|

|

|

#1201 |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,647

|

Re: 55 Wagon Progress

So a few months back when we bought the Powell Hammer there was this tubing notcher sitting there. It was for sale as well and I knew exactly who needed it. One phone call and it was sold minutes later to my buddy Mike Phillips in Downingtown PA. I brought it to my shop to hold it until he had a chance to come pick it up..

.PNG) In the meantime, Mike had some equipment he was selling. I had my eye on a press brake and Cousin JB (upholster in Fairfax SC) could use his jump shear. So Saturday was the day for equipment delivery/swap, Mike and his wife Stacy made the trek to Southern Maryland to the shop and dropped off my new press brake, dropped off JB‘s new foot shear (until it can make it to SC) and picked up the tubing notcher that I’m sure will be a welcome addition at Phillips Hot Rod & Customs for the next cage install.     So once we get the new press brake hooked up we will likely have one or both of these leaving...  .

__________________

Robert |

|

|

|

|

|

#1202 |

|

Post Whore

Join Date: May 2015

Location: Alabama

Posts: 14,662

|

Re: 55 Wagon Progress

Nice manchine swaparooni you did there Robert ..just saw the video you put up...could you futher explain the new press dies?..

https://m.youtube.com/watch?v=JQM5xUd6vpw

__________________

Mongo...aka Greg RIP Dad RIP Jesse 1981 C30 LQ9 NV4500..http://67-72chevytrucks.com/vboard/s...d.php?t=753598 Mongos AD- LS3 TR6060...http://67-72chevytrucks.com/vboard/s...34#post8522334 Columbus..the 1957 IH 4x4...http://67-72chevytrucks.com/vboard/s...63#post8082563 2023 Chevy Z71..daily driver |

|

|

|

|

|

#1203 | |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,647

|

Re: 55 Wagon Progress

Quote:

So the lower die in the latest video is one I got with the second 24" manual press brake.....so I've had it for awhile, but didn't use it that often. It is many times used with a radius die, and all the sorted details are in this post here..... https://www.garagejournal.com/forum/...&postcount=214 .

__________________

Robert |

|

|

|

|

|

|

#1204 |

|

Post Whore

Join Date: May 2015

Location: Alabama

Posts: 14,662

|

Re: 55 Wagon Progress

Ahhh..ok...I see now...thanks Robert..!!

__________________

Mongo...aka Greg RIP Dad RIP Jesse 1981 C30 LQ9 NV4500..http://67-72chevytrucks.com/vboard/s...d.php?t=753598 Mongos AD- LS3 TR6060...http://67-72chevytrucks.com/vboard/s...34#post8522334 Columbus..the 1957 IH 4x4...http://67-72chevytrucks.com/vboard/s...63#post8082563 2023 Chevy Z71..daily driver |

|

|

|

|

|

#1205 |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,647

|

Re: 55 Wagon Progress

More progress on the wagon, more bumper action. Part of the problem with using three pieces to form the bumper with a nice wide bumper guard to hide the overlaps, is there is less of a smooth transition from end to end. So in using those individual parts to make a single bumper, we need to trim to correct this. While on the car, painters tape is used to lay out a smooth transition from end to end.

