|

|

|

#176 |

|

Registered User

Join Date: Jun 2014

Location: dresden , ontario

Posts: 628

|

Re: Project "Second Chance" - Hot Rod 66' GMC

Very cool truck Siggy. That 3d printing is very interesting

__________________

Dale ---------------- My suburban's Twisted Little Sister http://67-72chevytrucks.com/vboard/s...d.php?t=655167 |

|

|

|

|

|

#177 |

|

Registered User

Join Date: Jun 2012

Location: Portland

Posts: 1,330

|

Re: Project "Second Chance" - Hot Rod 66' GMC

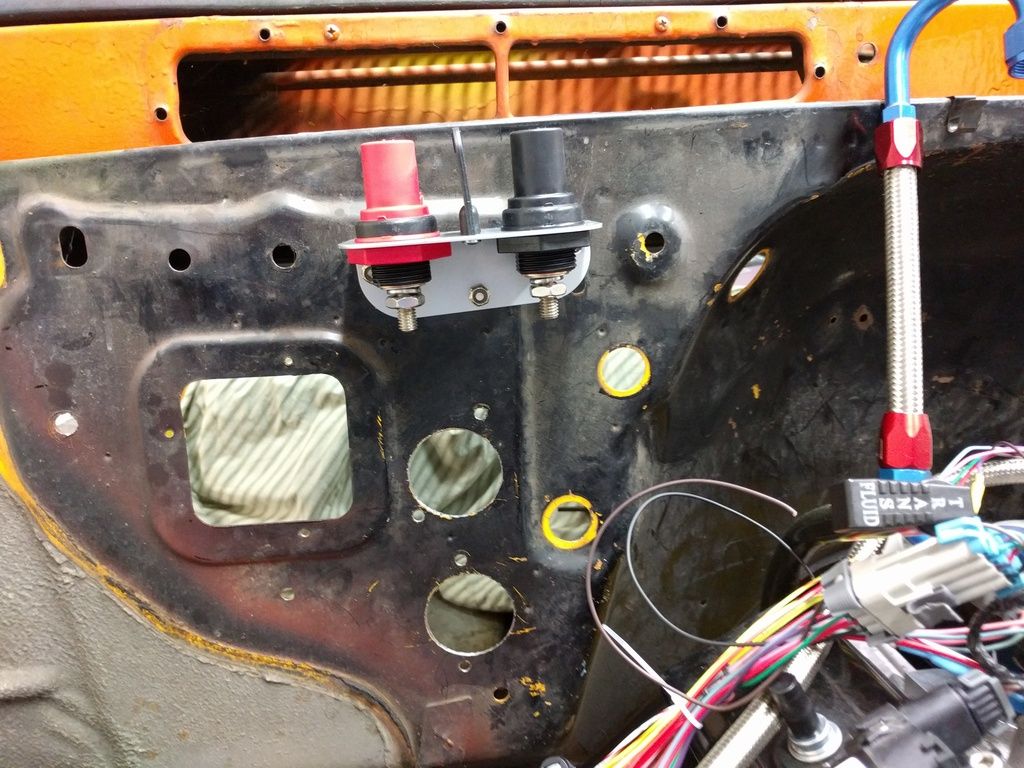

3.27.16 - Wiring underway

Hey all! So my 3d printing projects are on hold for the moment while I explore higher-strength/higher-heat resistant materials. Was printing in PLA, which is easy to print in, but it has a lower liquification temp than I'd like for a summer, underhood application. ABS is better, but really would like to print in Nylon, but have to see if my machine can handle it. In any case. Thought I'd start wiring up the EFI stuff! I'll primarily be using weatherpack connectors for this install:  For the engine stuff I will use 2 (if I can get away with that few) delphi bulkhead connectors through the firewall. This will make it super easy to take stuff off when it's time for paint.  I started by wiring the signal for all 8 fuel injectors, as well as 4 power leads since I'll power them in pairs. They'll fire sequentially, but since the ground runs to the ECM to trigger them, powering in clusters shouldn't be an issue. Right now I'm just wiring to the firewall connector. Next time I'll wire from the other side into the Megasquirt harness. The hole needed is a 2 1/16". I mocked up my vintage air on the inside, and found a spot where I could fit two bulkheads that wouldn't interfere with the AC (I hope). I made a template for drilling.  Then went at it.  And then I went to wiring. Ended up with both banks of fuel injectors run, and one bank of coils. The top bulkhead will be ignition/misc sensors, and the bottom will be injection/misc sensors:  After drilling I realize I didn't orient the two connectors the same way. Really only an aesthetic issue. We'll see how much it bugs me later. They're not held in tight at the moment, I just pushed them in to make wiring easier. That's all for now. Cheers! |

