|

|

|

#201 |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,648

|

Re: 55 Wagon Progress

Glad to help, thanks for all the comments!

__________________

Robert |

|

|

|

|

|

#202 |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,648

|

Re: 55 Wagon Progress

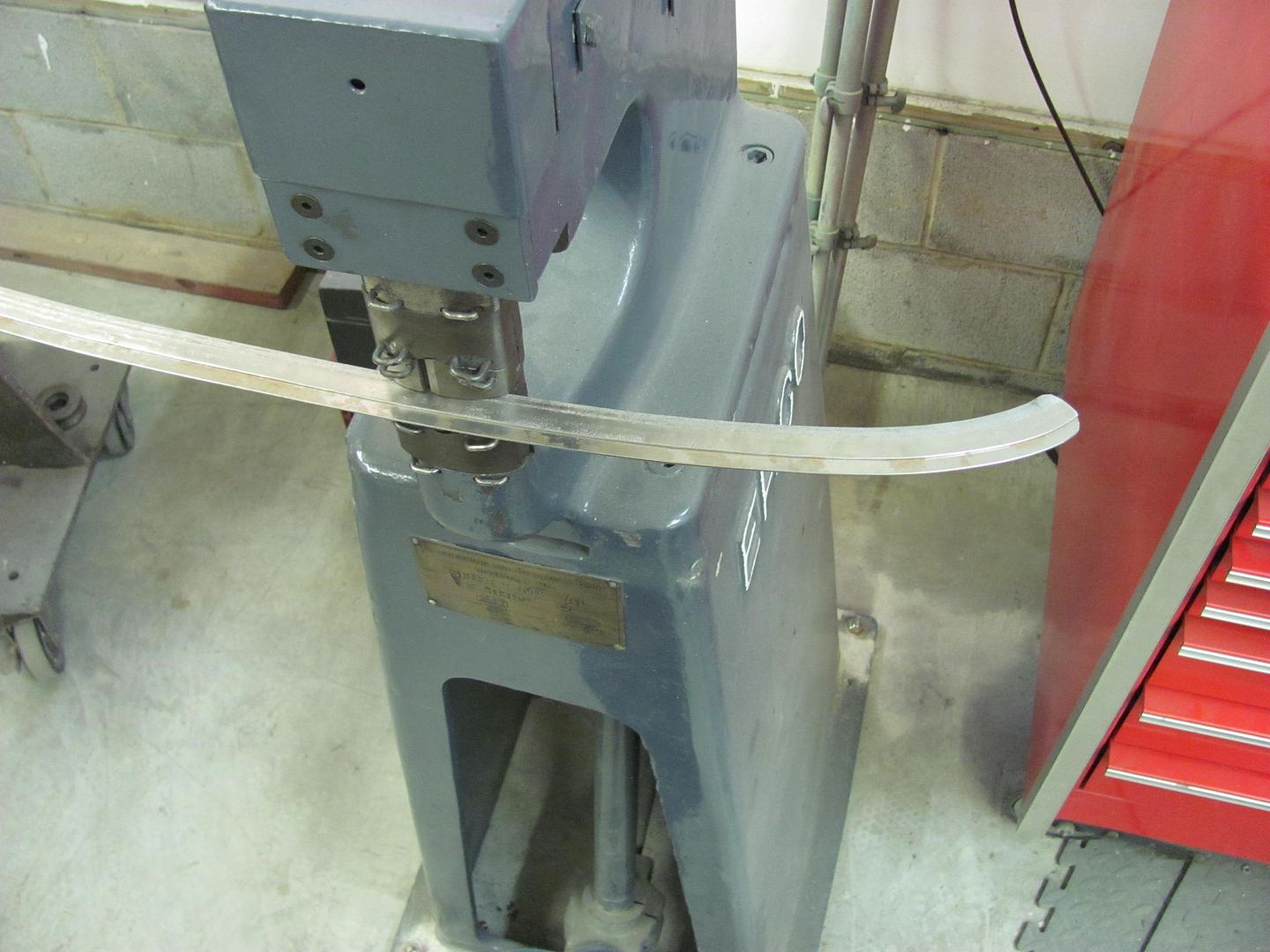

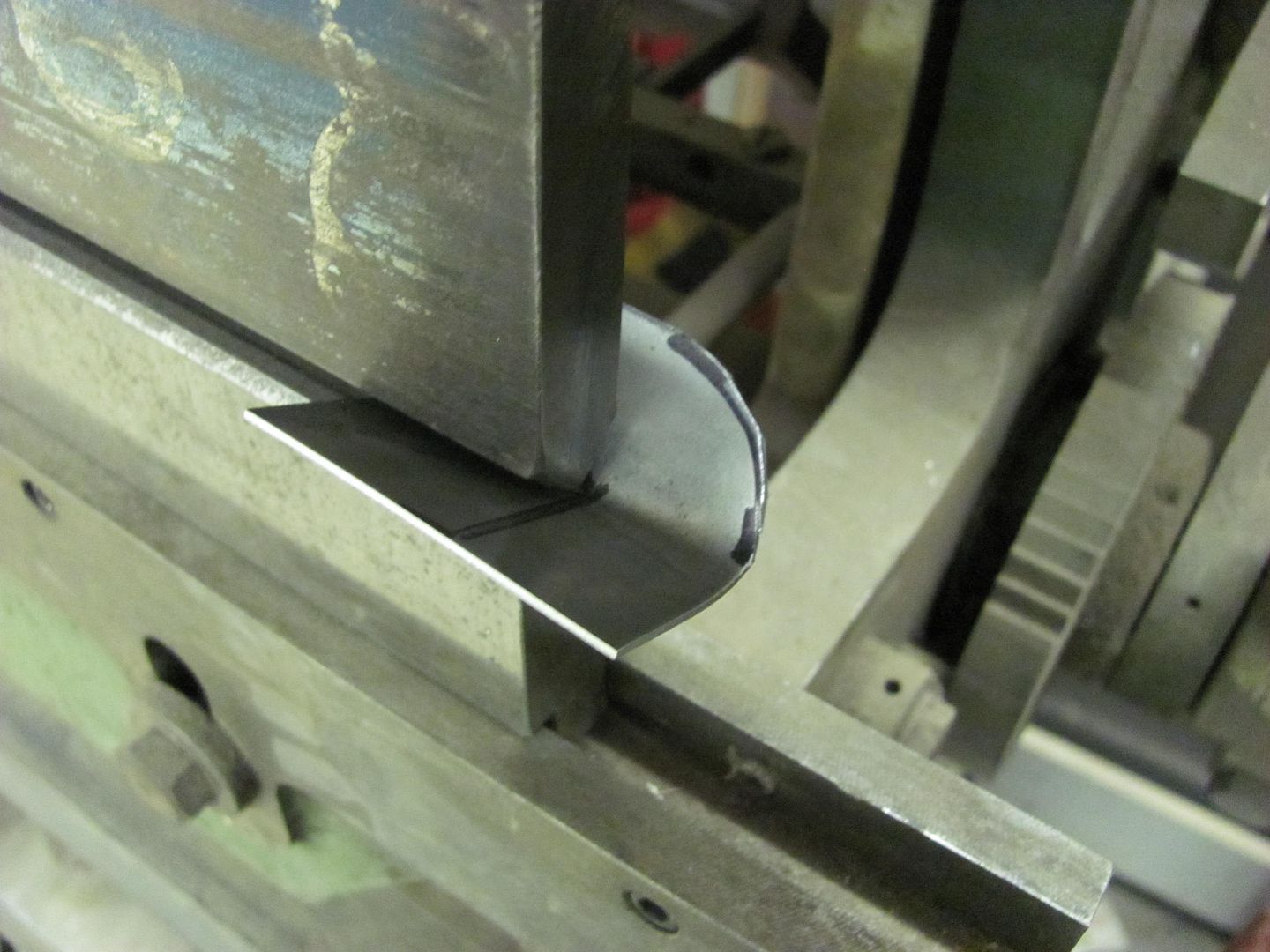

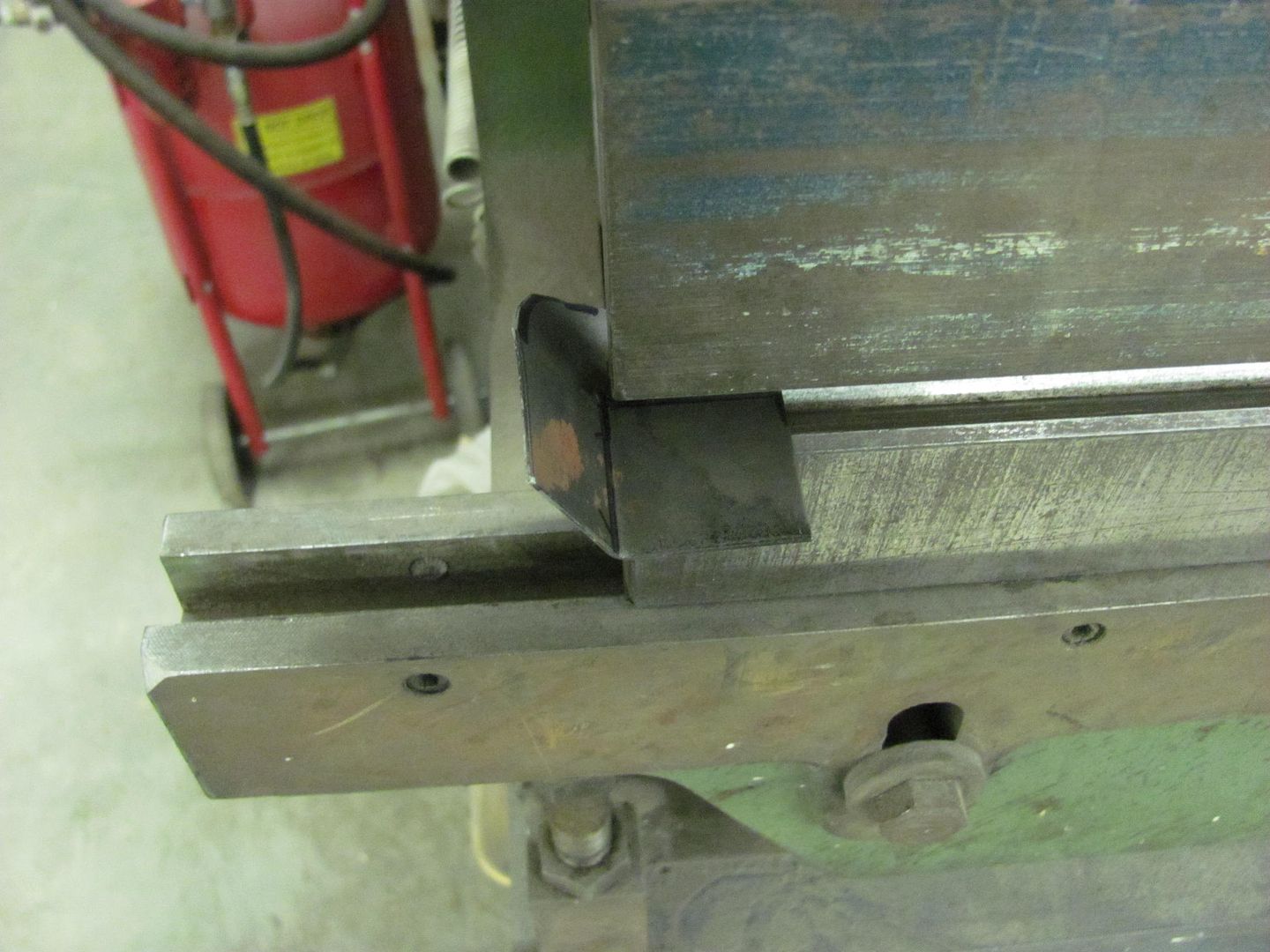

More progress today, working on some metal bumping on the drivers quarter, so a profile template was needed... Took a 1-1/2 x48 piece of 19 ga and used the mag brake to fold it, then the bead roller to flatten.

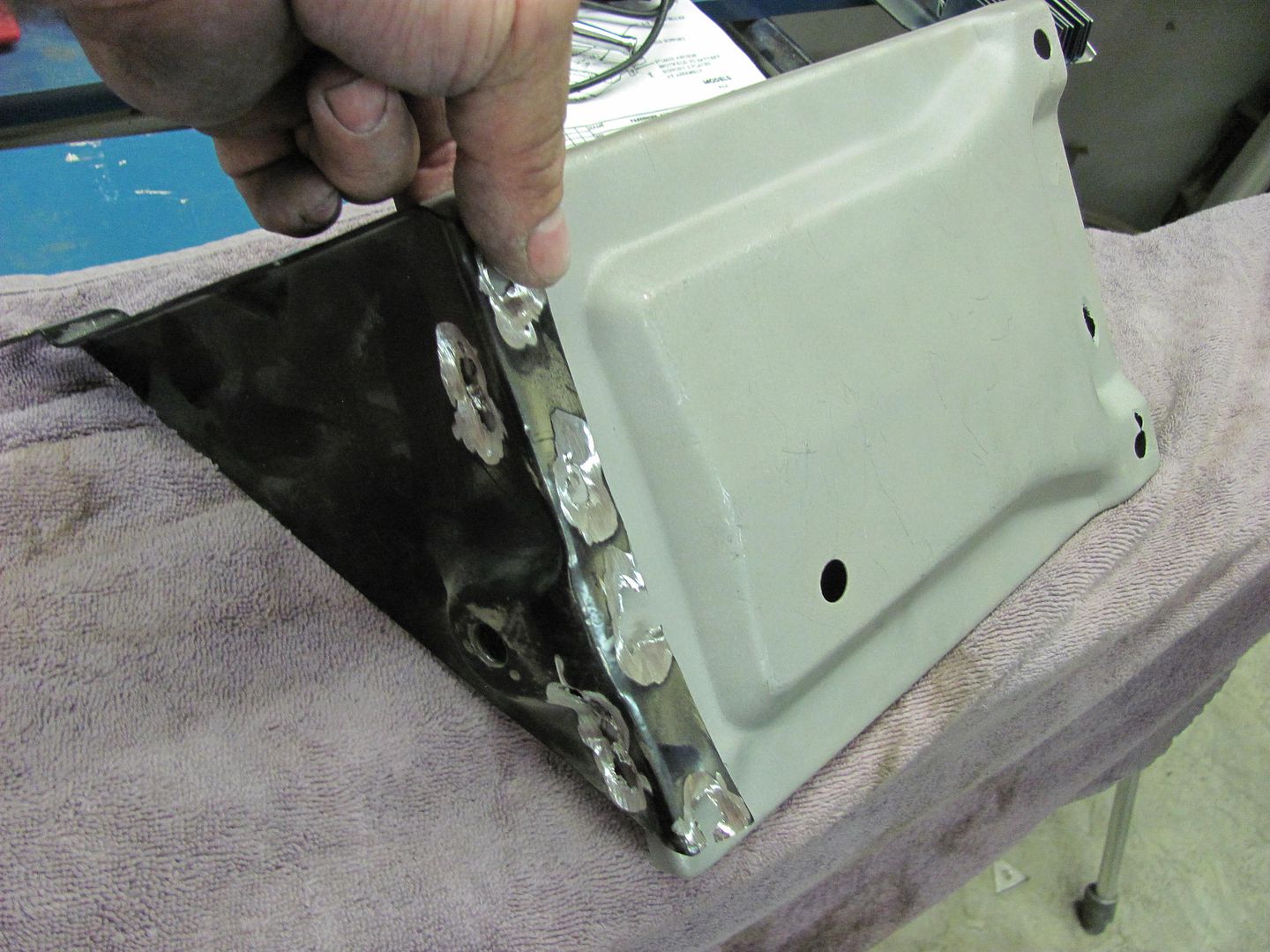

Then used the kick shrinker to get it to match the contour of the rear of the door, this will give us a close match to the front half of the quarter...   If you shrink too much, no need to change dies, just shrink the rear portion of the template (away from the body)  Ends are radiused...  Then the factory battery tray (firewall mounted) was dissected to use with the "Factory AC car" parts, in order to mount the battery in the passenger front corner behind the core support.  ...and all the parts were media blasted. We have some sheet metal plugs to punch out tomorrow for use on a couple of repairs of thin spots, and then the works will get mocked up on the inner fender for placement, weld the parts together, and off for powder coating.  One more tip for those doing mock-up/door fitment without latches, this will hold the door flush with the jamb. (Thanks to Laszlo Nobi for that idea)

