|

|

|

#1176 |

|

Registered User

Join Date: Oct 2013

Location: Sacramento Ca

Posts: 14

|

Re: Over 25 Years Later, Finally My 71 C-10 Truck Build

Aww yes, haven't read. Fingers got a little happy LOL!

|

|

|

|

|

|

#1177 |

|

GEARHEAD

Join Date: Aug 2003

Location: MN

Posts: 6,126

|

Re: Over 25 Years Later, Finally My 71 C-10 Truck Build

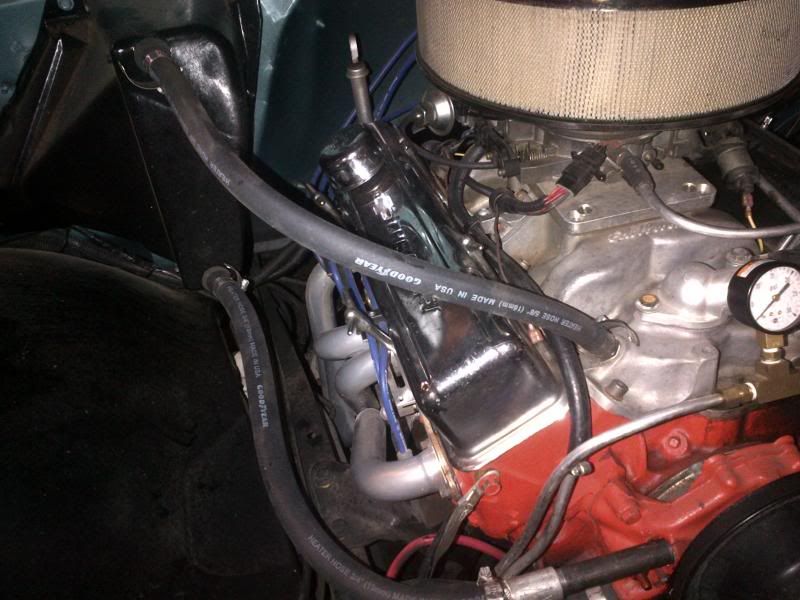

Since I got the heater working in the Jimmy I figured I better tackle this one. Better late than never. Everything on the cab was installed and I had pressure tested the heater core before installing it. What was left was hooking the hoses up. And I needed to jump a few hoops to do that. First, I didn't have the hose barb fittings for the engine end. And I was kinda missing a port on the intake to plug it into because I had the temp sensor for the EFI in there.

