|

|

|

|

|

#1 |

|

Registered User

Join Date: Jul 2006

Location: the netherlands europe

Posts: 4,335

|

Re: '66 Sunbeam Minx Project - F20C/6sp/4-link/Discs...

yeah it looks realy factory placed there

the electric motor of the setup is realy huge though most wipermotors i see in european cars are about the size of a normal size coca cola can

__________________

i got a job again and having fun at it too idea's for the trucks and the order of things to do are taking shape and get closer to being realized , a few more months and i be able to start building for real i complete 2 of the trucks intoo running fashion one custom and one basicly stock the thirth will be sacrificed for parts |

|

|

|

|

|

#2 | |

|

Registered User

Join Date: Aug 2005

Location: Hillsboro Oregon

Posts: 6,449

|

Re: '66 Sunbeam Minx Project - F20C/6sp/4-link/Discs...

Thanks man. It's this type of job that seems so simple but takes way too much time...

Quote:

|

|

|

|

|

|

|

#3 |

|

Registered User

Join Date: Apr 2008

Location: Redmond, WA

Posts: 679

|

Re: '66 Sunbeam Minx Project - F20C/6sp/4-link/Discs...

Wiper motor relocation is slick. Too bad no one will see...wait...that's the idea.

|

|

|

|

|

|

#4 |

|

Registered User

Join Date: Mar 2005

Location: apple valley, ca

Posts: 2,670

|

Re: '66 Sunbeam Minx Project - F20C/6sp/4-link/Discs...

I love your ability to think outside the box, and then use your amazing fab skills to make it all work. I think what I like the most about this build is how subtle and integrated your mods are. Anybody can build something and just bolt it in. It takes a skilled craftsman to make each piece work and then make it all look like it came that way from the factory. I don't see a lot of "credit card purchases" on this build, but I do see a lot of "hot rod recycling" of used parts, and to me, that's what this hobby is sorely missing. That's why I enjoy this build so much.

__________________

Check out my latest endeavor: https://roundsixpod.com My build threads: '55 Chevy: http://67-72chevytrucks.com/vboard/s...d.php?t=247512 '64 C-20: http://67-72chevytrucks.com/vboard/s...d.php?t=446527 |

|

|

|

|

|

#5 | ||

|

Registered User

Join Date: Aug 2005

Location: Hillsboro Oregon

Posts: 6,449

|

Re: '66 Sunbeam Minx Project - F20C/6sp/4-link/Discs...

Quote:

Quote:

