|

|

|

#176 |

|

Registered User

Join Date: Mar 2013

Location: Southern Oregon

Posts: 10,384

|

Re: 46 pickemup in NJ "the Rebuild"

Tom lowe's 270 cam? As in the "Mid range" cam on his sight? Any how...those are good numbers....I'll be at 9:5:1 on mine so it'll be making 285 hp with the big carb...390 is small for a hopped up 292. lol I'm going with a 625 cfm demond carb made specifically for the 292 with a cam duration of 218 @ .050...gonna see how that does.

__________________

1966 Chevy C10 "Project Two Tone" http://67-72chevytrucks.com/vboard/s...d.php?t=596643 1964 GMC "Crustine" semi-build:http://67-72chevytrucks.com/vboard/s...d.php?t=665056 My youtube channel. Username "Military Chevy": https://www.youtube.com/channel/UC_h...fzpcUXyK_5-uiw |

|

|

|

|

|

#177 |

|

Registered User

Join Date: Dec 2010

Location: washington NJ

Posts: 766

|

Re: 46 pickemup in NJ "the Rebuild"

Ok so the motor is home safe and sound and ready to go...........

[/URL] [/URL]So,..........The Paintman has been kind of quite lately on updates to the truck itself because he was trying to figure out what to do with the dilemma on the back of the cab. For those of you who have not been following along, when I bought the truck, one of the PO's booger-ed up the back by pop riveting a piece 36"x 24" stainless steel to the back of the cab (see post#3 for pic) to cover up whatever issues it had. I say boogered because instead of trying to fix the original issues he instead just made it worse by drilling about 50 holes in the back for the rivets. When he went and tightened up the rivets of course he deformed the metal around all the holes  So when I removed the patch I found a world of problems. Oil canning, waviness, all the holes, etc. etc. So when I removed the patch I found a world of problems. Oil canning, waviness, all the holes, etc. etc.So the obvious fix would have been to cut the back out, and stitch a new piece in like all the true hot rod craftsman do. But here's the thing, the Paintman was scared **** less to do that. Why you ask??????????????????? 1. The back of the cab although rough had absolutely no rust anywhere. 2. The Paintman does not have the equipment to cut, roll, and contour a piece of sheetmetal that big. 3. The Paintman does not have anybody to help him for the 3 or 4 hours it would take to cut and fit the panel properly other then his wife and 2 kids (that would have been a train wreck). 4. The Paintman has done nothing but struggle when he has had to stitch in some of the smaller work he has don on the front side of the cab. 5. The risk/ reward was just not there for me to cut out the back, I felt that there was a very good chance of me ruining the cab completely. So first off let me say that I was not going to post any of this because of the certain flaming and ridicule I am sure to get. But what the hell maybe there is somebody else out their in the same predicament. If you guys want to tear me down go right ahead I can handle it  First off I got back on a heavy dose of my medication so my analness would be under control because what I was about to do would kill me . So the plan I devised was to reinforce the back of the cab from the inside with some ribbing. First I cut 10 pieces of 16 guage sheet metal and gave them a slight bend to hopefully hold pressure on the back panel.  [/URL] [/URL]

|

|

|

|

|

|

#178 |

|

Registered User

Join Date: Dec 2010

Location: washington NJ

Posts: 766

|

Re: 46 pickemup in NJ "the Rebuild"

I think at some point this truck must of had a flatbed on the back and was used for a mobile bowling alley. Because of all the abuse, the inner vertical support ribs were not really touching the back wall of the cab. This was going to work to my advantage as it would give me enough space to slide the ribs behind the supports thus allowing them to "spring" and push the panel back to it's original curve. I had to futz with them for awhile to get the curve just right.

Once I was confident with the fitment of the ribs and the curve of the back of the cab, I pulle them back out and clened them up in preperation for final install with 3M panel bonding adhesive.  [/URL] [/URL]I then just glued them up according to the instructions and put them in place one by one working from the bottom to the top. After alot of adjusting and clean up this is what I ended up with.  [/URL] [/URL] [/URL] [/URL]Now your just going to have to trust me on this but, after the glue dried up the back of the cab is stronger then it ever was from the factory. There is absolutely no flex when I push on the back of the cab. All of the oil canning is gone. I think with a little more hammer and dolly work, (and more meds) it will look just fine. After all 90% of it will be hidden behind the bed.  [/URL] [/URL]Ok so here is my disclaimer: I know, I know this is probably the most half a$$ed way to fix the problem but again a man has to know his limitations

|

|

|

|

|

|

#179 |

|

Registered User

Join Date: Dec 2010

Location: washington NJ

Posts: 766

|

Re: 46 pickemup in NJ "the Rebuild"

In other news............... I did succeed in patching the fuel filler hole. doing this is what convinced me to not cut out out the back of the cab.