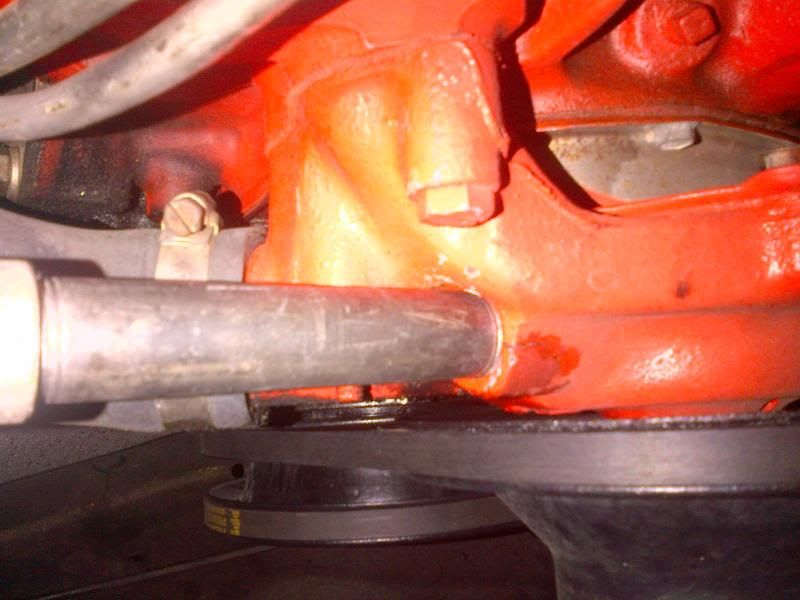

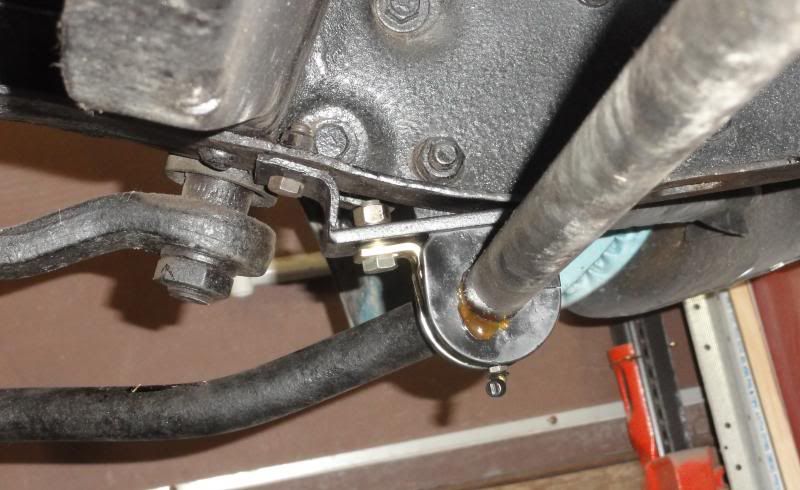

First thing was to get the hose fittings. I got to the junkyard with my handful of tools at exactly 5:00, closing time. I found what I needed in a few minutes though and it's all good. And like the ones I used in the Jimmy, the 5/8" hose fitting has a smaller opening. Also like the jimmy 1 I drilled it out. Before...  After...  Without any other choices for the heater hoses I had to move the temp sensor. There is 1 in the passenger side head for the temp gauge. So I pulled the plug on the driver side head and put the EFI temp sensor there. The wire is not connected yet but the truck ran fine without it. The hose fitting went into the into manifold hole without any issues. I mean, why should there be. The 1 on the water pump was not so easy. Getting the plug out was a bit of a challenge itself. It's a 9/16" square on the plug. I don't have a square socket that big. Can't really use a wrench to break it free cuz of a lack of space for the wrench. I managed to find a 11/16" socket that would grab it enough to get it out. I have my new fitting ready to go and I get it started and after about a turn and a half the hex is hitting on the pump casting. There is absolutely no way this fitting is gonna screw in far enough to seal. So I'm rummaging around my pipe fittings and I have a couple options for nipples but need a coupling for the hose fitting to go on. I look at the clock and it's 5:55 and the only place in town that is gonna have a fitting closes at 6:00. I snuck in. I bought a 45* elbow. So I get home, clean up the nipple, screw the pieces together and install them. I cut the hose and hook it up and it's not gonna fit right. The hose is pushing against the head.   I look through the fittings again and find a straight coupling. Pull it all apart and redo it with a longer nipple and the straight coupling. It's not pretty. It's far from elegant. But it works and isn't terrible looking.  In this pic I'm trying to show how tight that spot is to get a fitting installed.  I refilled the radiator, ran it for a while. It heats up great. No obvious leaks. All thats left is to reconnect the temp sensor wire and I have to put a new fan blower rheostat on the heater control so the fan will run in more than on/off mode. I don't really plan on driving it in the winter much, but if we have a nice day and the roads are clean, why not?

__________________

If no one knows what you're doing, they can't tell you you're doing it wrong HG's Dream Car Build - Shelby Cobra Kit Build your own adjustable track bar 71  Long Fleet C/10 Long Fleet C/10 72  Jimmy 4x4 (Junkyard Jimmy) Jimmy 4x4 (Junkyard Jimmy)HG's Plow Truck '78  K35 Dually K35 DuallyBigass Farm Truck HG's thread of miscellaneous stuff |

|

|

|

|

|

#1178 |

|

Not a bad nut after all..

Join Date: Dec 2000

Location: ND

Posts: 1,759

|

Re: Over 25 Years Later, Finally My 71 C-10 Truck Build

Your heater core connections are reversed compared to mine and what is shown here (see manual trans figure): http://67-72chevytrucks.com/vboard/s...7&postcount=18

__________________

'05 Chevy 2500HD 4x4 '72 GMC LWB 4x2 driver '72 Chevy LWB 4x4 plow truck '71 Blazer 4x4 driver '70 GMC LWB trailer |

|

|

|

|

|

#1179 | |

|

GEARHEAD

Join Date: Aug 2003

Location: MN

Posts: 6,126

|

Re: Over 25 Years Later, Finally My 71 C-10 Truck Build

Quote:

__________________

If no one knows what you're doing, they can't tell you you're doing it wrong HG's Dream Car Build - Shelby Cobra Kit Build your own adjustable track bar 71  Long Fleet C/10 Long Fleet C/10 72  Jimmy 4x4 (Junkyard Jimmy) Jimmy 4x4 (Junkyard Jimmy)HG's Plow Truck '78  K35 Dually K35 DuallyBigass Farm Truck HG's thread of miscellaneous stuff |

|

|

|

|

|

|

#1180 |

|

Still Learning

Join Date: Jul 2009

Location: Central Oklahoma

Posts: 10,108

|

Re: Over 25 Years Later, Finally My 71 C-10 Truck Build

I hate it when I cut it too short the first time. Been there, done that. Heat is a glorious thing in the winter.

|

|

|

|

|

|

#1181 |

|

GEARHEAD

Join Date: Aug 2003

Location: MN

Posts: 6,126

|

Re: Over 25 Years Later, Finally My 71 C-10 Truck Build

Badpeanut, the reason I plumbed it this way was just cuz it looks better. I can reverse it anytime by just swapping the fittings on the engine side. There are pro's and cons either way. Like I have it the flow goes down through the heater core so and out the bottom ensuring no air to the line back to the pump suction. The other way flows upward which keeps the heater core flooded more.

