|

|

|

|

|

#1 |

|

Registered User

Join Date: May 2007

Location: Deale Md

Posts: 4,663

|

Re: Project Goldilocks, '66 C10 SWB BBW Build

I'm trying to pay attention - the frame was together and good to go and now it's completely apart and being redone.

OCD no bolt is left untouched right

__________________

James 63 GMC V6 4speed carryall 65 chevy swb bbw V8 auto 68 K20 327/4 speed, buddy buckets 2002 GMC CC Dually Duramax 64 GMC lwb 3/4 V6 4speed SOLD 66 GMC swb bbw buddy buckets SOLD IG duallyjams The only thing that stays the same is constant change! |

|

|

|

|

|

#2 | |

|

Registered User

Join Date: May 2011

Location: Anderson SC

Posts: 3,898

|

Re: Project Goldilocks, '66 C10 SWB BBW Build

Quote:

Posted via Mobile Device

__________________

Project Goldilocks '66 C10 Short Fleet BBW Build '65 C10 Highly Detailed Stock Restoration Thread '78 Camaro Targa Roof Build '55 International Metal/Body/Paint Work '66 F100 Full Rotisserie Restoration '40 Packard 120 Convertible Coupe Restoration How To Restore and Detail an Original Gauge Cluster How To Detail Sand Body Panels, Edges, Corners, Etc |

|

|

|

|

|

|

#3 |

|

Registered User

Join Date: May 2011

Location: Anderson SC

Posts: 3,898

|

Re: Project Goldilocks, '66 C10 SWB BBW Build

Small update. I need a transmission so I can mock up the engine/trans to make mounts and to make sure that I leave room around the drivetrain when building the X member. I thought about a T5 from an S10 but I don't think those will be strong enough once I get the 250 built. I don't want an auto because I'd rather stir my own gears, and because real hot rods have three pedals.

I did some searching and found that a T56 six speed is rated at around 400-450 ft/lb and used ones aren't extremely expensive so I'll go with one of those. Should be able to run 4.56 or higher (numerically) gears to have fun around town and still be able to cruise comfortably at 80-90 mph since 6th gear is .50 to 1.00 ratio. A local shop that sends us all of their glass work has one and said I could borrow it to get the X member and engine/trans mounts built. I'll probably just go ahead and buy it from them after Christmas/New Year's since he's not wanting an arm and a leg for it. It'll get converted to mid shift so the shifter comes out ahead of the seat. Once I get the frame boxed and ready for engine mounts, I'm thinking about sitting the cab back on the frame to check for floor/firewall clearance and to see how far down and back I can move the engine for better weight distribution. We get a week off between Christmas and New Year's so I'm hoping to be able to get the frame boxed and engine/trans mounts made while we're off and the shop is empty. I did some searching and found that a T56 six speed is rated at around 400-450 ft/lb and used ones aren't extremely expensive so I'll go with one of those. Should be able to run 4.56 or higher (numerically) gears to have fun around town and still be able to cruise comfortably at 80-90 mph since 6th gear is .50 to 1.00 ratio. A local shop that sends us all of their glass work has one and said I could borrow it to get the X member and engine/trans mounts built. I'll probably just go ahead and buy it from them after Christmas/New Year's since he's not wanting an arm and a leg for it. It'll get converted to mid shift so the shifter comes out ahead of the seat. Once I get the frame boxed and ready for engine mounts, I'm thinking about sitting the cab back on the frame to check for floor/firewall clearance and to see how far down and back I can move the engine for better weight distribution. We get a week off between Christmas and New Year's so I'm hoping to be able to get the frame boxed and engine/trans mounts made while we're off and the shop is empty.Dad had a steel table frame that needed to be powdercoated so I went ahead and took the bed floor support channels and a few small peices with his table frame to the powercoaters, and they'll be ready to pick up this week. I've also decided to move the gas tank to behind the axle for better weight distribution, and may move the battery also. A trailer hitch will add some weight in the rear too.  Hopefully I'll be able to make more progress soon, just been too busy lately to get anything done. Hopefully I'll be able to make more progress soon, just been too busy lately to get anything done.