|

|

|

|

|

#178 |

|

Registered User

Join Date: Jun 2012

Location: Portland

Posts: 1,330

|

Re: Project "Second Chance" - Hot Rod 66' GMC

More parts ordered!

No major updates yet in terms of installations, but over the course of the past few days I have put in orders for various parts I'll need to get this moving:

Other than seats, which I'll find later, I should have most of what I need to get it rolling, and will just need to start saving for body and paint work. Unfortunately that's the most expensive item haha  . .

|

|

|

|

|

|

#179 |

|

Registered User

Join Date: Jun 2012

Location: Portland

Posts: 1,330

|

Re: Project "Second Chance" - Hot Rod 66' GMC

More progress today

Today I got around to installing the remote battery box. I decided to put it below the cab on the passenger side to help balance weight against the driver  . Figured any weight I can remove from the nose will help in drive-ability too. . Figured any weight I can remove from the nose will help in drive-ability too.The box isn't level, but the frame curvature up also makes it look more off than it is. After drilling on my back for awhile I didn't care to put two more holes to fix it. Mounting the holder:  Then the box:  Then put the battery in it to test:  Here is how it looks from the side. Though it looks low, I have my exhaust up pretty high under the truck. It actually hangs down about an inch less than the header collectors by comparison:  After that was done I started mounting the remote battery posts so that if I ever need a jump I won't be on my back reaching the battery:  That's all for now folks. Will continue wiring and getting the electrical all set. My hope is to get the engine and power wired enough to see if I can get this engine to start in the next month or so. |

|

|

|

|

|

#180 |

|

Registered User

Join Date: Jun 2012

Location: Portland

Posts: 1,330

|

Re: Project "Second Chance" - Hot Rod 66' GMC

|

|

|

|

|

|

#181 |

|

Registered User

Join Date: Dec 2012

Location: Rochester, KENT

Posts: 10,582

|

Re: Project "Second Chance" - Hot Rod 66' GMC

I made a relocating seat for my battery too.

I hope it never comes to grief when driving in a field etc. Your progress as always looks great.

__________________

MY BUILD LINK: http://67-72chevytrucks.com/vboard/s...585901]Redneck Express - 1966 C10 Short Fleetside MY USA ROADTRIPS http://forum.retro-rides.org/thread/...2018-humdinger IF YOU CAN'T FIX IT WITH A HAMMER, YOU'VE GOT AN ELECTRICAL PROBLEM MATE. |

|

|

|

|

|

#182 |

|

Registered User

Join Date: Oct 2014

Location: Location:

Posts: 8,450

|

Re: Project "Second Chance" - Hot Rod 66' GMC

.

. Just found this thread. Too cool that you got to buy your old truck back. Not many of us get that opportunity. Looking forward to following along and seeing how it turns out. . . |

|

|

|

|

|

#183 |

|

Registered User

Join Date: Apr 2013

Location: Fort Worth, Texas

Posts: 166

|

Re: Project "Second Chance" - Hot Rod 66' GMC

Looking good

|

|

|

|

|

|

#184 | ||

|

Registered User

Join Date: Jun 2012

Location: Portland

Posts: 1,330

|

Re: Project "Second Chance" - Hot Rod 66' GMC

Quote:

Quote:

. .Thanks bumwine! Appreciate the feedback. |

||

|

|

|

|

|

#185 |

|

Registered User

Join Date: Apr 2011

Location: .