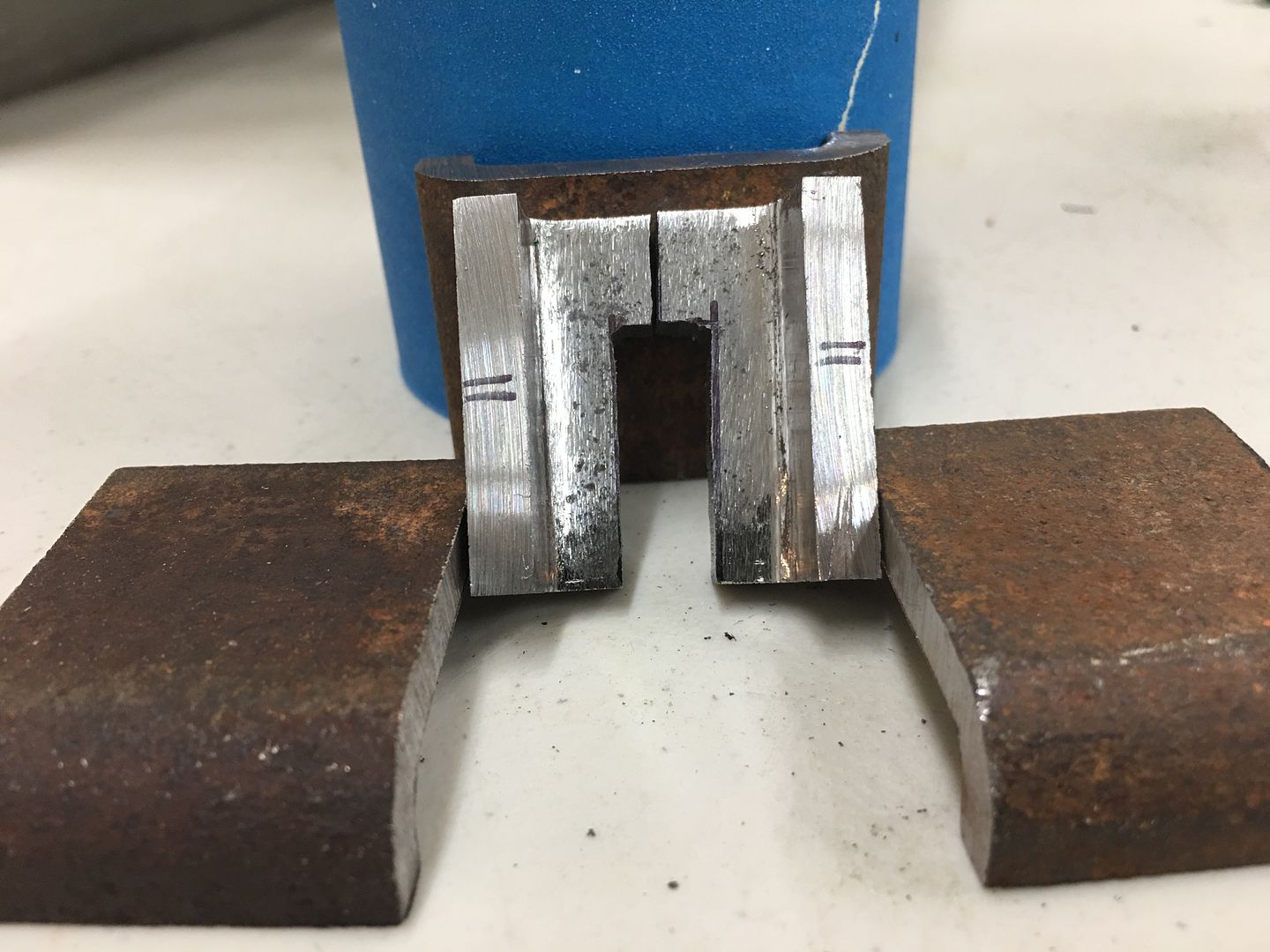

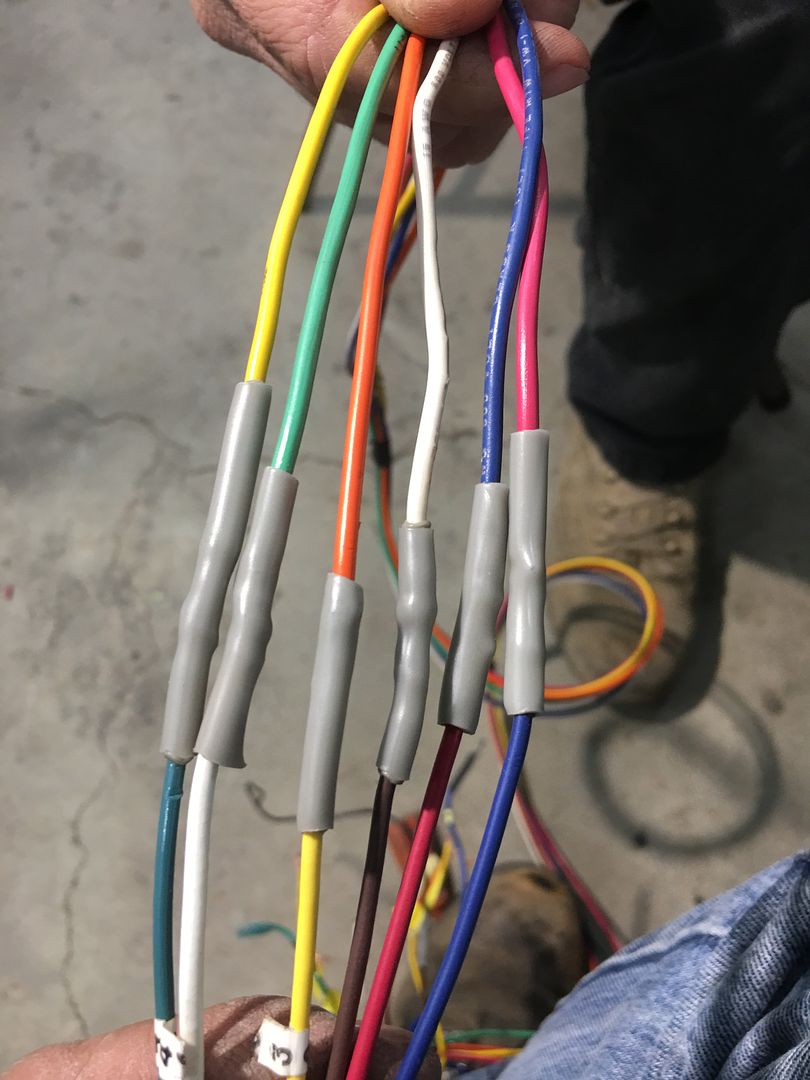

An air body saw is used to cut off the bulk and roloc sander for cleanup afterward...   Jared has been helping out with the bumpers, here making tight fitting plugs to fill in the old bolt holes for a smooth look on the outside.   Our front bumper center section had a bit more damage to repair, the center section showed it had been used to pull/tow/?? in a previous life... As the car was pulled, it added some creases as the center pulled outward..  A bit of off-dolly with a rather large hammer and we're much better now.  The center section also had a stepped flange on either end so the outer pieces would be flush when mounted. As we are making one-piece bumpers, the step is trimmed to length and the step is flattened using a precision flattening device..  Video version: https://www.youtube.com/watch?v=DCuKjivvr7Q Next, we wanted shaved fasteners but also still wanted some fine-tune adjustability. So that eliminates the old weld bolts on the back side caper.. Next option was a bracket that accepted the carriage bolt but also allowed some adjustment side to side. This design was graciously shared with us by Laszlo Nobi (aka Chevynut) as he had done on his 56 Nomad build (see here: https://www.trifivechevys.com/showth...final-assembly ). So we started with 2 x 2 x 1/4" thick square tubing. The 1/4" thickness allows for the height of the "square" of the carriage bolt, and we cut down on the width to just enough for the carriage bolt diameter, both to minimize size of the bracket and also to minimize the tendency for the center of the bracket to pull outward. Square tubing is cut to length and sliced and diced as shown...   Adjacent parts are beveled to insure full penetration on the 1/4" thick material..   A 7/16 hex nut is used to maintain the 3/8 width so our weld does not close up the slot when the weld shrinks while cooling..   The part is then cleaned up, here is our finished part that will weld to the back side of the bumper... https://www.youtube.com/watch?v=WFZePcoMK-U Meanwhile Mike has been working on electrical wiring, here getting the interior light wiring in place so we can load up and take to the upholsterer for headliner installation..

__________________

Robert |

|

|

|

|

|

#1206 |

|

Post Whore

Join Date: May 2015

Location: Alabama

Posts: 14,662

|

Re: 55 Wagon Progress

Man, it just keeps getting better and more betterer..

__________________

Mongo...aka Greg RIP Dad RIP Jesse 1981 C30 LQ9 NV4500..http://67-72chevytrucks.com/vboard/s...d.php?t=753598 Mongos AD- LS3 TR6060...http://67-72chevytrucks.com/vboard/s...34#post8522334 Columbus..the 1957 IH 4x4...http://67-72chevytrucks.com/vboard/s...63#post8082563 2023 Chevy Z71..daily driver |

|

|

|

|

|

#1207 |

|

6>8 Plugless........

