|

|

|

#151 |

|

Senior Member

Join Date: May 2009

Location: Fort Worth, TX

Posts: 6,370

|

Re: 4L80E & TH400 Tech.

Rollerizing the Output......

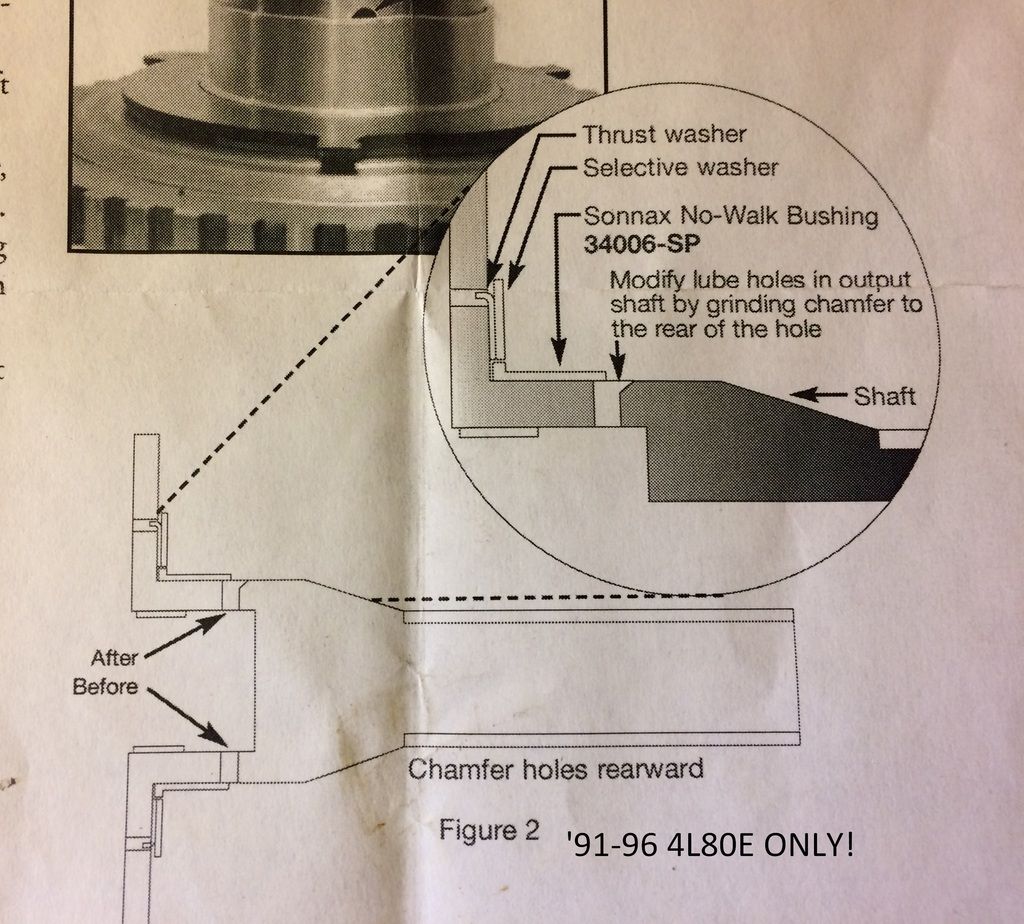

Parts needed.... TH350/TH125 Pump Bearing, GM part# 9436851 TH350 Unit End-play Shims (assortment) If building a TH400....4L80E Pump Bushing (.700" wide) If building a 4L80E....Sonnax 34006-SP Bushing (Special instructions!) Before tearing the unit down, Check rear unit end-play & record the reading, This will give a very good baseline when setting final end-play upon assembly. If you do find a bad Torrington, Sun-Gear, Carrier, Etc in the lower half....This measurement was for naught, But if your reusing everything....It can save alot of time. Case Bushing installation & Tech.... TH400 Directions When using a .700" wide '97 & up 4L80E Pump Bushing, You need to leave the bushing sticking up out of the Case about .080". Red Loctite the O.D. of the Bushing before installation. This Bushing has no oil grooves in it, But the Torrington doesn't require the amount of oil that the Thrust Washer did. I haven't had ANY problems with using a non-grooved bushing as lube oil is fed directly to the face of the bushing through a lube hole in the output shaft. **If you have a TH400 & want a bushing with oil grooves, Use a TH400 Case Bushing, It is only .620" wide so you will lose some support by offsetting the bushing .080" into the Case. I recommend Loctite & Stacking the Bushing in place in this scenario ** 4L80E Directions '91-'96 "Conventional Lube"...... Using a Sonnax 34006-SP, Sit the bushing in the back of the case & mark the location of the 2 lube holes on the lip of the bushing. Take a file & file 2 "V's" though the lip of the bushing. This will eliminate the bushing lip from restricting lube flow to the Geartrain, Case Bushing & Extension Housing Bushing. Coat the O.D. with Red Loctite. Drive the bushing in from