|

|

|

#101 | |

|

Registered User

Join Date: Jun 2014

Location: Beaverton, Oregon

Posts: 214

|

Re: Sullii the 72 GMC 1500

Quote:

__________________

My 1970 C10 ChassisFab LWB to SWB Build Thread |

|

|

|

|

|

|

#102 | |

|

Registered User

Join Date: Apr 2014

Location: Azle,Texas

Posts: 2,248

|

Re: Sullii the 72 GMC 1500

Quote:

This is one of the pictures of the work in progress.

__________________

Brian 1972 C10, "Loyd", LWB to SWB, 5.3, L83/6L80e, 4:11 Tru Trac, Air Ride, VA, DD, 20" Coys, 4 wheel disc, A quick LS swap turned into a 6 year frame off resto-mod. |

|

|

|

|

|

|

#103 |

|

Registered User

Join Date: Jun 2014

Location: Mocksville, NC

Posts: 1,760

|

Re: Sullii the 72 GMC 1500

Thanks guys for the refresher on Nacho. I completely forgot that Delmo did those wheel wells on that truck. It was also a blast from the past to go through that build thread. So many members that were once big contributors to the site that have moved on to other social media platforms.

Anyway, onto some updates on my build. After one year of messing around with the wiring harness, I finally wrapped it up and have it ready for install! I heavily utilized lt1swap.com to strip down the harness. I basically went by the book and pulled out everything he suggested plus all the automatic transmission stuff. I also added in the wires necessary for dual speed fans, for which I will be utilizing the Taurus fans. For the fuse panel, I went with the Michigan Motorsports B4100 LS swap fuse panel. It was a nice kit with all the necessary fuses/relays, OBD2 port, and wires to connect directly to the stock harness. The only other mod I made to the electrical components was swapping out the temp sensor for the 3 wire sensor from a Camaro (PN TX111) which includes the gauge signal within the same sensor. I saw this trick on clay68c10's build thread and it's a great idea! All I had to do was add the gauge wire into the harness and run it back to my gauge panel.   I was also able to complete the accessory drive. I like the original manual steering enough to leave it alone for now, and I am not installing A/C any time soon so I had to do something to clean up the accessories. At first I was going to just mount up the stock alternator bracket but it is quite bulky, especially after removing the power steering pump. I found a decent bracket from LSX Innovations that lets you mount the alternator in the LS1 location with the proper 5.3 truck accessory spacing. All I had to do was drill/tap the upper mounting hole (M10x1.5). It also requires a 38008 idler pully from a Camaro. With the original truck alternator, I calculated that I would need a K060557 belt which ended up being perfect. I think it all came together nicely and really cleans up the front of the engine without spending a fortune on a front accessory drive kit. If I want to add power steering in the future, I will utilize the LSX innovations upper mount which will couple with their low mount alternator bracket.   Oh, and to add to the craziness of life we decided to get a new puppy! Of course I have to introduce her to the truck. My daughter is in love.  That's it for now! Lights out in the shop.

__________________

Builds: Green Gus the 68 C10 | Bluey the 72 1500 | Lowly the 70 C10 - Instagram: @dr.hewitt - C10 Concept/Development Photos: Master Thread |

|

|

|

|

|

#104 |

|

Senior Member

Join Date: Aug 2004

Location: Centennial, CO

Posts: 2,979

|

Re: Sullii the 72 GMC 1500

Kids and dogs!

The truck is looking good, nice and clean

__________________

ClusterTruck: 68 C10 Bought in 89, wrecked in 03. Slow low $ rebuild started '17. 6.0 & TKO http://67-72chevytrucks.com/vboard/s...d.php?t=788602 93 K1500 Short Step, 350, NV4500, EBL flash ECU. Vortec heads & roller cam someday... 05 Jeep Wrangler Unlimited. 3 lift & 6-speed 02 E320 the insurance total free car 13 Tahoe LTZ |

|

|

|

|

|

#105 |

|

BlahBlahBlah

Join Date: Feb 2002

Location: Wa.

Posts: 19,992

|

Re: Sullii the 72 GMC 1500

I wish I had the skill set to pull off this kind of a build. I really like how it is all coming together. I thought the bed being shallow would be something I wouldn't care for, but it really isn't bad at all. When you think about it how often do you fill the bed to the brim?

