|

|

|

|

|

#1 | |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,647

|

Re: 55 Wagon Progress

Quote:

__________________

Robert |

|

|

|

|

|

|

#2 |

|

Registered User

Join Date: Oct 2007

Location: Spanaway

Posts: 8,451

|

Re: 55 Wagon Progress

Tips on making couture templates?? what tools you use? I tried making one out of cardboard but that was a total failure LOL!

__________________

Mike. Swamp Rat build thread : http://67-72chevytrucks.com/vboard/s...d.php?t=595019 72 3/4T 4X4 4" BDS Lift 33" BFG's |

|

|

|

|

|

#3 | |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,647

|

Re: 55 Wagon Progress

Quote:

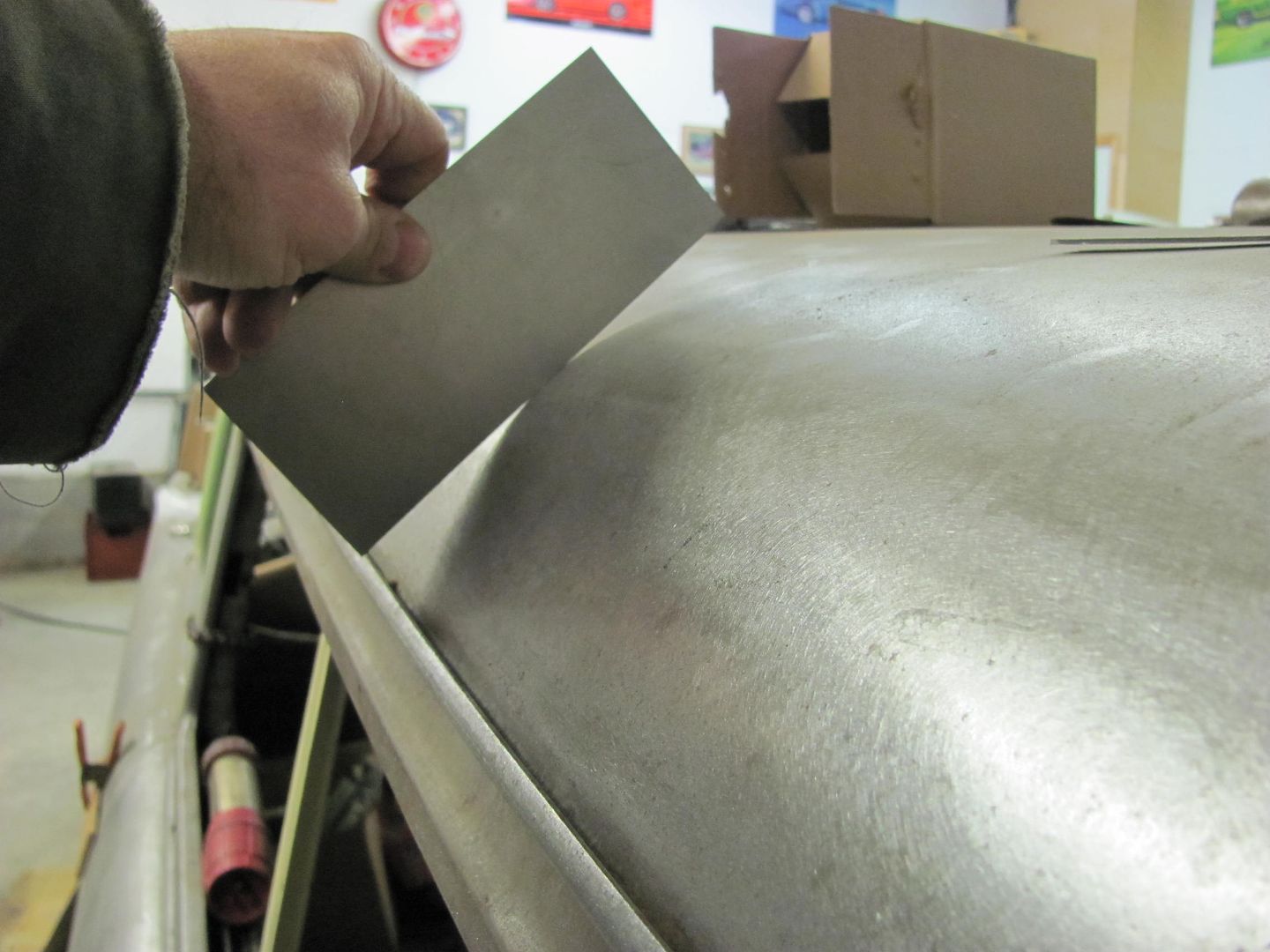

I used a scrap piece of 18 ga steel, held it against the roof, and opened up a compass to make a parallel mark. Cut it out on the band saw, checked the fit again, remarked, cut again...

__________________

Robert |

|

|

|

|

|

|

#4 |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,647

|

Re: 55 Wagon Progress

Just to clarify the process used for making the roof template....

Start with a profile "blank" and span the profile you need to copy.  Using a compass, open up the span to insure it is wide enough to make the mark on the blank on both ends ...  Don't rotate the compass as you move it, this will make the radius larger than the original. Keep it "locked" pointed in the same direction as you glide across the roof surface, leaving the profile to cut....  Cut with a band saw, jig saw, tin snips, whatever is easiest for you and most accurate. Test fit and adjust as needed. .

__________________

Robert |

|

|

|

|

|

#5 |

|

Registered User

Join Date: Apr 2011

Location: .

Posts: 3,104

|

Re: 55 Wagon Progress

Thank you for this tid bit of info. As obvious as it is I learned something.

|

|

|

|

|

|

#6 |

|

Registered User

Join Date: Oct 2007

Location: Spanaway

Posts: 8,451

|

Re: 55 Wagon Progress

Yep, I appreciate it too!

__________________

Mike. Swamp Rat build thread : http://67-72chevytrucks.com/vboard/s...d.php?t=595019 72 3/4T 4X4 4" BDS Lift 33" BFG's |

|

|

|

|

|

#7 |

|

Registered User

Join Date: Dec 2011

Location: Donaldsonville, La.

Posts: 1,024

|

Re: 55 Wagon Progress

Thank you for taking the time to show others like me how to do this. It's really appreciated and I've learned alot.

|

|

|

|

|

|

#8 |

|

Registered User

Join Date: Oct 2012

Location: Sweden - Gävle

Posts: 76

|

Re: 55 Wagon Progress

Im sitting here looking at the blinking marker in this text box and trying to figure out something flattering to type.. I thought that I was starting to learn how to do metal work.. but.. I.. you are a true inspiration! That knowledge you have is priceless.. I hope there is someone in your surrounding that can inherit your skills

thanks for sharing your work!

__________________

Johnny G -----------Vehicles-------------- * Chevrolet C-10 Stepside 1962 * Audi A4 Avant Quattro TDI 2008 * Sachs Compact 50cc 1967 |

|

|

|

|

|

#9 |

|

Registered User

Join Date: Apr 2011

Location: .

Posts: 3,104

|

Re: 55 Wagon Progress

Well, I started working on my 5" stretch cab '66 pickup roof skin project.

This is my second attempt on the skin. Before I read your thread my first attempt started well but crashed and burn. After studying your spot weld,planish,grind repeat I have a great start. Something doesn't feel like its going with the flow you have supplied the info on what to do next to get things back on track. Priceless! I have followed every step like you did on the '55 roof section. It is turning out WAY better this time than last. Planishing. I made some practice pieces like you did to show the full penetration spot welds. Learned how the metal is effected and studied how it moves. The way you show gives a guy a lot more control working the metal. Learned tons watchin. Thanks. You Sir have some, if not all, Serious Skillz Thank you again. |

|

|

|

|

|

#10 |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,647

|

Re: 55 Wagon Progress

Glad to hear it helped! Thanks for all the comments guys!