I appreciate you pointing out the difference though. If someone was gonna use mine as a guide they might not like that it's non-stock.

__________________

If no one knows what you're doing, they can't tell you you're doing it wrong HG's Dream Car Build - Shelby Cobra Kit Build your own adjustable track bar 71  Long Fleet C/10 Long Fleet C/10 72  Jimmy 4x4 (Junkyard Jimmy) Jimmy 4x4 (Junkyard Jimmy)HG's Plow Truck '78  K35 Dually K35 DuallyBigass Farm Truck HG's thread of miscellaneous stuff |

|

|

|

|

|

#1182 |

|

Senior Member

Join Date: May 2004

Location: johnstown, NY

Posts: 2,393

|

Re: Over 25 Years Later, Finally My 71 C-10 Truck Build

exhaust looks great. Love that x-pipe!

|

|

|

|

|

|

#1183 |

|

GEARHEAD

Join Date: Aug 2003

Location: MN

Posts: 6,126

|

Re: Over 25 Years Later, Finally My 71 C-10 Truck Build

Thanks for saying so. I'm happy with it.

Picked up the wife this morning to go to an auction. She saw that I had the truck and figured she would grab her coat out of her car but when she opened the door to get in the look on her face when she felt the heat was priceless. No dear, you won't need your coat to ride with me on cold mornings anymore.  We stopped at hardees for some breakfast and a delivery truck driver watched me pull in. Could see his face light up. He asked me if I was getting ready to put it away for the year. I smiled and said "Hell no. I just got the heater working. I'll drive every chance I get. As long as its dry out and the roads are clear." He later told me I should get a blazer that body style.   He just shook his head when I told him I already had a Jimmy. He just shook his head when I told him I already had a Jimmy. Truth is, it bugged the hell out of me having it in storage last winter. As for the auction, it was mostly beer collectibles and outdoor sporting goods. I don't collect that stuff and I'm not a hunter and I have all the fishing stuff I need. We just like looking at the stuff and occasionally we find some things we like or can use. It's quality time really. All I got was some posters. This is the one I really wanted and it came with 4 others similar to it. The camera view was at an angle so it looks a little off in the pic but it's pretty sweet.

__________________

If no one knows what you're doing, they can't tell you you're doing it wrong HG's Dream Car Build - Shelby Cobra Kit Build your own adjustable track bar 71  Long Fleet C/10 Long Fleet C/10 72  Jimmy 4x4 (Junkyard Jimmy) Jimmy 4x4 (Junkyard Jimmy)HG's Plow Truck '78  K35 Dually K35 DuallyBigass Farm Truck HG's thread of miscellaneous stuff |

|

|

|

|

|

#1184 |

|

State of Confusion!

Join Date: Jul 2002

Location: Gulfport, MS USA

Posts: 47,216

|

Re: Over 25 Years Later, Finally My 71 C-10 Truck Build

Nice poster!

__________________

Bill 1970 Chevy Custom/10 LWB Fleetside 2010 Toyota Tacoma PreRunner SR5 Double Cab - DD Member of Louisiana Classic Truck Club (LCTC) Bill's Gallery Life isn't tied with a bow, but it's still a gift. Live simply. Love generously. Care deeply. Speak kindly. Leave the rest to God! |

|

|

|

|

|

#1185 |

|

Registered User

Join Date: Dec 2011

Location: Ottawa, KS

Posts: 337

|

Re: Over 25 Years Later, Finally My 71 C-10 Truck Build

Slow times at work can find the time to read some builds, Very nice job on your truck.

|

|

|

|

|

|

#1186 | |

|

GEARHEAD

Join Date: Aug 2003

Location: MN

Posts: 6,126

|

Re: Over 25 Years Later, Finally My 71 C-10 Truck Build

Quote:

One of my winter projects is getting the front suspension rebuilt. It was never done in the past. All original parts, minus the brakes. And the sway bar, which I added back in the mid 80's with parts I found at a junkyard. During my driving this past summer I noticed a little shake at 50-55 mph. I figured there was some loose/worn parts and it was just a matter of time before it got worse. So last weekend I started pulling it apart. I'm doing 1 side at a time so I have a reference. It's not a complicated job, but new to me, so anyway. Parts on the floor...   Got the control arms and spindle separated...  Cleaned off the rest of the old bracket I had cut off years ago for clearance after I installed the drop springs.  Upper ball joint removed...  Here's how my sway bar was mounted. I'm pretty sure I had those brackets backwards, but it worked.  This is what it will be when I'm done. Borrowed from another thread discussing the sway bar mounts ( http://67-72chevytrucks.com/vboard/s...d.php?t=215735 )  I have my brackets cut already...  Here's the difference in sway bar bushings after about 25 years. I bought the fancy schmancy poly bushings for the bar back in 88 I think. The new ones have a bit more meat on them   This thread discusses improving the handling of these trucks in detail. http://67-72chevytrucks.com/vboard/s....php?p=5380520 Way more than most of us will ever need to know. But some of the things I gleaned from it are simply changing the alignment specs for improved handling and steering response. Going from work truck alignment to more of a cruiser car type alignment, which more how this is used now. Since I've got it all apart I'm going to change the caster a bit by moving the LCA forward a smidge. I'm not going for all out performance here, just an improvement. So I'm only moving the LCA 5/8" forward so I don't have any issues with parts binding, clearancing, etc. 5/8" was about as far fwd as I could go. Anyway, my new parts came from summit yesterday.  These are the new LCA shafts. One on the left is as ordered. The hole fits a pin on the front mount bracket. One on the right is after being drilled out by me on my drill press.  It wasn't too difficult. I did a couple pilot holes stepping up in size a couple times until I finished with the 11/16" hole like the original.  And that's where I'm at as of tonight. I have to get someone to pop out the old lower ball joint and press in the new one. Need to clean up the parts a bit, touch up the paint and it should be ready to put back together. Then just do the same to the other side and it'll be ready for the alignment shop. I talked to a guy I know about that and at their shop they can put whatever specs I want in the computer and set it up that way. As far as I know, this truck hasn't been aligned for as long as it's been in the family back to 1973 or so. Even after I dropped the altitude. It's always driven and tracked well and tire wear has been fine. Lucky me I guess.

__________________

If no one knows what you're doing, they can't tell you you're doing it wrong HG's Dream Car Build - Shelby Cobra Kit Build your own adjustable track bar 71  Long Fleet C/10 Long Fleet C/10 72  Jimmy 4x4 (Junkyard Jimmy) Jimmy 4x4 (Junkyard Jimmy)HG's Plow Truck '78  K35 Dually K35 DuallyBigass Farm Truck HG's thread of miscellaneous stuff |

|

|

|

|

|

|

#1187 |

|

Registered User

Join Date: Apr 2003

Location: Indep, MO

Posts: 5,893

|

Re: Over 25 Years Later, Finally My 71 C-10 Truck Build

O'reillys rents the tool for the balljoints. Easy peasy. Looks like a nice job! Let us know what you think of the 5/8 mod!

__________________

Boppa's Old Yeller Truck Build, Old Yeller's New Heart! Project Buzz Bomb Flyin' Low! |

|

|

|

|

|

#1188 |

|

Still Learning

Join Date: Jul 2009

Location: Central Oklahoma

Posts: 10,108

|

Re: Over 25 Years Later, Finally My 71 C-10 Truck Build

Looks like you are knee deep in suspension rebuild. I'm with low elco just rent that huge c-clamp press from Autozone. It works great, just use your impact to drive them out.

THIS is the one I used. It worked on my 40 year ball joints. |

|

|

|

|

|

#1189 |

|

State of Confusion!

Join Date: Jul 2002

Location: Gulfport, MS USA

Posts: 47,216

|

Re: Over 25 Years Later, Finally My 71 C-10 Truck Build

I got similiar if not same tool from harbor freight and it works great. Only thing I can say is that my new ball joints were a little loose in the original a-arms. I ended up adding some tack welds to the inside of the lower A-Arm socket and smoothed them out to make the press fit with the new ball joint tighter.

__________________

Bill 1970 Chevy Custom/10 LWB Fleetside 2010 Toyota Tacoma PreRunner SR5 Double Cab - DD Member of Louisiana Classic Truck Club (LCTC) Bill's Gallery Life isn't tied with a bow, but it's still a gift. Live simply. Love generously. Care deeply. Speak kindly. Leave the rest to God! |

|

|

|

|

|

#1190 |

|

Registered User

Join Date: Apr 2011

Location: .