__________________

... |

|

|

|

|

|

#106 | |

|

Registered User

Join Date: Jun 2014

Location: Mocksville, NC

Posts: 1,760

|

Re: Sullii the 72 GMC 1500

Quote:

__________________

Builds: Green Gus the 68 C10 | Bluey the 72 1500 | Lowly the 70 C10 - Instagram: @dr.hewitt - C10 Concept/Development Photos: Master Thread |

|

|

|

|

|

|

#107 |

|

Senior Member

Join Date: Mar 2014

Location: Toano, VA

Posts: 884

|

Re: Sullii the 72 GMC 1500

Really like that you did the firewall in a factory color rather than satin black. Looks awesome!

__________________

"Sometimes I do serve as a good bad example. Glad to be of service." My Build Thread (1967 C10, lowered, EFI, daily truck): http://67-72chevytrucks.com/vboard/s...d.php?t=830809 |

|

|

|

|

|

#108 |

|

Registered User

Join Date: Jun 2014

Location: Mocksville, NC

Posts: 1,760

|

Re: Sullii the 72 GMC 1500

The more I look at this motor, the more I realize there are so many little odds and ends required to complete this swap, who knew?! I am making progress, but none of it recently has been terribly exciting. In an effort to stay up to date and provide some useful info for anyone searching for answers in the future I will continue the mundane updates.

A while back when I installed the 302-1 oil pan I didn't think about the dip stick. Recently, I noticed the hole in my engine block and thought something ought to go there. That's when I realized I needed a new dipstick and the original truck one would not work. Apparently a 12625031 tube and 12669528 stick from a later model Camaro will work. I have since confirmed this is correct and it fits nicely around the Summit manifolds. Another thing here that has shown up in previous photos but I failed to mention are the plug wires. I went with original equipment Delphi XS10389 and they are niiice. Lastly, notice the PCV feed line from the manifold. This is stock for the 5.3 and I saved this guy from the junk yard. The return from the PCV on the other side of the manifold is also stock style.  For the steam vent (I may have mentioned this already) I added a 1/8 NPT fitting into the water pump and connected the stock hose directly to it. I decided to keep the line that feeds through the throttle body. I am not hot rodding this engine, so no need to delete this (for now). I will reuse the stock brake booster hose since it has a nice curve formed in it. I also disassembled the fuel rails/injectors and fully tested and rebuilt these with a kit from Amazon. All injectors tested fine w/ some backpressure from a can of carb cleaner and a pulse from a 9V battery. After a cleaning and new o-rings they are good as new. Also spy the ICT Billet purge valve block off. Can't leave any gaping holes in the manifold now can we? Also notice the copper line behind the manifold. I removed the 5.3 oil pressure sensor since apparently it isn't used for anything other than the CEL. I replaced it with an Auto Meter 2268 adapter that let me convert from the M16x1.5 in the block to a 1/8 NPT so I could connect a standard mechanical oil pressure line. It was about this point that I realized just how unsightly the stock truck manifold is. Originally I was going to leave the Vortec cover off because I think that piece is kind of hideous as well, but if the tradeoff is looking at this manifold, maybe I'll use the cover afterall. I could smooth this intake, but that's a lot of work!  For now, I threw the cover on just so I could stop looking at that intake. I may have to save this dilemma for another time. Right now, I am focused on making this thing run!  Here's another photo for fun. Just an old truck with an old small block. Come to think of it, this "modern" engine is already 20 years old!

__________________

Builds: Green Gus the 68 C10 | Bluey the 72 1500 | Lowly the 70 C10 - Instagram: @dr.hewitt - C10 Concept/Development Photos: Master Thread |

|

|

|

|

|

#109 | |

|

Registered User

Join Date: Apr 2014

Location: Azle,Texas

Posts: 2,248

|

Re: Sullii the 72 GMC 1500

Quote:

It's also good that you're so thorough. I can't tell you how many times when starting a new phase of my build that I'll go back and review my favorite truck builds and remind myself how it should be done before I tear into whatever it is. It's a huge help.

__________________

Brian 1972 C10, "Loyd", LWB to SWB, 5.3, L83/6L80e, 4:11 Tru Trac, Air Ride, VA, DD, 20" Coys, 4 wheel disc, A quick LS swap turned into a 6 year frame off resto-mod. |

|

|

|

|

|

|

#110 |

|

Senior Member

Join Date: Mar 2015

Location: washington

Posts: 2,280

|

Re: Sullii the 72 GMC 1500

Just think of the pain you are not having to deal with by going with a manual steering truck.

|

|

|

|

|

|

#111 | |

|

Registered User

Join Date: Jun 2014

Location: Mocksville, NC

Posts: 1,760

|

Re: Sullii the 72 GMC 1500

Quote:

That is very true! Hopefully I still like the manual steering as much as I did with the stock suspension. At the very least, I can get it driving as is and upgrade later if I don't like it.