[/URL] [/URL]I also have had a pair of nearly mint condition rockers panels sitting in the garage that I scored at a swap meet a few years ago. got them mounted  [/URL] [/URL]Next up is get the cab on the ground so i can flip it up on it's nose so I can strip, clean, and undercoat it with some KBS Frame coater. Also getting ready to order the torque converter so I can get the beast back in the chassis. |

|

|

|

|

|

#180 |

|

Registered User

Join Date: May 2013

Location: Centerville,Ma.

Posts: 1,223

|

Re: 46 pickemup in NJ "the Rebuild"

Looking good, nice to see you making more progress. Having the motor staring at you will be good motivation. I think you made a good decision on how to fix the back of the cab. Cutting the back out and trying to fab a replacement without experience with making panels and access to an english wheel could have created a bigger problem. You now have a solid panel to work with and when done even if it isn't perfect nobody will ever notice unless you point it out. Keep up the good work.

Bob |

|

|

|

|

|

#181 |

|

Registered User

Join Date: Feb 2012

Location: Warrington, PA

Posts: 26

|

Re: 46 pickemup in NJ "the Rebuild"

Paintman I didnt realize I'm only an hour from you. I would have come up for a day and helped you body work the back of the cab with you. The way you are heading I think it will work out good. If you need any parts for the truck let me know I have extras of some stuff. Here is my '46

|

|

|

|

|

|

#182 | |

|

Registered User

Join Date: Dec 2010

Location: washington NJ

Posts: 766

|

Re: 46 pickemup in NJ "the Rebuild"

Quote:

|

|

|

|

|

|

|

#183 | |

|

Registered User

Join Date: Dec 2010

Location: washington NJ

Posts: 766

|

Re: 46 pickemup in NJ "the Rebuild"

Quote:

|

|

|

|

|

|

|

#184 |

|

Registered User

Join Date: Dec 2010

Location: washington NJ

Posts: 766

|

Re: 46 pickemup in NJ "the Rebuild"

|

|

|

|

|

|

#185 |

|

SAVING ONE TRUCK AT A TIME

Join Date: Feb 2010

Location: sherwood oregon

Posts: 1,141

|

Re: 46 pickemup in NJ "the Rebuild"

progress is looking great. nice fix on the back panel.

__________________

53-suburban (99% done) 40-pick up (99.9% done) 12-cc lb dually D-max (dd) 61-crew cab D-max "PAY LESS FOR WHAT YOU NEED PAY MORE FOR WHAT YOU WANT" 53 BURBAN BARN FIND:http://67-72chevytrucks.com/vboard/s...d.php?t=404091 1940 PROJECT MOON SHINE:http://67-72chevytrucks.com/vboard/s...d.php?t=551088 1961 CREW MAX: http://67-72chevytrucks.com/vboard/s....php?p=6957999 |

|

|

|

|

|

#186 |

|

Senior Member

Join Date: Jul 2012

Location: Oblong, Illinois

Posts: 7,028

|

Re: 46 pickemup in NJ "the Rebuild"

Just went through your entire build. Great work and really appreciate your sense of humor with your updates! Nice work on the house and patio too. Looking forward to more updates.

|

|

|

|

|

|

#187 |

|

Registered User

Join Date: Dec 2010

Location: washington NJ

Posts: 766

|

Re: 46 pickemup in NJ "the Rebuild"

The Paintman is back with more fun filled adventures! Sorry for the slow updates but things have been kind of hectic at the Paintman's household. First off, with kids, the Holidays just seem to keep me out of the garage. Then our 6 month old Great Dane had some health issues. Unfortunately Mr. Magoo had a bad case of Pano (or long bone). For those of you who don't know, Pano is a condition that fast growing dogs sometimes get (Magoo gained 60 pounds in 4 months). Basically the bones grow faster then the rest of the body. Thus the muscles and tendons tear and swell the joints. This leads to taking care of a paralyzed 100 pound dog for 2 weeks. I'll let your imagination figure out what my wife and I were going through. Fortunately after a shot of morphine and 20 days on horse pain killer pills, Magoo is back to his old self, full of piss and vinegar! But I digress.