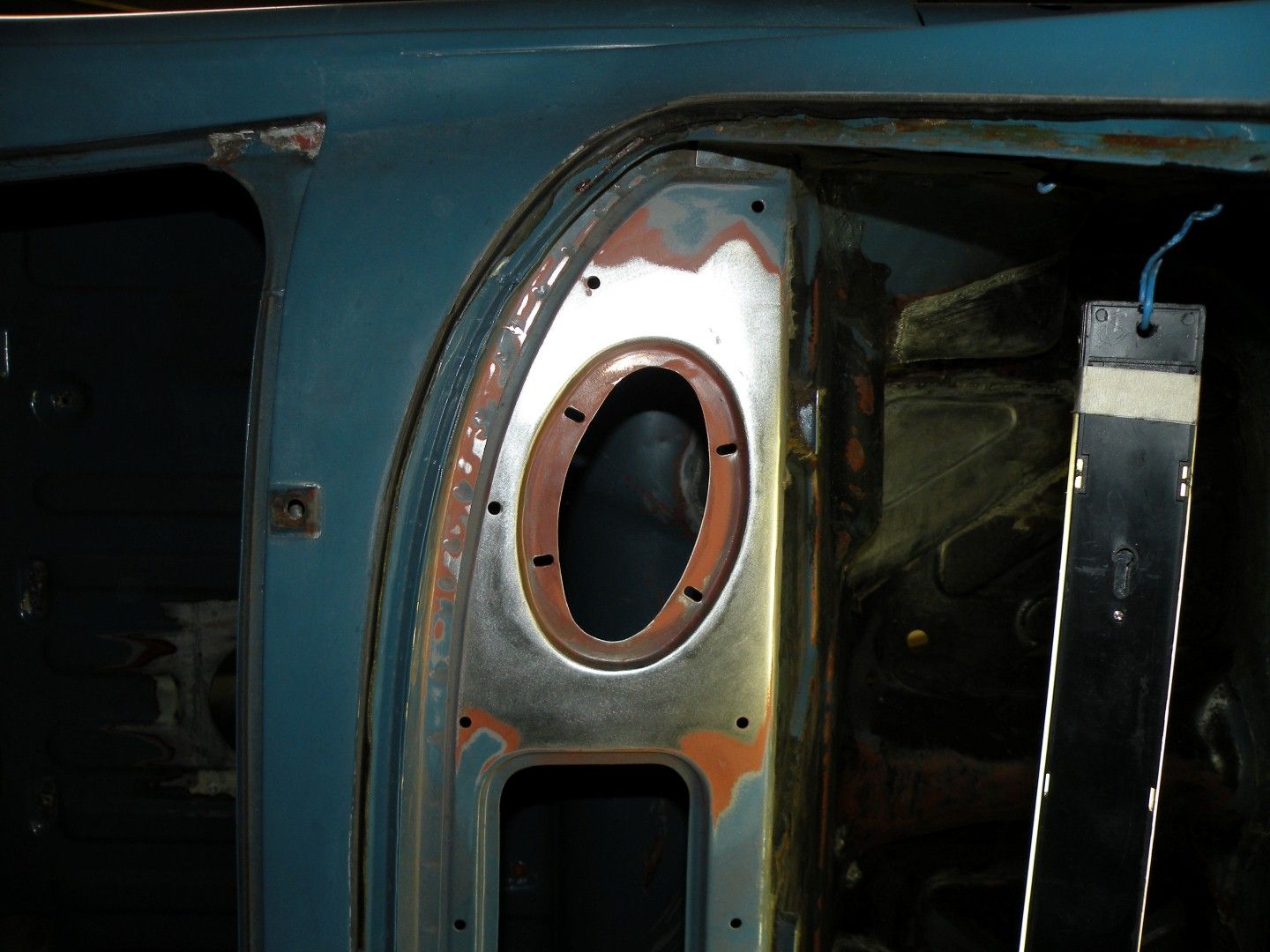

More subtle integration: Rear Deck - Second Speaker Provision Not only did this 66 Minx only have a spot for one rear deck speaker, it was apparently an optional upgrade because mine did not come with one installed  Since I had a spare Minx to pillage, this is one of the items donated to the cause. Here's the factory rear deck with only one speaker provision as I showed earlier:  Relieved of one side to allow alignment of the new panel:  New panel upside down to allow alignment of the matching holes and scribe lines:  Prep for surgery:  Weapon of choice and result:  I like to use low angle illumination to reveal the panel surface alignment:  Buzzed in:  Dressing:   Sealed from the elements:  Before and after:

|

||

|

|

|

|

|

#6 |

|

Registered User

Join Date: Feb 2007

Location: Marana, Arizona

Posts: 3,416

|

Re: '66 Sunbeam Minx Project - F20C/6sp/4-link/Discs...

[QUOTE=Frizzle Fry;6173280]

One consistent source of inspiration for me is build-threads.com But don't go there unless you have many hours to spend...  Oh man! Thanks a lot! Another site to interfere with me getting stuff done.

__________________

"I feel the need for speed!"... as soon as I am done with my nap. |

|

|

|

|

|

#7 |

|

Registered User

Join Date: Nov 2001

Location: Austin, TX

Posts: 308

|

Re: '66 Sunbeam Minx Project - F20C/6sp/4-link/Discs...

A couple of quick questions if you don't mind....?

When you do the fitment for a patch like this do you match the patch tightly to the opening, or do you leave a small gap around the perimeter (like the saw blade's width)?? It appears that you run with no gap at all which surprises me... it seems like that might encourage warpage or at least incomplete penetration of the weld to the back side? Most of my patches are cut with a fiber cutoff wheel which is .040" thick, and that ends up being my gap between my parts. I get pretty good results, but it's definitely hard to "bridge" the weld across the two panels to fill that small gap. I get good penetration to the other side and when I'm done (moving around a lot and allowing for lots of cooling) the results seem good with no warpage. It seems like you might have an easier way to accomplish the same thing, and I'm always looking for better methods to experiment with. What sort of product do you use for the final dressing of the welds? Roloc "green" discs? Roloc crimson discs? The end result is gorgeous with no waviness or signs of gouging or other imperfections... I'd love to know the secret to getting an end-result like that!  Excellent work as always... I've enjoyed this thread from the very beginning. -G

__________________

1972 K5 - 502BBC/4L80E/Magnum205/Mog-9s/5.26s/38" BFG KM2s Find me on INSTAGRAM @MIGHTASWELLK5 '72 K5 - Greg's "Might As Well™" Build |

|

|

|

|

|

#8 |

|

Registered User

Join Date: Feb 2010

Location: Fallbrook, CA

Posts: 910

|

Re: '66 Sunbeam Minx Project - F20C/6sp/4-link/Discs...