__________________

Builds: Green Gus the 68 C10 | Bluey the 72 1500 | Lowly the 70 C10 - Instagram: @dr.hewitt - C10 Concept/Development Photos: Master Thread |

|

|

|

|

|

|

#112 |

|

Registered User

Join Date: Jun 2014

Location: Mocksville, NC

Posts: 1,760

|

Re: Sullii the 72 GMC 1500

Here's another round of incremental updates. My photos are all starting to look the same, even to me. I think I should just post the photo and see if anyone spots the differences, like one of those pictures from when we were kids. Circle the differences!

Seriously, if you've been following along, you may have noticed that the wiring harness is installed and all engine side plugs are connected! It took a little finagling to get the harness through the 2" hole I cut in the firewall, but it eventually cooperated. The grommet I found on McMaster worked out as well, although I did end up needing to cut it to get it on the harness. There was no way to force the plugs through it. Ideally, I would have depinned everything and slid the grommet on. You can also just barely see my positive side power feed-through bulkhead thingy on the firewall. This is straight up racecar stuff. My dad works in NASCAR doing wiring and he gave me this. The plan is to run the alternator to this junction point, and then another wire to the starter. More details on this in a later update.  Inside the cab, things are coming together as well. Again, you can just barely see that bulkhead coming through the firewall where I have my LS harness and truck harness power source joined. I am probably going to add a fusible link on the truck side since there was one factory and I lopped it off when rerouting everything. The LS side is fairly well protected by the fuse panel, which you can see to the right. It is easily accessible from below the dash, even after I add a shallow glove box (one day). I also have my PCM mounted up using a GM 15995679 mount. The PCM has been flashed by Brendan at LT1swap.com and should be ready to play nice with my swap configuration. Lastly, note the TAC module for the DBW (thats drive by wire, for those like me who always think, what's that mean!?). I will add more details on the actual pedal later. There are some annoyances associated with that.  For the battery, I decided to move it to the passenger side framerail behind the cab. I had a perfect spot there since my frame is stepped. I wanted to get it off the nose and also clean up the engine bay in the process. Plus, with the air intake needing to occupy that real estate, I had to do something. I got this battery box from Summit (PN SUM-430023) and it turned out to be nice quality.  That's enough wiring for now. Onto something else. While the truck was sitting on the ground at one point I noticed my front brake hoses were very tight, like, guitar string tight. I did a quick search on the forum and found out I'm not the first one to discover this issue on lowered trucks! There were plenty of suggestions, most commonly that C20 front brake hoses would work since they are 2" longer. If you keep digging, it seems most retailers have phased out the real C20 lines and just sell the same part for C10 and C20s. Someone said Brothers has the right C20 lines, so I ordered up a set. Wrong! They were the exact same length as my C10 lines. At one point 67ChevyRedneck posted a nice solution here using Nova/Camaro brake hoses. So, I ordered up a set. Although they do work, they are too long given my drop! They rub quite extensively on the spindle through the range of motion.  At this point, I had to venture out and come up with my own solution. I noticed that if I could just rotate my original line and reclock the banjo fitting I would get some more slack in the hose. The original orientation has the line coming out towards the top. Problem is, there is a nub that locks the banjo fitting in place. I decided to pull the calipers and grind down the lip that clocks the banjo fitting so I could rotate it to exit the caliper more horizontally. On the left is the modified right side caliper, on the right is the original left side caliper. After doing this, it freed up just enough length and now fits perfectly. There is no rubbing or stretching of the hose in any position.    Last up for this edition of random updates is engine/trans fluids. I learned a little something in that GM changed the threads on the oil filter at some point. I mistakenly grabbed a filter for a 2004 Camaro (PF46), thinking the shortie filter would work with my 302-1 muscle car pan on my '04 engine. Turns out I need a PF48 filter, which is from 2007-later Camaros. I don't know why this was changed, but at least now I know what filter I need. So to my future self, you need a PF48 filter. Top it off with about 6 qt of 5w-30 oil and we are SO close to turning this motor over for the first time (since it was swapped).   My NV3500 transmission was also filled up with some GM recommended ACDelco 75W-80 Synchromesh Transmission Fluid. The drain plug had normal metallic sludge on it which was a good sign (no metal shavings!). After about 2.5 qt it was satisfied. My daughter joined me in the garage for this step. This photo was taken at 6 am. The new puppy I mentioned a few weeks ago thinks 4:30 am is a good time to wake up. I am on morning puppy duty on the weekends, so might as well make use of the extra time!  Since I like to always try and include a macroscopic view of the truck in with all these detail shots, here's another photo. Between my last post and this one I have now crossed over the 2 year mark of owning this truck. In that time I have driven it a total of only 30 miles! Definitely was not my original intent with this one, but I'm happy where it is headed nonetheless. Here it is the day I brought it home.