Posts: 3,104

|

Re: Project "Second Chance" - Hot Rod 66' GMC

Digging your wiring and new parts. Would like to check it out live one of these days.

|

|

|

|

|

|

#186 | |

|

Registered User

Join Date: Jun 2012

Location: Portland

Posts: 1,330

|

Re: Project "Second Chance" - Hot Rod 66' GMC

Quote:

. .

|

|

|

|

|

|

|

#187 |

|

Registered User

Join Date: Jun 2012

Location: Portland

Posts: 1,330

|

Re: Project "Second Chance" - Hot Rod 66' GMC

|

|

|

|

|

|

#188 |

|

Registered User

Join Date: Jun 2012

Location: Portland

Posts: 1,330

|

Re: Project "Second Chance" - Hot Rod 66' GMC

More to come on this build soon. In the process of selling some property that should provide the funds I need to finish this build.

Exciting times, but should be a few more months of garage work, then I can send it for body/paint, followed by some final wiring, and calibrating. I plan on updating more frequently after the home sale and once my current floor project finishes. Cheers all! |

|

|

|

|

|

#189 |

|

Registered User

Join Date: May 2013

Location: Centerville,Ma.

Posts: 1,223

|

Re: Project "Second Chance" - Hot Rod 66' GMC

Thanks for the update, Still following along.

|

|

|

|

|

|

#190 |

|

Registered User

Join Date: Jun 2012

Location: Portland

Posts: 1,330

|

Re: Project "Second Chance" - Hot Rod 66' GMC

Thanks Cape! Looking forward to kicking it back off full steam. For now though, some minor updates!

1. Bye-bye water pump: So as it turns out with my new pulley and tensioner setup I'm installing I need a reverse-flow water pump. So the new Weiand pump I had on won't work, so I pulled it and am going to sell it off. I ended up ordering an Edelbrock Victor Jr. aluminum pump, which was about 3x as expensive, I'm guessing because it's a) Edelbrock, and b) Reverse flow, which they sell fewer of. So new pump off for now    2. Hello Oil cooler!: Awhile back I bought a separate cooling unit that I planned on running my transmission oil through. However after I got my RnD Radiator I figured it was a quality-enough unit that I'd be okay running my transmission fluid through it to get proper cooling. So I was left with a spare cooler and thought, "hey, why not run my oil through it." I think I can remote-locate it, and run a 4" fan on there that I can program to kick on as a spare output from my Megasquirt computer. Oil temps usually run 20-30* above coolant, so I could program it based on coolant temp if I didn't get an actual oil temp sensor in there somewhere. Here is the Canton adapter:  And here is the spare cooler:  3. Blowing (not hot) air: I finally finished my air setup for the garage. Since I'll eventually be doing some minor powdercoating I wanted to setup a little air/oil separator for the air. I also wanted a reel setup that would reach out to the driveway, that wouldn't be intrusive when not in use. Right now I have a portable compressor, but eventually I'll get a bigger unit that will sit in the garage. The lines run from the compressor to a small separator, then up to a 50' reel. Should make filling up tires a lot easier  . . Well folks, that's it for now. Cheers! |

|

|

|

|

|

#191 |

|

Registered User

Join Date: May 2013

Location: Centerville,Ma.

Posts: 1,223

|

Re: Project "Second Chance" - Hot Rod 66' GMC

I was told by a compressor rep years ago to put your water separator and filter as far from the compressor as possible to allow the air to cool and condense any water before it gets there. I have an 80 gallon 7.5 hp compressor, I ran black iron pipe straight up through the ceiling then around the outer walls in the attic to the opposite side and dropped down between the overhead doors. Then down below where my filter is turn 90% with a drain valve then up to the filter. Most water condenses in the pipe and runs back down to the tank. I get a small amount at the drop drain when I open it about every two weeks and never get water to the filter that I very seldom ever drain. I work about 35 to 40 hours a week and we do get humid weather here in summer. I can get pics of the drop and filter arrangement if you can't visualize my description. My shop is 24x26 for an idea of scale the pipe from the compressor to where it drops is about 33 ft.