Join Date: Sep 2007

Location: Prairie City, Ia

Posts: 17,139

|

Re: 55 Wagon Progress

Man, she is looking so nice! Congrats on the new to you shop tools! I'm surprised the suv towed that stuff. That first machine looks pretty heavy?

__________________

Ryan 1972 Chevy Longhorn K30 Cheyenne Super, 359 Inline 6 cylinder, Auto Trans, Tilt, Diesel Tach/Vach, Buckets, Rare Rear 4-link and air ride option Build Thread 1972 GMC Sierra Grande Longhorn 4x4 1972 Chevy Cheyenne Super K20 Long Step side tilt, tach, tow hooks, AC, 350 4 speed 1972 C10 Suburban Custom Deluxe 1969 Chevy milk truck 1971 Camaro RS 5.3 BTR STG3 Cam Super T10 1940 Ford 354 Hemi 46RH Ford 9" on air ride huge project Tired of spark plugs? Check this out. |

|

|

|

|

|

#1208 |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,647

|

Re: 55 Wagon Progress

Thanks guys! Ryan, he did say it was a bit "hairy", mainly dealing with A-holes on the road..

__________________

Robert |

|

|

|

|

|

#1209 |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,647

|

Re: 55 Wagon Progress

The new press brake is up and operational, so I've got two press brakes in the shop available if anyone needs to do last minute Christmas shopping for the wife/girlfriend..

Brake #1 is Diacro 16-24 MANUAL press brake, 8 ton, SN J-1500. Comes with the home-made stand you see it on, and the dies that are installed. This one has the fully functioning back gauge, a must have for repeat bends. None of the junk laying under or next to it is part of the dealio. Modestly priced at 2100, about half of what they're on eBay for. Diacro makes good product and they hold their value.      Back gauge in operation: https://www.youtube.com/watch?v=NiSnrZCJC_g Brake #2 is Diacro 16-24 MANUAL press brake, 8 ton, SN J-1353. Comes with the home-made stand you see it on, and the dies that are installed. These are radius dies, two sets. Yes they are different heights, just installed both sets to show them. This one is missing some parts to the back gauge. None of the junk laying under or next to it is part of the dealio. Modestly priced at 1800, about half of what they're on eBay for. Diacro makes good product and they hold their value.       If someone would want both, which would assist in fabricating the rest of the backstop for the second brake, package deal for 3750. No shipping, prefer you come and kick the tires. We can load onto your truck/trailer. Located in Leonardtown MD

__________________

Robert |

|

|

|

|

|

#1210 |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,647

|

Re: 55 Wagon Progress

Lowered price and offered shipping...

Year end sale, last chance for a tax deduction for the year. Diacro 16-24 MANUAL press brake, 8 ton, SN J-1500. Comes with the home-made stand you see it on, and the dies that are installed. This one has the fully functioning back gauge, a must have for repeat bends. None of the junk laying under or next to it is part of the dealio. Modestly priced at 1900, less than half of what similar ones are on eBay for. Stand has a full shelf for storage of dies. These brakes are 24” wide and rated at 16 gauge capacity. Ideal for a small shop or home garage where space is a premium. I would prefer the buyer come and kick the tires, and we can load onto your truck/trailer. Located in Leonardtown Maryland. We can help prep for shipping if needed, buyer pays all shipping costs. I also have a second one if someone would like a package deal..      Back gauge in operation: https://www.youtube.com/watch?v=NiSnrZCJC_g

__________________

Robert |

|

|

|

|

|

#1211 |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,647

|

Re: 55 Wagon Progress

Lowered price, shipping offered, second machine…

Year end sale, last chance for a tax deduction for the year. Diacro 16-24 MANUAL press brake, 8 ton, SN J-1353. Comes with the home-made stand you see it on, and the dies that are installed. These are two sets of radius dies. Yes they are different heights, we just installed both to better display what goes with the machine. This brake is missing some parts of the back gauge. None of the junk laying under or next to it is part of the dealio. Modestly priced at 1600, less than half of what similar ones are on eBay for. Stand has a full shelf for storage of dies. These brakes are 24” wide and rated at 16 gauge capacity. Ideal for a small shop or home garage where space is a premium. I would prefer the buyer come and kick the tires, and we can load onto your truck/trailer. Located in Leonardtown Maryland. We can help prep for shipping if needed, buyer pays all shipping costs. I do have two available if someone would like a package deal.

__________________

Robert |

|

|

|

|

|

#1212 |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,647

|

Re: 55 Wagon Progress

Well we are about to get started on some automotive electrical work when the wagon returns from Upholstery, and in an attempt to limit/eliminate any need for butt splices, I was looking around for various automotive "W" crimp terminals that were available. I found a gem of a store, www.repairconnector.com that carries much of the old style crimp on terminals, as well as some of the newer stuff. We do have some new light fixtures going in, and to help in eliminating excessive connections (ie: butt splices) I found they carry the replacement terminals for lamp base sockets.. (and terminals for fuse blocks, and.....)

Some of the terminals we just picked up from Repair Connector  Typical replacement light housing has pigtails that will require some type of splice...  New lamp base terminals from Repair Connector   These terminals will help us get rid of some splices..  If you have a need to repair/replace any of your automotive electrical wiring, give them a look, they may have something you can use..