__________________

Builds: Green Gus the 68 C10 | Bluey the 72 1500 | Lowly the 70 C10 - Instagram: @dr.hewitt - C10 Concept/Development Photos: Master Thread Last edited by hewittca; 05-04-2023 at 07:01 AM. |

|

|

|

|

|

#113 |

|

Senior Member

Join Date: Mar 2011

Location: Hanover NJ

Posts: 4,252

|

Re: Sullii the 72 GMC 1500

I have to thank you for your recent visit to my build as a result I just spent the last 2 hours going back to Green Gus which I visited in 2016 for the first time( I was in my mid sixties at that point )and today I found this new build of yours ...ill say it once again,7 very good years later you are blessed with family and talent ...thanks for sharing good luck on the first drive its around the corner awesome build looking forward to hearing that motor run with that custom exhaust ,.....amazing

__________________

Doc & Kim build http://67-72chevytrucks.com/vboard/s...d.php?t=722288 I am from the desert http://67-72chevytrucks.com/vboard/s...d.php?t=650332 basket case build SOLD http://67-72chevytrucks.com/vboard/s...d.php?t=648557 |

|

|

|

|

|

#114 | |

|

Registered User

Join Date: Jun 2014

Location: Mocksville, NC

Posts: 1,760

|

Re: Sullii the 72 GMC 1500

Quote:

__________________

Builds: Green Gus the 68 C10 | Bluey the 72 1500 | Lowly the 70 C10 - Instagram: @dr.hewitt - C10 Concept/Development Photos: Master Thread |