__________________

Robert |

|

|

|

|

|

#203 |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,648

|

Re: 55 Wagon Progress

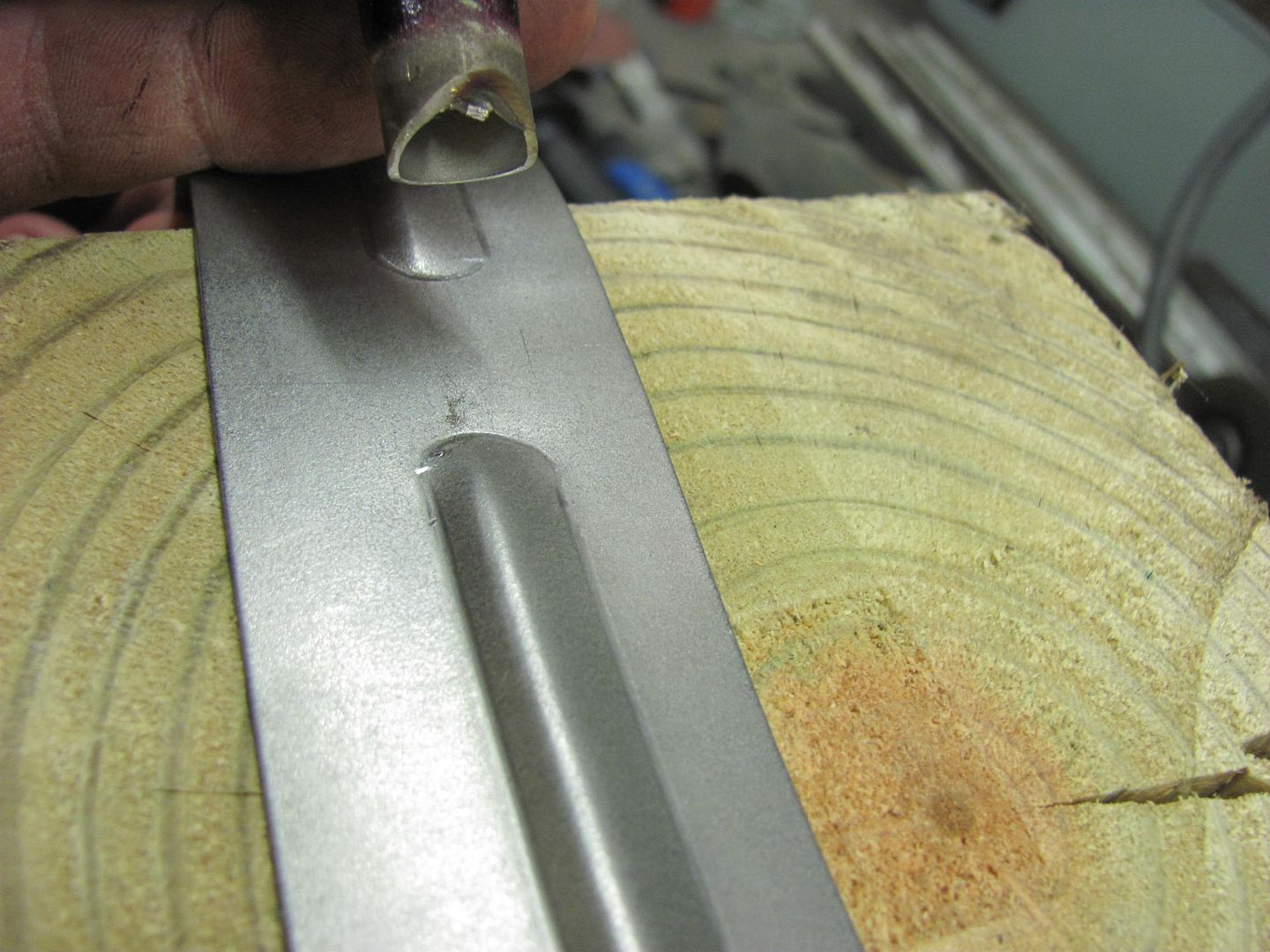

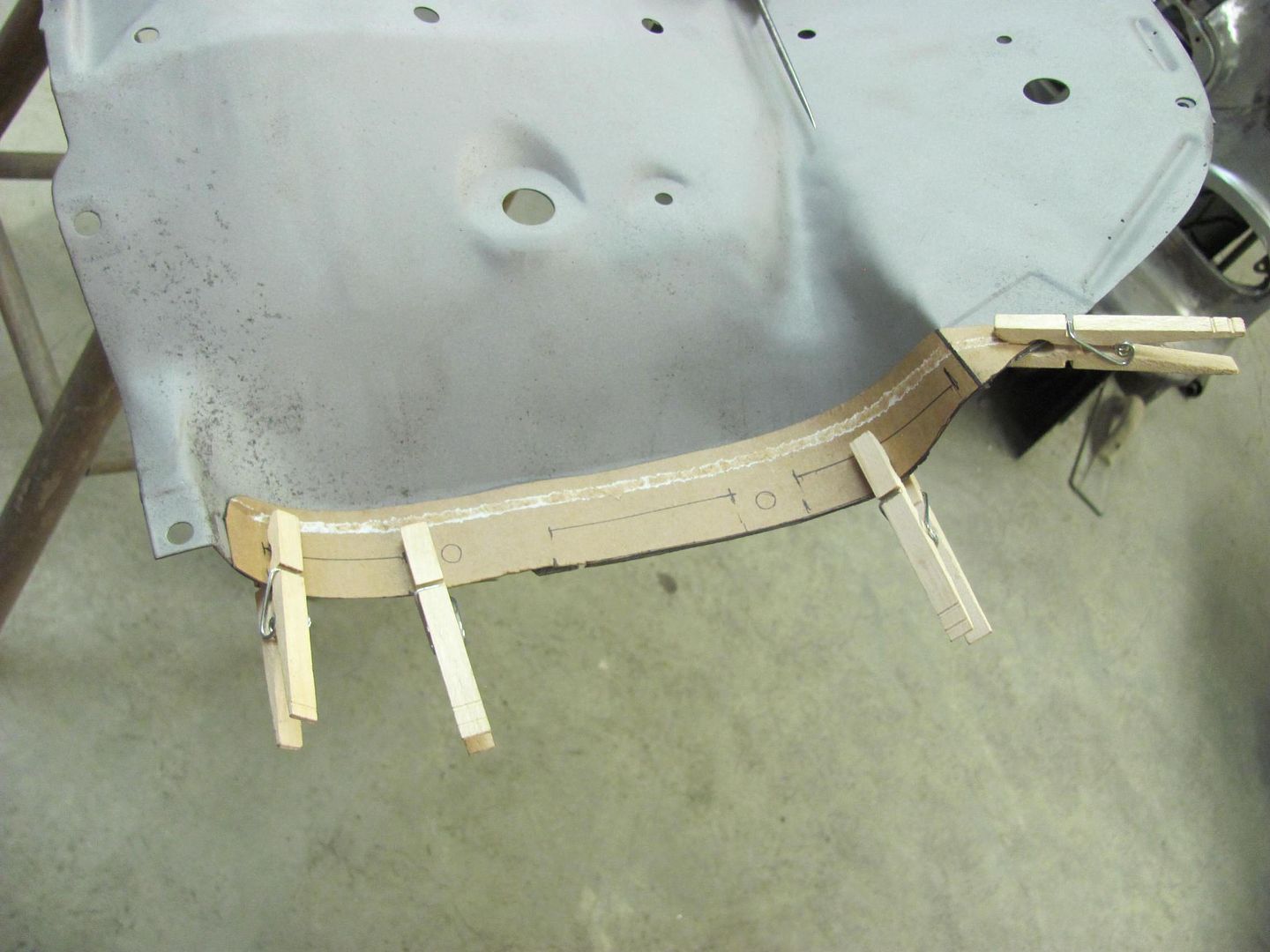

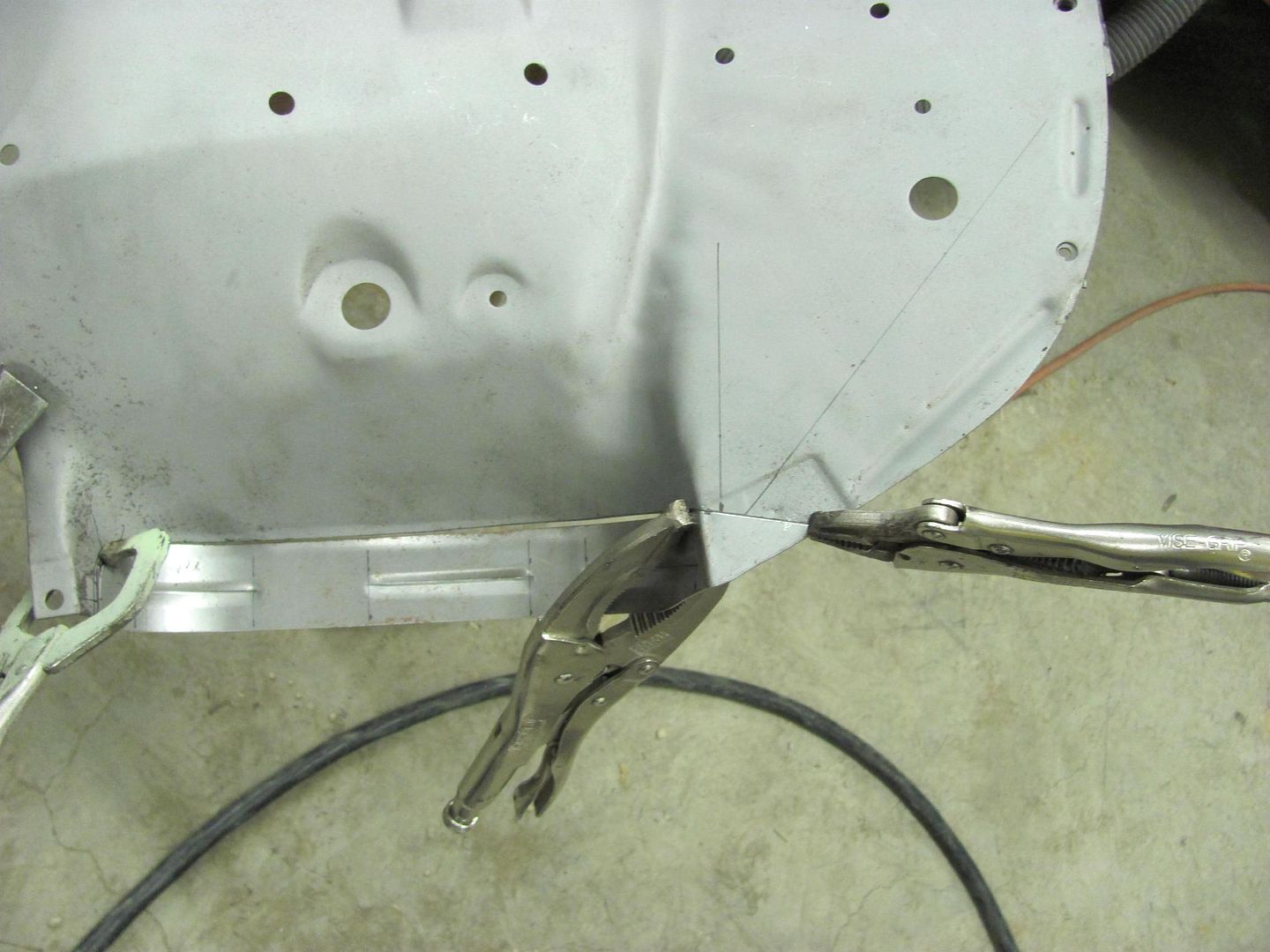

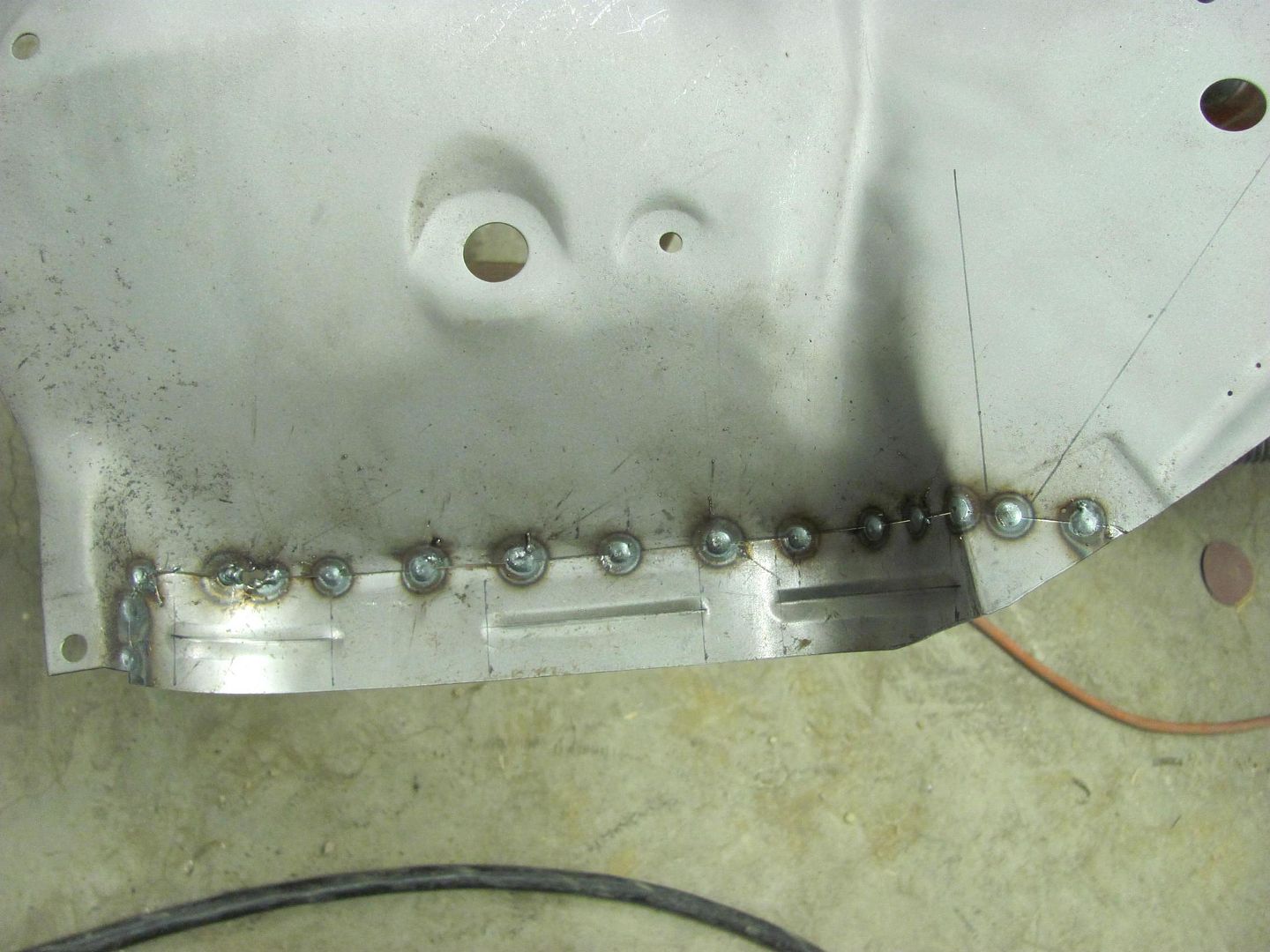

Tonight we turned our attention to inner fenders. We've got some items slated for powder coating, and these will get added to the pile.

The front edge that bolts outside the grille is showing remnants of water retention...   Mountain Dew template  Bead details to match the originals.....  Bead roller was set up with a backstop die...   Skateboard wheel and "rolling" wheel used to add radiused ends....    Grabbed a suitable scrap from the pile and used the sander to make a bead ender tool thingie, used on the treated 6x6 anvil...    Clamped and tacked....   More tomorrow......

__________________

Robert |

|

|

|

|

|

#204 |

|

Registered User

Join Date: Jan 2012

Location: Eastern Ontario, Canada

Posts: 1,041

|

Re: 55 Wagon Progress

Nice!

__________________

1952 Canadian Chevy 1300 C4 IFS & D44 IRS 5.3 HO L33 My Build: http://67-72chevytrucks.com/vboard/s...d.php?t=632938

|

|

|

|

|

|

#205 |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,648

|

Re: 55 Wagon Progress

Well the Wheeling Machine finally has paint!

Napa Econo-etch primer....  H/K Pavo Purple and Flo Klear. I tried playing with the camera settings to get it to capture the true color, but it just wasn't happening. It may look blue in the pic, but it's about as close to Chrysler's Plum Crazy as you can get without putting a HEMI under the hood..    Here's the actual color...

__________________

Robert |

|

|

|

|

|

#206 |

|

Registered User

Join Date: May 2007

Location: Deale Md

Posts: 4,663

|

Re: 55 Wagon Progress

Ya gonna add some art work on it.

__________________

James 63 GMC V6 4speed carryall 65 chevy swb bbw V8 auto 68 K20 327/4 speed, buddy buckets 2002 GMC CC Dually Duramax 64 GMC lwb 3/4 V6 4speed SOLD 66 GMC swb bbw buddy buckets SOLD IG duallyjams The only thing that stays the same is constant change! |

|

|

|

|

|

#207 |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,648

|

Re: 55 Wagon Progress

I'll have to find someone that does some striping..