__________________

Robert |

|

|

|

|

|

#1213 |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,647

|

Re: 55 Wagon Progress

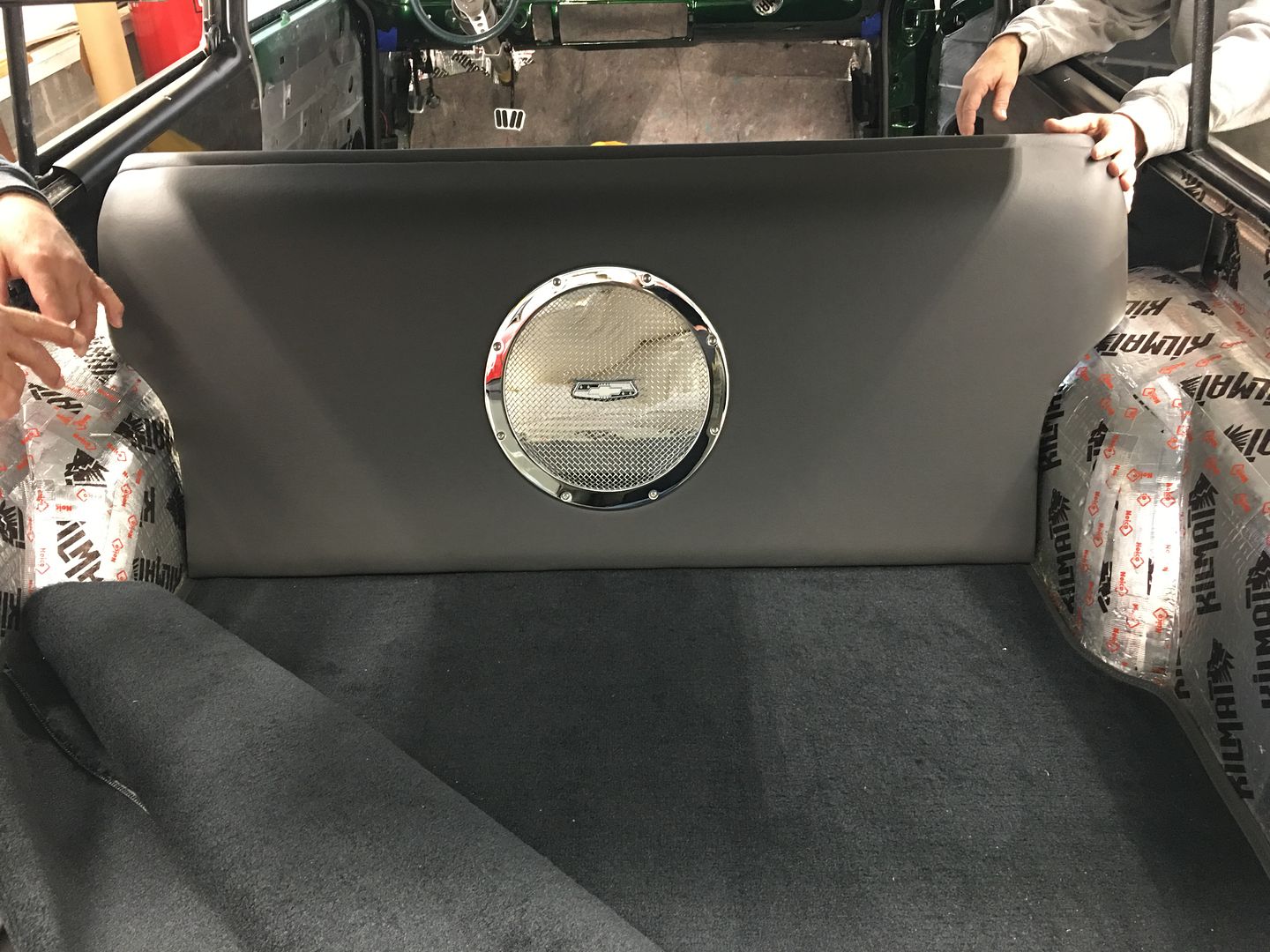

Wagon update, we stopped by Norris Upholstery on Saturday to check on the progress and go over some door panel design ideas. Getting closer!

Back in the shop, Mike and I got the assembly line action going on the hidden bumper brackets. These weld to the back side of the bumpers for hidden fastening and the slot allows for slight adjustment side to side. This idea was shared with me by Laszlo Nobi.