|

|

|

|

|

|

#115 |

|

Registered User

Join Date: Jun 2014

Location: Mocksville, NC

Posts: 1,760

|

Re: Sullii the 72 GMC 1500

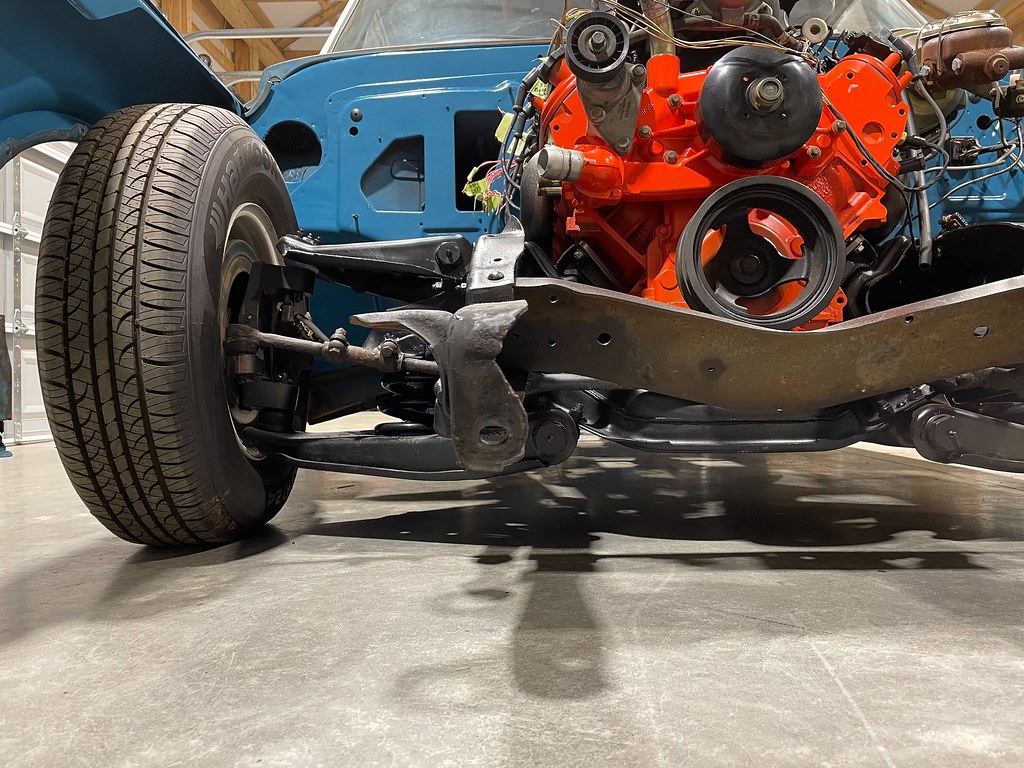

I think I've already mentioned my flipped tierod mod, but I was finally able to wrap that up. I went back and forth about whether I wanted to get one of those (expensive!) kits, or find a way to do it myself. I looked at tapered sleeves and couldn't find any that were right. Looked at getting spindles that haven't been drilled yet but CPP said nope. Ultimately I decided to just ream out the hole from the bottom like the VW crew does. I know this leaves an hourglass shaped hole in the spindle and reduces contact area on the tierod end, but if you look at the tierod compared to the depth of the hole it's not as much of a concern as you'd think. The tierod only engages in about 2/3 of the hole anyway, so tapering it from the opposite side results in a loss of only 1/6 of the contact depth. I'm not towing, autocrossing, or running large wheels so I think it will be just fine! I will monitor them closely for a while and if I see any excessive wear I will readdress this again later. By the way, if you wanted to know, the correct reamer is PN 89411 from Speedway which is a 1.5" per foot taper.

Here is a comparison before and after the tierod flip. My tierod angle was terrible after sectioning the crossmember. With the sectioning, every suspension point moved up 1.5" except the inner tierod connection point. This created a drastic bump steer condition that needed to be addressed. After flipping the tierod, the angle is pretty much back to where it needs to be. Before  After  The clearance to the wheel is close but it will work. This is a stock 15x6 wheel, so anything 15" with more backspacing would not work. If you're running larger wheels, then no problem.  While I was working on the front suspension, I decided to finally finish off the notch on the upper arm. This is for clearance to the steering shaft since I sectioned the crossmember. Normally you don't have to notch this much, but since I also body dropped the truck 1" I had to go a little deeper.

__________________

Builds: Green Gus the 68 C10 | Bluey the 72 1500 | Lowly the 70 C10 - Instagram: @dr.hewitt - C10 Concept/Development Photos: Master Thread |

|

|

|

|

|

#116 |

|

Senior Member

Join Date: Mar 2015

Location: washington

Posts: 2,280

|

Re: Sullii the 72 GMC 1500

I am watching this with interest.

Always something when you change one item it affects three others. Do it once and do it right seems to be your motto. Nice work. Cheers |

|

|

|

|

|

#117 |

|

Senior Member

Join Date: Mar 2011

Location: Hanover NJ

Posts: 4,252

|

Re: Sullii the 72 GMC 1500

X2

__________________

Doc & Kim build http://67-72chevytrucks.com/vboard/s...d.php?t=722288 I am from the desert http://67-72chevytrucks.com/vboard/s...d.php?t=650332 basket case build SOLD http://67-72chevytrucks.com/vboard/s...d.php?t=648557 |

|

|

|

|

|

#118 |

|

Registered User

Join Date: Jun 2014

Location: Mocksville, NC

Posts: 1,760

|

Re: Sullii the 72 GMC 1500

Yes, that is definitely the lesson learned with this build! I am still chasing the cascading effects of lowering my truck so much. My goal is to make sure everything on this truck is mechanically sound and functions properly.

__________________

Builds: Green Gus the 68 C10 | Bluey the 72 1500 | Lowly the 70 C10 - Instagram: @dr.hewitt - C10 Concept/Development Photos: Master Thread |

|

|

|

|

|

#119 |

|

Registered User

Join Date: Jun 2014

Location: Mocksville, NC

Posts: 1,760

|

Re: Sullii the 72 GMC 1500

I've been very slowly making progress on my center crossmember throughout this entire build. It started with flipping my trailing arm mounts to help correct pinion angle and limit the downstream effects of lowering my rear end so much. Then I eventually cut the 4.5" holes to allow for the exhaust pass throughs. Then I added the reinforcing hoops to strengthen the holes I cut. Through all this, I kept noticing how low the center of the crossmember actually hangs below the frame rails. Additionally, the front scoops down and would make for a very bad day if it were to catch on something. I decided I needed to flatten the bottom of my crossmember. I know I've seen it done before, but for this mod I decided to skip the forum research and do it on my own. I wanted to flatten it such that it was no longer the lowest part of the frame. I was able to get it high enough to where it's level with the bottom of the rivets holding in the crossmember.