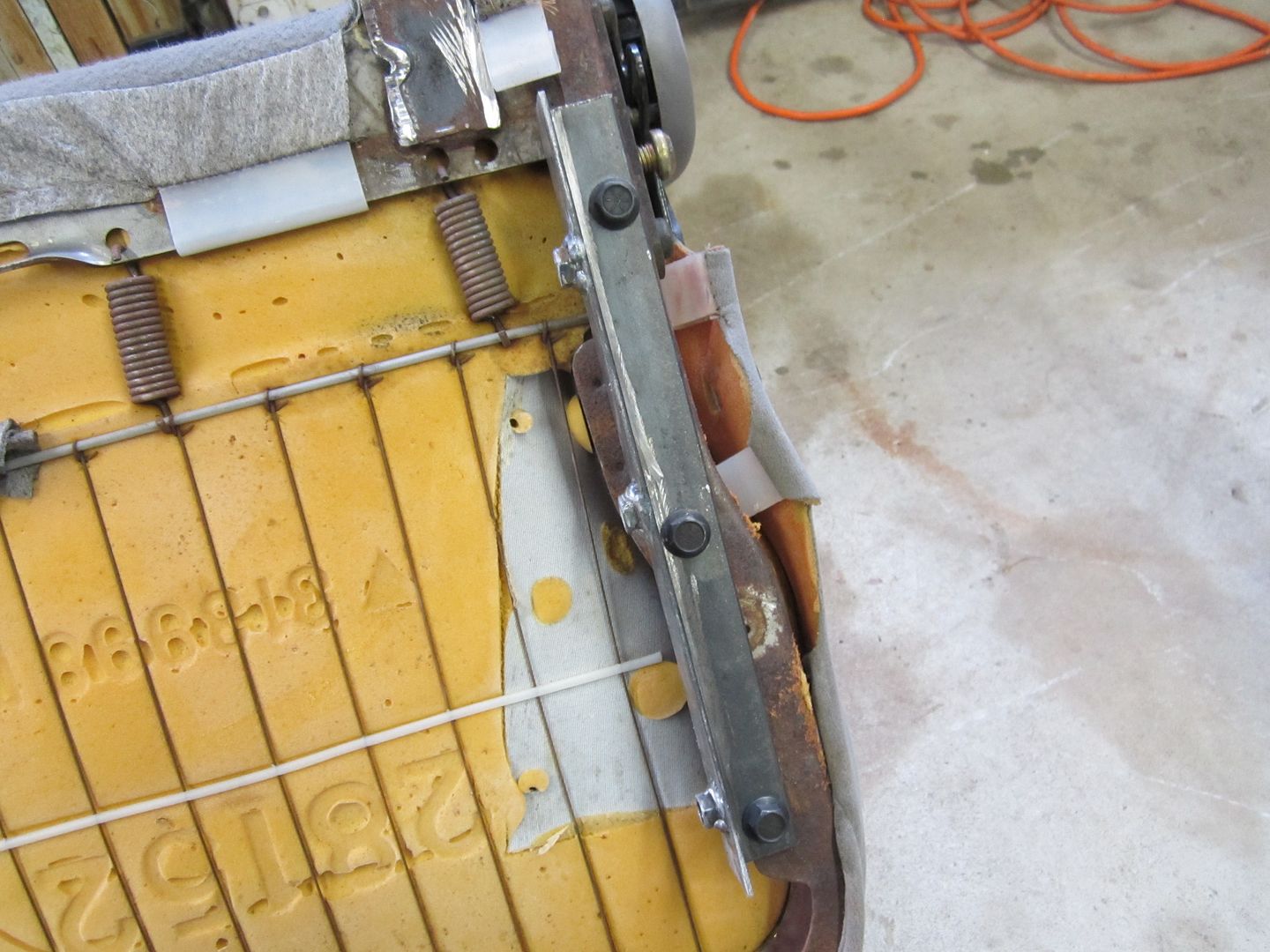

[/URL] [/URL]In between caring for Magoo,working, and entertaining the wife and kids, I spent a few days prepping the inside of the cab for paint. After going through about 50 sheets of sand paper, 10 sanding discs, and a whole bunch of skinned knuckles... I thought I was ready set the cab down on the floor and flip it up on its nose for prepping and painting of the underside. Then I remembered that one of the previous owners of the truck had absolutely no business building hot rods. "What do you mean you ask"? Well the seat that came in the truck was never mounted to anything! That's right it was just sitting on a 1/2" piece of plywood that was cut oversize so it would rest on the seat riser. that meant if I was to stop short...well you get the picture, Paintman hood ornament. Sooooo, the Paintman (who also has absolutely no business building a hot rod), set forth on an epic adventure in seat mounting. First off I thought about buying a new seat because the one that came with the truck, although comfy, was a little bit to wide as it rubbed the doors. Also the seat frame did not lend itself to making a mounting bracket easily. I considered buying a seat from either Glide or Bengals but kind of coughed at $700. I really like the way the base of their seats tilted forward though because I plan on mounting the fuse block under the seat. So after I a quick trip up the road to the local junkyard and spending $50 this is what I came home with.  [/URL] [/URL] . |

|

|

|

|

|

#188 |

|

Registered User

Join Date: Dec 2010

Location: washington NJ

Posts: 766

|

Re: 46 pickemup in NJ "the Rebuild"

I have know idea what the seat came out of because I found it in a trailer full of all kinds of other seats. And of course as usual the kid working at the front desk had know idea either. I am assuming its out of some kind of mini van as it measures just under 49".

So for this lesson class we will attempt to mount a seat that is only about 10 years old into a truck that is about 70. First off I stripped all the junk off the bottom of the frame so I had a nice clean slate to work with.  [/URL] [/URL] [/URL] [/URL]Because the base of the new seat is somewhat thicker and tilted towards the back I needed to trim down the seat riser. Heres a pic of the old and new seat.  [/URL] [/URL]

|

|

|

|

|

|

#189 |

|

Registered User

Join Date: Dec 2010

Location: washington NJ

Posts: 766

|

Re: 46 pickemup in NJ "the Rebuild"