the BACK of the case, This is opposite from the directions that come with the bushing. Seat the bushing all the way & it will be sticking up out of the case far enough to register the bearing without you having to measure. Note the 2 Lube Holes in the Output Shaft....... Temporarily install .030 worth of shims over the Bushing inside the case. Temporarily install the Bearing over the Bushing (Silver side up). Use TransJel if needed to hold the shims & bearing in place. Temporarily install the Output Shaft. IF the 2 lube holes in the Ouput are blocked or partially blocked by the bushing.....You will NEED to chamfer the holes toward the REAR. See picture. '91-'96 4L80E's lube the geartrian backwards from a TH400, It is imperative that the lube holes on the shaft are open to the area between the bushing & Seal!! '97 & up Center Lube 4L80E.......Using a Sonnax 34006-SP, Sit the bushing in the back of the case & mark the location of the 2 lube holes on the lip of the bushing. Take a file & file 2 "V's" though the lip of the bushing. This will eliminate the bushing lip from restricting lube flow to the Case Bushing & Extension Housing Bushing. Coat the O.D. with Red Loctite. Drive the bushing in from the BACK of the case, This is opposite from the directions that come with the bushing. Seat the bushing all the way & it will be sticking up out of the case far enough to register the bearing without you having to measure. These units do not lube the geartrain from the back of the case, They Lube from the Center Support....The reason there are no lube holes in the Output. Case Lube Hole Locations  Bushing Modification Drawing  Sonnax 34006-SP, Install with lip toward the rear of the case!  '91-'96 Output Lube Hole Modifications

Last edited by clinebarger; 06-15-2017 at 09:43 PM. |

|

|

|

|

|

#152 |

|

Senior Member

Join Date: May 2009

Location: Fort Worth, TX

Posts: 6,370

|

Re: 4L80E & TH400 Tech.