You may have noticed the tab hanging off the rear of this plate. That is my integrated carrier bearing mount. On my other truck, I had to flip the carrier bearing mount from top to bottom so I could raise the bearing up to correct driveshaft angles. This is a consideration that must be made when lowering this much with a two piece driveshaft. I like to keep the two piece because it helps with clearance under the cab. I figured, since I'm going through all this work I might as well make the mount part of the crossmember.   At this point, I was able to do all my driveshaft measurements. First was length. I determined the stock driveshaft will work if I shorten the front shaft 3.25". I will leave this task to a professional driveshaft shop. Next up, driveshaft angles. Starting with the engine, it is at a fixed -3.7 degrees. I can't change that because my clearances are already tight enough to the cab. That means driveshaft 1 has to either be -4.7 or -2.7 degrees (1 degree difference from engine). If I go -4.7, that means my pinion has to be -4.7 as well, which puts driveshaft 2 at +4.3 degrees. That results in 8.9 degrees on the universals which is unfavorable. The -4.7 option was appealing because I could bolt the carrier bearing directly to the mount with no spacers. The -2.7 degree option requires a 1/4" spacer to reach this angle. Not a big deal though. This gives me an angle of +2.3 degrees on driveshaft 2 and a universal angle of 5 degrees. This is much more acceptable. In order to achieve this on the rear end, it must match driveshaft 1 and therefore needs to be -2.7 degrees. Bolted straight to the drop blocks, the rear is at -6.7 degrees, so I will need to add some 4 degree shims and it will be perfect.  While figuring all this out, my little helper was very confused.

__________________

Builds: Green Gus the 68 C10 | Bluey the 72 1500 | Lowly the 70 C10 - Instagram: @dr.hewitt - C10 Concept/Development Photos: Master Thread |

|

|

|

|

|

#120 |

|

Senior Member

Join Date: Mar 2011

Location: Hanover NJ

Posts: 4,252

|

Re: Sullii the 72 GMC 1500

lol on the helper

__________________

Doc & Kim build http://67-72chevytrucks.com/vboard/s...d.php?t=722288 I am from the desert http://67-72chevytrucks.com/vboard/s...d.php?t=650332 basket case build SOLD http://67-72chevytrucks.com/vboard/s...d.php?t=648557 |

|

|

|

|

|

#121 |

|

Registered User

Join Date: Jun 2014

Location: Mocksville, NC

Posts: 1,760

|

Re: Sullii the 72 GMC 1500

This next round of updates is a big milestone for me. It's when I finally get to put some power to the electrical system and make some things move! But before we get to that, I had to finish up my throttle pedal. I bought a 5.3 DBW throttle pedal mounting plate specifically made for 67-72 trucks from a board member here. I wanted to like this plate, I really did (esp for the price), but it just did not work that well. The mounting holes didnt line up, the hardware it came with was terrible, and it put the pedal in an awkward position. It was very high off the ground and made it hard to push the pedal. It was designed to get "full pedal travel", which technically it did. However, these DBW sensors reach wide open throttle at about 50% travel, so you really could move the pedal closer to the floor. With that in mind, I ended up making an angled mounting surface attached to the original plate I bought. With the original bracket the pedal mounting surface was vertical. After modification, it was at about 75 degrees. This got the pedal in a much more comfortable position.