An acoustic bass guitar - not something you see everyday.

|

|

|

|

|

|

#9 | |||

|

Registered User

Join Date: Aug 2005

Location: Hillsboro Oregon

Posts: 6,449

|

Re: '66 Sunbeam Minx Project - F20C/6sp/4-link/Discs...

Quote:

Quote:

Quote:

I was wondering if anyone would catch that. Good eye. |

|||

|

|

|

|

|

#10 | |

|

Still Learning

Join Date: Jul 2009

Location: Central Oklahoma

Posts: 10,108

|

Re: '66 Sunbeam Minx Project - F20C/6sp/4-link/Discs...

Awesome metal work as always!

Quote:

I just figured it was because I got the panel too hot and caused the warping. BTW, I have never had any penetration issues with my mig or tig with no gap. thanks for all the detailed explainations. |

|

|

|

|

|

|

#11 |

|

VA72C10

Join Date: Mar 2008

Location: Midlothian, VA

Posts: 25,269

|

Re: '66 Sunbeam Minx Project - F20C/6sp/4-link/Discs...

nice and subtle and super clean!

__________________

Looking for a 67-72 swb or blazer project in or around VA.

|

|

|

|

|

|

#12 |

|

Registered User

Join Date: Apr 2003

Location: Indep, MO

Posts: 5,893

|

Re: '66 Sunbeam Minx Project - F20C/6sp/4-link/Discs...

Nice! Do they make a speaker that fits that opening, or are you going to plate them and use rounds?

Posted via Mobile Device

__________________

Boppa's Old Yeller Truck Build, Old Yeller's New Heart! Project Buzz Bomb Flyin' Low! |

|

|

|

|

|

#13 | |

|

Registered User

Join Date: Aug 2005

Location: Hillsboro Oregon

Posts: 6,449

|

Re: '66 Sunbeam Minx Project - F20C/6sp/4-link/Discs...

Thanks brotha

Quote:

Yes, the opening is 5x7. Plenty of options in that size. Yes, the opening is 5x7. Plenty of options in that size.

|

|

|

|

|

|

|

#14 |

|

Tot Roddin'

Join Date: Apr 2005

Location: Mid-MO

Posts: 24,461

|

Re: '66 Sunbeam Minx Project - F20C/6sp/4-link/Discs...

Awesome work!

__________________

-Nate  1969 CST SWB - Project Blank Slate (4.5/6" ECE Static Drop, 6-lug disc brake upgrade (manual), Billet Specialties Vintec 20x8.5 255/40 (F) 20x10 295/40 (R), 250 I-6) 1960 AMF Skylark - Tot Roddin' (Lowered with custom frame; soon to include custom push bar and interior) 2008 Silverado CrewCab 1LT (5.3L, 3:73, 4x4, LT1, Z-71, Towing Package) |

|

|

|

|

|

#15 |

|

Registered User

Join Date: Aug 2005

Location: Hillsboro Oregon

Posts: 6,449

|

Re: '66 Sunbeam Minx Project - F20C/6sp/4-link/Discs...

|

|

|

|

|

|

#16 |

|

Registered User

Join Date: Aug 2005

Location: Hillsboro Oregon

Posts: 6,449

|

Re: '66 Sunbeam Minx Project - F20C/6sp/4-link/Discs...

I can only guess at the mechanics behind it. It may be that when you tack next to the gapless point the joint is pulled tighter as the weld shrinks and the gapless area has no where to go but lateral. Or maybe a small expansion area is needed. Not sure. I can only speak from experience. While doing the Tahoe roof, for example, gapless points along that long and relatively flat joint wanted to bow up. Only when I opened them with a cutoff wheel did they cooperate.

|

|

|

|

|

|

#17 | |

|

Still Learning

Join Date: Jul 2009

Location: Central Oklahoma

Posts: 10,108

|

Re: '66 Sunbeam Minx Project - F20C/6sp/4-link/Discs...

Quote:

|

|

|

|

|

|

|

#18 |

|

Registered User

Join Date: Aug 2005

Location: Hillsboro Oregon

Posts: 6,449

|

Re: '66 Sunbeam Minx Project - F20C/6sp/4-link/Discs...

I'm a full-on believer in this drivetrain after driving it around for a week. Performance was beyond all expectations!