Posts: 3,104

|

Re: Over 25 Years Later, Finally My 71 C-10 Truck Build

If you liked the way it handled then you're going to love it when your done.

|

|

|

|

|

|

#1191 | ||||

|

GEARHEAD

Join Date: Aug 2003

Location: MN

Posts: 6,126

|

Re: Over 25 Years Later, Finally My 71 C-10 Truck Build

Quote:

I will definitely post results from the test drive afterwards. That may be a few months away though. Quote:

Quote:

Quote:

I also bought new front shocks. I went with sensa-traks based on Low Elco's recommendation somewhere else. So if I don't like them I have a fall guy to blame it on.  The shocks I put on during the rebuild rode fine for cruising. But they were a little too soft. It would bottom out on parking lot speed bumps then bounce a little more afterwards. Just not enough damping power. I might have time tomorrow to make some more progress on it. There's no rush. Still have a good 3-4 months of snow to deal with. I think I might order these front shock mount tabs too. I don't care for the single shear design GM went with on these.  I looked at the CPP ones too but but like the simplicity of this. If anyone has opinions on these or other options for the front shock mounts go ahead and speak up. I will probably do shock mounts outboard the frame for the rear when I get to that in the future. No Limit has a real nice set up for that. That stuff in the back can wait til I do rear disc brakes though.

__________________

If no one knows what you're doing, they can't tell you you're doing it wrong HG's Dream Car Build - Shelby Cobra Kit Build your own adjustable track bar 71  Long Fleet C/10 Long Fleet C/10 72  Jimmy 4x4 (Junkyard Jimmy) Jimmy 4x4 (Junkyard Jimmy)HG's Plow Truck '78  K35 Dually K35 DuallyBigass Farm Truck HG's thread of miscellaneous stuff |

||||

|

|

|

|

|

#1192 |

|

GEARHEAD

Join Date: Aug 2003

Location: MN

Posts: 6,126

|

Re: Over 25 Years Later, Finally My 71 C-10 Truck Build

Passenger side is mostly together now. No real problems but a couple things that slowed me down a bit. Slowness of putting things together yourself rather than as a typical mechanic would isn't always about lack of skill. Some of it is that. The hobbiest takes his time and is more deliberate from less experience. But the real drag is cleaning and making it pretty.

Cleaned everything up in the parts washer. The paint all came off because the guy that I had sandblast and paint my frame used an undercoat on the bare metal before he painted it. Kinda pissed me off cuz it gets sticky and soft in the heat and basically rubs off on anything that touches it when any oil based product hits it. Its a mess and I wish I had him strip it again before I rebuilt the truck, but thats really only 1 regret I've had. And not many others. I had a local shop swap the lower ball joint.  Painted all the bits and pieces.  First trouble I had was with the upper ball joint. It fit fine and the quality of the part seems ok. The trouble was torquing the bolts to the 45 ft-lbs the service manual said. Only 2 of 4 would torque that high without stretching. At first I thought it was just junk bolt quality so I went and got grade 8 hardware. The same thing happened with those. It's just too high for this size (5/16") bolt to take. The bolts that came with it were marked 10.9 and I looked that up and it's basically the same strength (slightly higher actually) as grade 8. I just settled for tightening to what I thought was good enough. There must be another torque spec for these out there. I even checked to make sure my torque wrench was working right to eliminate that as the problem. Anyway, eventually I got both control arms reassembled with new shafts and ball joints and got them mounted up. The second problem came from my own mistake. I grabbed the wrong nut for 1 of the u-bolts for the LCA. It was fine thread and it screwed up the U-bolt threads. So I took 1 off the driver side to get it together and will buy another 1 this week for the other side. Then the 3rd problem was with clearance on the aft end of the LCA. Even with just a 5/8" shift I still had some touching where the LCA hit the clamp mount bracket when it was any higher than normal ride height. Its touching here.  Some people have done 3/4" and were fine. It probably is just variance between trucks. Not a big deal really. I just got my die grinder out and cleaned it up in there a bit.  After that I just got the spindle back on and torqued everything down, got the cotter pins in, and lubed it up.  A couple further notes. None of the parts I replaced was showing much wear. They were pretty tight yet. The control arm shafts were not lubed well. The ball joints were tight but the rubber seals were cracking. So it was due anyway. The only real problem I found was that the u-bolts holding the LCA's were just snugged tight. They had loosened over the years, maybe from corrosion and just general use. So you might want to check yours out. It's not something most mechanics are gonna look for and it might be causing just enough looseness to show the beginning of a problem where there really isn't a wear part issue at all. I will tear down the driver side this week and get it cleaned up and pretty too. Then do the tie rod ends after that.

__________________

If no one knows what you're doing, they can't tell you you're doing it wrong HG's Dream Car Build - Shelby Cobra Kit Build your own adjustable track bar 71  Long Fleet C/10 Long Fleet C/10 72  Jimmy 4x4 (Junkyard Jimmy) Jimmy 4x4 (Junkyard Jimmy)HG's Plow Truck '78  K35 Dually K35 DuallyBigass Farm Truck HG's thread of miscellaneous stuff |

|

|

|

|

|

#1193 |

|

GEARHEAD

Join Date: Aug 2003

Location: MN

Posts: 6,126

|

Re: Over 25 Years Later, Finally My 71 C-10 Truck Build

After I got home from work I tore down the driver side. Control arms are soaking in the parts washer.