|

|

|

|

|

|

#192 |

|

Registered User

Join Date: Jun 2012

Location: Portland

Posts: 1,330

|

Re: Project "Second Chance" - Hot Rod 66' GMC

That's interesting. To get it furthest from the compressor I'd really have to just attach it to the end of the reel lol. With the permanent setup it will be about 10ft away. I could put the reel on the opposite side of the garage, but would somewhat defeat the purpose of having the 50ft reel to begin with. Guess I'll see how it goes and if I'm still getting water post-filter I'll consider moving it like you've suggested. One thing that should help is that the garage is temp and humidity controlled.

|

|

|

|

|

|

#193 |

|

Senior Member

Join Date: Jan 2014

Location: Portland, Oregon

Posts: 449

|

Re: Project "Second Chance" - Hot Rod 66' GMC

wow looking good man! Way to keep it up and keep making progress. I wish I had your shop. If you need any help with the body I'm in West Linn and a self-proclaimed expert on floor or rocker panel replacement.

__________________

Hey man  67 GMC Short Stepside 400 small block, turbo 350. Build thread:http://67-72chevytrucks.com/vboard/s...d.php?t=650603 |

|

|

|

|

|

#194 |

|

Registered User

Join Date: Jun 2012

Location: Portland

Posts: 1,330

|

Re: Project "Second Chance" - Hot Rod 66' GMC

I've decided to turn the body over to the pros once I'm ready. I want to drive it, and if I take the time to learn and do it myself it'll be years before I complete it all. But I appreciate the offer! Same goes to you. Let me know if you need a hand on a project.

|

|

|

|

|

|

#195 |

|

Senior Member

Join Date: Jan 2014

Location: Portland, Oregon

Posts: 449

|

Re: Project "Second Chance" - Hot Rod 66' GMC

Sounds good Siggy... Good luck with it all. I keep saying I'll update my project thread but I want to make more progress even though the cab is about done. It's the little things that add up like the doors alone are a job all to themselves.

__________________

Hey man  67 GMC Short Stepside 400 small block, turbo 350. Build thread:http://67-72chevytrucks.com/vboard/s...d.php?t=650603 |

|

|

|

|

|

#196 |

|

Registered User

Join Date: Jun 2012

Location: Portland

Posts: 1,330

|

Re: Project "Second Chance" - Hot Rod 66' GMC

Hey all,

So did a video walking people through my motor/fuel/spark/control units. Haven't edited it or anything, and really my first time narrating a longer video, so it's rough, but I'll get better. Hopefully it's accurate, and explains things well enough. Cheers all! *If it's shaky come back in a bit, youtube is fixing it for me* *Removing link while I edit* Will post back soon.* Just FYI you have to remove the S from HTTPS in order for this to work. I hope they fix that, as HTTP will be going away at some point in favor of secure-only linking.

__________________

Current Build - Project "Ghost of Poseidon" 72 C10 Pro-touring build Previous Build - 66 GMC Pro-touring build. Sold. Last edited by siggyfreud; 09-25-2016 at 02:32 PM. |