Geartrain Install & Rear Unit End play

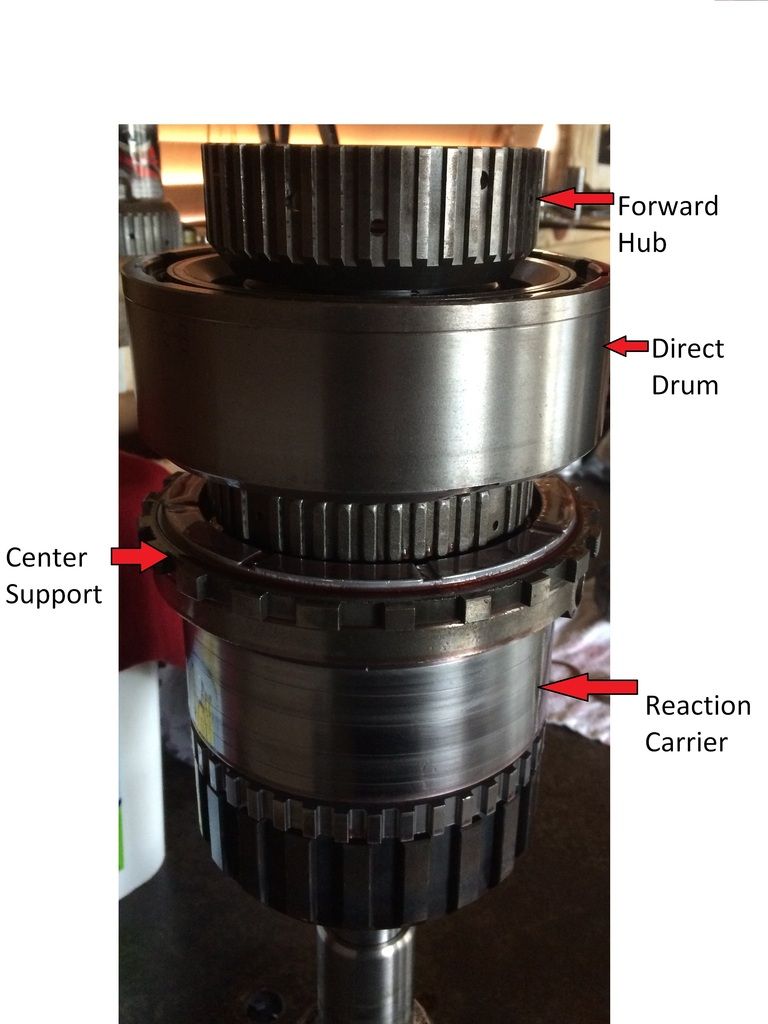

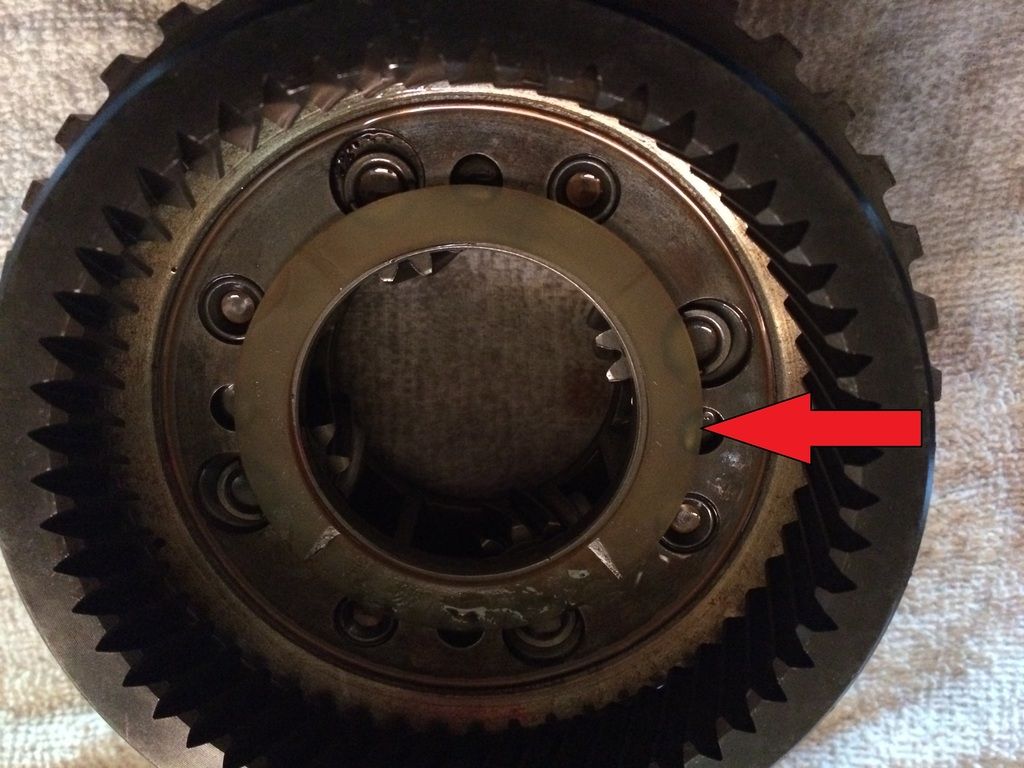

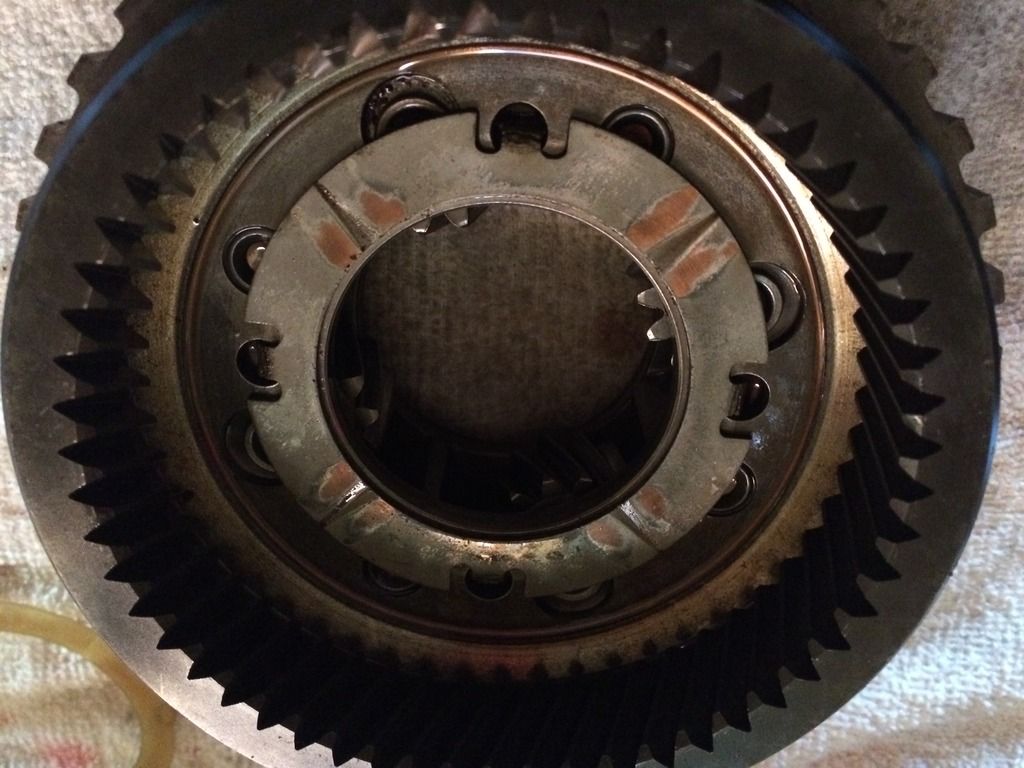

Measure the thickness of the 3-Tab selectable Washer & 4-Tab Thrust Washer, (Measure them while stacked together) Lets say they measure .150" & your pre-teardown end play was .025"......You will want the Bearing & Shims to measure .170".....This will give you about .005" rear unit endplay, You can run as tight as .003" with a bearing on the Output. .008" is my limit. Install the Shims then the Bearing over the Bushing (Silver side UP, Black side DOWN. Before stacking the geartrain in the Case, Check the Reaction Carrier End Play buy stacking the unit up to the Center Support on the bench, Use both your thumbs to hold the center support down while lifting the reaction carrier up with your fingers. There is not really a way to use a Dial Indicator here so you have to go by feel. Set to .008" to .015" using Sonnax shim pack 34006-05 "IF" the old Brass REAR thrust washer is in good shape.......Replace the Plastic Thrust Washer between the 2 Carriers with it, They are about the same thickness (.060") & the Sonnax shims work with it also. You can now stack the trans up to the Center Support, Install the center support snap ring & check rear unit end play. Selectable & Thrust on the bottom, Bearing & Shims on top  Bearing & Shim installed in the Case, The Bearing is upside down in the photo!  Check Reaction Carrier End Play, Check Direct Drum to Forward Hub End Play at the same time  Replace the Plastic Thrust on the Output Carrier with the Brass Washer you removed from the Output Shaft. Plastic  Brass  Final Check Rear Unit End Play

Last edited by AussieinNC; 07-07-2020 at 06:40 PM. |

|

|

|

|

|

#153 |

|

Registered User

Join Date: Jun 2015

Location: Indanapolis, IN

Posts: 603

|

Re: 4L80E & TH400 Tech.