That is all. Go about your business.

__________________

If no one knows what you're doing, they can't tell you you're doing it wrong HG's Dream Car Build - Shelby Cobra Kit Build your own adjustable track bar 71  Long Fleet C/10 Long Fleet C/10 72  Jimmy 4x4 (Junkyard Jimmy) Jimmy 4x4 (Junkyard Jimmy)HG's Plow Truck '78  K35 Dually K35 DuallyBigass Farm Truck HG's thread of miscellaneous stuff |

|

|

|

|

|

#1194 |

|

GEARHEAD

Join Date: Aug 2003

Location: MN

Posts: 6,126

|

Re: Over 25 Years Later, Finally My 71 C-10 Truck Build

Quick update. Have only been working on it sporadically but making steady progress. I got the driver side control arms cleaned up and painted with the new shafts and ball joints installed.

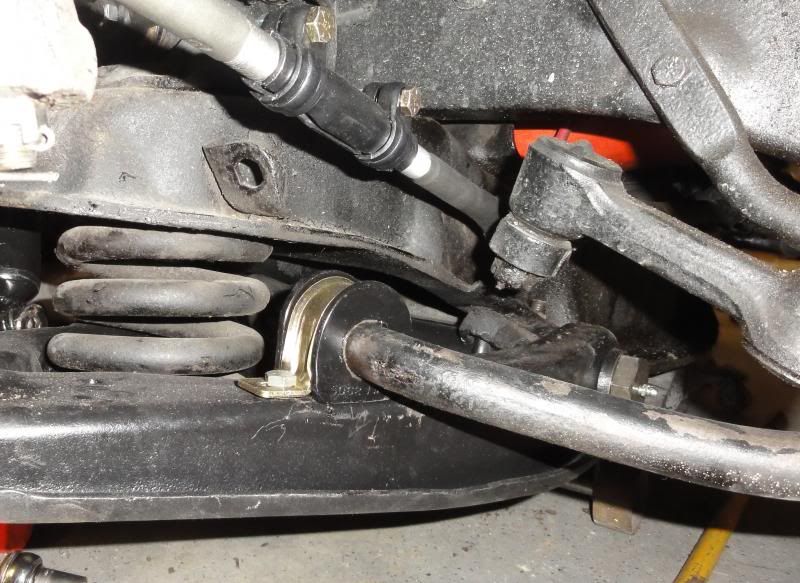

Then a couple nights ago I got them reinstalled on the truck...  Last night I replaced all the tie rod ends and got the sway bar loosely mounted back up. But ran into a small problem and I'm not sure the cause. The ends of the bar are not where I need them on the LCA's. I did change the frame bushing mounts, but I have 1 side longer than the other. Looks ok on the passenger side...  But it's not back far enough on the driver side and it's too far inboard to line up with the holes for the bracket. And remember the LCA's are fwd of original by almost 3/4".  Next I will take the bar back off and measure it. I think it may be shorter on one side than the other. And to solve the placement issue I will probably just mount the bar directly to the frame as I've seen done on other lowered trucks. As it sits now the bar is pretty level front to rear and removing my shortened brackets will move the bar rearward a couple inches and not really move it higher very much. Just need to see if I will have any binding issues with the tie rod, etc. I might even have to cut the longer side (if I'm right about that) of the bar so it's not too far back on the passenger side LCA. And another little issue I found was that the driver side spindle bearing was a bit loose. It had just a little wiggle in it. Tightened the nut a flat and it seems ok now. After the bar situation is settled all that's left is to put the brake calipers back on and the tires. Will probably change the oil since it's sitting on the stands anyway. Then just hoping for a day when the roads are a bit less icy or slushy for a road test.

__________________

If no one knows what you're doing, they can't tell you you're doing it wrong HG's Dream Car Build - Shelby Cobra Kit Build your own adjustable track bar 71  Long Fleet C/10 Long Fleet C/10 72  Jimmy 4x4 (Junkyard Jimmy) Jimmy 4x4 (Junkyard Jimmy)HG's Plow Truck '78  K35 Dually K35 DuallyBigass Farm Truck HG's thread of miscellaneous stuff |

|

|

|

|

|

#1195 |

|

GEARHEAD

Join Date: Aug 2003

Location: MN

Posts: 6,126

|

Re: Over 25 Years Later, Finally My 71 C-10 Truck Build

Getting the sway bar sorted out wasn't as easy as I had hoped. I did take it off and measure it and one side is about 1/4" longer than the other. I put the 2 LCA bushings on and snugged them down. Then checked where the bar should be mounted at the frame. But before I did that I put jack stands on the front hubs and set the weight of the truck on the suspension to get the sway bar up where it would be at ride height. It actually moved up quite a ways and the front of the bar at the frame was now hitting the outer bumper brackets. And on the passenger side was very close to the idler arm.