|

|

|

|

|

#197 |

|

Registered User

Join Date: Jun 2012

Location: Portland

Posts: 1,330

|

Re: Project "Second Chance" - Hot Rod 66' GMC

|

|

|

|

|

|

#198 |

|

Registered User

Join Date: Jun 2012

Location: Portland

Posts: 1,330

|

Re: Project "Second Chance" - Hot Rod 66' GMC

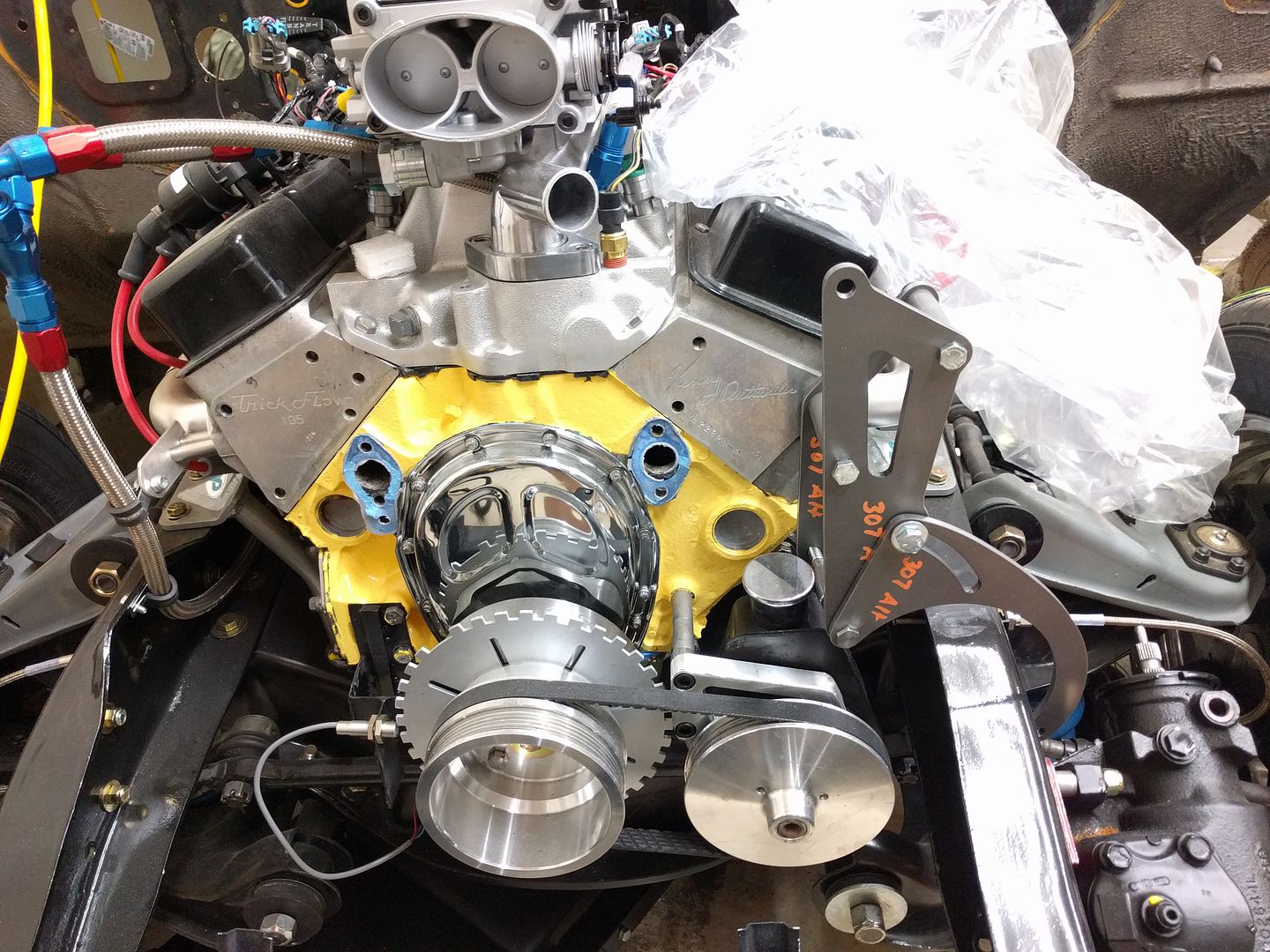

Well as it turns out reverse flow pumps for 87-95 years had a different pulley bolt pattern. So I've had to order a new water pump pulley to fit. Also ordered a new crank pulley since my current one is a retro design to run two serpentine belts, whereas my new setup will be over big belt. Pics to come when they arrive.