__________________

Robert |

|

|

|

|

|

#11 |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,647

|

Re: 55 Wagon Progress

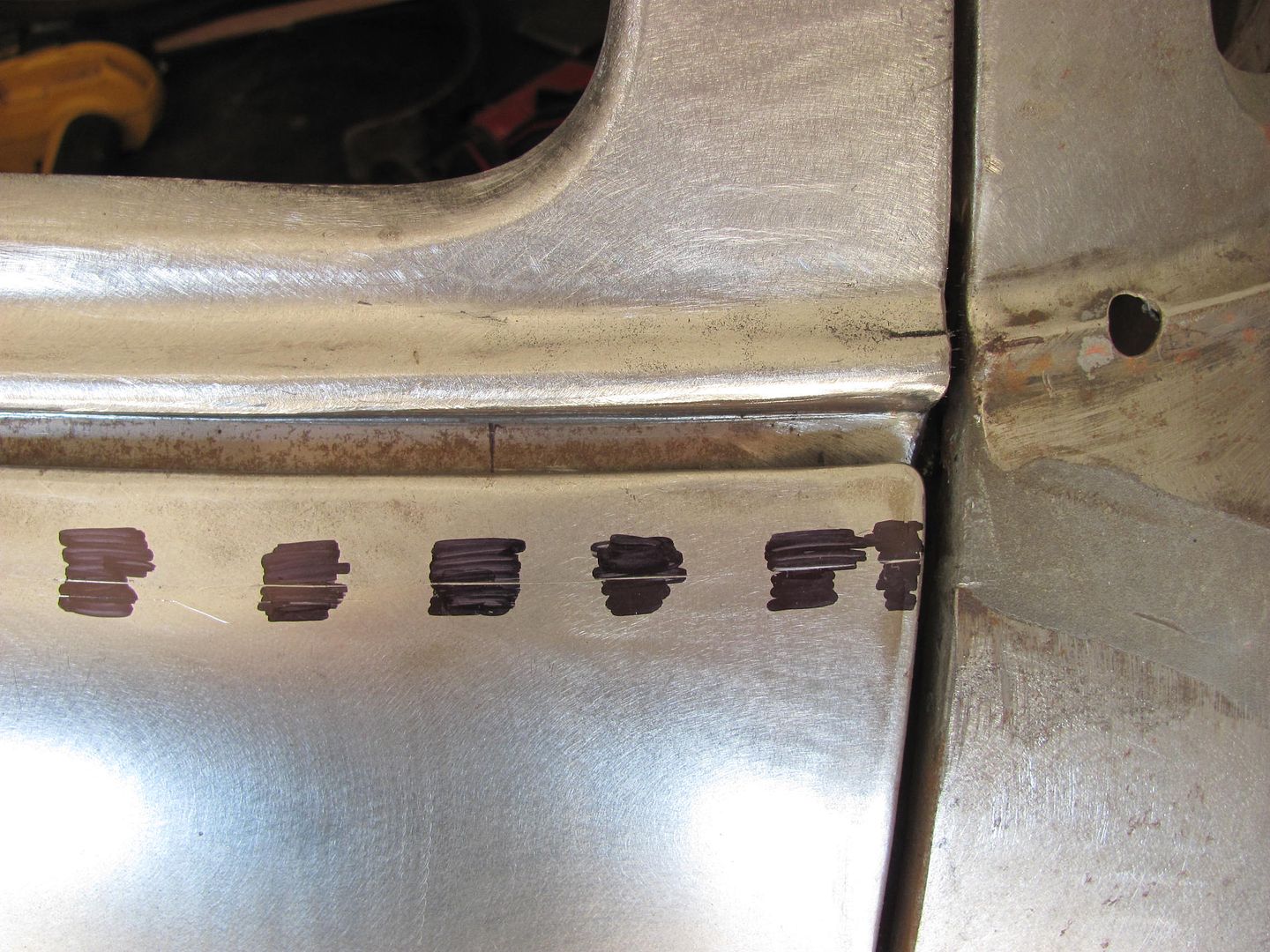

Trying to finalize the rear end of this car.. The tailgate skin didn't align too well to the upper lift gate, the gap was way out of whack. I guess this is what I get for installing the skin based on the old tailgate.

Note to self, don't fold door skins unless adjacent panel is there to set gaps..  Time to break out the door skin removal tool....    Flange unfolded....  Spoon was slid between the skin and inner panel and body hammer used to flatten out the crease...  Right side flange is now a bit short, so added a strip of metal..    Flange re-folded, just needs some fine tuning and finishing the corners..    Much better...

__________________

Robert |

|

|

|

|

|

#12 |

|

Registered User

Join Date: Oct 2007

Location: Spanaway

Posts: 8,451

|

Re: 55 Wagon Progress

I understand all you did right up to the folding it over.

The outer skin was originally rolled over against the inner panel correct? but the outside edges of the inner panel were probably a little low creating the gap between the gate, so i guess you just placed a back up dolly where ya wanted the new fold to be? or did you also extend the inner panel lip as well? I hope that made sense..

__________________

Mike. Swamp Rat build thread : http://67-72chevytrucks.com/vboard/s...d.php?t=595019 72 3/4T 4X4 4" BDS Lift 33" BFG's |

|

|

|

|

|

#13 |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,647

|

Re: 55 Wagon Progress

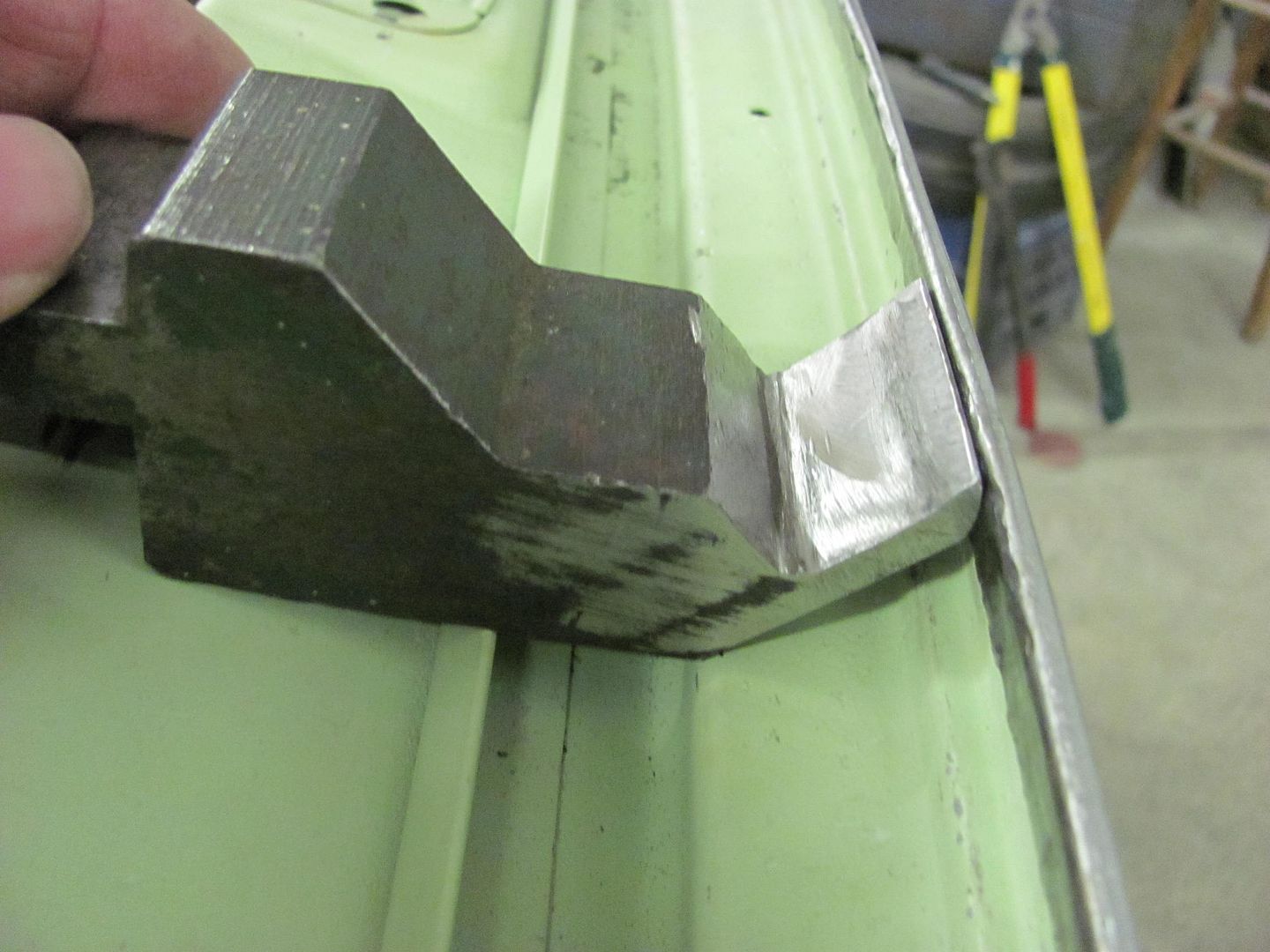

The inner panel's lip was left as was. I'll get some pics this evening of the tools used to fold the flange...

__________________

Robert |

|

|

|

|

|

#14 |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,647

|

Re: 55 Wagon Progress

Here's the tools used to re-fold the flanges. (don't mind the hammer marks)

A mark was used on the front to indicate the new fold line. This press brake die was placed against the back side, and the flange tapped over. A flush tap against the face every now and then keeps the folded edge crisp..  That took the flange over about 90 degrees, then this modified gooseneck die was used to take it over to about 135 degrees...  At this point the gate was closed to verify gaps. A door skin hammer on the inside and a dolly against the outside skin was used to complete the fold..