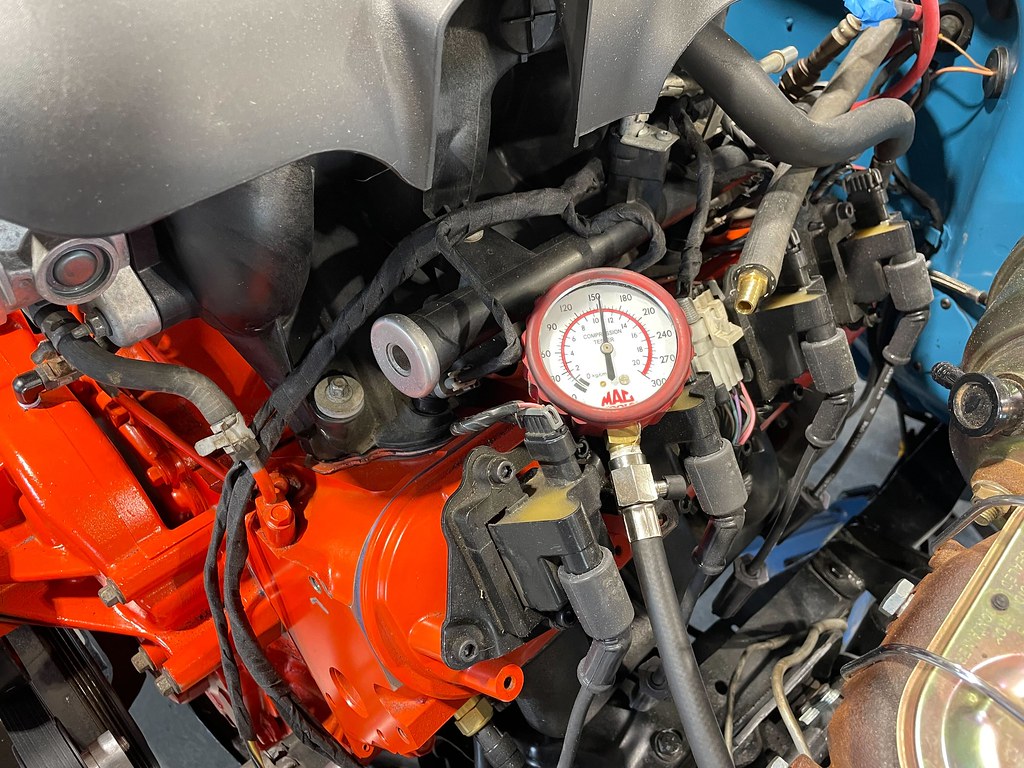

Now that I had a throttle pedal, it was time to have some fun! At this point, everything was in place to turn the key and see if things would power up. For this test, I just ran a temporary battery cable from my battery to my starter, and another from starter to my firewall bulkhead. Cautiously, I turned the key and I could hear the fuel pump relay switching which was a good sign. Next, I hit the throttle and sure enough the throttle body sprung into action. I know this is just a photo but I promise that throttle body is actuated by my daughter holding the throttle wide open from inside the cab! We were able to get a full wide open throttle body with the pedal mashed to the floor, which is exactly what I wanted with the modified bracket.  Next test was to turn the key a little further and see if the starter would come alive. I don't have photographic proof, but the engine did indeed start to turn over. I removed the spark plugs to make this task easier on the starter. After a few seconds, the oil pressure jumped up to a solid 30 psi. I think at cranking speeds this is acceptable for now. We will see where it ends up once the motor is running. This really just confirms for me that the oil pump is working, I installed the new barbell correctly, and the new oring on the oil pickup is properly in place!  With all that excitement out of the way, it was time to do a compression test. This is where things start to get serious. I followed all the recommended steps for this test. Throttle wide open, coils disconnected, spark plugs out, and crank with starter for several compression cycles. My results are shown below. They ranged from 60 psi up to 170 psi. When I first saw the 60 psi my heart sank. After some reading, I tried a common test which is to put a bit of oil in the cylinder and retest. For cylinder #2, that brought the compression from 60 psi up to 145 psi. At this point, I feel like I'm at a crossroads with this motor. I can either keep pressing on, or pull it back out and try to dig deeper into these compression results. I think the fact that this motor sat for 2 years before I could get it to this point may have contributed to these poor compression readings. If I can start the motor and quite literally "knock the rust off" it may bring these readings back to acceptable values. I wonder if there's anything I could hurt by trying to start a motor if it has bad compression...   Side note, I did not mess with cylinder 8 because I could not tighten down the compression test fitting in the spark plug port due to poor clearance with the firewall, so this result may not be accurate. All other cylinders had a good seal on the fitting. With this new dilemma to ponder, I decided to take care of a simple task on my checklist. Reinstalling the heater box was simple enough with a new seal kit. Originally I was going to paint this box black, but after cleaning it up I kinda liked the original grey against the blue. A little turn of the key and slide of the air control demonstrated that the blower motor still works properly. Don't forget to reinstall the little ground strap on the motor!  Oh what to do about my poor compression results... These numbers are going to haunt me until I either decide to pull the motor for further investigation, or just fire it up and see what happens.

__________________

Builds: Green Gus the 68 C10 | Bluey the 72 1500 | Lowly the 70 C10 - Instagram: @dr.hewitt - C10 Concept/Development Photos: Master Thread |

|

|

|

|

|

#122 |

|

Senior Member

Join Date: Aug 2004

Location: Centennial, CO

Posts: 2,979

|

Re: Sullii the 72 GMC 1500

Nice progress. It's great to know that all the electrical mods are functioning.

Just fire it and see what happens. Mine was very similar. It sat with Kroil in the cylinders for about a year after I tested it. I finally fired it up and it's running just fine idling in the garage. That may be different once it's under load, but that's a problem for future me. It was pretty rough for the first minute of so, then evened out. That may have been the rings un-sticking or the injectors clearing out, but either way it smoothed out and appears to be ok now. These engines are known for gumming up the rings and I suspect that's what you (and I) are seeing. I haven't re-tested it, but I probably should. Maybe this summer.