I think I trimmed about 1 1/2" off the top of the riser. Because the base of the seat was tilted back at an angle I had to trim the riser level with the floor to get the correct comfort for my fat but. I just took a piece of duct tape and used it as a guid for cutting the riser.

[/URL] [/URL]Because I trimmed the original factory lip off the top of the riser it left the riser somewhat flimsy. so I went about reinforcing the inside perimeter of the riser with some 1" square stock. This is all pinned in with about 16, 1/4-20 bolts, and lock nuts. This not only stiffened the riser bak up but also gave me a structure on which I could reinstall the factory cross sills and mount a base for the mounting brackets.  [/URL] [/URL]Next up was making 2 filler plates out of 16 gauge on each end of the riser. This would give me a surface to mount the seat brackets to.  [/URL] [/URL]

|

|

|

|

|

|

#190 |

|

Registered User

Join Date: Dec 2010

Location: washington NJ

Posts: 766

|

Re: 46 pickemup in NJ "the Rebuild"

So now the tricky part. Since I knew I was going to mount the fuse block and possibly the heater under the seat, I wanted to make the removal and installation as easy as possible. After much thought and of course alcohol consumption I came up with making a bracket out of 2 pieces of angle iron. One permanently mounted to the seat riser the other mounted in reverse direction on the seat. ( If that makes any sense.

First off I cut and fitted the 2 pieces of 1" angle iron and bolted them to the seat frame using 9/16 bolts.  [/URL] [/URL]Then I took 2 pieces of 1-1/2 angle iron and set them in place where I kind of thought their final resting place would be. Ignore the tack welds and holes that came later  [/URL] [/URL]Then I took the seat with the brackets bolted to the bottom and set it in the truck and adjusted to center and front to back were I thought was best  [/URL] [/URL]After being certain of the position of the seat was correct, I just drilled 3 small holes on each side of the seat through the bracket on the riser and bracket mounted to the seat. Then I screwed it all together with some small sheet metal screws. This step was crucial as I needed everything to stay in perfect alignment when I took the seat back out, as the plan was to use welded nuts on the back side of the brackets bolted to the seat. so once I got the seat back out I took the brackets of and drilled larger holes through the brackets. Then I bolted them back together and tacked nuts to the back side.  I guess I got penetration... The nuts were cherry red and this is what the back side looked like.