__________________

Robert |

|

|

|

|

|

#15 |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,647

|

Re: 55 Wagon Progress

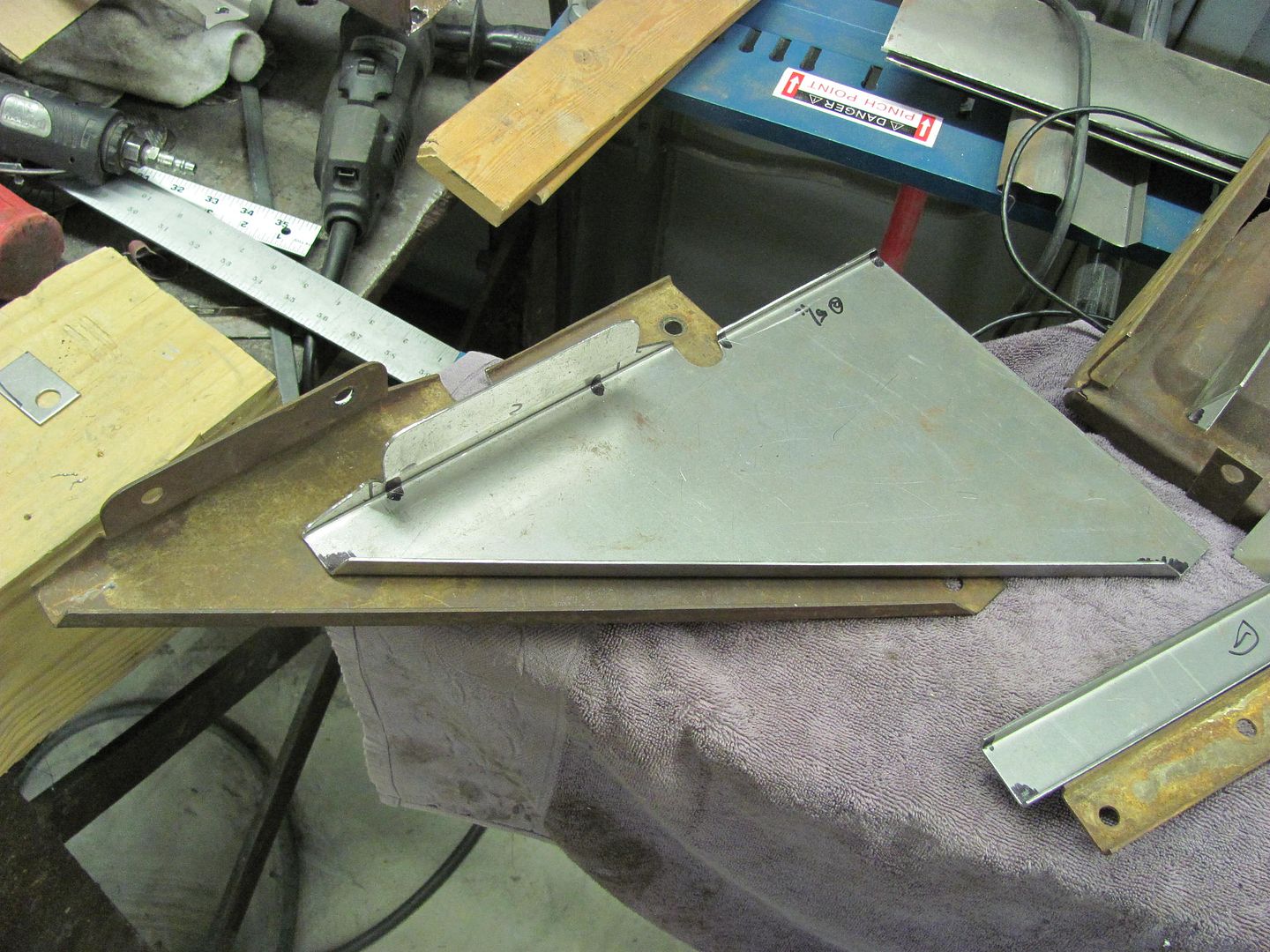

Worked tonight on building new mounting brackets for the 55's battery tray..

This bracket supports the battery tray, bolts to the core support..   This bracket spot welds to the bottom of the tray and bolts to the inner fender.     This bracket goes on the wheel side of the inner fender well as a backer to bolt through.   The tabs spot weld to the ends of the tray for the battery hold downs..  Now just need to finish drilling holes and weld the parts to the "new" tray..

__________________

Robert |

|

|

|

|

|

#16 |

|

Registered User

Join Date: Apr 2005

Location: redding ca

Posts: 1,438

|

Re: 55 Wagon Progress

Wow impressive metal working!

|

|

|

|

|

|

#17 |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,647

|

Re: 55 Wagon Progress

Thanks!

Had a bit of time in the shop this evening, so I worked some more on the rear of the wagon... I had left the outer part of the lower repair patch's seam of the lift gate (going through the bead detail) un-welded until the flanges all got folded, so tonight I got one side of that finished up...   Then the welds were cleaned up and some more tweaking of the tailgate gaps....    Much better...

__________________

Robert |

|

|

|

|

|

#18 |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,647

|

Re: 55 Wagon Progress

Got the tail gate and lift gate gaps done this evening.

Now on to some quarter panel weld planishing..

__________________

Robert |

|

|

|

|

|

#19 |

|

Registered User

Join Date: May 2013

Location: Centerville,Ma.

Posts: 1,223

|

Re: 55 Wagon Progress

Looking nice good fit. A few post back someone asked about mixing small amounts of epoxy, I have a set of stainless measuring spoons from the dollar store that are great for small mixes to touch up with a brush. They are easy to clean too.

