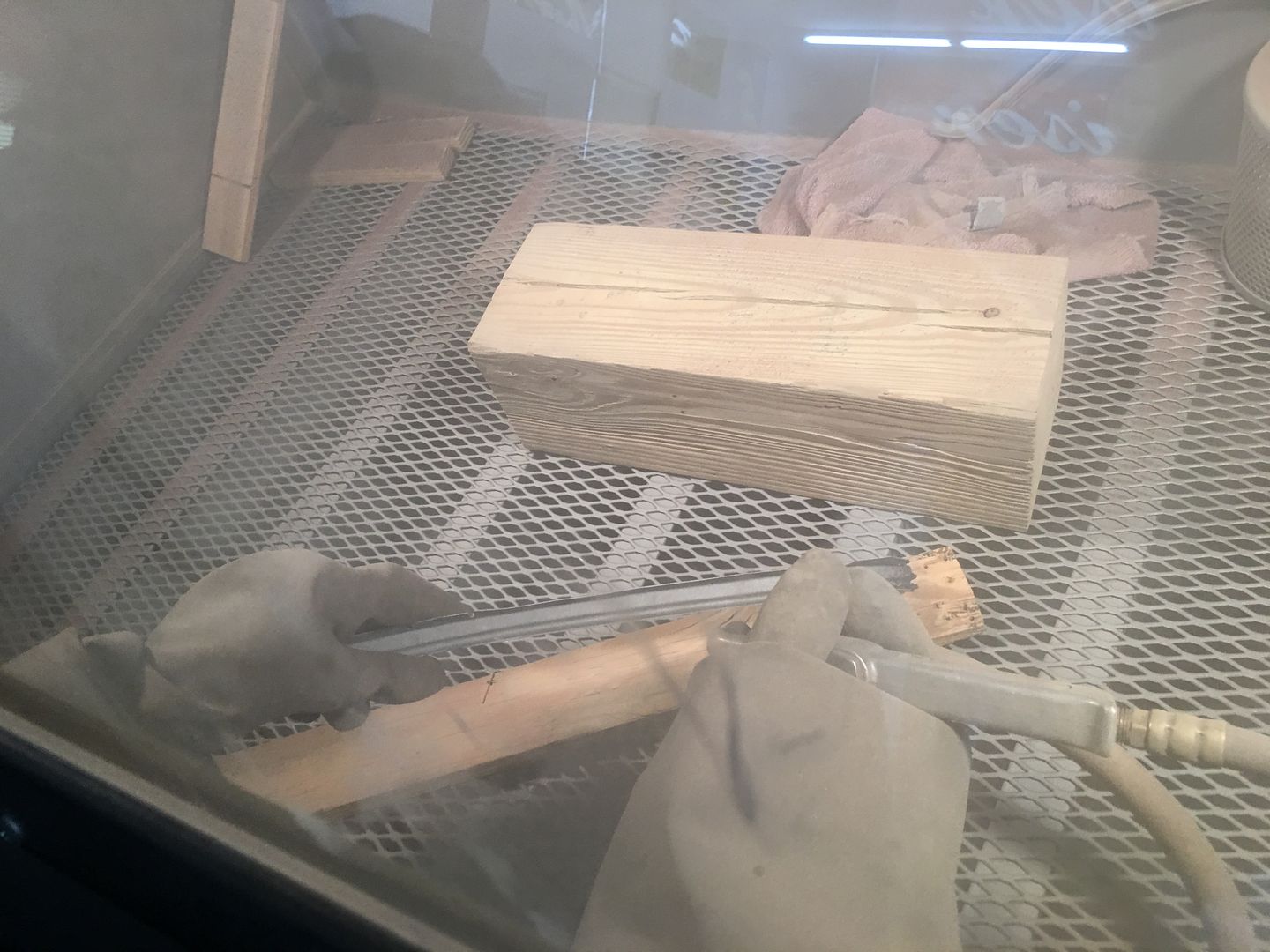

Today Vince was doing more media blasting of additional interior pieces as well as some hand painting on the parking brake for the wagon. It had some bare steel still so he got most of that covered. The ratchet/gear was left alone as we thought the epoxy would anchor it permanently..