While I was finishing up the paint on the English Wheel, Kyle stripped the driver's inner fender. This one has the same issues in the front as well as a spot up top where the flange of the fender had some rust issues we previously repaired..   Looks like our same template will work here as well..     And while I was trimming more rust away, Kyle was working on the passenger side learning the fine art of dressing welds...

__________________

Robert |

|

|

|

|

|

#208 |

|

Registered User

Join Date: May 2007

Location: Deale Md

Posts: 4,663

|

Re: 55 Wagon Progress

Young ears no hearing protection.

__________________

James 63 GMC V6 4speed carryall 65 chevy swb bbw V8 auto 68 K20 327/4 speed, buddy buckets 2002 GMC CC Dually Duramax 64 GMC lwb 3/4 V6 4speed SOLD 66 GMC swb bbw buddy buckets SOLD IG duallyjams The only thing that stays the same is constant change! |

|

|

|

|

|

#209 |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,648

|

Re: 55 Wagon Progress

I picked up new safety glasses and respirator for him, had a brain cramp on the hearing protection. Thanks for the reminder...

__________________

Robert |

|

|

|

|

|

#210 |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,648

|

Re: 55 Wagon Progress

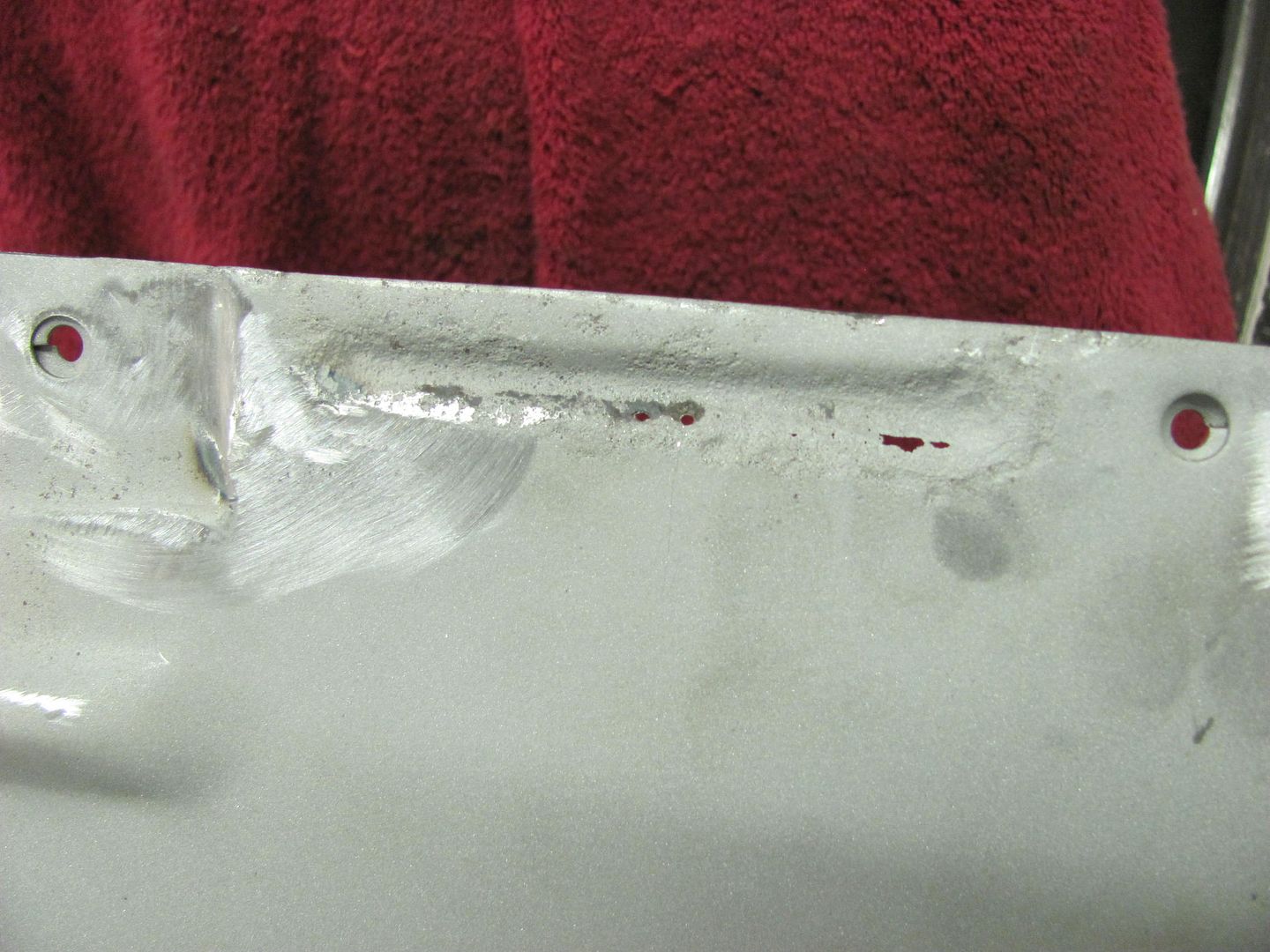

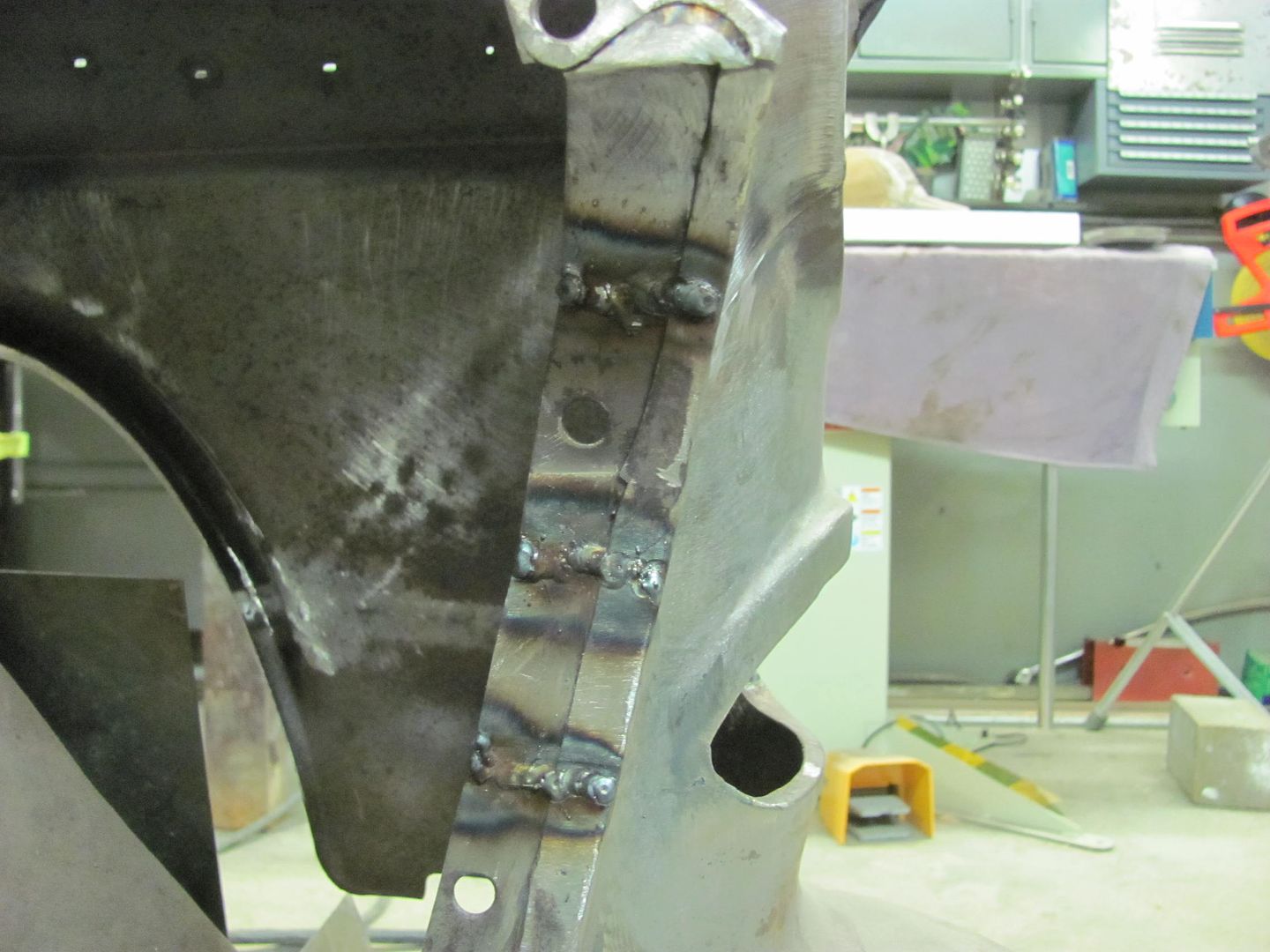

While Kyle was working on dressing some welds this evening, I took some time to planish the weld on the driver's fender eyebrow. Here's the previous.....