|

|

|

|

|

|

#20 |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,647

|

Re: 55 Wagon Progress

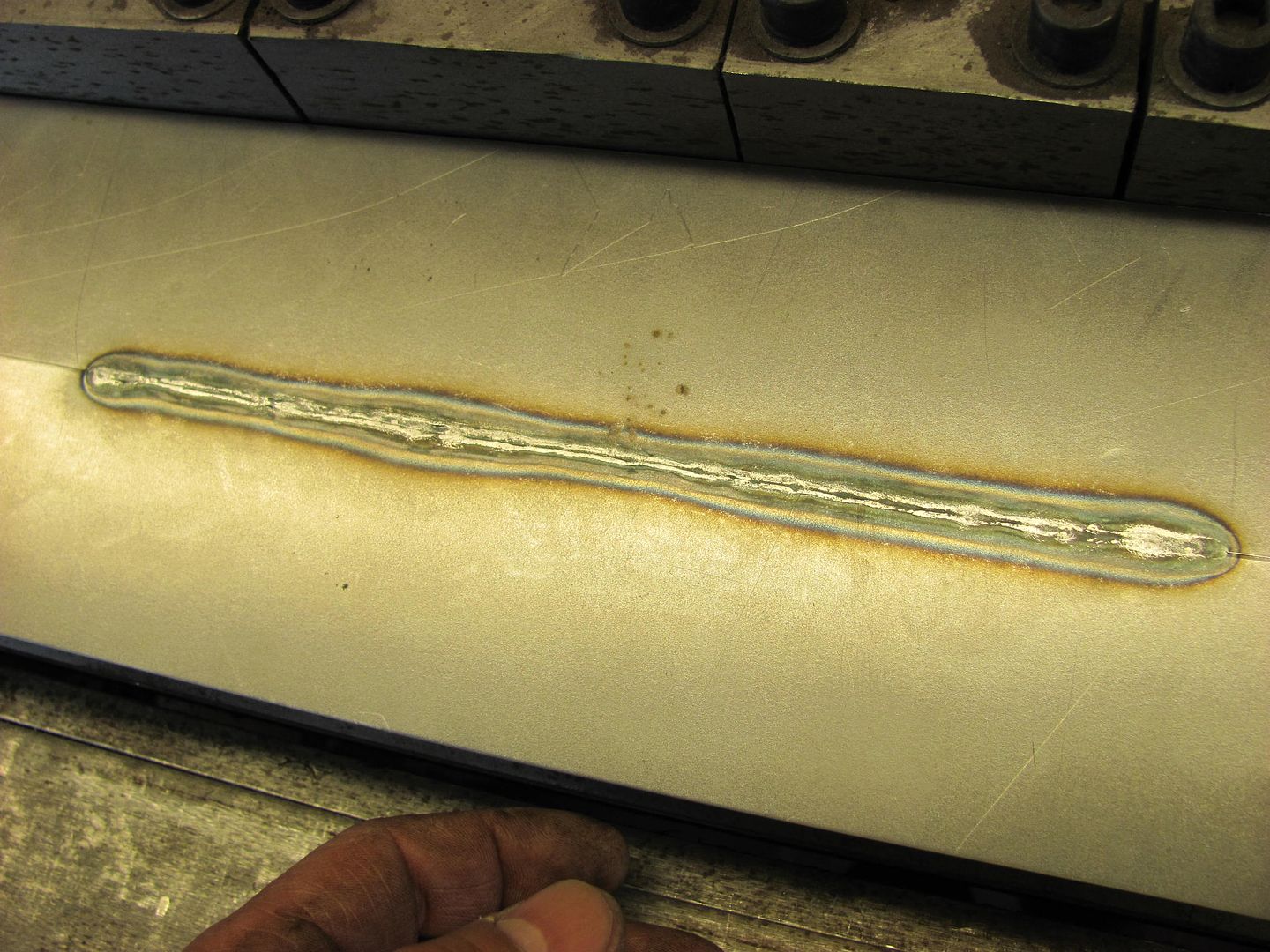