|

|

|

|

|

|

#199 |

|

Registered User

Join Date: Jun 2012

Location: Portland

Posts: 1,330

|

Re: Project "Second Chance" - Hot Rod 66' GMC

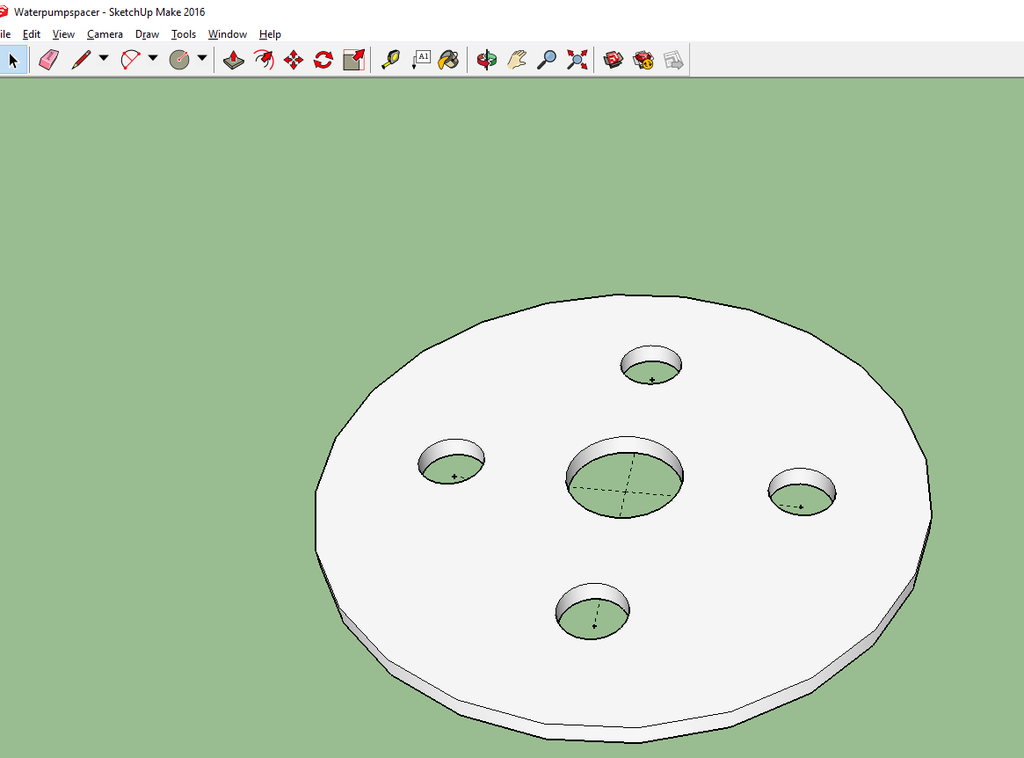

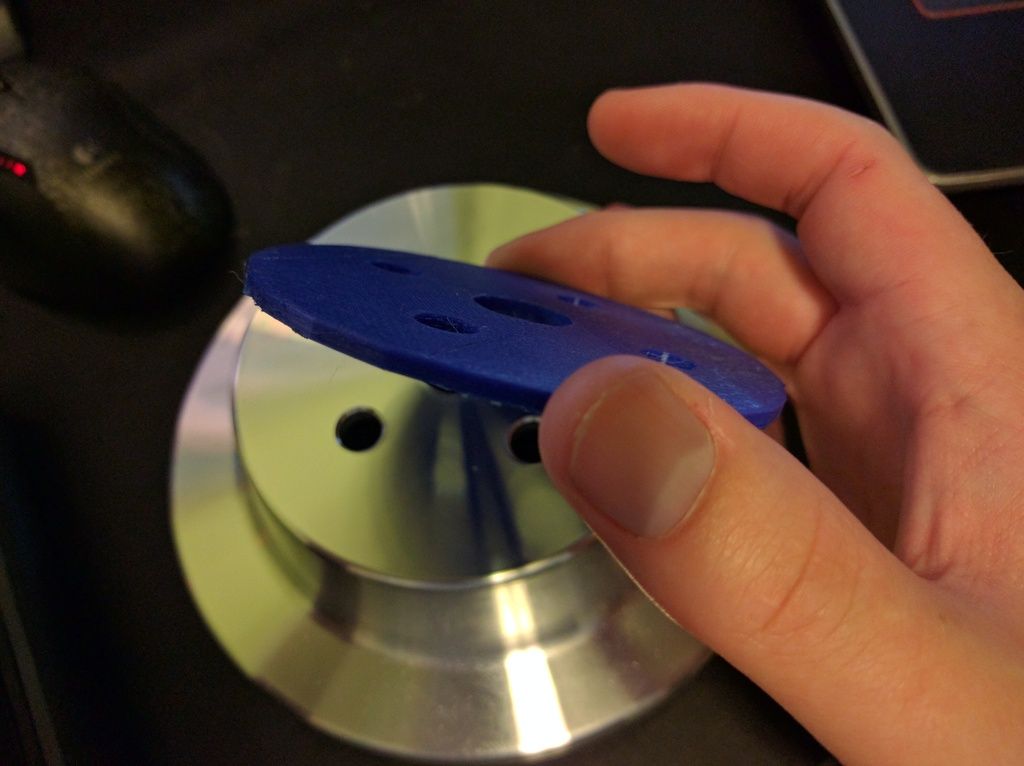

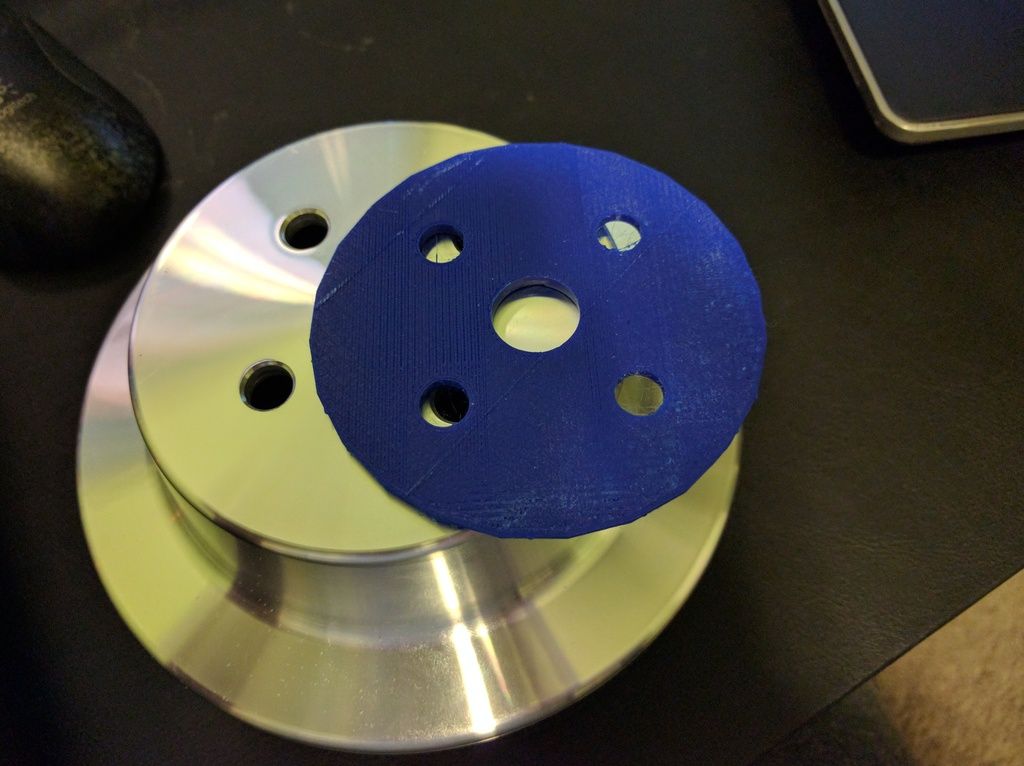

A little more progress. I received my new crank and water pump pulleys. They fit great, though with the crank position wheel I needed to space the water pump pulley out about 3mm. I couldn't find shims that match the 87+ pulley bolt pattern, so I decided to make my own. I fired up Sketchup and measured the spacing needed.

Then I cleaned off the CNC/Printer and started a print. I set this one to print with a 70% infill at 1mm layers to be really dense, so it took like 7 hours. I probably could have done a standard 2mm/30% in about an hour and it would have been okay, but since it is thin I wanted to solid. Quality turned out okay. Not the greatest. I probably need to tweak settings, but since it's a hidden part it should be okay.    That's all for now folks

|

|

|

|

|

|

#200 |

|

Registered User

Join Date: May 2013

Location: Centerville,Ma.

Posts: 1,223

|

Re: Project "Second Chance" - Hot Rod 66' GMC

Technology at it's finest. I bet I could have knocked that out with a drill press and hole saw in less than an hr. though.

|

|

|

|

|

| Bookmarks |

|

|