So now that my 4l80e is built... how about a slightly different kind of topic.

Proper "care?" of a 4l80e in high horsepower use. Not so much change the fluid etc, but how to treat it. A few things I have read: -race in 3rd not overdrive because it engages the front band? and 4th doesn't like high power full throttle shifts -don't shift into neutral at high speed to prevent over spinning the direct drum -there was something about how to do a proper burn out but I don't remember what it was Anything else you guys can think of? |

|

|

|

|

|

#154 | |

|

Senior Member

Join Date: May 2009

Location: Fort Worth, TX

Posts: 6,370

|

Re: 4L80E & TH400 Tech.

Quote:

2. That is correct. 3. With a manual shift valve body....Start the burnout in 2nd....Then shift to 3rd. With auto shift.......Back into the water box, start in 1st shift to 2nd then to 3rd gear, get into 3rd gear as soon as possible. Pull away from the water fairly aggressively for a few feet, and then lift quickly off the throttle. |

|

|

|

|

|

|

#155 |

|

Senior Member

Join Date: May 2009

Location: Fort Worth, TX

Posts: 6,370

|

Re: 4L80E & TH400 Tech.

Photobucket has decided to extort their members, I will have NO part of it & will no longer be posting to this thread now that it is basically useless.

|

|

|

|

|

|

#156 |

|

Registered User

Join Date: Nov 2010

Location: Alabama

Posts: 740

|

Re: 4L80E & TH400 Tech.

Why use 3rd party hosting when photos can be uploaded to this site directly?

|

|

|

|

|

|

#157 | |

|

Registered User

Join Date: Dec 2009

Location: Kirkland, WA

Posts: 1,302

|

Re: 4L80E & TH400 Tech.

Quote:

Too bad, because this thread is great. I'll see if I can find an archived copy on the internets to save as a pdf. It looks like the photos are still on photobucket but embedded img tags are blocked... I already didn't like photobucket but this is ridiculous. imgur.com is free, fast, and has none of that nonsense fwiw.

__________________

1968 LWB C20 / AC / Wood Bed |

|

|

|

|

|

|

#158 | |

|

Registered User

Join Date: Jun 2015

Location: Indanapolis, IN

Posts: 603

|

Re: 4L80E & TH400 Tech.

Quote:

This is a shame. Photobucket used to be great. It has slowly gone down hill over the years and is now 100% traah. I have switched to imgur and am resonably happy with it. Photobucket basically ruining this thread is a tremendous loss. |

|

|

|

|

|

|

#159 | |

|

Registered User

Join Date: Dec 2009

Location: Kirkland, WA

Posts: 1,302

|

Re: 4L80E & TH400 Tech.

Quote:

https://chrome.google.com/webstore/d...fegnfnflicjjgj

__________________

1968 LWB C20 / AC / Wood Bed |

|

|

|

|

|

|

#160 |

|

Registered User

Join Date: Aug 2004

Location: phoenix az

Posts: 105

|

Re: 4L80E & TH400 Tech.

Just wanted to say thanks for this thread I rebuilt my TH400 using these modifications everything worked great I didn't do the full manual I did disable the auto shift out of 1st gear I went with the 34 Element Sprag upgrade over the roller clutch. Too bad about the photobucket it's affecting 1000's of forum threads on the internet. There seems to be a move to stop allowing free cloud storage across the board not sure what the problem is be nice if they at least allowed the existing photo's to stay.

|

|

|

|

|

|

#161 | |

|

Registered User

Join Date: Jun 2016

Location: Phoenix, AZ

Posts: 574

|

Re: 4L80E & TH400 Tech.

