|

|

|

#126 |

|

Registered User

Join Date: Aug 2011

Location: Yellowknife, NWT

Posts: 39

|

Re: 4L80E & TH400 Tech.

Thank you for the replies.

Is this piece a straight replacement in the newer units or does it require other changes. http://www.ebay.com/itm/111453434374...%3AMEBIDX%3AIT Would these fittings restrict volume of oil flow? I want to use just regular fittings not the factory snap in. http://www.ebay.com/itm/231278300872...%3AMEBIDX%3AIT At first I thought- yes I am capable of doing a 4l80e, not so much anymore...more so the looming specter of taking the trans out again because I missed something. Clineberger- I like the idea of the Sonnax reamer and sleeve- does your shop have these, could I ship valve body for service. I cannot justify buying that particular kit and don't like the wearing characteristics of the cheaper technique. The damaged oil cooler lines were not on a Allison trans, and yes this is a cold climate here, I just didn't see the cooler lines as a maintenance item. Either way I think hard line is a lot of work but a good quality hydraulic line will fit the bill. |

|

|

|

|

|

#127 |

|

Senior Member

Join Date: May 2009

Location: Fort Worth, TX

Posts: 6,370

|

Re: 4L80E & TH400 Tech.

The larger O/D Roller Clutch requires a matching O/D Carrier & Overrun Hub.

The trick with a small O/D Roller Clutch is to not Hammer it with the shifter in D4/OD, Put the trans in D3/3rd, This brings on the Overrun Clutch & helps support the Roller Clutch. Those fitting work fine, We use them on 3rd & 4th Gen Camaros all the time, But you can use straight fittings in a Truck. Are you inquiring about the AFL Valve Bore repair? |

|

|

|

|

|

#128 | |

|

Registered User

Join Date: Aug 2011

Location: Yellowknife, NWT

Posts: 39

|

Re: 4L80E & TH400 Tech.

Quote:

Alto has screwed me to many times with their JUNK Can you enlighten me to this warranty logic- Alto just lost future sales of not only you but anybody reading this- it's not like there's no competing product out there. What do you think of this pan? I'm not happy with extra welds/potential leaks, but can't see paying big dollars for a cast pan. I understand these are heavy guage- too bad they don't offer a version sans tubes. https://www.amazon.ca/Derale-14207-T...keywords=4l80e Last edited by dfarr67; 02-11-2017 at 05:00 PM. |

|

|

|

|

|

|

#129 |

|

Registered User

Join Date: Aug 2011

Location: Yellowknife, NWT

Posts: 39

|

Re: 4L80E & TH400 Tech.

Moving to the front end of the trans- I'm thinking of a reman'd 200ish Express van 4.3L toque converter- how would this behave with a 383?

|

|

|

|

|

|

#130 |

|

Registered User

Join Date: Sep 2013

Location: Vacaville CA

Posts: 490

|

Re: 4L80E & TH400 Tech.

What's the opinion on Torlon check balls vs steel? Do they save wear on the plate, and do they last?

|

|

|

|

|

|

#131 |

|

Senior Member

Join Date: May 2009

Location: Fort Worth, TX

Posts: 6,370

|

Re: 4L80E & TH400 Tech.

I missed dfarr67 last 2 post.......I have the Sonnax AFL repair tools, But my own testing has proven that the Trans Go repair is adequate.

A stock pan is fine, Spend your money on a good cooler! Buy a quality converter!!!!! Circle D, Precision, Jake's, North Texas converter, Yank etc......... |

|

|

|

|

|

#132 | |

|

Senior Member

Join Date: May 2009

Location: Fort Worth, TX

Posts: 6,370

|

Re: 4L80E & TH400 Tech.

Quote:

The trick is to angle/chamfer the edge of the holes the balls seat against on the plate, Some Emroy cloth on the end of a push rod works well. |

|

|

|

|

|

|

#133 | |

|

Registered User

Join Date: Aug 2011

Location: Yellowknife, NWT

Posts: 39

|

Re: 4L80E & TH400 Tech.

Quote:

I looked into Circle-D and I had to go billet$$ for SBC gen1 flexplate otherwise he did have a reasonably priced non billet GM unit I couldn't use. |

|

|

|

|

|

|

#134 |

|

Registered User

Join Date: Jun 2015

Location: Indanapolis, IN

Posts: 603

|

Re: 4L80E & TH400 Tech.