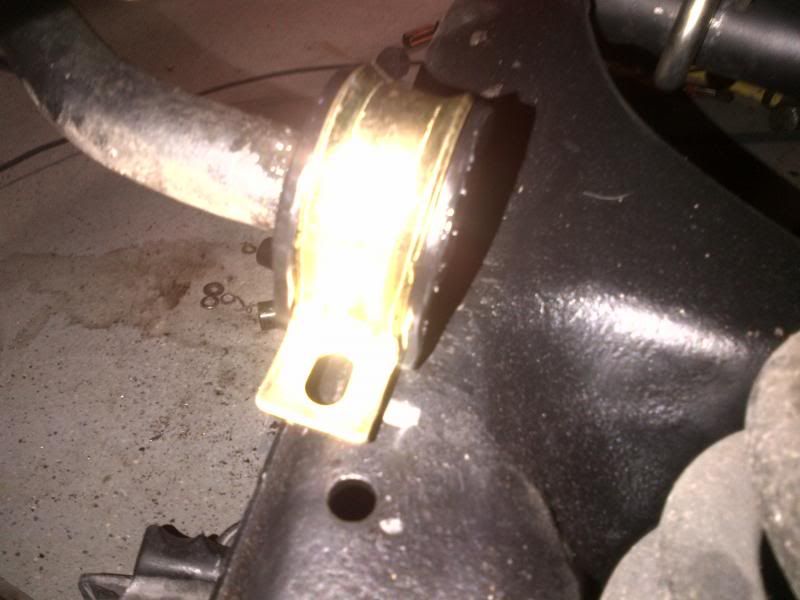

So I played around with my brackets (the shortened originals) and figured they could work if I punched out the rivets for the front cross member and bolted it through there. Not fun. Then I thought just using a plate as a spacer between the bushing and frame would be ok, with some clearancing on the bumper bracket. But it was just too high up and too close to the idler arm. It didn't look or feel right. So I made my own brackets instead. I used some flat stock, drilled holes for the bushing brackets, and figured out about how much room I was gonna need to get the rearward end down where I wanted it. I took my modified originals and bent part of it into a 90* and cut that off, then welded it to the flat stock, front and back side.  I got that fit in and it was good, so I made another one...  Pretty good match if you ask me. I got both of the new brackets mounted up and drilled new holes for the forward end bolts. Took them back out again and sprayed them black.  Now I just need to bolt them back in with the new frame bushings and snug them all up. Oh and I still cut a corner off the bumper brackets for some extra room. There will be better pics once I get it all back together. So do that, get the calipers sprayed black and re-installed, change the oil and put the tires back on and call it a month.

__________________

If no one knows what you're doing, they can't tell you you're doing it wrong HG's Dream Car Build - Shelby Cobra Kit Build your own adjustable track bar 71  Long Fleet C/10 Long Fleet C/10 72  Jimmy 4x4 (Junkyard Jimmy) Jimmy 4x4 (Junkyard Jimmy)HG's Plow Truck '78  K35 Dually K35 DuallyBigass Farm Truck HG's thread of miscellaneous stuff |

|

|

|

|

|

#1196 |

|

GEARHEAD

Join Date: Aug 2003

Location: MN

Posts: 6,126

|

Re: Over 25 Years Later, Finally My 71 C-10 Truck Build

Here's some better pics of the sway bar brackets I made...

Got the bar installed...    Got the brakes back together and brake lines re-attached to the upper control arm. Greased everything, checked for tightness and that I got all the cotter pins in. All that's left was the shocks. And another little problem.  There is more of an angle now. And I think my shocks are too long. I only have about an inch of up travel before it's bottomed out. They are a stock length shock. And that's what I have run on it for many years but I think now is the time to address it. So maybe I need something like this... http://www.classicperform.com/Store/...k/6072FUSB.htm  Or something like this from ORD. These are intended for 4x4s but the idea is the same. Just allows for a higher mounting point for the upper end. http://offroaddesign.com/catalog/Bilstein%205125.htm  Or I will just make my own mounts.