|

|

|

|

|

|

#191 |

|

Registered User

Join Date: Dec 2010

Location: washington NJ

Posts: 766

|

Re: 46 pickemup in NJ "the Rebuild"

Well that last post was kind of confusing but maybe these pics will help give a clear view of what I was trying accomplish. Once I had all the nuts welded, it was just a matter of re-assembling everything onto the seat and then setting the seat back onto the riser. This is where the tack welds came into play. Once I had the seat back in place I needed to be able to keep the lower brackets in place while I removed the seat again. I needed to take the seat back out so I could mount the lower brackets to the filler plates. So as I said I just shot some tack welds down to holed them in place. Then I drilled 4 holes in each bracket to hold it in place on the filler plate with 9/16ths bolts

[/URL] [/URL]And here is the final mounting assembly all mounted down without the seat.  So to review class, once the truck goes back together the top bracket will be mounted to the underside of the seat. All you have to do is set the seat in place over the riser and align the 3 holes on each side and bolt it together with 9/16ths bolts tightened against the welded nuts.  Well the bottom of the seat doesn't flip up, but at least the back folds forward somewhat!  [/URL] [/URL]

|

|

|

|

|

|

#192 |

|

Registered User

Join Date: Dec 2010

Location: washington NJ

Posts: 766

|

Re: 46 pickemup in NJ "the Rebuild"

Not to sure if Mr. Magoo approves though. lol!

So next up I will try and attempt to mount some seat belts. This is going to cause some trouble. I know Juliano's has some nice belts but the 46's don't look like they have enough meat to mount the upper retractor.  [/URL] [/URL] There also doesn't seem to be enough room on the floor to mount the belt strap mount, its kind of tight in there.......  [/URL] [/URL]

|

|

|

|

|

|

#193 |

|

Registered User

Join Date: Dec 2010

Location: washington NJ

Posts: 766

|

Re: 46 pickemup in NJ "the Rebuild"

I forgot to mention that because of all the issues with mounting conventional belts, I am considering a 4 or 5 point racing harness. Stayed tuned for my next adventure.

|

|

|

|

|

|

#194 |

|

Registered User

Join Date: May 2013

Location: Centerville,Ma.

Posts: 1,223

|

Re: 46 pickemup in NJ "the Rebuild"

Just a thought, I would rather spend hours now engineering a seat belt that will work even if you need to add some bracing to the pillars,than dealing with a harness for years. You will soon find yourself sitting on the harness. Even if you use a 70's style setup that needs to be manually tightened instead of an enertia setup used in modern cars.

|

|

|

|

|

|

#195 |

|

SAVING ONE TRUCK AT A TIME

Join Date: Feb 2010

Location: sherwood oregon

Posts: 1,141

|

Re: 46 pickemup in NJ "the Rebuild"

Your new seat looks great. I made the mistake of measuring my old seat and had my new seat made to the same bottom height. I did not take into consideration how much the old springs would give compared to the new foam. End result is good but sit a little higher in the cab.

__________________

53-suburban (99% done) 40-pick up (99.9% done) 12-cc lb dually D-max (dd) 61-crew cab D-max "PAY LESS FOR WHAT YOU NEED PAY MORE FOR WHAT YOU WANT" 53 BURBAN BARN FIND:http://67-72chevytrucks.com/vboard/s...d.php?t=404091 1940 PROJECT MOON SHINE:http://67-72chevytrucks.com/vboard/s...d.php?t=551088 1961 CREW MAX: http://67-72chevytrucks.com/vboard/s....php?p=6957999 |

|

|

|

|

|

#196 |

|

Registered User

Join Date: Dec 2002

Location: Cactus Patch So. Az

Posts: 4,749

|

Re: 46 pickemup in NJ "the Rebuild"