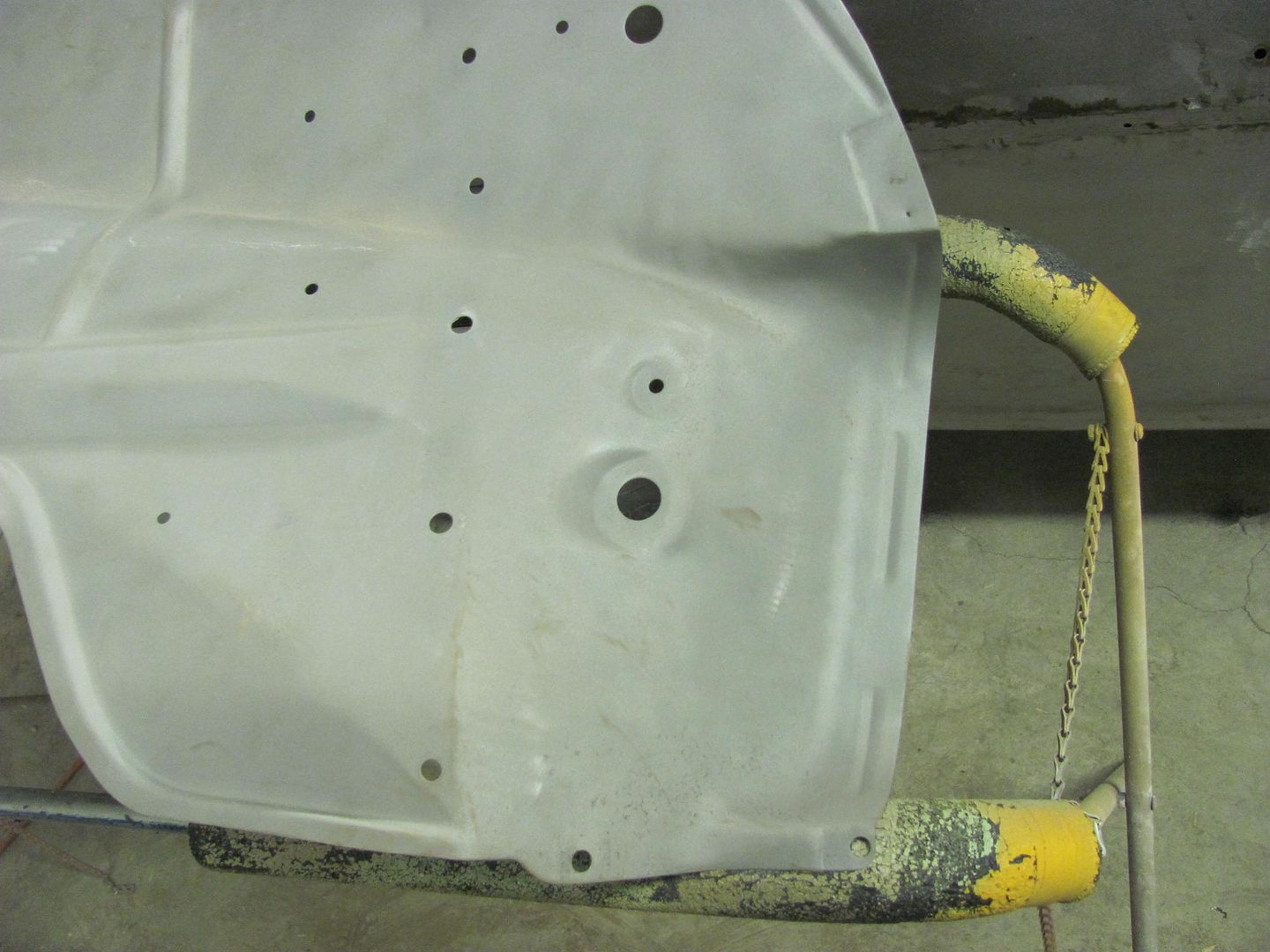

It had a noticeable dip throughout the weld seam. Here's the tool used.....   The eyebrow on the passenger side was planished all by hand, and probably has a couple hours of work. The Watervliet planishing hammer made short work of the driver's side, it took all of five minutes time to have it in a comparable state as the passenger side... with the dip all but disappeared  Continuing on with more inner fender work, starting on the driver's side....   Back side, full penetration welds.....  Staple holes for seal filled...   Should get both these finished up Saturday morning and mocked up with the battery tray..

__________________

Robert |

|

|

|

|

|

#211 |

|

Registered User

Join Date: Jan 2012

Location: Eastern Ontario, Canada

Posts: 1,041

|

Re: 55 Wagon Progress

Nice welds as usual! I'd love to have one of the hand held planishing hammers. What lower die did you use?

__________________

1952 Canadian Chevy 1300 C4 IFS & D44 IRS 5.3 HO L33 My Build: http://67-72chevytrucks.com/vboard/s...d.php?t=632938

|

|

|

|

|

|

#212 |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,648

|

Re: 55 Wagon Progress

Sid, it was about a 4 or 6" radius die, can't remember which one I ended up using