__________________

If no one knows what you're doing, they can't tell you you're doing it wrong HG's Dream Car Build - Shelby Cobra Kit Build your own adjustable track bar 71  Long Fleet C/10 Long Fleet C/10 72  Jimmy 4x4 (Junkyard Jimmy) Jimmy 4x4 (Junkyard Jimmy)HG's Plow Truck '78  K35 Dually K35 DuallyBigass Farm Truck HG's thread of miscellaneous stuff |

|

|

|

|

|

#1197 |

|

Registered User

Join Date: Aug 2012

Location: nantucket,ma

Posts: 230

|

Re: Over 25 Years Later, Finally My 71 C-10 Truck Build

i know it is a old tread but i am interested in the damage on the drivers firewall and back of cab.was the truck in a accident and how did your panels fit? looks to me like during the collision the hood hit the firewall and the bed hit the back of cab.

|

|

|

|

|

|

#1198 | |

|

GEARHEAD

Join Date: Aug 2003

Location: MN

Posts: 6,126

|

Re: Over 25 Years Later, Finally My 71 C-10 Truck Build

Quote:

I woke up with an idea for my front shock mounts. I will post it up if it will work. If it doesn't, forget you ever read that statement.

__________________

If no one knows what you're doing, they can't tell you you're doing it wrong HG's Dream Car Build - Shelby Cobra Kit Build your own adjustable track bar 71  Long Fleet C/10 Long Fleet C/10 72  Jimmy 4x4 (Junkyard Jimmy) Jimmy 4x4 (Junkyard Jimmy)HG's Plow Truck '78  K35 Dually K35 DuallyBigass Farm Truck HG's thread of miscellaneous stuff |

|

|

|

|

|

|

#1199 |

|

GEARHEAD

Join Date: Aug 2003

Location: MN

Posts: 6,126

|

Re: Over 25 Years Later, Finally My 71 C-10 Truck Build

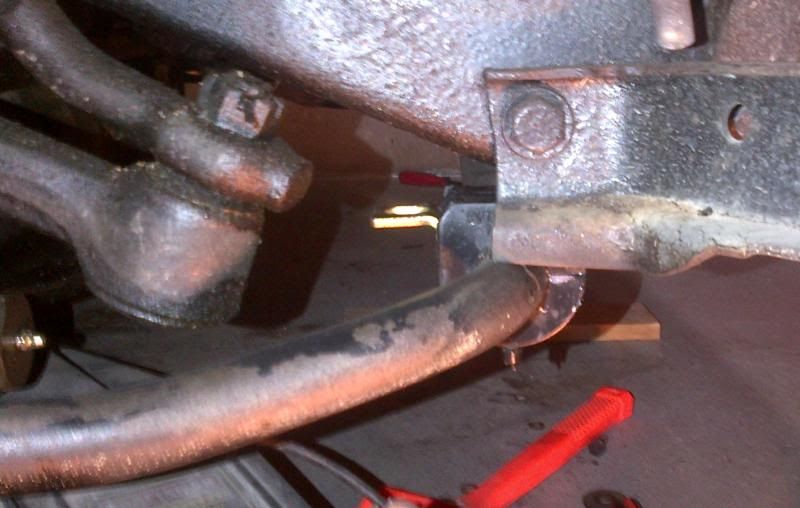

This isn't exactly what I was thinking, but when I started looking through my scrap metal I found something else that I think will just add strength. And it's what was available from the scrap metal.

I'm starting with a 7" long chunk of I beam.  I cut it in half in my band saw. Then cut half an "I" off each one.  It just happens to fit in this area...  As of right now I'm just thinking simple and strong. This will be totally over built for the task, but again, it's what I had available. Something like this is where I'm going, but I will see how things fit up once I get the I beams bolted to the frame. I'm thinking of getting rid of the bump for the original shock mount so this will be able to go forward a bit more. I just don't know yet if that's needed.

__________________

If no one knows what you're doing, they can't tell you you're doing it wrong HG's Dream Car Build - Shelby Cobra Kit Build your own adjustable track bar 71  Long Fleet C/10 Long Fleet C/10 72  Jimmy 4x4 (Junkyard Jimmy) Jimmy 4x4 (Junkyard Jimmy)HG's Plow Truck '78  K35 Dually K35 DuallyBigass Farm Truck HG's thread of miscellaneous stuff |

|

|

|

|

|

#1200 |

|

GEARHEAD

Join Date: Aug 2003

Location: MN

Posts: 6,126

|

Re: Over 25 Years Later, Finally My 71 C-10 Truck Build

Looks like my design will work out just fine.

Full droop...  Ride height...  Tacked the tabs on. I notched it so I could slide if forward some..  With shock...  In place...  Just need to weld it out, drill holes, paint and repeat for the other side. Pretty simple set up though.

__________________

If no one knows what you're doing, they can't tell you you're doing it wrong HG's Dream Car Build - Shelby Cobra Kit Build your own adjustable track bar 71  Long Fleet C/10 Long Fleet C/10 72  Jimmy 4x4 (Junkyard Jimmy) Jimmy 4x4 (Junkyard Jimmy)HG's Plow Truck '78  K35 Dually K35 DuallyBigass Farm Truck HG's thread of miscellaneous stuff |

|

|

|

|

| Bookmarks |

|

|