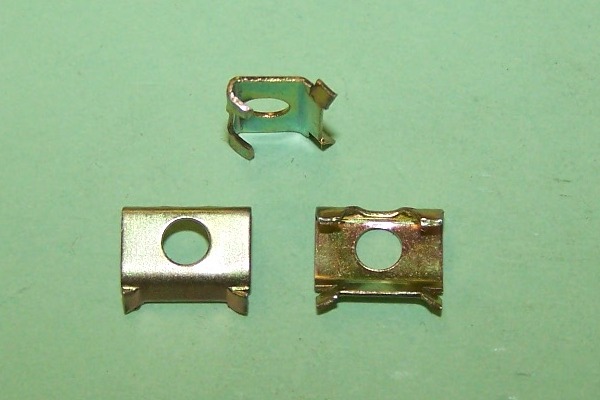

Need a little help here guys. Gathering the last few items needed (that I'm currently aware of). Need to replace the trim clips. They are a cup washer style attached via pop-rivet. Didn't realize they are apparently made of unobtanium based on the price.  Anyone know of a US supplier for these? That site says they are also used for Austin Mini Cooper 'S', Riley Elf, and Wolseley Hornet. Alternative suggestions welcome. |

|

|

|

|

|

#19 |

|

Registered User

Join Date: Mar 2005

Location: apple valley, ca

Posts: 2,670

|

Re: '66 Sunbeam Minx Project - F20C/6sp/4-link/Discs...

Wow, very nice work on the speaker!

Again, so nicely done that it appears that the factory put it there in 1966. I love that kind of attention to detail!

__________________

Check out my latest endeavor: https://roundsixpod.com My build threads: '55 Chevy: http://67-72chevytrucks.com/vboard/s...d.php?t=247512 '64 C-20: http://67-72chevytrucks.com/vboard/s...d.php?t=446527 |

|

|

|

|

|

#20 | |

|

Still Learning

Join Date: Jul 2009

Location: Central Oklahoma

Posts: 10,108

|

Re: '66 Sunbeam Minx Project - F20C/6sp/4-link/Discs...

Quote:

|

|

|

|

|

|

|

#21 |

|

Registered User

Join Date: Jul 2006

Location: the netherlands europe

Posts: 4,335

|

Re: '66 Sunbeam Minx Project - F20C/6sp/4-link/Discs...

i think thats a better option , as long as you either make those in stainless or zinkplate them

maibe pushbuttons will work too

__________________

i got a job again and having fun at it too idea's for the trucks and the order of things to do are taking shape and get closer to being realized , a few more months and i be able to start building for real i complete 2 of the trucks intoo running fashion one custom and one basicly stock the thirth will be sacrificed for parts |

|

|

|

|

|

#22 |

|

Registered User

Join Date: Feb 2010

Location: Fallbrook, CA

Posts: 910

|

Re: '66 Sunbeam Minx Project - F20C/6sp/4-link/Discs...

How about buying "cup washers" (without the rivet) and then use a rivet to attach it?

http://www.hkmetalcraft.com/Products...1-5800CP.shtml |

|

|

|

|

|

#23 | ||

|

Registered User

Join Date: Aug 2005

Location: Hillsboro Oregon

Posts: 6,449

|

Re: '66 Sunbeam Minx Project - F20C/6sp/4-link/Discs...

Thanks man!

Quote:

Thanks for the idea. They'ed have to be ~7.9-8.1mm diameter and couldn't have a shoulder. Quote:

Some good news though. I was able to recover ~50 of these things out of the dirt/debris in front of the shop with a magnet wand and compressed air...  It was kinda fun It was kinda fun  Then I checked the spare fenders/doors I pulled from that parts Minx and found that they have a different style clip. Like this:  So worst case scenario I can restore all the originals clips from the two cars and I'm covered. New stainless is sounding better and better... |

||

|

|

|

|

|

#24 |

|

Registered User

Join Date: Jul 2006

Location: the netherlands europe

Posts: 4,335

|

Re: '66 Sunbeam Minx Project - F20C/6sp/4-link/Discs...

maibe you can find them small enough and mount them backwarths so the shoulder becomes the edge holding the trim on

__________________

i got a job again and having fun at it too idea's for the trucks and the order of things to do are taking shape and get closer to being realized , a few more months and i be able to start building for real i complete 2 of the trucks intoo running fashion one custom and one basicly stock the thirth will be sacrificed for parts |

|

|

|

|

|

#25 |

|

Registered User

Join Date: May 2011

Location: Anderson SC

Posts: 3,882

|

Re: '66 Sunbeam Minx Project - F20C/6sp/4-link/Discs...

Just sayin...

__________________

Project Goldilocks '66 C10 Short Fleet BBW Build '65 C10 Highly Detailed Stock Restoration Thread '78 Camaro Targa Roof Build '55 International Metal/Body/Paint Work '66 F100 Full Rotisserie Restoration '40 Packard 120 Convertible Coupe Restoration How To Restore and Detail an Original Gauge Cluster How To Detail Sand Body Panels, Edges, Corners, Etc |

|

|

|

|

| Bookmarks |

|

|