Mike blocked out the pieces we primed last week, drilled some holes we'll need for the fan shroud, and got pieces hung up for the next round of epoxy primer.   ….and please don't tell anyone you've seen her patio table in the paint booth! On another note, our resident shop ghost who likes to hide things has done something with the stainless trim door points. So I had put in a call to Mikey at The Stainless Shoppe. He had some original take offs in stock, and even polished them up for us. Now we have our work cut out for us in matching these!! https://www.youtube.com/watch?v=S0xRFAlW2dQ .

__________________

Robert |

|

|

|

|

|

#12 |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,647

|

Re: 55 Wagon Progress

We got some more epoxy sprayed on the core support parts and hood latch...

And Brandon sent some pictures of the wagon in final primer..      A little bit closer....

__________________

Robert |

|

|

|

|

|

#13 |

|

Post Whore

Join Date: May 2015

Location: Alabama

Posts: 14,662

|

Re: 55 Wagon Progress

Yall making good progress...cant wait to see it complete

__________________

Mongo...aka Greg RIP Dad RIP Jesse 1981 C30 LQ9 NV4500..http://67-72chevytrucks.com/vboard/s...d.php?t=753598 Mongos AD- LS3 TR6060...http://67-72chevytrucks.com/vboard/s...34#post8522334 Columbus..the 1957 IH 4x4...http://67-72chevytrucks.com/vboard/s...63#post8082563 2023 Chevy Z71..daily driver |

|

|

|

|

|

#14 |

|

Senior Member

Join Date: Mar 2011

Location: West Plains, Missouri

Posts: 7,559

|

Re: 55 Wagon Progress

Looks good...Jim

__________________

my build thread: http://67-72chevytrucks.com/vboard/s...d.php?t=459839 Jimbo's long bed step build:http://67-72chevytrucks.com/vboard/s...t=464626<br /> |

|

|

|

|

|

#15 |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,647

|

Re: 55 Wagon Progress

Thanks for following along with our progress guys!

Today I was block sanding some core support parts for one more spray. Making black powder out of black epoxy primer. Not all that exciting, so I didn't take any pictures.. But wait... it gets better! Brandon and Richard have been sanding as well, only they put some color on the roof today:      Clear:   Can't wait for the green and some sunlight.... .

__________________

Robert Last edited by MP&C; 04-11-2020 at 07:04 PM. |

|

|

|

|

|

#16 |

|

Post Whore

Join Date: May 2015

Location: Alabama

Posts: 14,662

|

Re: 55 Wagon Progress

That looks great..!!...ready for more...

__________________

Mongo...aka Greg RIP Dad RIP Jesse 1981 C30 LQ9 NV4500..http://67-72chevytrucks.com/vboard/s...d.php?t=753598 Mongos AD- LS3 TR6060...http://67-72chevytrucks.com/vboard/s...34#post8522334 Columbus..the 1957 IH 4x4...http://67-72chevytrucks.com/vboard/s...63#post8082563 2023 Chevy Z71..daily driver |

|

|

|

|

|

#17 |

|

Senior Member

Join Date: Mar 2011

Location: West Plains, Missouri

Posts: 7,559

|

Re: 55 Wagon Progress

Looks super...Jim

__________________

my build thread: http://67-72chevytrucks.com/vboard/s...d.php?t=459839 Jimbo's long bed step build:http://67-72chevytrucks.com/vboard/s...t=464626<br /> |

|

|

|

|

|

#18 |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,647

|

Re: 55 Wagon Progress

Thanks guys! Long while getting here..