I think the Mopar third seat was made for these trucks,

1 & 2 are in the 46 and 3 is in a 37 Chevy

__________________

53 TuTone Extended Cab 350 4-Spd 3:08 (SOLD) 53 Chevy Moldy pearl green ZZ-4 4L60E 9" 3:25 55 GMC 1st Black Mll (ZZ4) ZZ6 TKO 600 5 sp 3:73 62 Solidaxle Corvette Roman Red (327 340hp 4spd 3:36) C4 & C5 suspension tube chassis LS 3 4L70E 65 Corvette Coupe 327 350hp 4spd 4:11 78 Black Silverado SWB (350/350) 5.3 & 4L60E 3:42 2000 S-Type 3.0 (wife cruiser) 2003 GMC SCSB 5.3 4L60E 3:42 |

|

|

|

|

|

#197 |

|

Registered User

Join Date: Dec 2010

Location: washington NJ

Posts: 766

|

Re: 46 pickemup in NJ "the Rebuild"

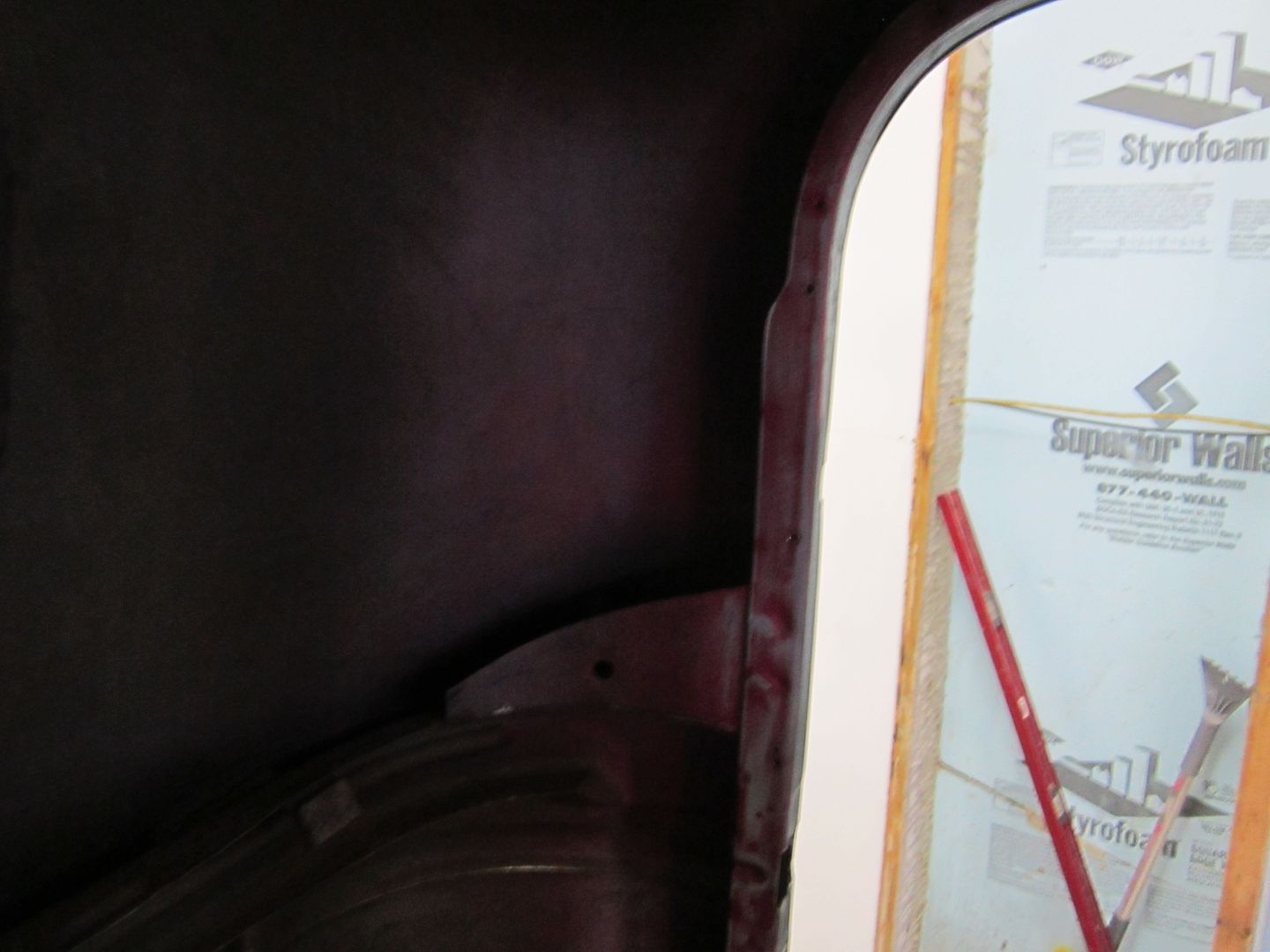

Ok back at it! The next adventure for Paintman is seat belts. As mentioned previously the door pillar on the 46 is way to small to have any hope in mounting the belt slide. I had considered a 4 or 5 point harness but that seemed to be even more trouble figuring out a safe mounting configuration. With a racing type harness set up, if you do not have the mounting points in the right geometry to one another, there is a good chance having your back compressed or even broken in an accident.

Sooooo after a quick click on the "Buy it Now" button, a set of Juliano's bench seat belts were on their way. Here's what comes in the box.  [/URL] [/URL] [/URL] [/URL]So now that I have all the pieces, I can further evaluate just how much room I will need on the door pillar to mount the bracket. From what I understand the bracket needs to be directly above the locking mechanism which will be mounted on