__________________

Project Goldilocks '66 C10 Short Fleet BBW Build '65 C10 Highly Detailed Stock Restoration Thread '78 Camaro Targa Roof Build '55 International Metal/Body/Paint Work '66 F100 Full Rotisserie Restoration '40 Packard 120 Convertible Coupe Restoration How To Restore and Detail an Original Gauge Cluster How To Detail Sand Body Panels, Edges, Corners, Etc |

|

|

|

|

|

#4 |

|

Registered User

Join Date: May 2011

Location: Anderson SC

Posts: 3,898

|

Re: Project Goldilocks, '66 C10 SWB BBW Build

Got up Saturday and started the day off right.

I got all the crossmembers out and was going to finish making templates for the frame boxing but Christmas shopping got in the way. Which was a good thing since I've decided to not box the frame, just do an upper and lower X member. From what I've read lately boxing doesn't add much torsional rigidity, and I don't want to add the extra weight if it won't help much. Here's another reason I'm not boxing the frame. Hotchkis didn't do boxing on the C10 they built (pictured below), so that's reason enough for me. You have to be logged in to veiw the pics in the link, but it's worth signing up for. http://c10forum.com/forum/showthread.php?t=8455 I'll still double or triple box the frame in the C notch area since boxing the frame helps alot with horizontal loading, and I do plan on towing with the truck. I'll be off all next week so I'll hopefully be able to get a good bit of the bracing done, depending on how many Christmas/family gatherings we have going on.

__________________

Project Goldilocks '66 C10 Short Fleet BBW Build '65 C10 Highly Detailed Stock Restoration Thread '78 Camaro Targa Roof Build '55 International Metal/Body/Paint Work '66 F100 Full Rotisserie Restoration '40 Packard 120 Convertible Coupe Restoration How To Restore and Detail an Original Gauge Cluster How To Detail Sand Body Panels, Edges, Corners, Etc |

|

|

|

|

|

#5 |

|

Rollin' Old Skool

Join Date: Jun 2007

Location: Hattiesburg, MS

Posts: 5,371

|

Re: Project Goldilocks, '66 C10 SWB BBW Build

man, now i'm gonna have to go out & get a Yoo-hoo,

i haven't had one in a long time i haven't had one in a long time

__________________

_____________________________________________ Phillip My Build threads: 1966 Chevy C-10 "Black Betty" shortbed, fleetside, BBW, 327 V8/ Powerglide (under construction) http://67-72chevytrucks.com/vboard/s...ighlight=betty 1997 Chevy Tahoe, 2dr/2wd, mild custom (Daily driver) http://67-72chevytrucks.com/vboard/s...d.php?t=601142 Pics: '66 C-10 https://flic.kr/s/aHsjHWD4h9 '97 Tahoe https://flic.kr/s/aHsjGZ7wKP '93 C-1500 https://flic.kr/s/aHskxdpdnQ '88 S-10 Blazer https://flic.kr/s/aHsjYGx4Md Previous Rides: 1993 Chevy S-10 ext. cab, 4.3L, 4/5 drop (Sold) 1993 Chevy C-1500 short/step Retro-Rod (Sold) 1988 S-10 Blazer 2dr/2wd mild custom (Sold) |

|

|

|

|

|

#6 | |

|

Registered User

Join Date: May 2011

Location: Anderson SC

Posts: 3,898

|

Re: Project Goldilocks, '66 C10 SWB BBW Build

Quote:

I forgot to post this earlier, but since the plans have changed slightly  since I started the build, I have been thinking about changing the wheels to match. I've considered using a company that makes pressed centers for off road wheels to make a set of centers for my Titian 18's, but I came across this truck in an old Street Rodder mag last night and the wheels instantly caught my attention. They're patterned after Aero Racing wheels (think Nascar) but are custom made billet 17's since Aero doesn't offer larger sizes than 15ish. I could use my Titan rims and have pressed centers made to match the Aero center pattern. My moon disc/stock cap idea would still work over these wheels if I ever wanted to do that later on. The tire decals are pretty awesome so those may have to go on the "to do" list as well. since I started the build, I have been thinking about changing the wheels to match. I've considered using a company that makes pressed centers for off road wheels to make a set of centers for my Titian 18's, but I came across this truck in an old Street Rodder mag last night and the wheels instantly caught my attention. They're patterned after Aero Racing wheels (think Nascar) but are custom made billet 17's since Aero doesn't offer larger sizes than 15ish. I could use my Titan rims and have pressed centers made to match the Aero center pattern. My moon disc/stock cap idea would still work over these wheels if I ever wanted to do that later on. The tire decals are pretty awesome so those may have to go on the "to do" list as well.

__________________

Project Goldilocks '66 C10 Short Fleet BBW Build '65 C10 Highly Detailed Stock Restoration Thread '78 Camaro Targa Roof Build '55 International Metal/Body/Paint Work '66 F100 Full Rotisserie Restoration '40 Packard 120 Convertible Coupe Restoration How To Restore and Detail an Original Gauge Cluster How To Detail Sand Body Panels, Edges, Corners, Etc |

|

|

|

|

|

|

#7 | |

|

Registered User

Join Date: Aug 2011

Location: summerfield NC

Posts: 82

|

Quote:

|

|

|

|

|

|

|

#8 |

|

I'm just glad to be here!

Join Date: Jan 2008

Location: Longview, TX

Posts: 4,788

|

Re: Project Goldilocks, '66 C10 SWB BBW Build

WOW! Just read this whole thread. Makes me rethink what building a "driver" means as far as detail goes...

Looks great! Posted via Mobile Device

__________________

Karl  1965 Chevy Stepside(Grandpa's Old Blue) and (July 2015 Shop Build!)(2020, the Saga Continues) http://67-72chevytrucks.com/vboard/s...d.php?t=372424 The LST Challenge: http://67-72chevytrucks.com/vboard/s...=1#post7812257 Korbin's 1st Square: "Sunburn" http://67-72chevytrucks.com/vboard/s...d.php?t=418618 1985 GMC Sierra: "White Trash", Korbin's 2nd now... http://67-72chevytrucks.com/vboard/s...d.php?t=632305 Henry - 1984 Chevrolet, Owen's 1st Square |

|

|

|

|

|

#9 |

|

Registered User

Join Date: Mar 2011

Location: tulsa,ok.

Posts: 1,803

|

Re: Project Goldilocks, '66 C10 SWB BBW Build

i got the same c-notch as you and was thinking of welding it in and double brace it, with one in the middle and one on the outside out of 1/4" plate, i think that would work! i'm still waiting to be able to tow with it too!! one thing about having a project is plans change often, lol!!

__________________

my project: http://67-72chevytrucks.com/vboard/s...d.php?t=456163 |

|

|

|

|

|

#10 | |

|

Registered User

Join Date: May 2011

Location: Anderson SC

Posts: 3,898

|

Re: Project Goldilocks, '66 C10 SWB BBW Build

Quote:

We had a stock '65 with a 230/250 I6 in the shop today for a new windshield so I took some pics for reference.  There's not much room to drop the engine like I had hoped to be able to since the steering linkage is in the way. I wanted to notch the crossmember a few inches, but I'd also have to come up with a dropped center steering cross bar. I had planned on using No Limit's rack and pinion kit later on, but I'm not sure it would work with a notched crossmember/dropped engine. The only other option would be to notch the oil pan, but I don't think there's much clearance to be gained there. So dropping the engine may get scratched off the "to do" list. I guess this works for other guys that have shorter V8's.   There's also not much room to move the engine rearward without moving the engine down. Maybe an inch at the most without reworking the firewall- which for sure isn't gunna happen. Hopefully the T56 will clear the floor (low hump) without dropping the engine. The dropped center steering linkage is doable if I have to though.   I picked up the bed support rails and a few parts from the powdercoaters this week and ordered the steel for the X member and frame bracing, which should be here mid next week. I decided to go with 1"x2" 14g rectangle tube. I'm thinking that most all the load on the tubing will be a compression load (trying the make the tubing shorter) so thicker .125" wall tube wouldn't really be that helpful, and weigh more.  And lastly, Danbury Mint now makes a 1:24 scale model of my truck! It's a short/fleet BBW with Saddle Poly two tone! I may have to pick one of these up as a Christmas gift to myself! Thanks to sigshooter for sending me the info on these!