__________________

Robert |

|

|

|

|

|

#19 |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,647

|

Re: 55 Wagon Progress

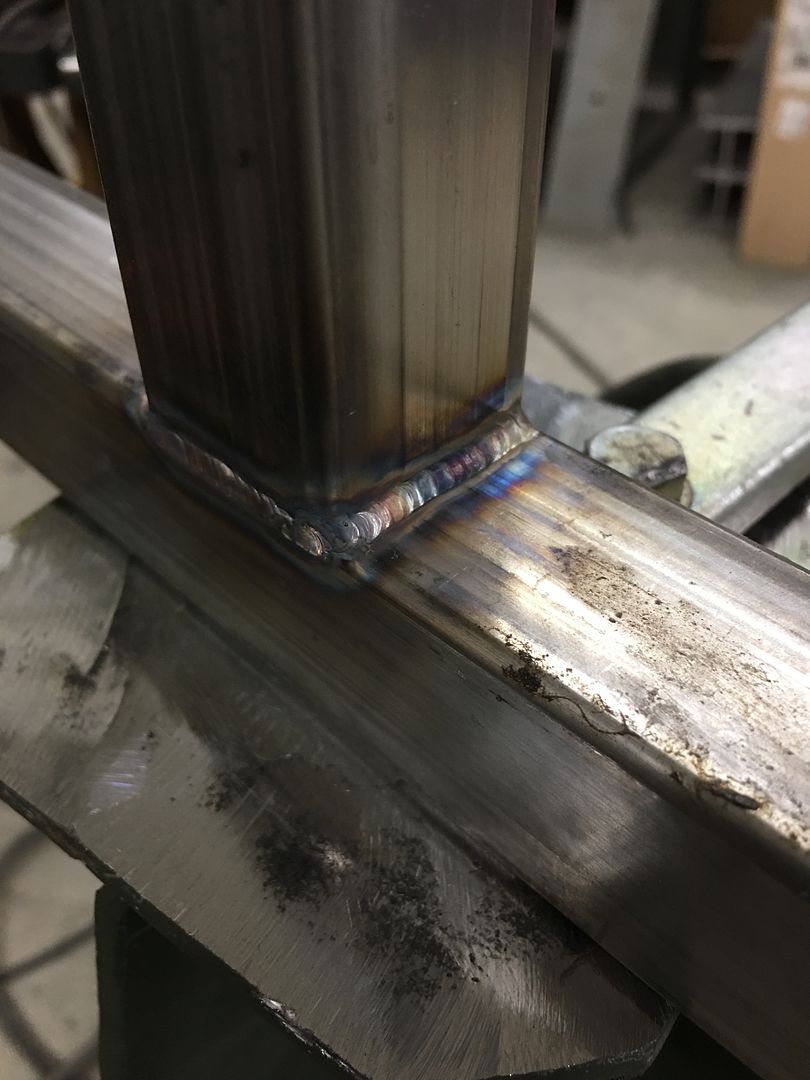

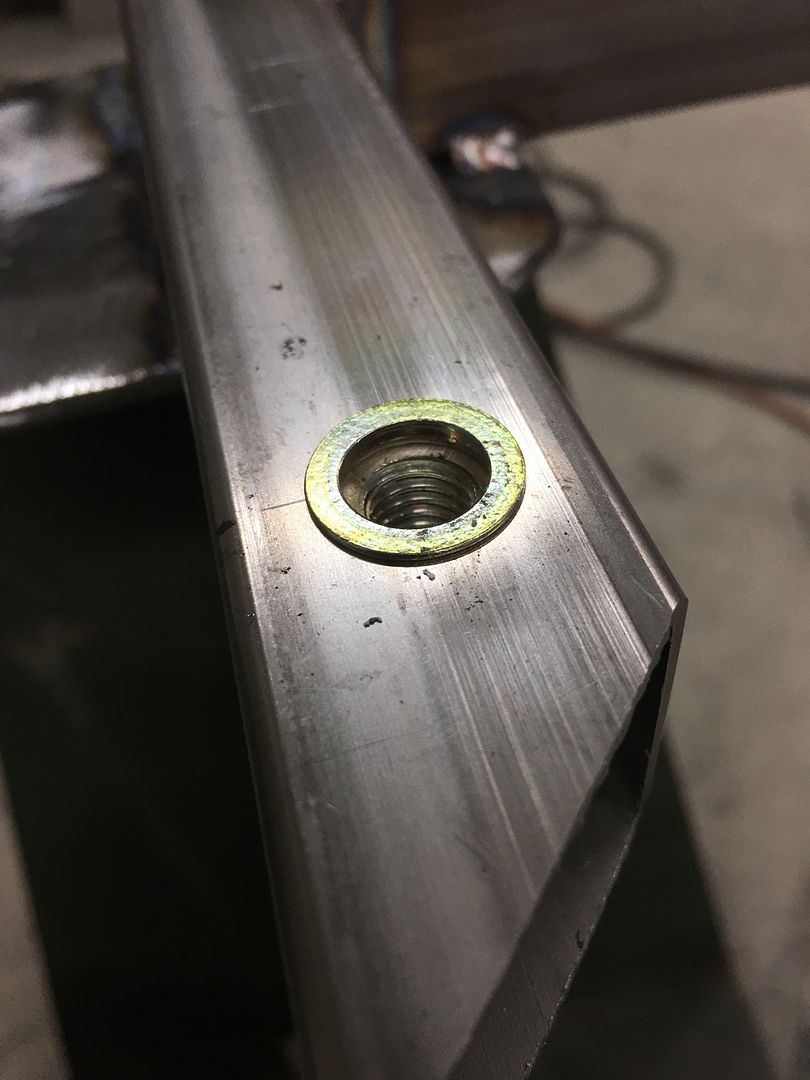

Some spring cleaning.... Picked up a 12" disc sander quite a few months back, and Mike has been using this on the floor.. So I decided to help the guy out and put it at a more useable height... Added a "bolting framework" to the top of one of the paint tripods, already set up with casters so you can push it in the corner....