Quote:

__________________

87 R30 CC Dually, TBI 454, NV4500, zero rust barn find 87 Jeep Grand Wagoneer, 6.5 turbodiesel, 700R4 |

|

|

|

|

|

|

#162 | |

|

Senior Member

Join Date: May 2009

Location: Fort Worth, TX

Posts: 6,370

|

Re: 4L80E & TH400 Tech.

Quote:

Intermediate Clutch Tech As the 4L80E ages, I have noticed something interesting about the Intermediate Piston Return Spring assembly......It is VERY weak & bows up at the spring perches, As the "Rear Unit" end-play grows.....The Intermediate Sprag Retainer starts to rub the spring retainer. I have seen this get really bad.....But the unit had other issues that caused the direct drum to really get down on the retainer. Install a TH400 Intermediate Piston Return Spring retainer, Carefully pry the 12 spring out of the 4L80E retainer & reuse them, The TH400 piece is 3x as thick & will not distort. 4L80E Spring Retainer, Notice the rub marks  TH400 Spring Retainer  Installed in a 4L80E Center Support with the 12 springs

|

|

|

|

|

|

|

#163 |

|

Registered User

Join Date: Jan 2012

Location: Petal,Ms.

Posts: 428

|

Re: 4L80E & TH400 Tech.

Glad to see this thread alive again.

|

|

|

|

|

|

#164 |

|

Senior Member

Join Date: May 2009

Location: Fort Worth, TX

Posts: 6,370

|

Re: 4L80E & TH400 Tech.

Intermediate Clutch Tech continued....

Intermediate Clutch Pistons There are 3 different styles of pistons used in TH400's & 4L80E's. The Stamped Steel "Multi-Piece" piston was used only in TH400 & TH375 units throughout the 70's & 80's as a cost cutting measure, Using a plastic lower retainer & 3 return springs. (Though you can run 6) DO NOT use this piston in any HP build.....Or ANY build if you have a choice. Not only does it have a very thin work surface, They can also come apart & burn up the intermediate frictions! Up next is the Aluminum TH400 Piston, Largest work surface of any production piston. Has a higher "Installed" height than a 4L80E Piston allowing you to set a fullsize Wave Plate OR a Flat Steel directly on the Piston. Has 12 return spring pockets. Most production TH400 only used 3 of them. Last up is the 4L80E piston. Very similar to the TH400 version.....Albeit 2 important differences. 1. The Counter Bore is larger to allow use of a Spring Steel Wave Plate, The Wave has teeth that center it on the Counter Bore. 2. Has a shorter Installed Height to make the "Crests" in the Wave the same height as a Aluminum TH400 Piston. I prefer the TH400 Piston because I prefer 3 Friction Intermediate set-up's......It takes up some of the height/distance when building a 4L80E. It's a absolute MUST when not running a Wave/Cushion Plate in the Intermediate Clutch!!!! The 4L80E piston is a decent piece but as I stated......You HAVE to run the 4L80E Wave Plate, If you don't.....The first Steel/TH400 Wave will set on the Case Lugs NOT the Piston & cause the steels to wear on the case & put aluminum debris in your unit. The Piston will also have to move about .040" before making contact making whatever clearance you measured incorrect. The 4L80E Wave Plate is the most effective at cushioning the 1-2 shift. The TH400 Wave Plate allows a little more of a crisp 1-2....But not shock the Intermediate Sprag to bad. Unless your running a Aluminum Direct Drum with a 36 Element Sprag or a "Fly Weight Car".....I DO NOT under any other circumstances recommend omitting the Wave/s altogether! I recommend running 12 return spring in all builds, This allows more pressure to build before the piston starts to move improving 1-2 shift feel. If building a 4L80E....Use the original springs, If building a TH400 CK Performance sells spring kits. Running all the springs also makes 2-1 & 3-1 downshifts "Cleaner" Stamped Steel Piston  Failed Stamped Steel Piston  4L80E Piston(left) & a TH400 Piston(right)  4L80E Wave(left) & a TH400 Wave(Right)

|

|

|

|

|

|

#165 |

|

Registered User

Join Date: Sep 2017

Location: bc canada

Posts: 1

|

Re: 4L80E & TH400 Tech.

this work great in firefox, https://addons.mozilla.org/en-US/fir...t-fix/?src=api

|

|

|

|

|

|

#166 | |

|

Registered User

Join Date: Mar 2013

Location: Hubbard TX

Posts: 73

|

Re: 4L80E & TH400 Tech.