__________________

Project Goldilocks '66 C10 Short Fleet BBW Build '65 C10 Highly Detailed Stock Restoration Thread '78 Camaro Targa Roof Build '55 International Metal/Body/Paint Work '66 F100 Full Rotisserie Restoration '40 Packard 120 Convertible Coupe Restoration How To Restore and Detail an Original Gauge Cluster How To Detail Sand Body Panels, Edges, Corners, Etc |

|

|

|

|

|

|

#11 |

|

Artist

Join Date: Jan 2010

Location: Rockwell NC

Posts: 422

|

Re: Project Goldilocks, '66 C10 SWB BBW Build

Couple things.... If you look up the Bapst truck here... hes the guy that runs the autocross at the Charlotte Goodguys... He set his engine back and moved it down then made a custom firewall for it all to work. That may be an idea. As for a NASCAR inspired 60-66 truck.... Dig up the pics of the on Richard Childress' Cup shop built... absolutely AWESOME!! Remember.... Nascar trailing arms bolt right up!

__________________

66 Chevy C10 283ci~cough~ SBW Fleet Buttercup '66 |

|

|

|

|

|

#12 | ||

|

Registered User

Join Date: May 2011

Location: Anderson SC

Posts: 3,898

|

Re: Project Goldilocks, '66 C10 SWB BBW Build

Quote:

Quote:

I can't cut the firewall, it's too nice of a truck to start hacking it. And I want to be able to use the stock style firewall insulation/cover. I don't really want to cut a hole in the floor for the shifter, but that's the only way to get a decent manual transmission. I'll leave the engine where it is and use the stock mounts, as long as the T56 will fit without having to drop it any. I guess I got carried away planning all the go fast tricks and now reality is setting in.

__________________

Project Goldilocks '66 C10 Short Fleet BBW Build '65 C10 Highly Detailed Stock Restoration Thread '78 Camaro Targa Roof Build '55 International Metal/Body/Paint Work '66 F100 Full Rotisserie Restoration '40 Packard 120 Convertible Coupe Restoration How To Restore and Detail an Original Gauge Cluster How To Detail Sand Body Panels, Edges, Corners, Etc |

||

|

|

|

|

|

#13 | |

|

Registered User

Join Date: Apr 2001

Location: DALLAS,TX

Posts: 22,039

|

Re: Project Goldilocks, '66 C10 SWB BBW Build

Quote:

__________________

67SWB-B.B.RetroRod 64SWB-Recycle 89CCDually-Driver/Tow Truck 99CCSWB Driver All Fleetsides @rattlecankustoms in IG Building a small, high rpm engine with the perfect bore, stroke and rod ratio is very impressive. It's like a highly skilled Morrocan sword fighter with a Damascus Steel Scimitar..... Cubic inches is like Indiana Jones with a cheap pistol. |

|

|

|

|

|

|

#14 |

|

Registered User

Join Date: May 2011

Location: Anderson SC

Posts: 3,898

|

Re: Project Goldilocks, '66 C10 SWB BBW Build

Correct, and filling the shifter hole later on wouldn't be a big deal to weld up and bodywork so the repair is undetectable.