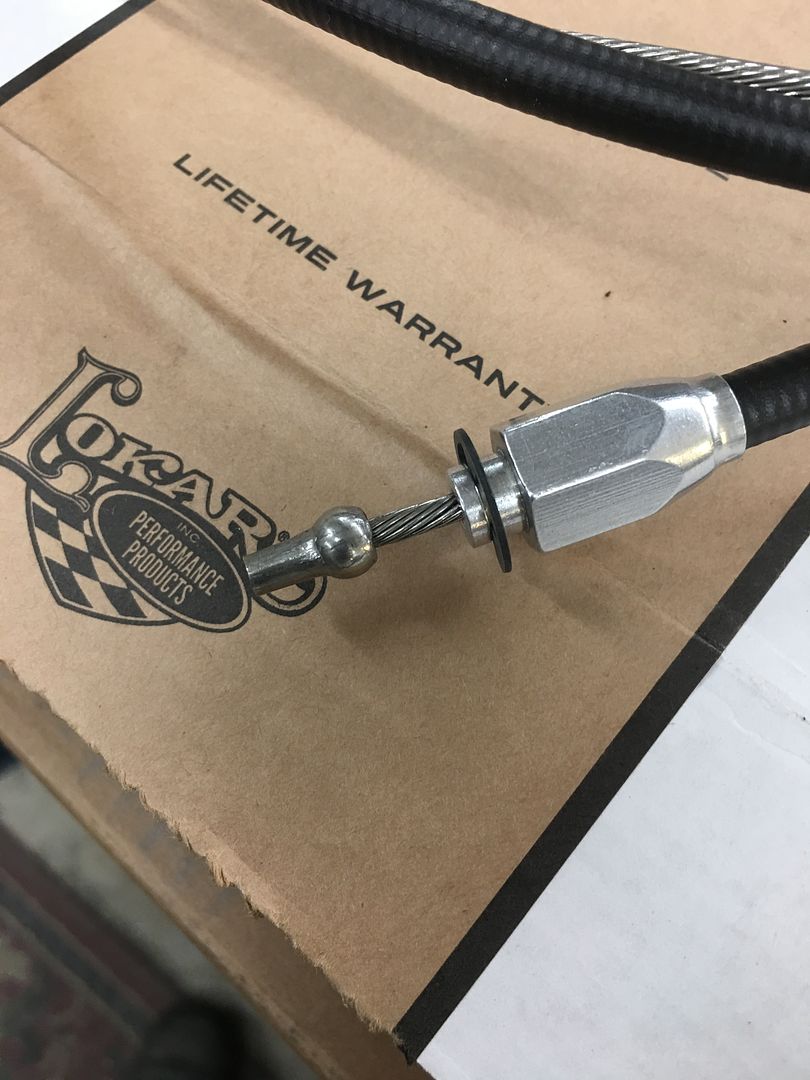

Rivnuts installed since I didn't have bolts in stock long enough to go all the way through..   Ready for some sanding...  Dana dropped off the new brake cables for the wagon the other day. The single cable that attaches to the pedal has a shouldered ferrule that sits in the bottom of the parking brake bracket. Only this shoulder was much too small for the factory hole, the Hex portion almost pulled through the hole.  I considered making an adapter sleeve on the lathe, but the figured resizing the hole would be quicker. Found a nice thick 3/8 flat washer in stock that fit the ferrule shoulder perfectly and matched the thickness of the parking brake bracket. In order to get the weld heat farther from the 3/8 hole, the bracket opening was oversized up to 7/8" (largest step drill that I could find) and the washer slightly downsized to fit.. Some 3/8 standoffs made a quick arbor for the drill, and the die grinder does the rest. we had our correct size in about a minute..    Installed, much better fit... Now Vince needs to do some touch up on the paint!