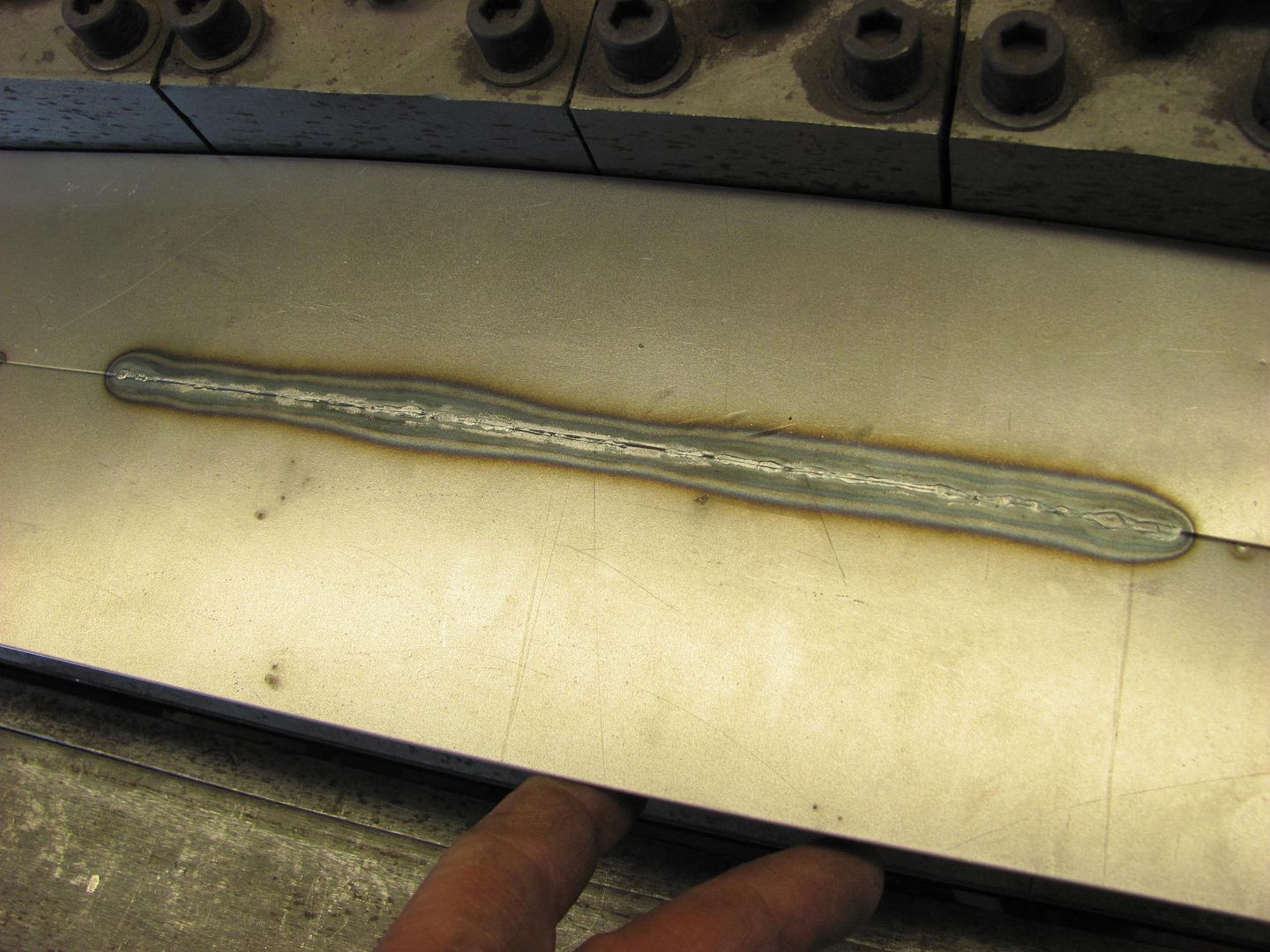

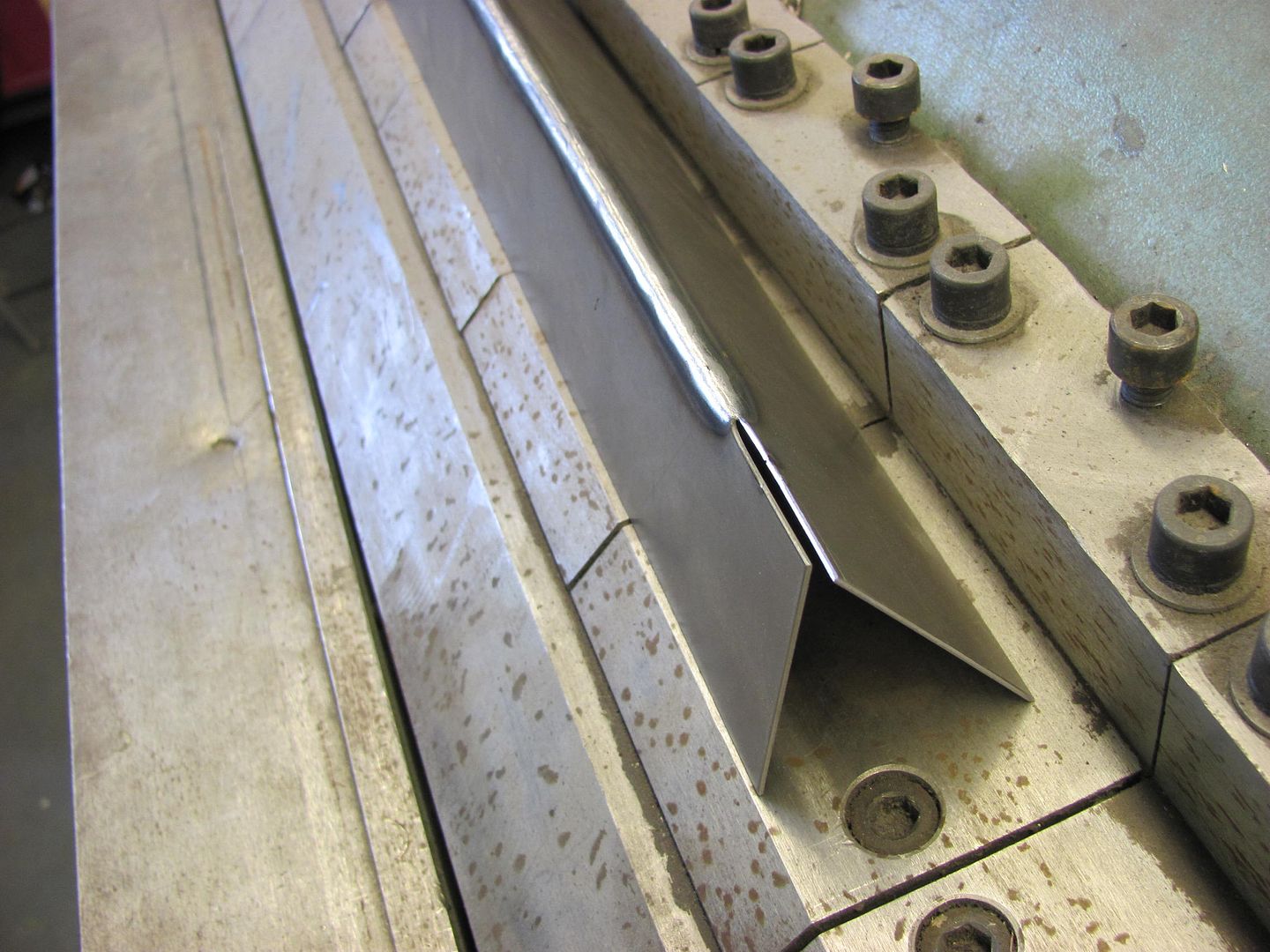

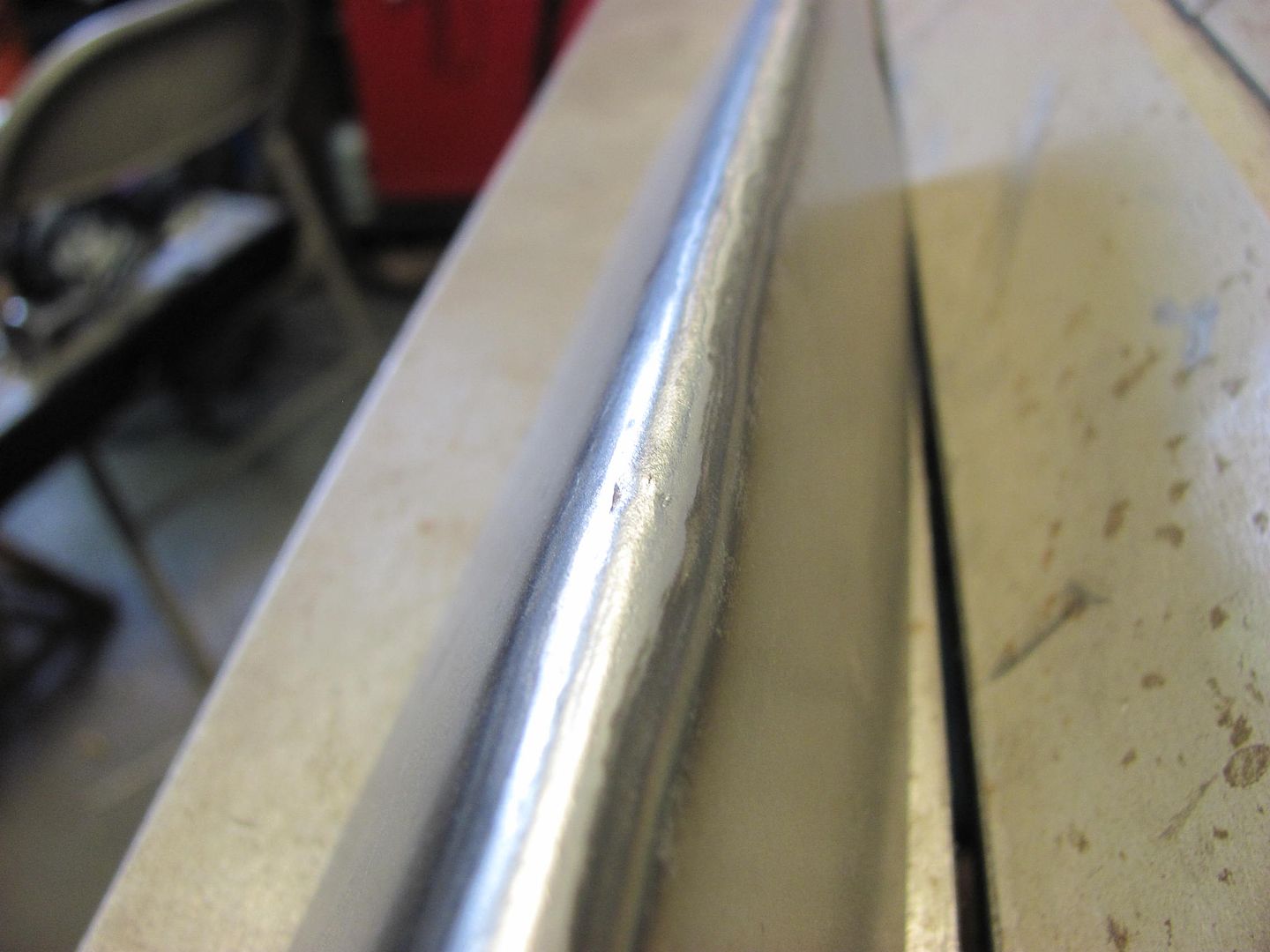

Thanks for the tips!