Quote:

|

|

|

|

|

|

|

#167 |

|

Registered User

Join Date: Nov 2014

Location: Toledo Ohio

Posts: 520

|

Re: 4L80E & TH400 Tech.

Okay guys, quick question. I've got a 4l80e in my 03 2500hd, the converter locks fine around town, until you're on the highway and then it will unlock after about 73mph. I read somewhere that the pcm sends a ground signal to the tcc solenoid. Is this correct?

|

|

|

|

|

|

#168 |

|

Registered User

Join Date: Nov 2017

Location: Rapid City South Dakota

Posts: 3

|

Re: 4L80E & TH400 Tech.

Anyone know where clinebarger went?

|

|

|

|

|

|

#169 |

|

Registered User

Join Date: Aug 2004

Location: phoenix az

Posts: 105

|

Re: 4L80E & TH400 Tech.

His thread was very helpful glad I was able to get answers to my questions before he left. Ill leave the transmissions to pro next time took to many hours to figure everything out ill just take it to a shop. Problem is not too many shops here do mods mostly just stock rebuilds.

Looks like he stopped posting here back in 2017. I saw a post from him on other forums seems to still be around not here. Last edited by kell490; 02-19-2019 at 12:34 AM. |

|

|

|

|

|

#170 | |

|

Registered User

Join Date: Sep 2010

Location: Southern California

Posts: 4

|

Re: 4L80E & TH400 Tech.

Quote:

__________________

59' Chevy Apache S/10 frame swap-bagged, 355 w/ mild cam, work in progress. 15' Chevy Suburban 15' Chevy Silverado 01' Ford F350 04' VW GTI |

|

|

|

|

|

|

#171 |

|

Registered User

Join Date: Jan 2012

Location: Petal,Ms.

Posts: 428

|

Re: 4L80E & TH400 Tech.

He is on LS1 Tech going by same name. Last time I was there anyway.

|

|

|

|

|

|

#172 |

|

Registered User

Join Date: Aug 2004

Location: phoenix az

Posts: 105

|

Re: 4L80E & TH400 Tech.

I just google searched his name. If you go to this forum yellowbullet there is a guy named Hutch he is an expert on transmission builds has a sub-forum there. You probably search / post over there find out lot of good information also if you can't find Clinebarger.

https://www.yellowbullet.com/forum/f...splay.php?f=30 Last edited by kell490; 06-09-2019 at 08:27 PM. |

|

|

|

|

|

#173 | ||

|

Registered User

Join Date: Sep 2010

Location: Southern California

Posts: 4

|

Re: 4L80E & TH400 Tech.

Quote:

Quote:

Thats what I like about this forum, most people are genuine and willing to help each other.

__________________

59' Chevy Apache S/10 frame swap-bagged, 355 w/ mild cam, work in progress. 15' Chevy Suburban 15' Chevy Silverado 01' Ford F350 04' VW GTI |

||

|

|

|

|

|

#174 |

|

At the body shop.

Join Date: Aug 2009

Location: Land of fruits and nuts.

Posts: 5,238

|

Re: 4L80E & TH400 Tech.

Is clinebarger still active here?

Did a 4l80 in my 73 and the tailshaft won't stop leaking 2 bushings 3 seals and all I've made it do is leak worse.

__________________

" That didnt make it any newer " " Dont antique the equipment " |

|

|

|

|

|

#175 |

|

Registered User

Join Date: Jul 2021

Location: Keller, Texas

Posts: 524

|

Re: 4L80E & TH400 Tech.

Good thread, thanks for posting.

|

|

|

|

|

| Bookmarks |

|

|