__________________

Robert |

|

|

|

|

|

#20 |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,647

|

Re: 55 Wagon Progress

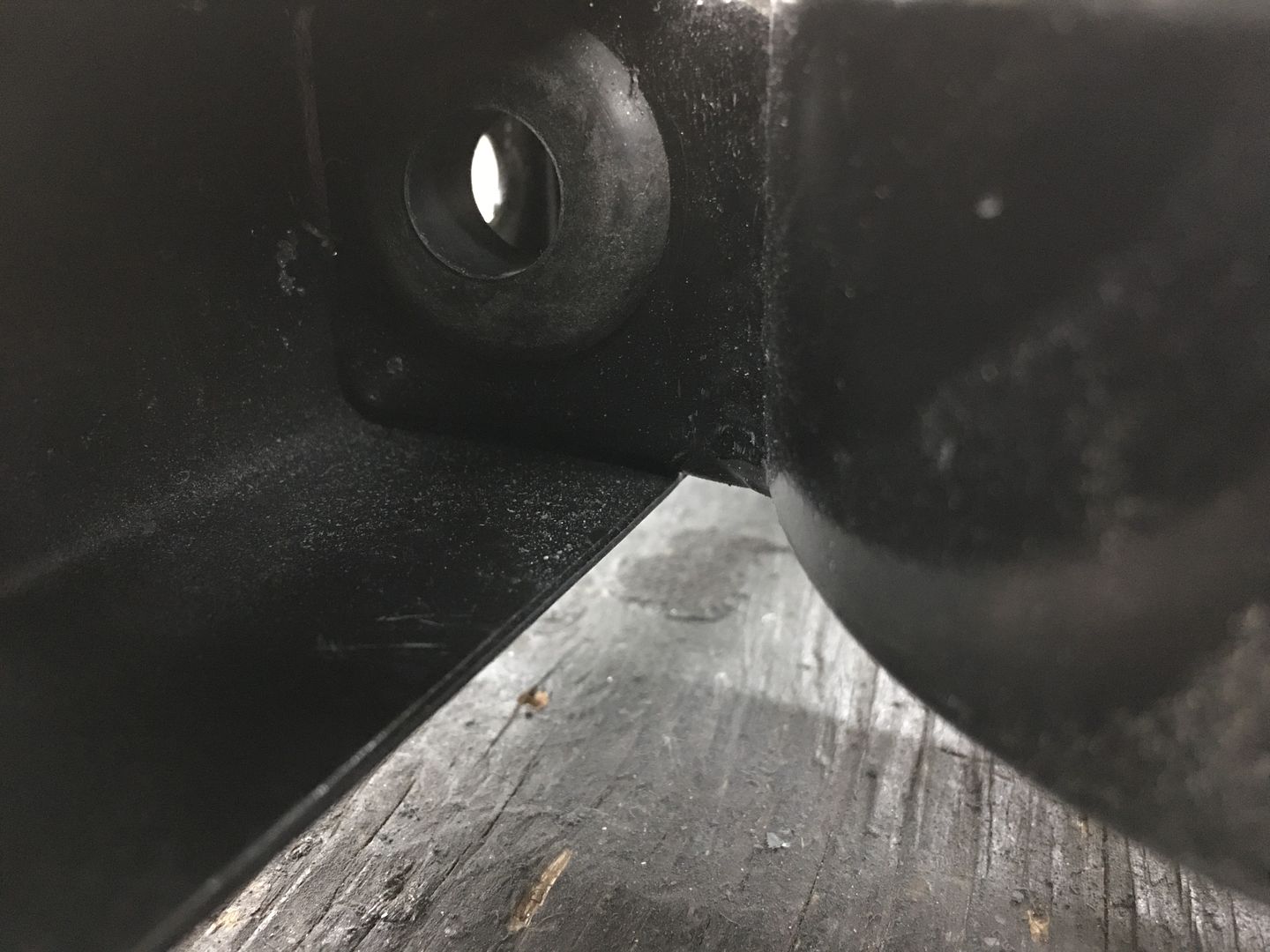

We're in the middle of blocking paint today on the core support and happened to notice someone forgot to add the holes in the new vertical uprights for the light wires to go across above the radiator.

We have some rotary cutters that would do the trick but they are a bit short to reach from the outside (to keep things perpendicular) so lets make an extension. The set screw for the spring loaded center point is a 5/16-24 and we happened to have some in stock. So we used a piece of stainless fuel line and plug welded a stud in one end and a plug in the other for tightening in the drill chuck..     Holes drilled, deburred, and grommet test fitted..     Now for a test fit of our Parking brake lines to mock up the routing prior to adding rivet nuts and adel clamps...     And here's our one cable to two parts layout..