__________________

Robert |

|

|

|

|

|

#1214 |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,647

|

Re: 55 Wagon Progress

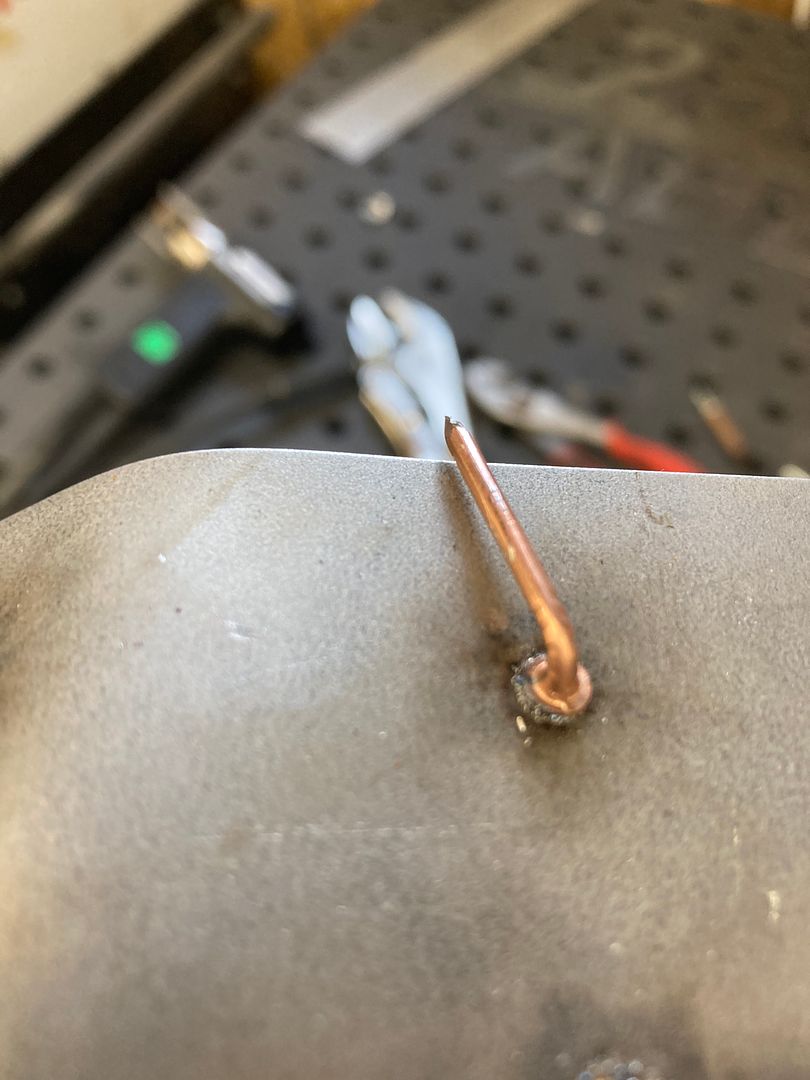

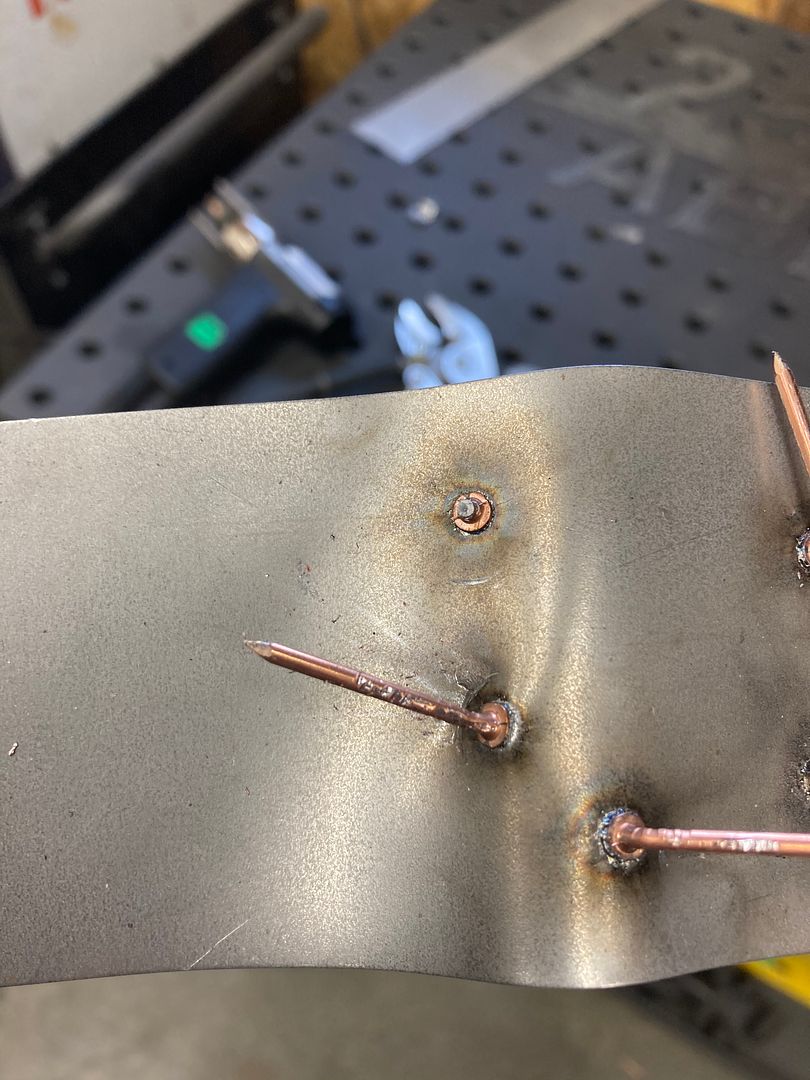

Busy weekend, Norris Upholstery is in the process of getting the door panels done..

We plan on using the original stainless that was used on the door panels but some of the factory "nails" that get folded over were very fatigued and in some cases, gone..  To try and fix these we needed a machine that would weld on new nails, which were originally .06 diameter. Using a dent puller stud welder would require resistance welding, which means heat generated. Not good. We have a local sign shop, A&A MetalWorks, that has a Capacitive Discharge stud welder that does not produce the same type of heat.. He did not have the small studs needed so I picked up some of the type that fits the dent puller. Since a collet was needed, Allen dropped off one of his larger collets and Mike became more fluent on a worn out South Bend this weekend, making a collet so we could do a trial run... Here's a collet for a 1/4-20 stud, our sample...  Mike in action....   Our fabricated collet, borrowing some parts from the sample...  Testing out the welder, we did have to reshape the ends of the studs to have a point, much like the 1/4-20 sample above, but here are the results.. As you can see there is no appreciable heat introduced into the panel, no heat mark, no distortion. A stress test performed using pliers showed the metal would pull inward and the stud still did not release..   Welder in action: https://www.youtube.com/watch?v=MSq_ZX9V2y8 With our trial run complete and deemed a success, Allen is ordering some 14 gauge pins to fit his machine so we won't need to modify them. The size goes up about .01, from .06 to .074, but they seemed plenty malleable to bend over for trim retention. I'll add, these CD stud welders work on steel, stainless, or aluminum. Needing to put a fork in our bumper bolt brackets, the inside slots needed cleanup work and the 12" disc sander seemed ideal for doing such. But some clearance was needed on the machine..     All ready for welding..  Lastly, we visited the last known remaining milk truck from the Leonardtown Dairy. It had been sold to a local waterman, who used its refrigeration capability to store crabs and oysters. Needless to say, it wreaked havoc on what remained of the truck, the lower sides had been patched over with galvanized sheet metal long ago. It did give us enough details to capture what we need for lettering/sign painting the Divco, our next shop project.

__________________

Robert Last edited by MP&C; 01-25-2021 at 01:47 PM. |

|

|

|

|

|

#1215 |

|

Post Whore

Join Date: May 2015

Location: Alabama

Posts: 14,662

|

Re: 55 Wagon Progress

the side of that old milk truck would make some cool wall art...

__________________

Mongo...aka Greg RIP Dad RIP Jesse 1981 C30 LQ9 NV4500..http://67-72chevytrucks.com/vboard/s...d.php?t=753598 Mongos AD- LS3 TR6060...http://67-72chevytrucks.com/vboard/s...34#post8522334 Columbus..the 1957 IH 4x4...http://67-72chevytrucks.com/vboard/s...63#post8082563 2023 Chevy Z71..daily driver |

|

|

|

|

|

#1216 |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,647

|

Re: 55 Wagon Progress

Greg, the guy that took us down there is in the process of buying as "yard art" and may cut those sides out as billboards... or leave it intact...