Has anybody here bought the actuator feed limit valve kit from transgo? If so, want to share?

Edit: I bought the kit. For future reference, I will share after I am done with mine. Last edited by indymachinist; 04-02-2017 at 07:35 PM. |

|

|

|

|

|

#135 | |

|

Senior Member

Join Date: May 2009

Location: Fort Worth, TX

Posts: 6,370

|

Re: 4L80E & TH400 Tech.

Quote:

I am OVERLY picky when it comes to converters, Circle D stands behind their products! Never charged me a cent for Cut/Clean or Refresh, And a re-stall is free within a time window. |

|

|

|

|

|

|

#136 |

|

Registered User

Join Date: Jun 2015

Location: Indanapolis, IN

Posts: 603

|

Re: 4L80E & TH400 Tech.

clinebarger, when doing the 91-93 to 94-03 EPC solenoid upgrade, do I need to use a different hold down clamp also? The older style clamp doesn't seem to fit the newer EPC solenoid quite right.

|

|

|

|

|

|

#137 |

|

Senior Member

Join Date: May 2009

Location: Fort Worth, TX

Posts: 6,370

|

Re: 4L80E & TH400 Tech.

Yes, GM part# 8684217

|

|

|

|

|

|

#138 | ||

|

Registered User

Join Date: Apr 2017

Location: Ventura County CA

Posts: 4

|

Re: 4L80E & TH400 Tech.

clinebarger, thank you for the great tech advice!

Quote:

Quote:

Last edited by -TheBandit-; 04-12-2017 at 01:03 PM. |

||

|

|

|

|

|

#139 | |

|

Senior Member

Join Date: May 2009

Location: Fort Worth, TX

Posts: 6,370

|

Re: 4L80E & TH400 Tech.

Quote:

Vehicle specifics would help a lot...... HP, Torque, stall speed, gear ratio? |

|

|

|

|

|

|

#140 |

|

Registered User

Join Date: Apr 2017

Location: Ventura County CA

Posts: 4

|

Re: 4L80E & TH400 Tech.

It's a 70 Nova roughly 3500lbs dynod peak 410rwhp/390ft-lb rwtq. BTE 2,800rpm 10" stall. 3.73so 28" tall tires. It is a street driven car 90% of the time but I want to take it to autocross a few times a year and maybe to the strip a few times too. I'd love to also try road course. It's not the right transmission for that exactly but it will have to do for now. I don't need the transmission upsetting the tires with banging harsh shifts, but firm would be fine.

Thanks for any suggestions. |

|

|

|

|

|

#141 |

|

Senior Member

Join Date: May 2009

Location: Fort Worth, TX

Posts: 6,370

|

Re: 4L80E & TH400 Tech.

Are you building from scratch, Or just pulling the VB & Plate?

I like blocking the 2-3 accumulator because the results are more consistent & repeatable. Dual Fed Directs also affects 2-3 shift feel, As does the Direct Clutch return springs. Use of Hi-Energy (Flat Face) 4L80E frictions in the Direct Clutch produces a less harsh shift than TH400 Tan Paper frictions once the frictions are broke-in/compressed to their final form. Friction Modifiers or lack of in the ATF also plays a roll, All my recommendations are based on the use of Dexron III ATF. The use of Wave Plate/s in the clutch pack also has a tremendous affect. It seems I'm answering questions with questions, Not my intent.....But I want to give the most accurate advice I can. |

|

|

|

|

|

#142 |

|

Registered User

Join Date: Apr 2017

Location: Ventura County CA

Posts: 4

|

Re: 4L80E & TH400 Tech.

Questions are just fine! The transmission is of unknown build. I am not pulling the transmission from the car, or at least I don't plan to. I was having some trouble with my 2-3 shift sporadically shifting back and forth at cruise after swapping in the ls engine. I also could not get the car to shift 2-3 under wot and in fact any real throttle would cause a 3-2 downshift even though the kickdown switch is disconnected.. After checking the modulator and governor, I decided to pull the valvebody and check for any sticking valves. I decided to install a transgo 400-pro kit while I'm in there.