__________________

Robert |

|

|

|

|

|

#21 |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,647

|

Re: 55 Wagon Progress

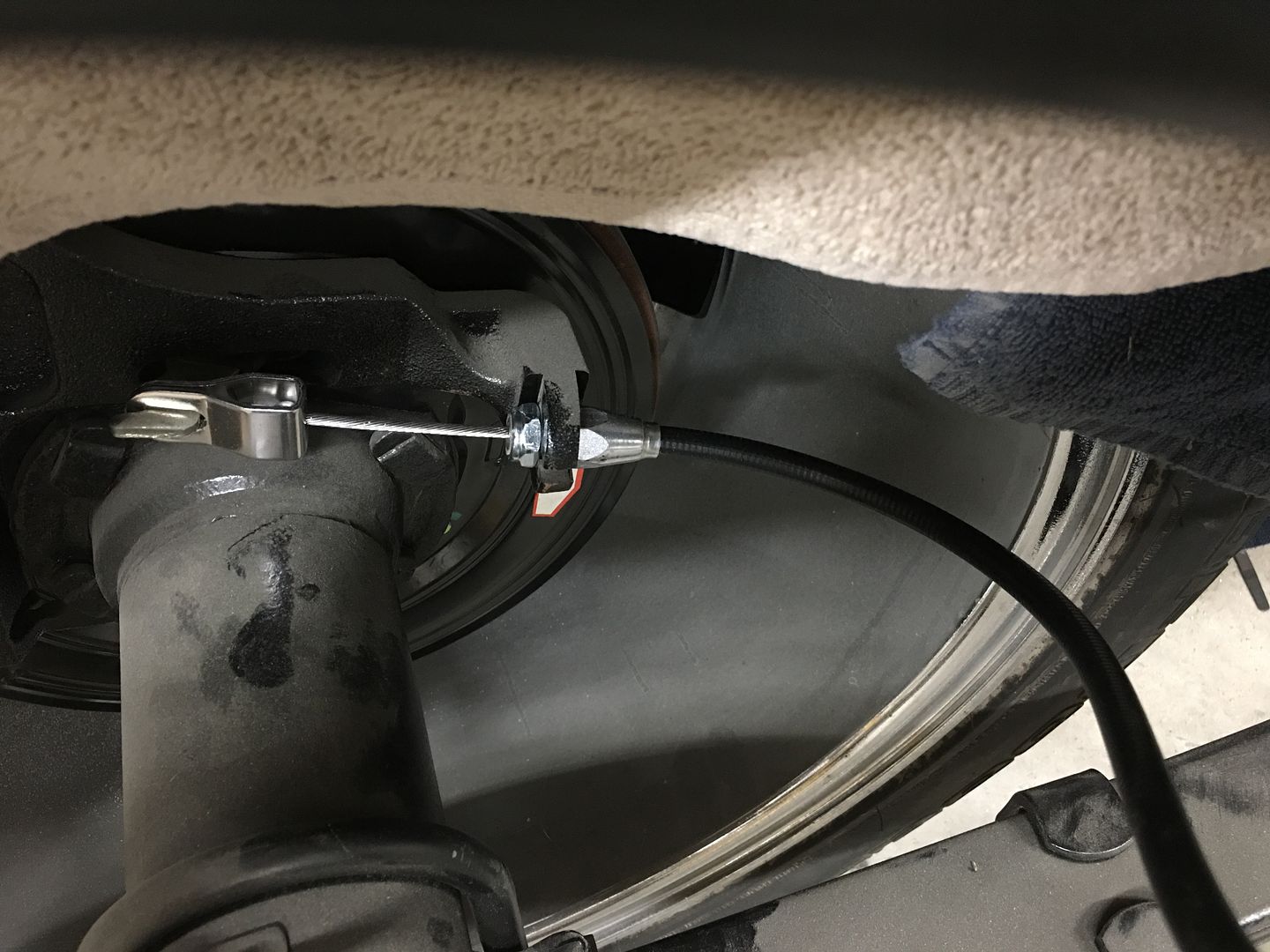

With our adel clamps arrived, Mike and I worked on the brake cables while Vince was prepping things for paint...

.JPG) .JPG) I think he's having too much fun... We had to wait for -5 clamps as these were snug enough to hold the cable from moving. This allows us to set the length to the backing plate such that it clears the frame during suspension travel..  The clamps were held in place using rivet nuts installed into the frame. Here is a video showing rivet nuts and the proper installation: https://www.youtube.com/watch?v=3jrrf_VbTsc  Outer sheaths are marked for trimming..  Be sure to pull cables out of the way prior to cutting...  Our implement of destruction...   Using Gripple cutters to cut the cable... Also made by Knip-ex, both are designed for cutting steel wire rope.. https://www.youtube.com/watch?v=kWrpry0XgAU Our parking brake assembly used an integral "return spring" to pull the pedal back upwards when the brake is released, so that part is saved for this installation as well. To keep the end of the spring from rubbing against the cable in one spot, we machine a landing in the adjuster. We will also use some Teflon heat shrink over the cable to help prevent wear.  Final trim on the rear cables will come when we drop the body back on the frame for proper fitment to the brake pedal assembly.  .

__________________

Robert Last edited by MP&C; 04-26-2020 at 02:35 PM. |

|

|

|

|

|

#22 |

|

Registered User

Join Date: Jan 2003

Location: Safford,AZ

Posts: 3,612

|

Re: 55 Wagon Progress

Nice! Getting Closer!

|

|

|

|

|

|

#23 |

|

Registered User

Join Date: Jul 2019

Location: Beebe, AR