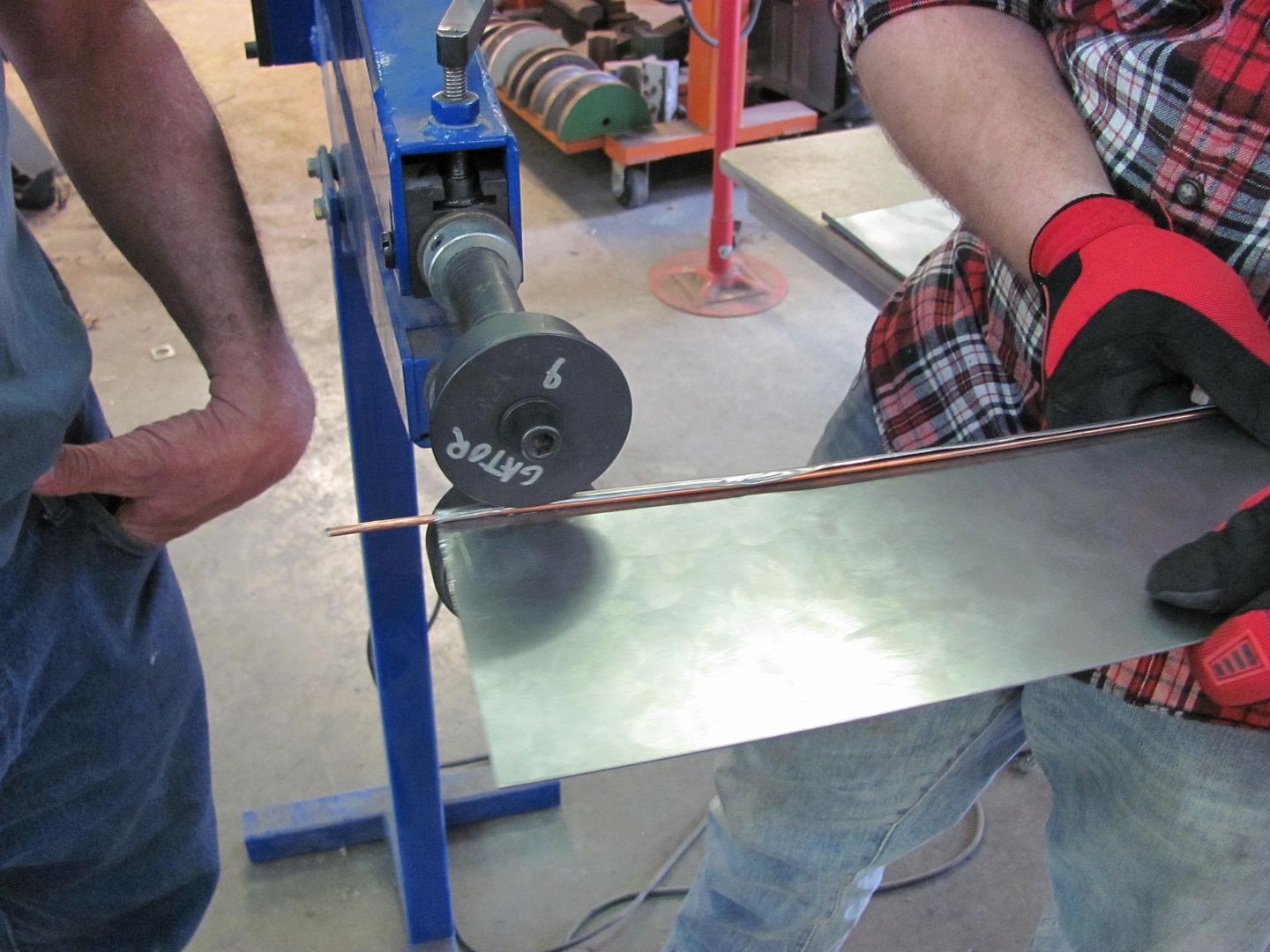

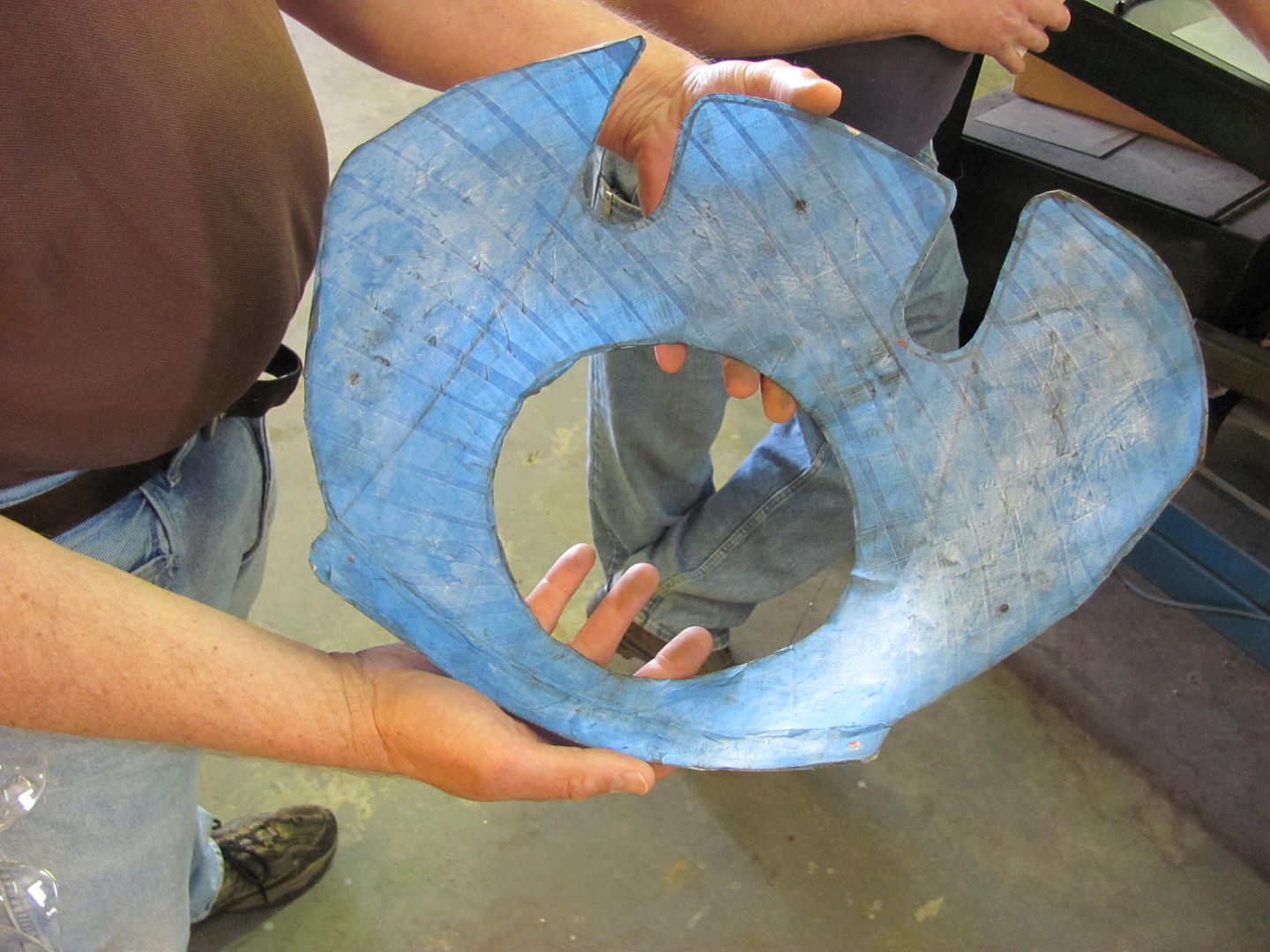

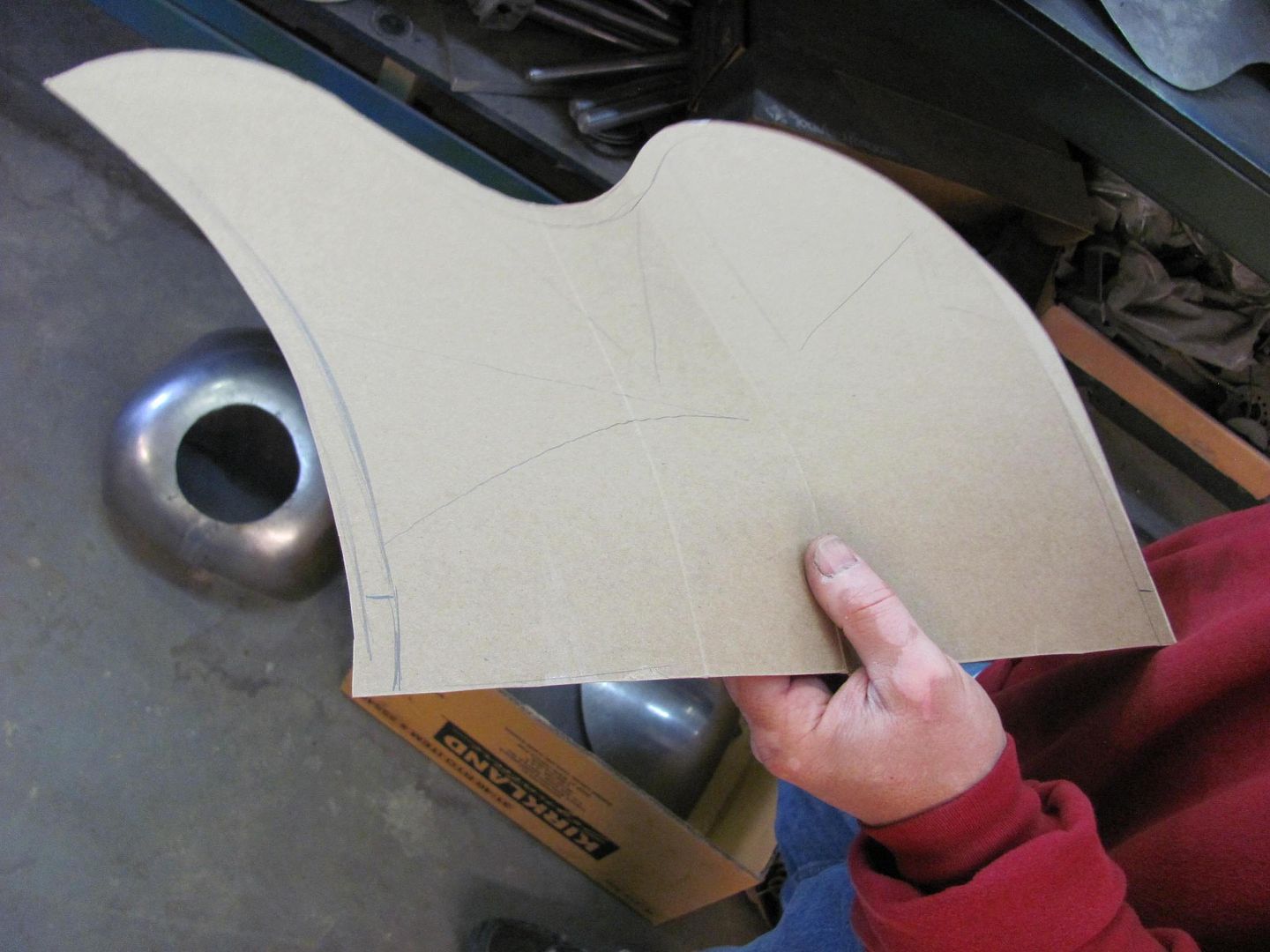

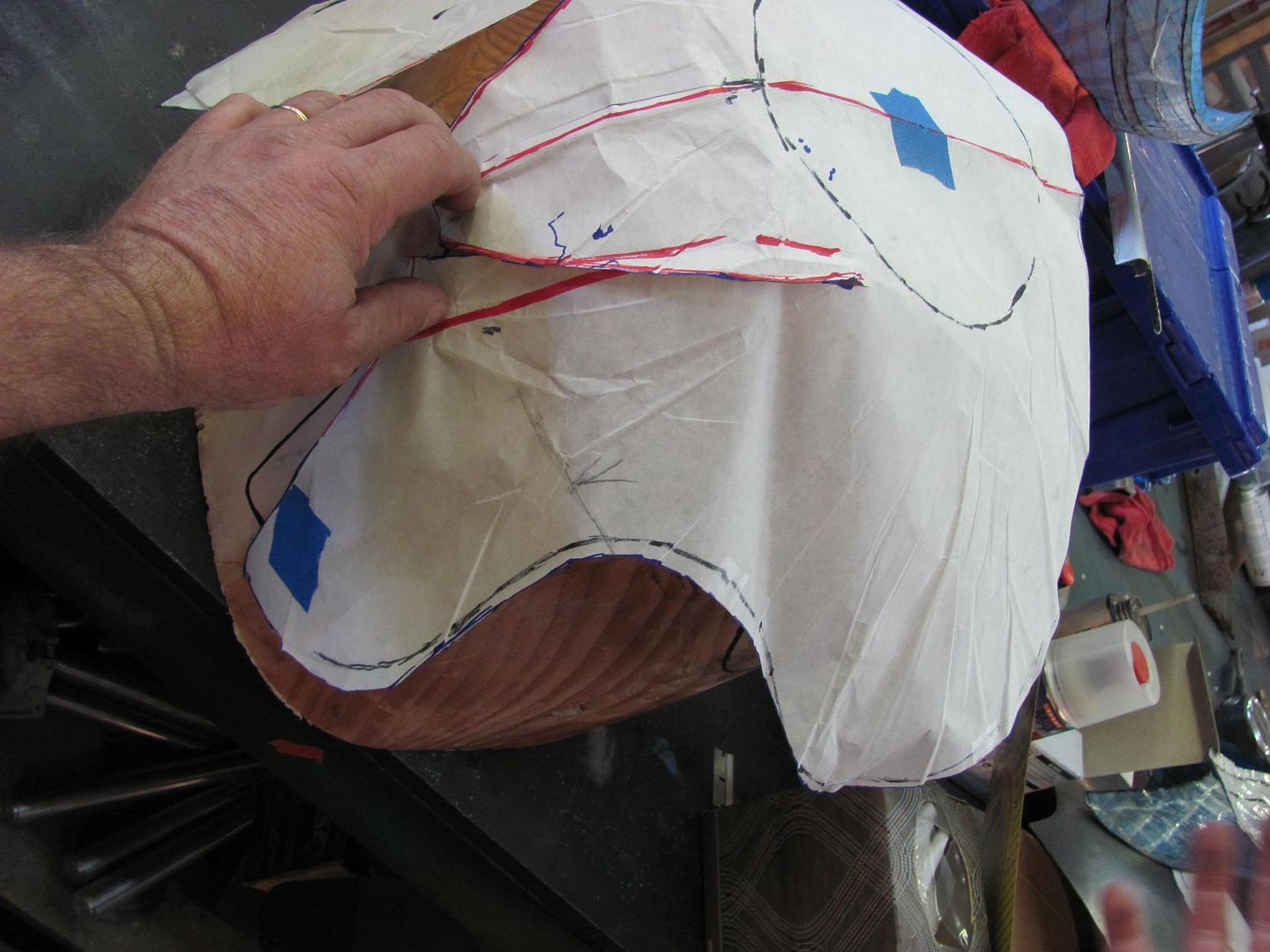

Spent this past weekend at Gatormeet for a metal shaping workshop. The first day started with a tuck shrinking demo, and showing the basics of the process and how the metal reacts. We also had the tuck shrinking fixture to use.     Camaro quarter panels are being fitted with gills for installation on a Firebird. This included fit up, trimming, Tig welding, and planishing..        The International farm truck had returned, so we were able to see the finished fenders from last year..     The rear fenders need reproducing as well, so the wire edging this year used bead roller dies..   We also discussed using hammer forms, and various pattern methods to determine shape..           Our new attendee this year learning some shaping...  Some rear corners fabricated for a truck bed..  Some practice at fusion welding using the Tig, here's the front showing some slight undercutting..  The rear side shows some good weld penetration in some areas and needs more practice in others..  Just to show that slight undercutting on fusion welding was not an issue in the joint's strength, the seam was clamped in the apron brake and bent to 135 degrees, with no detriment to the weld..   Saturday afternoon we spent some time discussing tips and tricks to help productivity and also to help open up to new methods and ideas. Here is a rotisserie style mount for a door, helping to locate it for ease of welding or other panel repairs....   Another project that Gator just picked up was this Camaro. The previous owner's substandard welding attempts severely warped and damaged many of the panels where most of the exterior panels will need replacing..        Looks like a project for the next Gatormeet! All in all, an awesome weekend for sharing and learning methods and ideas..