But when I pulled off the valvebody, I found the reverse feed had a screw in plug. When I removed it I confirmed air passed freely between the 3rd feed hole and the reverse feed hole, indicating to me the seal was omitted i.e dual feed was already done internally. I put the plug back into the reverse feed and I plan to run that as is, but I will not be able to use the transgo plate. I also found the 2-3 accumulator piston had been locked down against the valvebody using nuts between the piston and the e-clip. I went ahead and installed the transgo supplied spring and took out all the nuts so it's functional again. I also found the front servo e-clip was broken and floating around under the spring seat. No idea what that might do beyond preventing the front band from applying. I have never had engine braking in 2nd and I assume that's why. I installed a new e-clip. I am getting ready to put it back together with a stock separator plate, feed holes drilled however I decide and I don't know whether or not I should block the accumulator feed. Looking at the transgo plate, I think they restrict the flow to the accumulator using a small orifice. I didn't find any sticky valives in the valve body. Last edited by -TheBandit-; 04-15-2017 at 12:55 AM. |

|

|

|

|

|

#143 |

|

Senior Member

Join Date: May 2009

Location: Fort Worth, TX

Posts: 6,370

|

Re: 4L80E & TH400 Tech.

Pull the governor out & check for the "head" being loose, Measure the "lands" if under .797".....Replace Governor, Check Governor "end-play"....Adjust to .030"-.040" Strike the center of the cover to tighten end-play.

Try .101 2nd feed hole, And .125" on 3rd with the accumulator blocked (They already blocked it by shimming the piston to bottom) |

|

|

|

|

|

#144 |

|

Registered User

Join Date: Apr 2017

Location: Ventura County CA

Posts: 4

|

Re: 4L80E & TH400 Tech.

Thanks clinebarger. I inspected the governor and it seemed to function properly, but I did not measure the lands or check endplay. I will take a look at that if this doesn't work out. Thank you!

|

|

|

|

|

|

#145 |

|

Senior Member

Join Date: May 2009

Location: Fort Worth, TX

Posts: 6,370

|

Re: 4L80E & TH400 Tech.

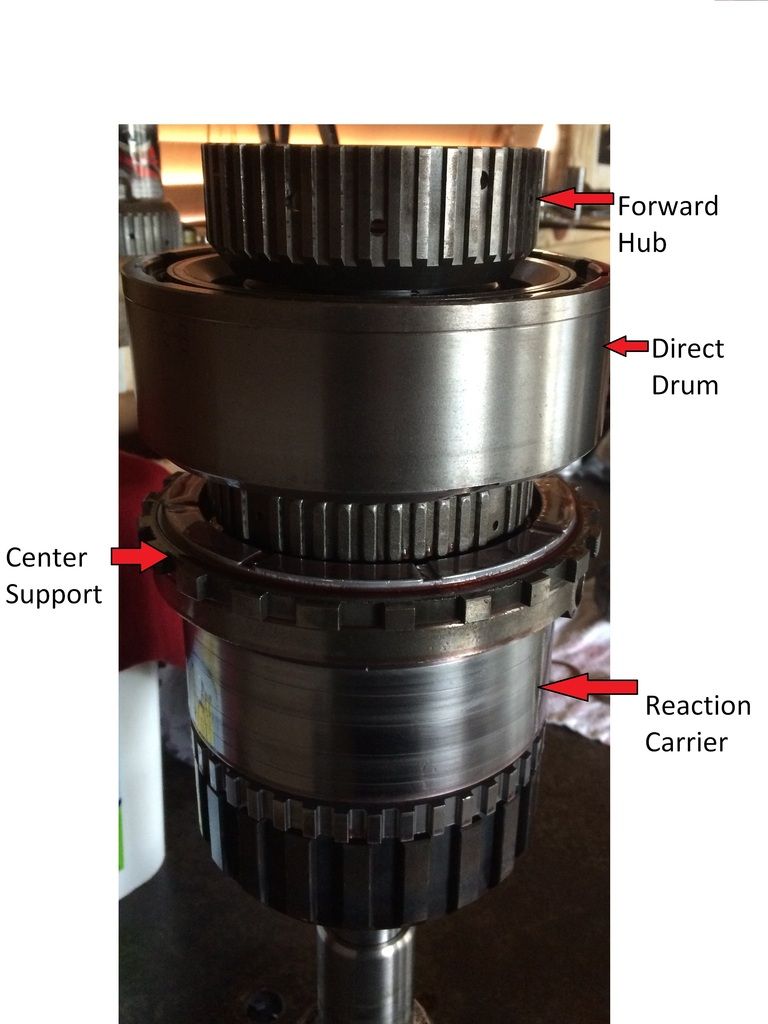

Forward Hub Tech.......