Posts: 2,471

|

Re: 55 Wagon Progress

That's a football field of sheet metal to work with right there! Looks superb.

Going to be beyond great and cannot wait to see it together.

__________________

1967 C10 1980 Jeep CJ5 2020 Toyota 4Runner 2024 Toyota Tundra |

|

|

|

|

|

#24 |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,647

|

Re: 55 Wagon Progress

Guys, thanks for the comments and following along with our progress!

__________________

Robert |

|

|

|

|

|

#25 |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,647

|

Re: 55 Wagon Progress

So yeah, we work on just about anything. File this one away under "everything's a tool". You need to be able to look at the problem, and figure out what you have readily available as a solution (especially when working weekends)

Vince is still milking the media blast job..  Another of the lids had been used and abused with a hammer over it's life, the center was concaved inward, the outer rim had several flat spots. So while Vince was busy, I came up with a dent removal tool to help straighten out the next lid.    The half hitch ball was used as a punch straight down into the lid to add a consistent shape back to the outer ring. Some hammer and dolly work straightened the center concave, giving it a slight crown. A deep dent was heated to make it more pliable, the punch pushed to the bottom and used as fulcrum to push the dent outward (heated spot)  Then our "punch" was clamped in the vise to use as a post dolly. The lid was positioned where any low spots were placed against the "dolly" and hammering around the perimeter of the dent raised it outwards..   Some fine tuning left, but this is much better than where we started: https://www.youtube.com/watch?v=80YGom51gc0 .

__________________

Robert |

|

|

|

|

| Bookmarks |

|

|