The press brakes have been sold, and have left the building...

__________________

Robert |

|

|

|

|

|

#1217 |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,647

|

Re: 55 Wagon Progress

Time for a wagon update, all of our mounting holes in the bumpers are filled, and the three pieces assembled into one..

We picked up the wagon from upholstery, still needs door panels done so we need to finish stainless trim for them.. Boy that sunlight is like turning on a light switch!!   How our brackets will work....  video explanation of our next modification... https://www.youtube.com/watch?v=p6yCAQ5rJPc With brackets clamped in place the "weld locations" are found by starting with centerline of the bumper, adjusting to actual offset of the car, and locating the spacing needed.  Jared and I add some tweaks to fine tune ear placement and test our tig welds at the same time..  In the meantime, Mike is doing some cleanup of the door stainless, bumping up dings, filing, and taking to a Trizact 5000 finish. Then we'll get the studs welded on and final polish..

__________________

Robert |

|

|

|

|

|

#1218 |

|

Post Whore

Join Date: May 2015

Location: Alabama

Posts: 14,662

|

Re: 55 Wagon Progress

Looks great Robert...that thing really does shine in the sun...

That's some serious "adjustment " on the bumper..brings back memories of when I was working on the IH bumper...I was amazed at how much springback was in the bumper..

__________________

Mongo...aka Greg RIP Dad RIP Jesse 1981 C30 LQ9 NV4500..http://67-72chevytrucks.com/vboard/s...d.php?t=753598 Mongos AD- LS3 TR6060...http://67-72chevytrucks.com/vboard/s...34#post8522334 Columbus..the 1957 IH 4x4...http://67-72chevytrucks.com/vboard/s...63#post8082563 2023 Chevy Z71..daily driver |

|

|

|

|

|

#1219 |

|

Senior Member

Join Date: Mar 2011

Location: West Plains, Missouri

Posts: 7,559

|

Re: 55 Wagon Progress

Great work as always...Jim

__________________

my build thread: http://67-72chevytrucks.com/vboard/s...d.php?t=459839 Jimbo's long bed step build:http://67-72chevytrucks.com/vboard/s...t=464626<br /> |

|

|

|

|

|

#1220 |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,647

|

Re: 55 Wagon Progress

Thanks fellas!

Back to our door panel stainless, the correct studs came in for the CD stud welder, and tests have shown them to provide the solution we need..  These studs have much less mass at the end, for a lesser capacitive charge needed.   Tested on a piece of 19 gauge steel, note the back side has no discoloration whatsoever. Allen used a pair of Vise grips to give it a twist test to see if the weld would release. Where the one that is cut got too close to the cutters, the others did not release, and in fact distorted the shape of the metal because they held so well. The one pin shows a good 90* bend, which is what will be used to hold the stainless onto the door panel per the same design as original.    And now for the next wrench thrown in our bumper modifications.. Welding causes shrinking, so TIG welding the slotted brackets onto the back side of the bumper invariably causes flat spots on the front side of where the brackets reside.. So some quick work on the South Bend to make a purpose built punch so we can do some metal bumping on the bumper..      ….or the motion picture visual.... https://www.youtube.com/watch?v=dH5F7VZRwvI And after a bit of metal bumping, we have the area down to less than a 1/32 depression, which should be just fine for the copper stage of plating..  Note the minimal gap behind the straightedge. One down, three to go...

__________________

Robert |

|

|

|

|

|

#1221 |

|

Registered User

Join Date: Dec 2015

Location: Beaver Falls, Pa

Posts: 168

|

Re: 55 Wagon Progress

Robert, Its a small world! I saw the corner of the orange paper where you bought the latest weld-studs. That place is 15 min. from me! Im in Wexford on a regular basis. Always looking forward to your latest update. Lorne

|

|

|

|

|

|

#1222 |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,647

|

Re: 55 Wagon Progress

Thanks Lorne! Yeah, those weld studs work awesome! Hope to get back to A&A Signs next week to finish them up...