TH400 Forward Hubs are Cast Iron, Good to around 500 ft lbs in most applications, More if your not shocking it with a big stall or a big hit of nitrous. 4L80E Forward Hubs are Cast Steel, Good to around 750 ft lbs in most applications, Not phased by big stall's or small hit's of nitrous. Identification.......TH400 Forward Hubs will make a dull thud sound when lightly struck with a wrench, A 4L80E piece will ring like a Bell. End Play, Forward Hub to Direct Drum specs....... Using a Thrust Washer..... .008"-.015" Using a Torrington Bearing....... .003"-.008" If using a Thrust Washer between the Forward Hub & Direct Drum, You will need to buy a thicker Thrust Washer as no shims are available for this location. Stock Plastic or Brass thrust thickness...... .059"-.064" Sonnax Part# 34301-078 ...... .078" Sonnax Part# 34301-094....... .094" This is the one usually needed. Rollerizing the Forward Hub..... This is highly recommended mod.....Almost needed if your trans spends long stints in low gear. The best fitting bearing to use is a final drive sun gear bearing out of a Ford AXOD Part# E6DZ-7F404-A Ford has discontinued this part, But Green Sales has them in stock Phone# 1-800-543-4959 Machining the Forward Hub rear thrust pad is necessary, Be very careful on your measurements because you will need to set Forward Hub to Direct Drum end play with the machining. Start with +.035"......Lets say the bearing is .150", The original thrust is .064" .150"-.064"=.086", .086"-.035"=.051"........051" is what you need to remove from the Thrust Pad. These are hypothetical numbers!! Measure your new Bearing & old thrust BEFORE machining!! Checking Forward Hub to Direct Drum end play, Stack the gear train up to the Direct drum, Place the Forward Hub over the Main Shaft, Hold the forward hub down with your palms & lift the direct drum with your fingers.....The play you feel is the end play.....Picture......

Last edited by clinebarger; 06-15-2017 at 07:52 PM. |

|

|

|

|

|

#146 |

|

Senior Member

Join Date: May 2009

Location: Fort Worth, TX

Posts: 6,370

|

Re: 4L80E & TH400 Tech.

|

|

|

|

|

|

#147 |

|

Senior Member

Join Date: May 2009

Location: Fort Worth, TX

Posts: 6,370

|

Re: 4L80E & TH400 Tech.

|

|

|

|

|

|

#148 |

|

Senior Member

Join Date: May 2009

Location: Fort Worth, TX

Posts: 6,370

|

Re: 4L80E & TH400 Tech.

|

|

|

|

|

|

#149 |

|

Registered User

Join Date: Jun 2016

Location: Phoenix, AZ

Posts: 574

|

Re: 4L80E & TH400 Tech.

Clinebarker, thanks for the 700R4 info in the other thread. Next project is a 4L80E into my dually. Currently a stock 454, but plans are for a diesel swap with torque in the 600-700 range. I have a couple cores to choose from - a 1995 or a 2000. Both come from 1-ton trucks behind small block V8. Which would be the better starting point? Reading through the thread, I'm leaning towards the 2000. Both are same price. Thanks!

__________________

87 R30 CC Dually, TBI 454, NV4500, zero rust barn find 87 Jeep Grand Wagoneer, 6.5 turbodiesel, 700R4 |

|

|

|

|

|

#150 | |

|

Senior Member

Join Date: May 2009

Location: Fort Worth, TX

Posts: 6,370

|

Re: 4L80E & TH400 Tech.

Quote:

, I know.....You don't know 'til you open it up. , I know.....You don't know 'til you open it up.I would probably go with the 2000 model for the 34 element intermediate sprag. |

|

|

|

|

|

| Bookmarks |

|

|