__________________

ClusterTruck: 68 C10 Bought in 89, wrecked in 03. Slow low $ rebuild started '17. 6.0 & TKO http://67-72chevytrucks.com/vboard/s...d.php?t=788602 93 K1500 Short Step, 350, NV4500, EBL flash ECU. Vortec heads & roller cam someday... 05 Jeep Wrangler Unlimited. 3 lift & 6-speed 02 E320 the insurance total free car 13 Tahoe LTZ |

|

|

|

|

|

#123 |

|

Registered User

Join Date: Apr 2014

Location: Azle,Texas

Posts: 2,248

|

Re: Sullii the 72 GMC 1500

Fantastic progress! I'd say fire it up and let it get up to temp. I'm expecting the same results when I get to that stage, since mine has been sitting for over 5 years.

__________________

Brian 1972 C10, "Loyd", LWB to SWB, 5.3, L83/6L80e, 4:11 Tru Trac, Air Ride, VA, DD, 20" Coys, 4 wheel disc, A quick LS swap turned into a 6 year frame off resto-mod. |

|

|

|

|

|

#124 |

|

Registered User

Join Date: Jun 2014

Location: Mocksville, NC

Posts: 1,760

|

Re: Sullii the 72 GMC 1500

I've decided for now to keep pressing on and at least fire this thing up before I go to extremes and tear the motor back out. Thanks everyone for the feedback. With that, I'm back to knocking things off the list. First up is correcting the rear pinion angle. I gave the details in my previous post on how I arrived at needing a 4 degree adjustment. This was easy enough with some 4 degree shims from Speedway. I realized that with these I will also gain another 1/4" of drop. Not much, but when you consider how low my truck is already it all starts to add up. When I dropped the truck back on the ground I noticed how low everything was hanging and feared I was way below the dreaded scrub line. The technical definition of scrub line is an imaginary line from the contact patch of one tire to the opposite rim (the flat tire). This is the blue line below and I am juuust barely in the good. Now, if both rear tires go flat (red line) then I am royally screwed but I may have much greater issues if that's the case.

Before I let the truck down on the ground, I threw some shims on the front upper control arms because I had a ton of negative camber with the 3" drop springs. Like, 9 degrees worth. I'm not opposed to camber, my R32 is running 5 degrees in the rear (Camber Gang); however, on my truck I want it to be close to stock alignment specs. I don't like the look of camber on the front of these trucks. Anyway, in doing this I realized that I had an oversight when I notched my upper arm for my steering shaft. I placed the notch BEFORE I added the shims. If you've ever aligned the front of a dropped truck you know you need a healthy stack of shims to get it back in alignment. Now, my notch is shifted compared to my steering column. I ran it through it's range of motion and it is close, very close. I may need to address this in the future.  Next, it was time to roll the truck out of the way and work on something I've been putting off for a while: prepping parts for paint. That's right, paint. I don't know exactly why the patina outside and clean interior/engine is really a thing, but I like that style as well. So, I had to do something about my exhaust and core support. For the exhaust I tried something that ended up looking really good. This is just mild steel pipe so it rusts pretty quickly, even after touching it with greasy hands. I decided to scuff it all up and give it a brushed look and then hit it with some high heat flat clear. The final result is plenty good enough for me.   For the core support, I was originally going to just leave it but when you get some natural light on it you start to notice how terrible it looked. Especially with the open grill on a GMC, this had to be addressed. With inspiration from KyleSeal and his recently completed core support, I decided it was time to tackle mine as well. I spent about two hours hitting it with a wire wheel and then sand paper. After that it was a quick bath and then set outside to bake in the sun. I used Krylon Fusion matte black and I really like this spraypaint. My old go-to paint was Rustoleum but that stuff takes an eternity to dry. The Krylon dries much quicker and looks better.    I have an aluminum radiator on the way and now I'm trying to decide if I should paint it black so the whole core support area looks uniform behind the grill. That's something I can figure out once I start test fitting the radiator.

__________________

Builds: Green Gus the 68 C10 | Bluey the 72 1500 | Lowly the 70 C10 - Instagram: @dr.hewitt - C10 Concept/Development Photos: Master Thread |

|

|

|

|

|

#125 |

|

Registered User

Join Date: Apr 2014

Location: Azle,Texas

Posts: 2,248

|

Re: Sullii the 72 GMC 1500

If you find that your new 4 degree shims lowered the truck too much for comfort, you can do what I did, which was to shave the angle you need directly into the lowering block. Accomplishes the same thing and adds no more drop.

I noticed the same thing on the Krylon vs the Rustoleum. Core support looks great man.

__________________

Brian 1972 C10, "Loyd", LWB to SWB, 5.3, L83/6L80e, 4:11 Tru Trac, Air Ride, VA, DD, 20" Coys, 4 wheel disc, A quick LS swap turned into a 6 year frame off resto-mod. |

|

|

|

|

| Bookmarks |

|

|