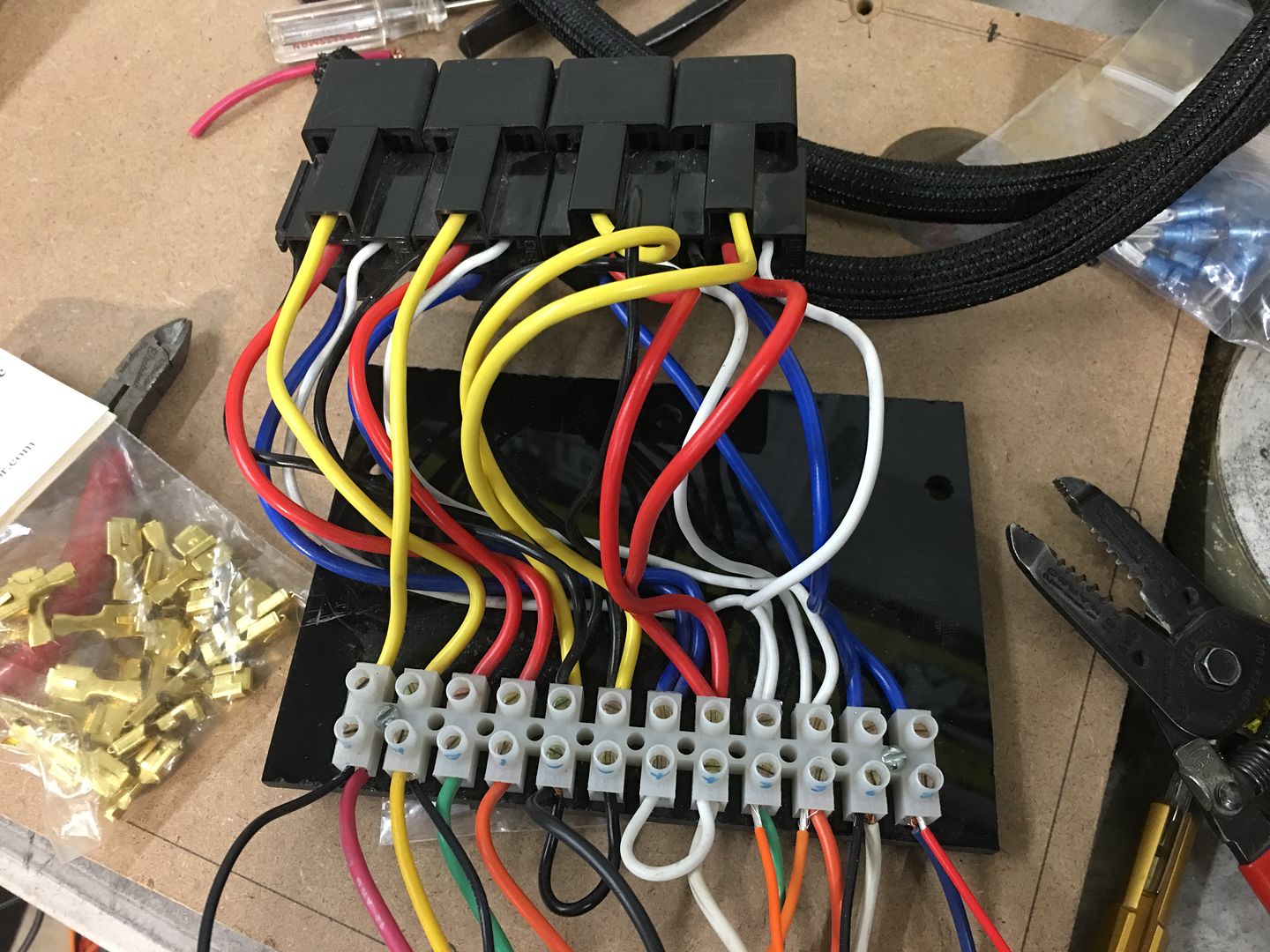

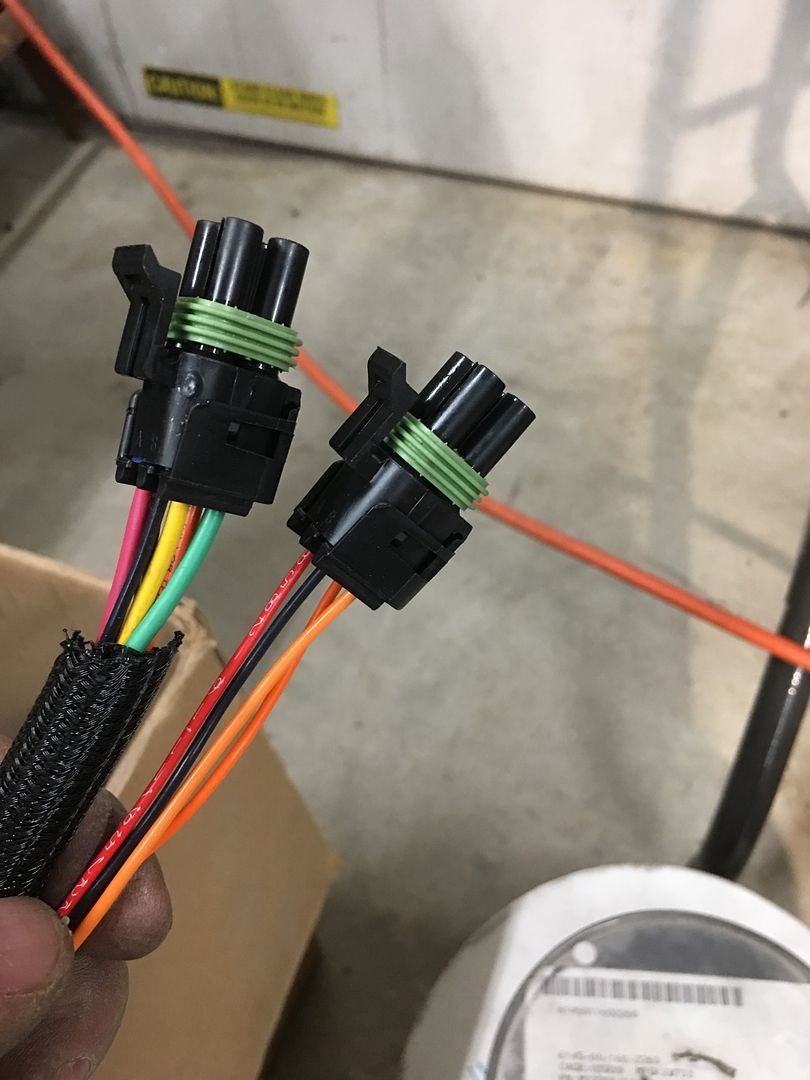

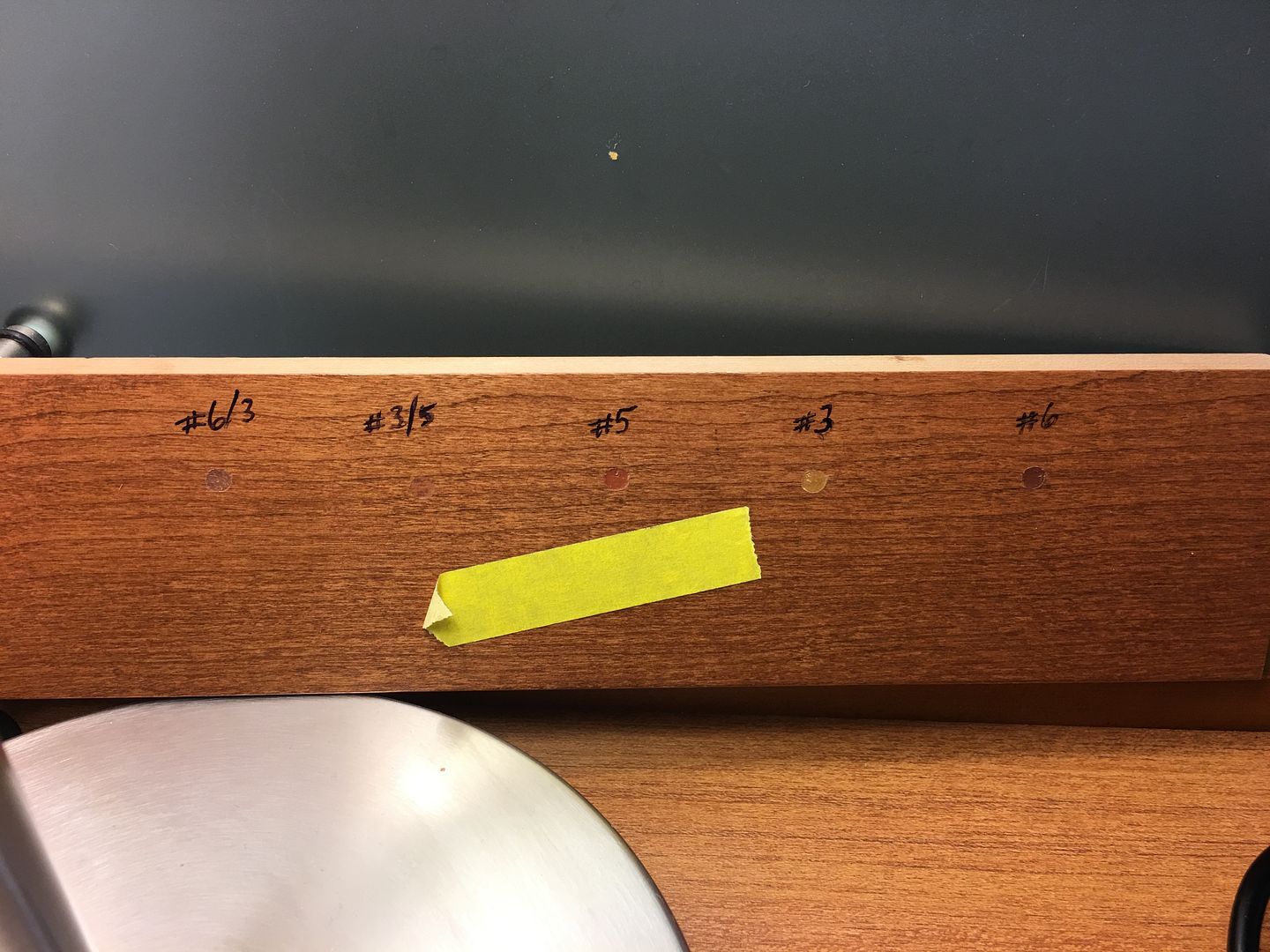

In another back up and punt moment, we found some interference with the new bumper brackets and the rear tailpan. In order to tuck things in nice and close, we need to trim a portion of the rear channel in the tail pan. Nothing a pair of tin snips and a file can't resolve. Pay no attention to that green paint. The bare edges will be touched up with SPI epoxy primer..    Our final test fit on the back bumper before chroming: https://www.youtube.com/watch?v=MzeOzhcYrSg On to our tail light hidden fuel fill...… https://www.youtube.com/watch?v=848V2PbuQJw This thing had been giving us fits in intermittent operation, and it hasn't even been exposed to water yet. Looking at the wiring (why can't we keep the colors consistent through?)…..  Well this isn't part of the problem... found a couple loose terminals..   So we decided to eliminate the original trailer connector and term board connections and replace with Weather Pack connectors. The relays will be mounted behind the rear seat for a closer proximity to the tail light, and the DPDT toggle switch will be replaced with a DPDT momentary rocker.   On a side note, a recent task for the day job involved some cherry trim boards that were pre-stained and we had difficulty finding a match using Minwax blend-fill pencils. The Number 3, 5, and 6 were all off....  However, kneading the 3 and 5 together showed promise. But how to do that on a larger, less time consuming scale. I will say none of the wife's wax melting pots were harmed in this experiment, but the trim screw holes in stained trim were all but invisible when done. The pencils were unwrapped, cut up into 1" lengths, then melted and mixed together. In case someone else needs to do the same...

__________________

Robert |

|

|

|