__________________

Robert |

|

|

|

|

|

#21 |

|

Registered User

Join Date: Oct 2007

Location: Spanaway

Posts: 8,451

|

Re: 55 Wagon Progress

I would love to be able to attend a metal shaping workshop some day, i don't even know if they have something like that around here. At least i have some experience with shrinkers and stretchers, although don't own any of my own.

__________________

Mike. Swamp Rat build thread : http://67-72chevytrucks.com/vboard/s...d.php?t=595019 72 3/4T 4X4 4" BDS Lift 33" BFG's |

|

|

|

|

|

#22 |

|

Registered User

Join Date: May 2007

Location: Deale Md

Posts: 4,663

|

Re: 55 Wagon Progress

How does one get a invite.

__________________

James 63 GMC V6 4speed carryall 65 chevy swb bbw V8 auto 68 K20 327/4 speed, buddy buckets 2002 GMC CC Dually Duramax 64 GMC lwb 3/4 V6 4speed SOLD 66 GMC swb bbw buddy buckets SOLD IG duallyjams The only thing that stays the same is constant change! |

|

|

|

|

|

#23 | |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,647

|

Re: 55 Wagon Progress

Quote:

Where are you located? Peter Tommasini is going to be giving some workshops later this year.. Gator normally announces his meets on either Metalmeet or Allmetalshaping...

__________________

Robert |

|

|

|

|

|

|

#24 |

|

Registered User

Join Date: Oct 2007

Location: Spanaway

Posts: 8,451

|

Re: 55 Wagon Progress

Washington state. I hear its pretty pricy too.. I'll google the Metalmeet or Allmetalshaping sites.

__________________

Mike. Swamp Rat build thread : http://67-72chevytrucks.com/vboard/s...d.php?t=595019 72 3/4T 4X4 4" BDS Lift 33" BFG's |

|

|

|

|

|

#25 |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,647

|

Re: 55 Wagon Progress

Swamprat, Larry at West Coast Metalshapers was asking if anyone was interested in a PNW metalshaping meet. Check it out....