__________________

Project Goldilocks '66 C10 Short Fleet BBW Build '65 C10 Highly Detailed Stock Restoration Thread '78 Camaro Targa Roof Build '55 International Metal/Body/Paint Work '66 F100 Full Rotisserie Restoration '40 Packard 120 Convertible Coupe Restoration How To Restore and Detail an Original Gauge Cluster How To Detail Sand Body Panels, Edges, Corners, Etc |

|

|

|

|

|

#15 |

|

Registered User

Join Date: May 2011

Location: Anderson SC

Posts: 3,898

|

Re: Project Goldilocks, '66 C10 SWB BBW Build

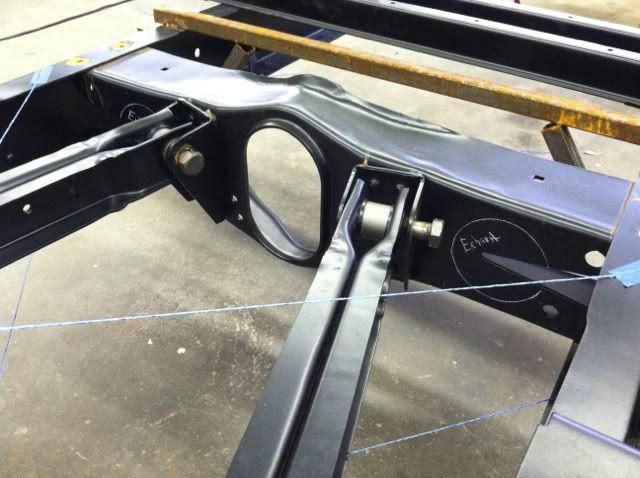

I got the rear bracing mocked up today with string to check for clearance issues. I put the trailing arm crossmember in upside down so the trailing arm brackets would be flipped, which was much easier than drilling out all of those rivets to flip the bracket!

Crossmember flipped and arms/axle in place at lowest drop height.  String pulled to check bed floor clearance at full drop.  X member bracing pattern laid out with string. The bottom tubing will have to be curved downward in the center to clear the driveshaft, which I can do with my tubing roller. The upper tubes will only need a slight bend to clear the trailing arms at full drop.    The bottom tubes will be curved to roughly match the shape of the frame rails. I'll double check the amount of drop I'll need when I bring the driveshaft back to the shop and have the engine/T56 installed.   Also decided to make the exhaust run through the crossmember and out the side through the frame rail. This will give more ground clearance and make routing the exhaust tubing easier than trying to go over the rear axle.

__________________

Project Goldilocks '66 C10 Short Fleet BBW Build '65 C10 Highly Detailed Stock Restoration Thread '78 Camaro Targa Roof Build '55 International Metal/Body/Paint Work '66 F100 Full Rotisserie Restoration '40 Packard 120 Convertible Coupe Restoration How To Restore and Detail an Original Gauge Cluster How To Detail Sand Body Panels, Edges, Corners, Etc |

|

|

|

|

|

#16 |

|

Senior Member

Join Date: Oct 2011

Location: Lewiston, ID.

Posts: 628

|

Re: Project Goldilocks, '66 C10 SWB BBW Build

Man this build is over the top!!! (and I thought I was crazy :-)

__________________

Wade  , JUST WALK AWAY, AND I'LL SPARE YOUR LIVES!!! , Build thread "TANGERINE" http://67-72chevytrucks.com/vboard/s...d.php?t=498570 Board Members Met: bigblock68, ol_skool_chevy ,68TT,atvpro |

|

|

|

|

|

#17 |

|

Registered User

Join Date: Sep 2011

Location: Tacoma, WA

Posts: 2,425

|

Re: Project Goldilocks, '66 C10 SWB BBW Build

So with this much frame reinforcement, you are.....

dropping in a badazz drivetrain with sheetons of torque, or do you just live on a really bad road? I just figure this much engineering has to be for something (of course I probably missed it if you already explained it. Either it didnt sink in, or you didnt use small enough words and concepts for me to follow) Hahahahah. I do really like reading, Ok .... looking .... at this thread. I am gonna sit in the corner with my crayons now and not be a nusince....