|

|

#1223 |

|

Post Whore

Join Date: May 2015

Location: Alabama

Posts: 14,662

|

Re: 55 Wagon Progress

Robert,,, that fuel fill is cool....sounds like a robot.....cant wait to see that bumper in chrome..

__________________

Mongo...aka Greg RIP Dad RIP Jesse 1981 C30 LQ9 NV4500..http://67-72chevytrucks.com/vboard/s...d.php?t=753598 Mongos AD- LS3 TR6060...http://67-72chevytrucks.com/vboard/s...34#post8522334 Columbus..the 1957 IH 4x4...http://67-72chevytrucks.com/vboard/s...63#post8082563 2023 Chevy Z71..daily driver |

|

|

|

|

|

#1224 |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,647

|

Re: 55 Wagon Progress

Thanks Greg, let's just hope there's never any electrical failures when the fuel needs filling..

So part of our fitment exercises with the bumpers has been to get them in a little closer to the body for more consistent gaps to the body. The rear bumper had it's challenges with needing to notch out the lower lip of the tailpan.      The front would be no different. The front nose of the frame rails was hitting the rear side of the factory brackets and preventing us from locating the bumper for a good consistent gap..  So some modification was in order so that the frame horn could fit in closer to the rear side of the bumper..  We now have a much better fit..

__________________

Robert |

|

|

|

|

|

#1225 |

|

Post Whore

Join Date: May 2015

Location: Alabama

Posts: 14,662

|

Re: 55 Wagon Progress

Details details..!!...those are gonna look great when they get shiny..

__________________

Mongo...aka Greg RIP Dad RIP Jesse 1981 C30 LQ9 NV4500..http://67-72chevytrucks.com/vboard/s...d.php?t=753598 Mongos AD- LS3 TR6060...http://67-72chevytrucks.com/vboard/s...34#post8522334 Columbus..the 1957 IH 4x4...http://67-72chevytrucks.com/vboard/s...63#post8082563 2023 Chevy Z71..daily driver |

|

|

|

|

| Bookmarks |

|

|