the floor behind there seat riser. If I just add a little more material to the pillar it still would not put the bracket above the locking mechanism and it's to far forward. It seems to me it has to go up and back  [/URL] [/URL] [/URL] [/URL]So here's my plan. I made a template out of cardboard to see what a larger pillar would look like. I don't think just butt welding a piece to the pillar would be strong enough in the case of an accident. I think what I will do is tuck a piece of 18 gauge behind the pillar, make a bunch of small holes in the pillar, and butt weld it in place. Then go along the entire length of the seem and weld it all in place. Here's a pic of the cardboard tucked in tight behind the pillar and cab frame work. Anybody see anything wrong with how I plan on welding this in place? Any better or stronger way to do this??????  [/URL] [/URL]

|

|

|

|

|

|

#198 |

|

Registered User

Join Date: May 2013

Location: Centerville,Ma.

Posts: 1,223

|

Re: 46 pickemup in NJ "the Rebuild"

That looks like it would work ok. The worst case scenario is that if you did have a wreck it might bend over some but it would still keep you in place. Lets face it old cars or trucks are not built as safe as new stuff, but they are usually driven a lot more carefully.

|

|

|

|

|

|

#199 | |

|

Registered User

Join Date: Dec 2010

Location: washington NJ

Posts: 766

|

Re: 46 pickemup in NJ "the Rebuild"

Quote:

|

|

|

|

|

|

|

#200 |

|

Registered User

Join Date: Dec 2010

Location: washington NJ

Posts: 766

|

Re: 46 pickemup in NJ "the Rebuild"