__________________

Michael McMurphy My 66 Stepside My 64 Tow Truck My 66 Tempest Table Of Contents Added to Page1 Last edited by McMurphy; 01-06-2012 at 11:49 PM. Reason: Caution: dork spelling in progress !! |

|

|

|

|

|

#18 | ||

|

Registered User

Join Date: May 2011

Location: Anderson SC

Posts: 3,898

|

Re: Project Goldilocks, '66 C10 SWB BBW Build

Quote:

Quote:

Crayons huh... Somebody should send you a PPG coloring book!  I'm bracing the frame to keep it from twisting down its length. Right now it twist quite easily, much like a torsion bar would twist. The overall goal is to make the frame stiff so that the suspension works as it should instead of the frame deflecting and changing/reducing the effectiveness of the suspension's geometry. I'd like to eventually autocross the truck occasionally just for fun; I really enjoy driving anything that is nimble and responsive but I don't think just bolting on performace suspension parts will get the truck to the level I want it. A stiffer frame should make the truck more predictable, more solid feeling, have less sqeaks and rattles, and give a better overall driving experience. As far as the drivetrain, I'll eventually build an original 250 inline 6 for it, looking to get 350+hp from it. It'll get backed by a T56 six speed and a posi rear end. Posted via Mobile Device

__________________

Project Goldilocks '66 C10 Short Fleet BBW Build '65 C10 Highly Detailed Stock Restoration Thread '78 Camaro Targa Roof Build '55 International Metal/Body/Paint Work '66 F100 Full Rotisserie Restoration '40 Packard 120 Convertible Coupe Restoration How To Restore and Detail an Original Gauge Cluster How To Detail Sand Body Panels, Edges, Corners, Etc |

||

|

|

|

|

|

#19 | ||

|

Registered User

Join Date: Sep 2011

Location: Tacoma, WA

Posts: 2,425

|

Re: Project Goldilocks, '66 C10 SWB BBW Build

Quote:

Quote:

With the dual exhaust there is still the option of installing electric exhaust dumps at an H or X crossover. No doubt you are planning on a hotter ignition system, if not full electonic? What are your plans for air flow? Cold air induction, or some form of forced air like a blower or ram air? And I am guessing you are going to go with the smaller high torque starter as well, or will your flywheel shaving not make that a good idea? I guess the last thing you want to do is disintegrate your flywheel.... I hope to keep up with your engine build a lot easier than I can with the re-engineering of your frame!! This is going to be a great build...glad I got into it on the first posting !! Rock on man !!

__________________

Michael McMurphy My 66 Stepside My 64 Tow Truck My 66 Tempest Table Of Contents Added to Page1 Last edited by McMurphy; 01-07-2012 at 04:07 PM. Reason: muddle brained fingers at the keyboard |

||

|

|

|

|

|

#20 | ||

|

Registered User

Join Date: May 2011

Location: Anderson SC

Posts: 3,898

|

Re: Project Goldilocks, '66 C10 SWB BBW Build

Quote:

Quote:

Posted via Mobile Device

__________________

Project Goldilocks '66 C10 Short Fleet BBW Build '65 C10 Highly Detailed Stock Restoration Thread '78 Camaro Targa Roof Build '55 International Metal/Body/Paint Work '66 F100 Full Rotisserie Restoration '40 Packard 120 Convertible Coupe Restoration How To Restore and Detail an Original Gauge Cluster How To Detail Sand Body Panels, Edges, Corners, Etc Last edited by theastronaut; 01-07-2012 at 06:43 PM. Reason: Spelling, again. |

||

|

|

|

|

|

#21 |

|

1 thing at a time is progress.

Join Date: Jun 2007

Location: Ball Ground GA

Posts: 5,511

|

Re: Project Goldilocks, '66 C10 SWB BBW Build

Very nice thought process, looks like you have thought of everything.

I'm watching and learning. I'm watching and learning.