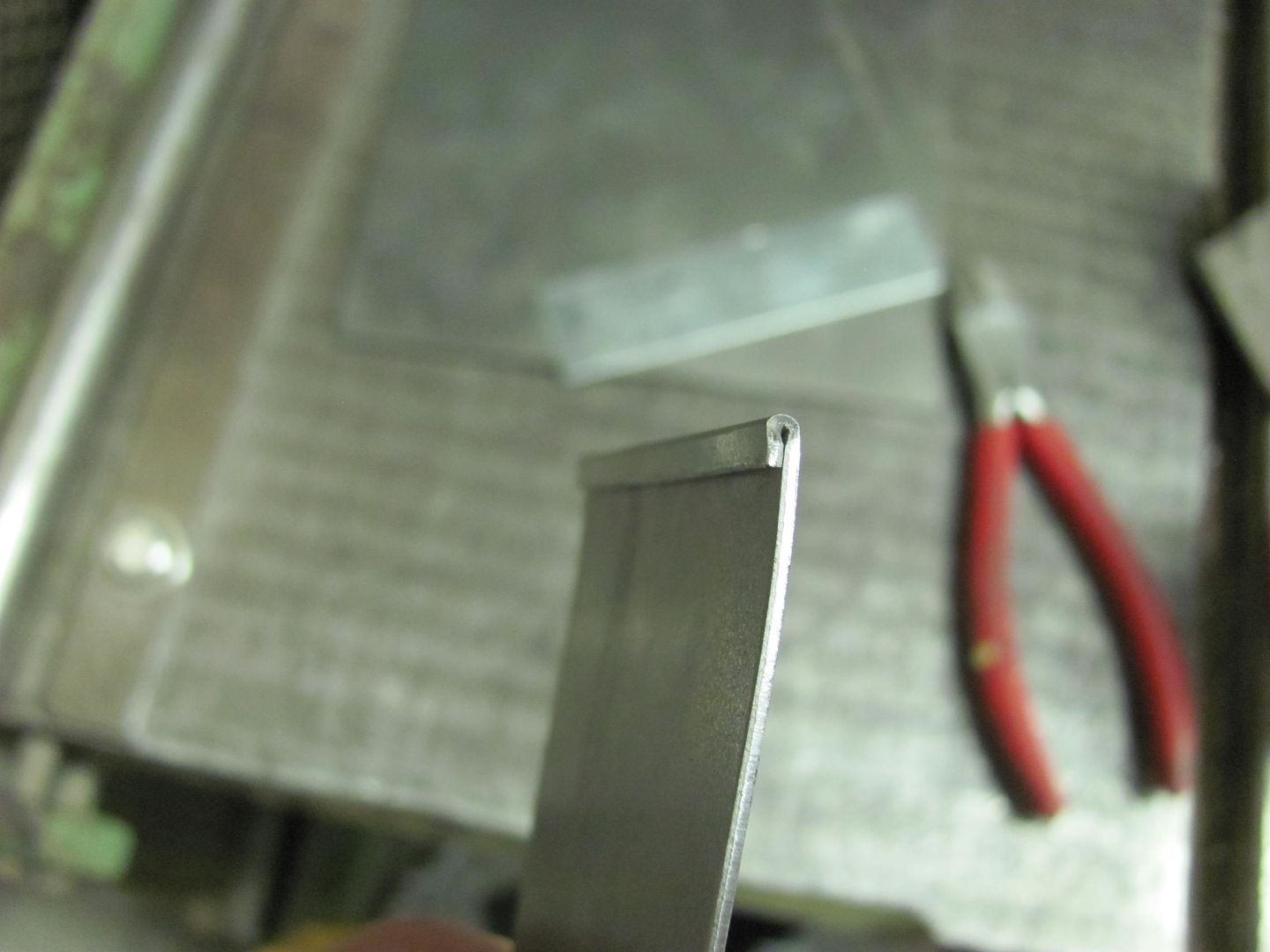

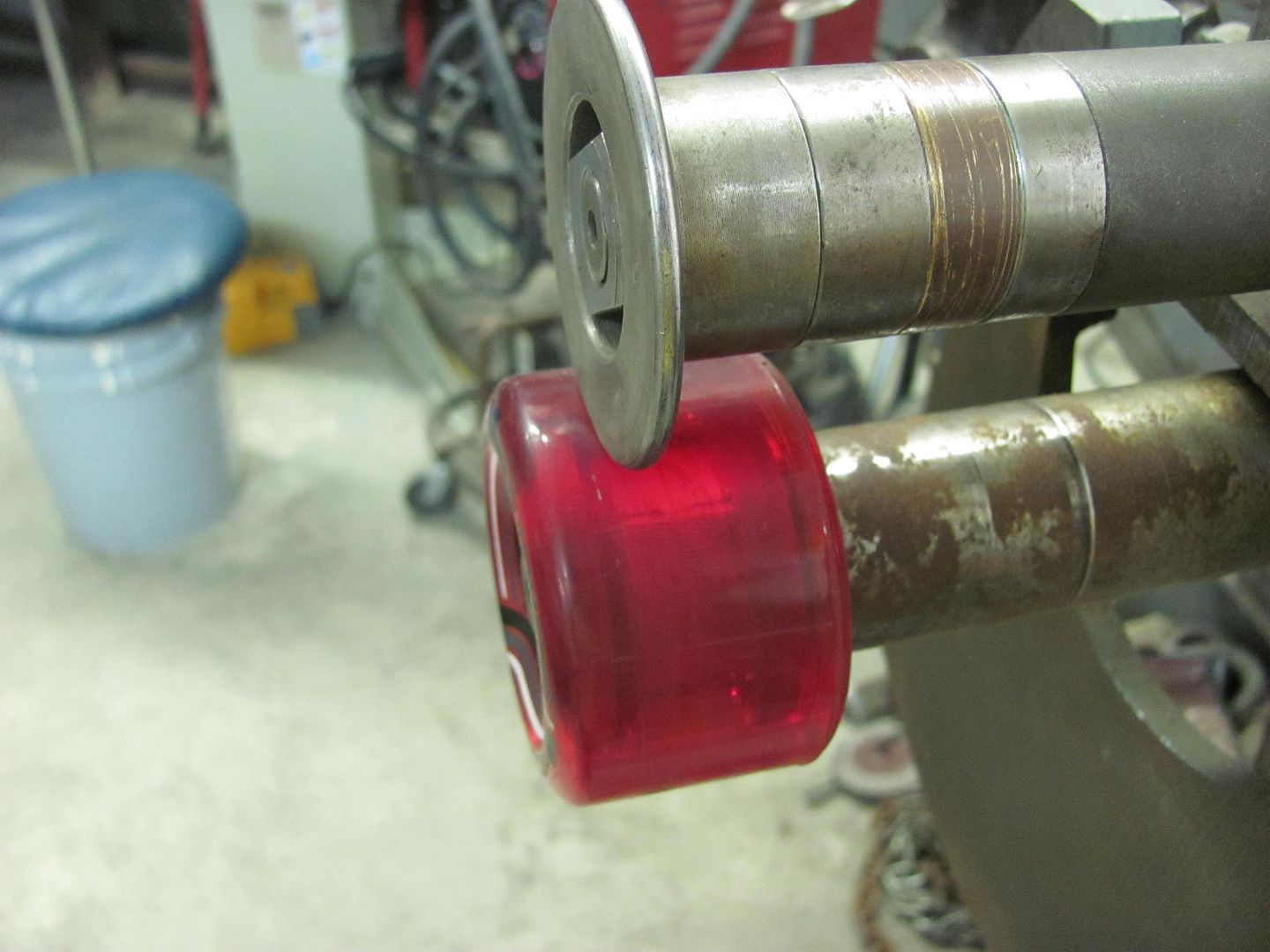

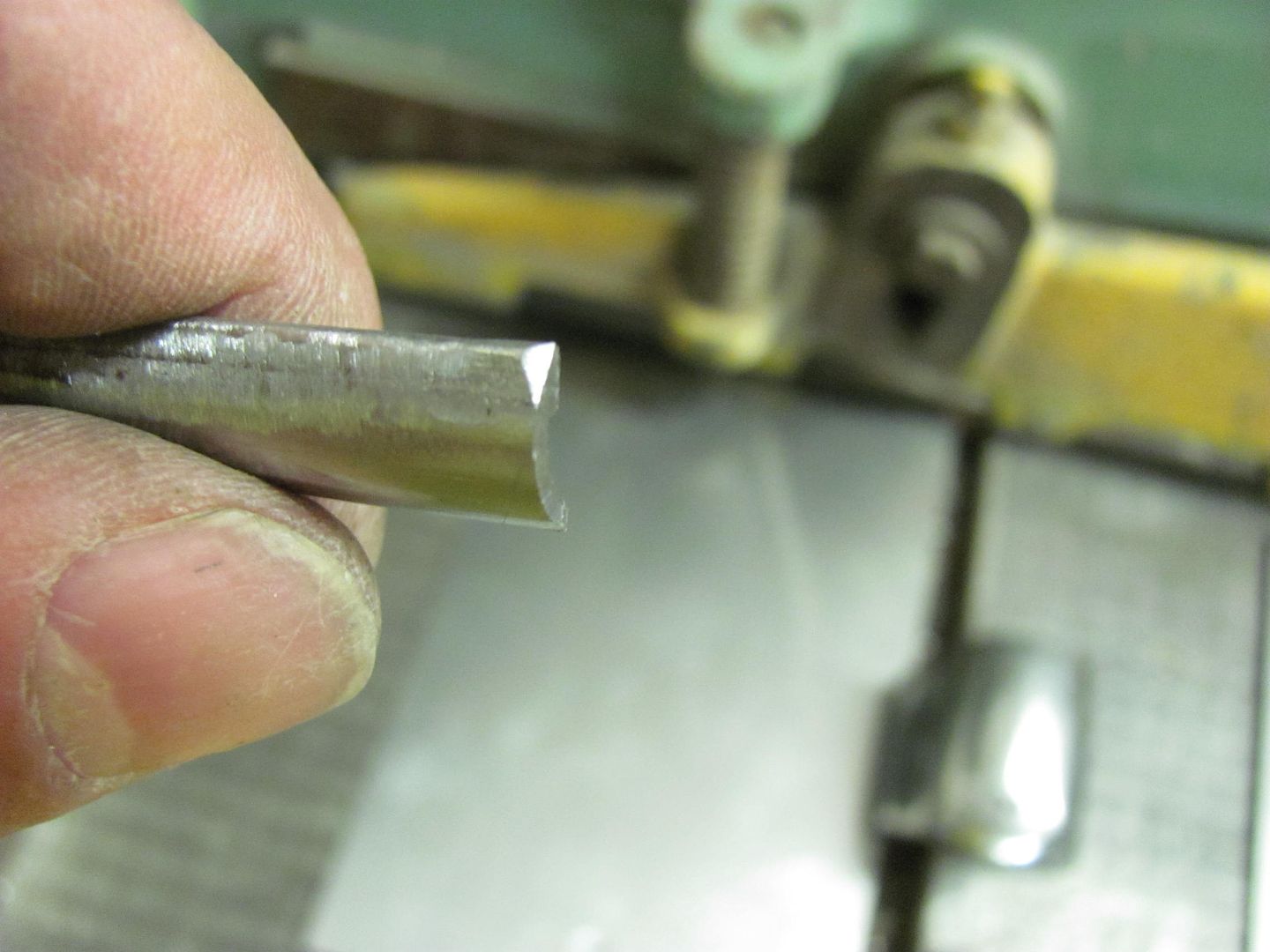

http://westcoastmetalshapers.com/for...ead.php?t=7015 Another item to get crossed off the list, there was a questionable spot on the drip rail above the lift gate.   After cutting it out, this appears to be the factory seam for joining two sections.  Looking at the profile, we'll add the top hem first...   Then a radius die and the skateboard wheel in the bead roller was used to add the profile to the replacement...   The area where the hem adds another thickness is chamfered to insure good weld penetration...  All welded in place and welds dressed...   Much better!

__________________

Robert |

|

|

|

|

| Bookmarks |

|

|