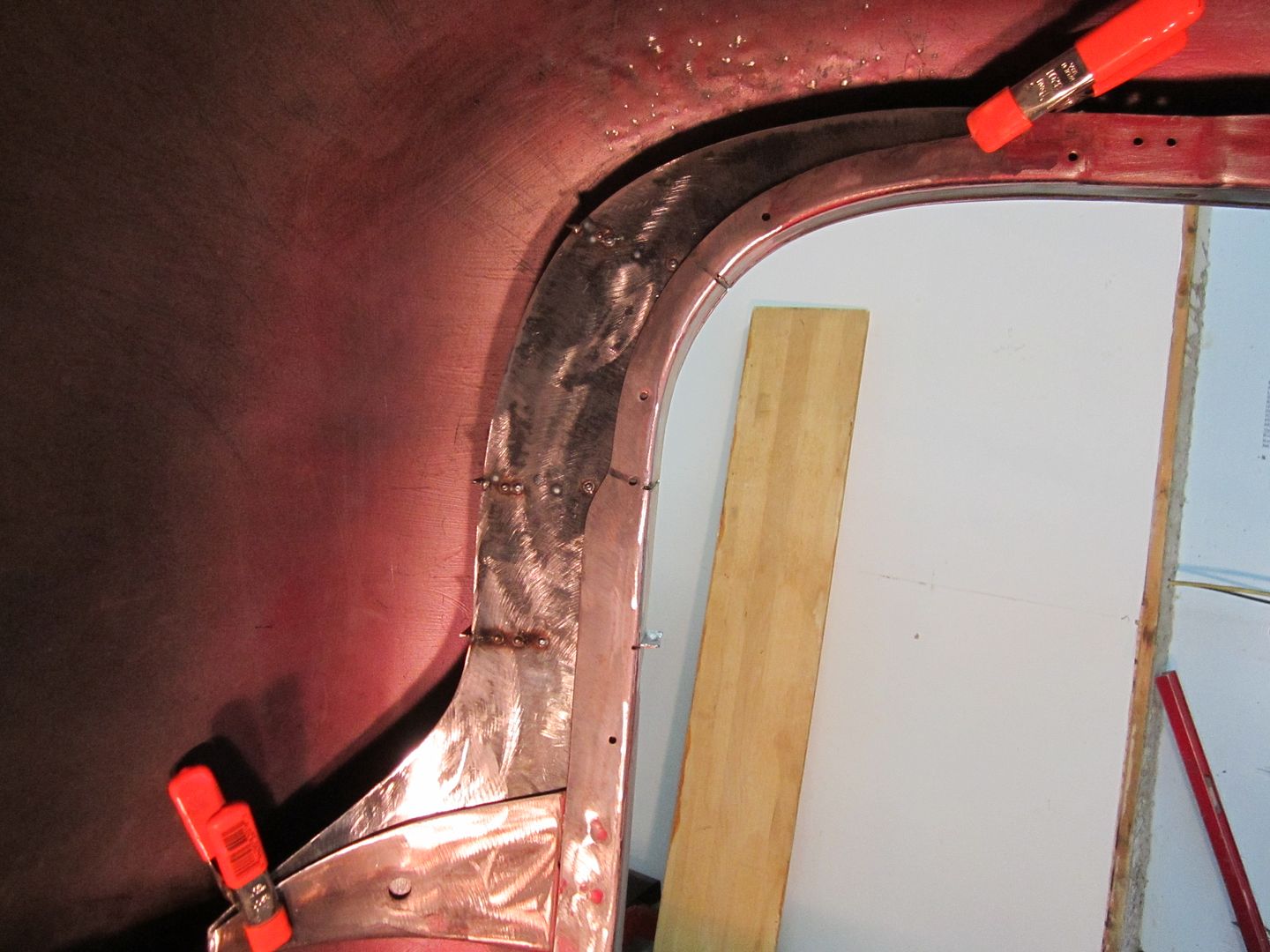

Next up is making the pillar extensions.......

I just cut them out of 18 guage and spent some time bending, hammering, and massaging them to fit the contour of the factory pillar. As mentioned previously the plan is to tuck them behind the pillar and weld along the entire length of the seem and also do some plug welds for additional strength.  [/URL] [/URL] [/URL] [/URL]Once the extensions where made I had to figure out a way to keep them from folding forward in the event of an accident. The only solution I could come up with was to add some structural ribbing on the back side of the pillar welded to the extension at a 90 degrees. The biggest problem would be the lack of space behind the pillar extension as there is barely enough room to get your hand behind , much less the welding gun. So here's what I did. First I did 3 plunge cuts on the inside of the door jam. This would allow me to slide the ribs in from the front side. I made the ribs slightly longer then I needed them this would allow me to get one spot weld on the far back end of the rib to hold in in place. I did the ribbing one at a time so I could keep going back to the truck to make sure I could still get the pillar back in place and not have the ribs move.  [/URL] [/URL] [/URL] [/URL] [/URL] [/URL]to further hold the ribbing in place I spot welded through the pillar to the ribbing. This was crucial as I needed all the ribbing to stay in place so that it wouldn't move around when I took the pillar back out for final welding of the ribs   [/URL] [/URL]Once I had the pillar and the ribbing back out I could finish welding the ribs in place on the bench.  [/URL] [/URL]After a looooong day of work, I had 2 matching pillar extensions complete with some support ribbing in hopes of keeping the pillar from folding forward.  [/URL] [/URL]After the ribbing was complete I trimmed the front side of the ribbing off keeping only about a 1/4" protruding through the inside front of the door jam. This will give me enough material to weld the ribbing fast to the inside of the jam when I close up the access holes, thus (hopefully) giving me added strength to the webbing.  [/URL] [/URL]

|

|

|

|

|

| Bookmarks |

|

|