__________________

Alan

Philippians 2:14-16 |

|

|

|

|

|

#22 |

|

Registered User

Join Date: May 2009

Location: Rathdrum, Idaho

Posts: 1,135

|

Re: Project Goldilocks, '66 C10 SWB BBW Build

Astronaut love what's happening with your build, I am curious though how or what is your plan to extract 350 hp out of that 250 inline? I know they are doing crazy things with the inline down in Brazil so I know it's possible. Just wondered what your thoughts were on the motor so far. Thanx...Vernski

|

|

|

|

|

|

#23 | ||

|

Registered User

Join Date: May 2011

Location: Anderson SC

Posts: 3,898

|

Re: Project Goldilocks, '66 C10 SWB BBW Build

Quote:

Quote:

Here's what I've got planned so far. The hp numbers I posted are just a rough guess, but it shouldn't be too hard to make around 1.4 hp per cubic inch with a roller cam; my vw motor will make right at 1.5 hp/ci with a solid flat cam. 250x1.4 is 350, and I'm not sure how many cubic inches will be added from boring yet. Bore the block enough to clean up the cylinders and leave enough meat for any future rebuild. Balanced stock crank. Lighten the flywheel. Eagle forged 4340 rods, 5.7" Forged pistons, haven't found any "off the shelf" yet. I think it can be bored enough to fit 305 pistons. Head bolt boss removed from intake port, lump port kit installed. Larger valves, ported heads, decked for more compression. Block decked for .040-.050 deck height/quench. 13:1ish compression (will be running E85, 105 octane) Solid roller cam, wanting it to pull to around 7000-7200 rpm. Comp Cams Aluminum roller rockers, 1.75 ratio. ARP main and head stud kit. Triple Weber/Dellorto 2 barrel side draft carbs, or triple throttle bodies/efi. 6 into 1 header, single 3" exhaust, magnaflow/dynomax straight through muffler? I'll probably go though a few mufflers to get the sound I want, I'm pretty picky about how I want it to sound.

__________________

Project Goldilocks '66 C10 Short Fleet BBW Build '65 C10 Highly Detailed Stock Restoration Thread '78 Camaro Targa Roof Build '55 International Metal/Body/Paint Work '66 F100 Full Rotisserie Restoration '40 Packard 120 Convertible Coupe Restoration How To Restore and Detail an Original Gauge Cluster How To Detail Sand Body Panels, Edges, Corners, Etc Last edited by theastronaut; 01-07-2012 at 11:06 AM. Reason: My kindergarten spelling skills... |

||

|

|

|

|

|

#24 |

|

Registered User

Join Date: May 2007

Location: Deale Md

Posts: 4,663

|

Re: Project Goldilocks, '66 C10 SWB BBW Build

I like the race magnum that they have. My buddy has them on his race truck and I them on my Duramax Diesel and they sound great.

__________________

James 63 GMC V6 4speed carryall 65 chevy swb bbw V8 auto 68 K20 327/4 speed, buddy buckets 2002 GMC CC Dually Duramax 64 GMC lwb 3/4 V6 4speed SOLD 66 GMC swb bbw buddy buckets SOLD IG duallyjams The only thing that stays the same is constant change! |

|

|

|

|

|

#25 |

|

Registered User

Join Date: Oct 2009

Location: Mooresville, NC

Posts: 46

|

Re: Project Goldilocks, '66 C10 SWB BBW Build

Nice build thread! I texted you last year about the extra bbw cab you had for sale, and I think I still have your number saved in my phone. I'm originally from Abbeville. I was looking through your posts and I think I recognize the place in some of your pics. Do you work at the place behind the high school right off of the 28 bypass? I remember taking a 50 Pontiac Chieftain convertible there to have a windshield put in when I worked at John's Rod Shop. After I left John's I worked at the Line-X right there across from the high school on 28 bypass.

__________________

64 Stepside.. A work in progress..

|

|

|

|

|

| Bookmarks |

|

|