__________________

Robert |

|

|

|

|

|

#213 |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,648

|

Re: 55 Wagon Progress

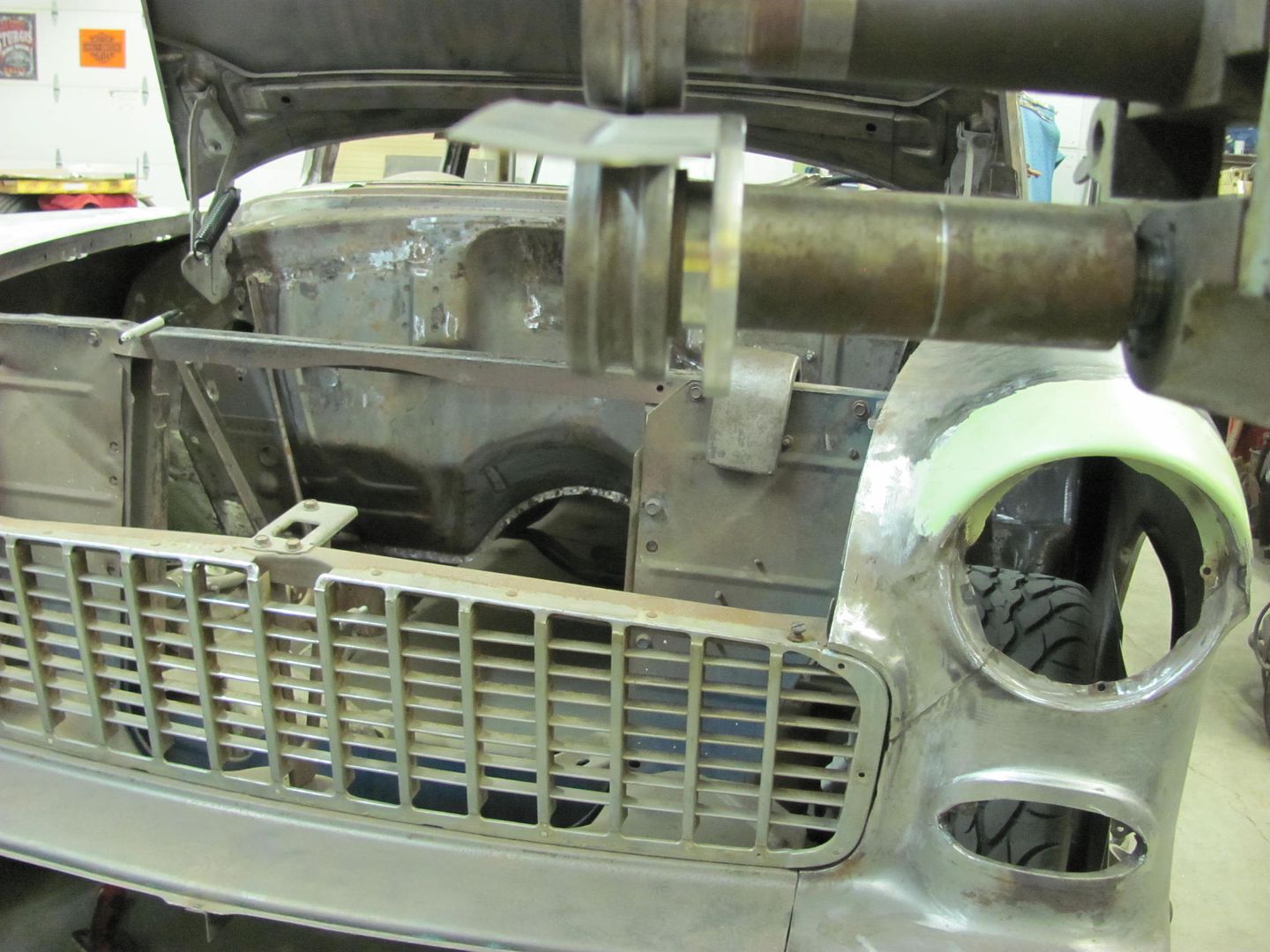

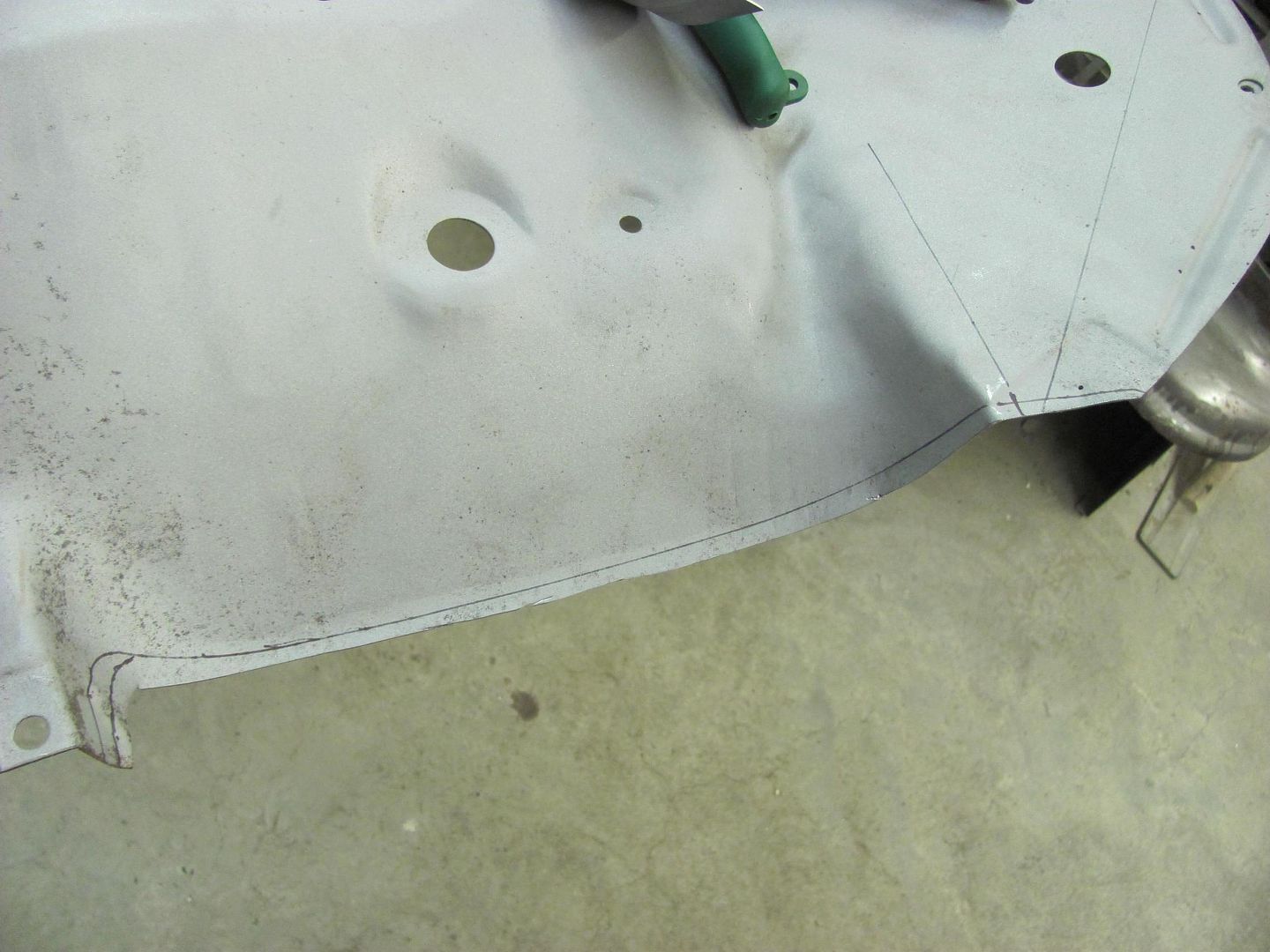

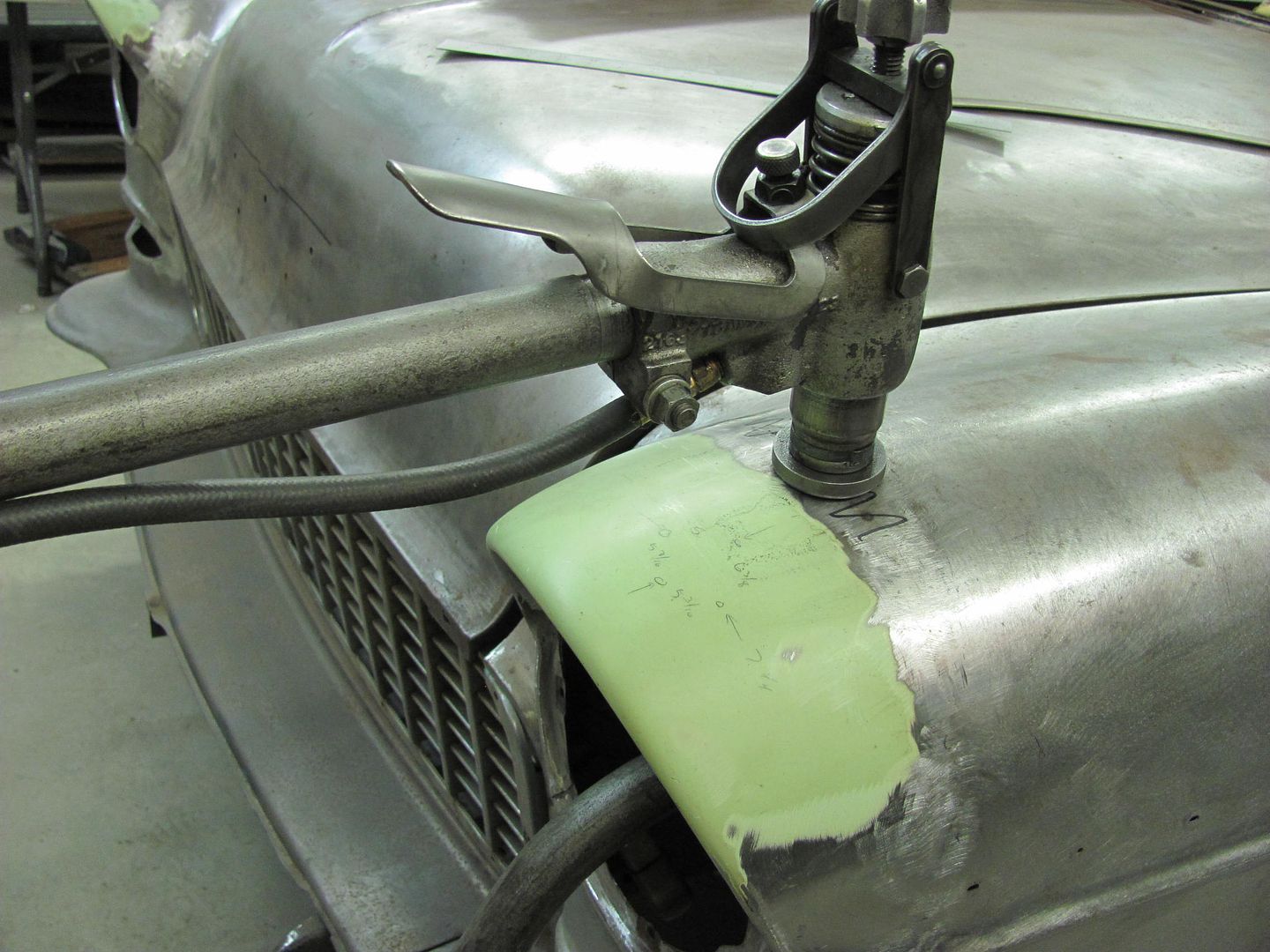

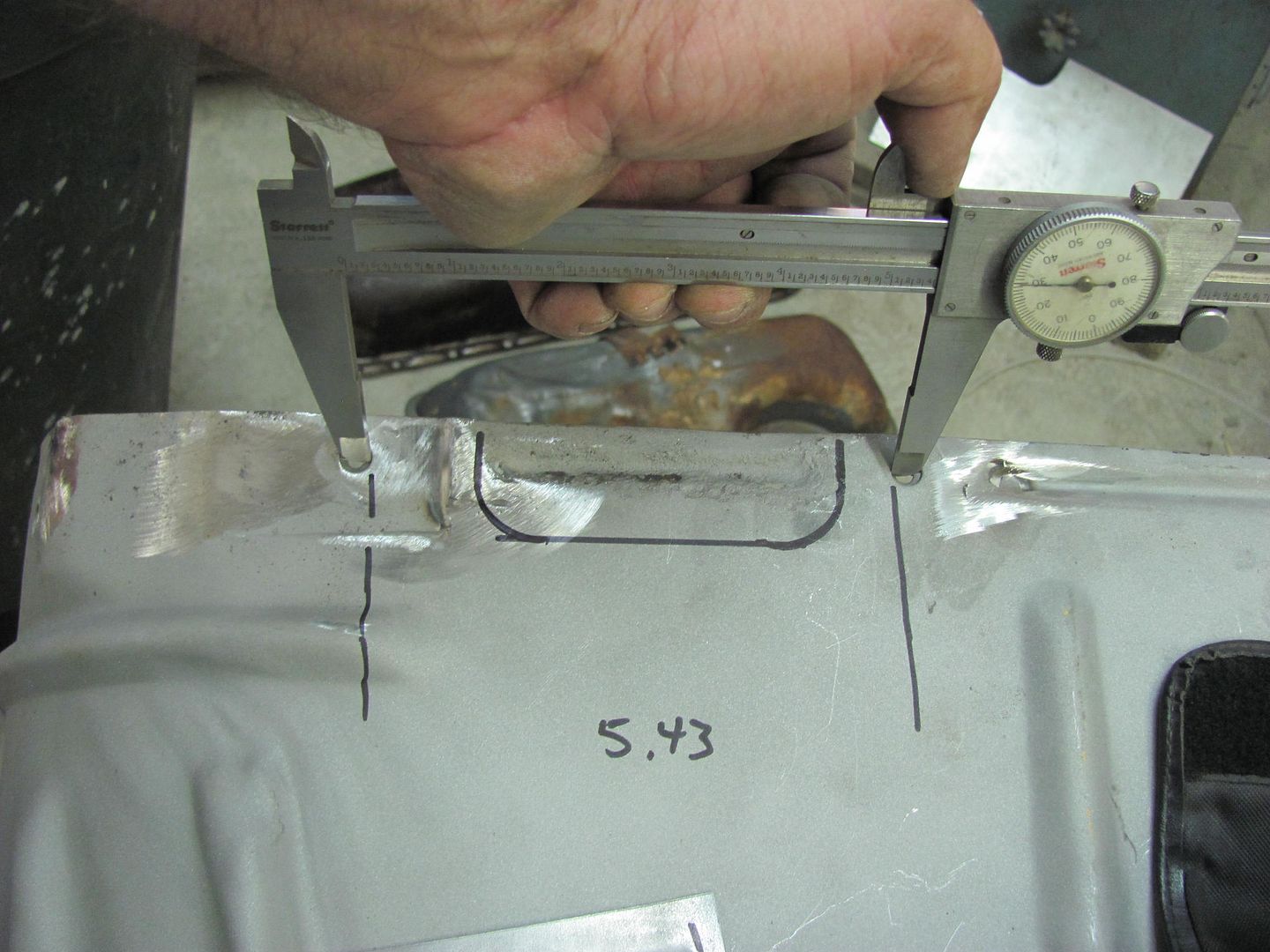

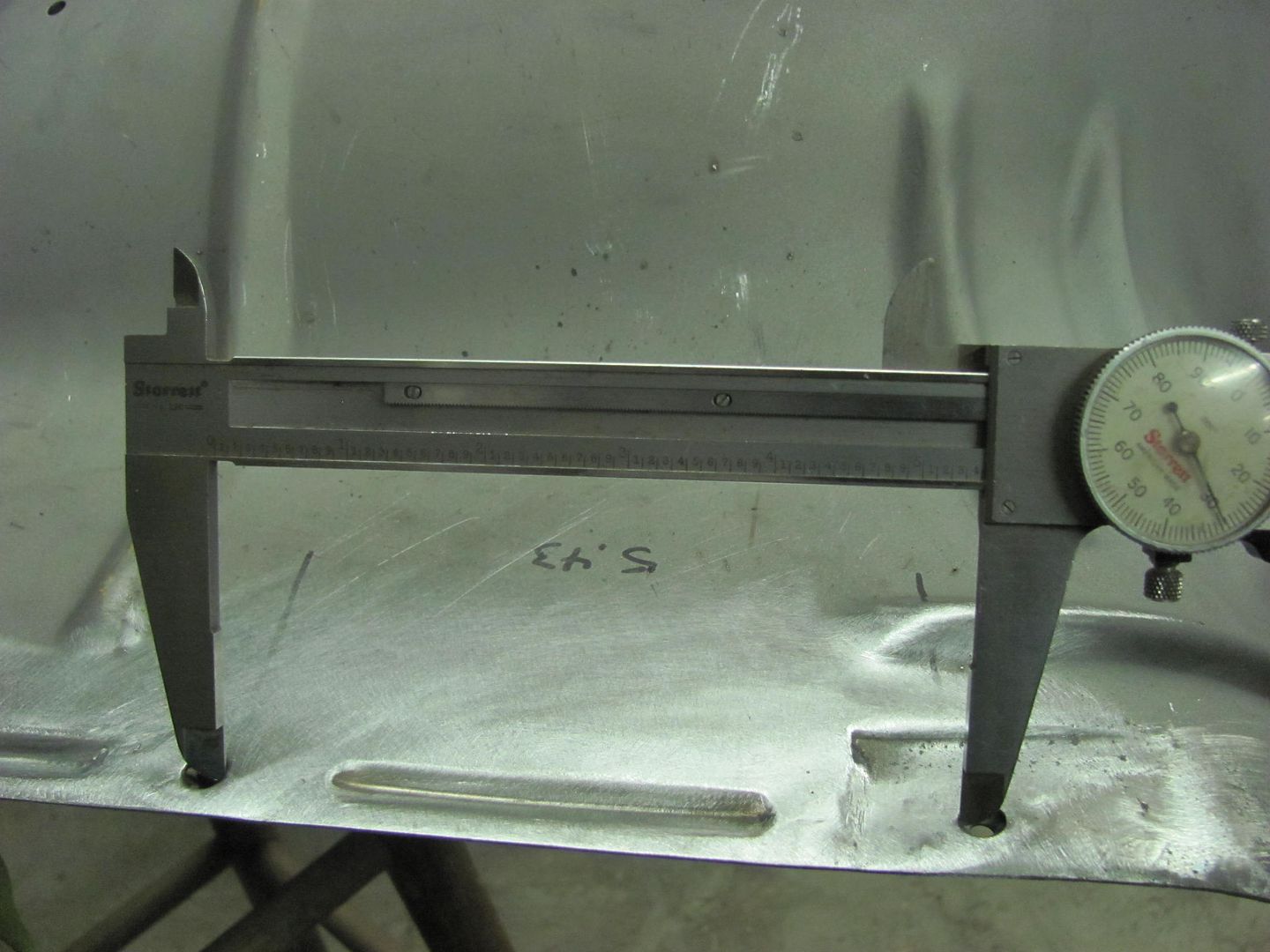

Here's the passenger side with the welds dressed and mocked up to the grille....

While Kyle media blasted the passenger side, I did some finish work on the driver's side. We still had this up at the top to fix...  A replacement was made and marked out on the inner fender..  Took a reference measurement to insure any shrinking effects were properly planished out...  Ice pick works well in marking the cutout pattern...   Trimmed and fitted  Tacked in place...  Rear side   After planishing and dressing the welds, re-checking the reference measurement....   Passenger side complete....   Driver's side complete.....   Next task will be to assemble the battery tray and send off the goodies for powder coating.

__________________

Robert |

|

|

|

|

|

#214 |

|

Senior Member

Join Date: Jul 2012

Location: Oblong, Illinois

Posts: 7,028

|

Re: 55 Wagon Progress

Very nice work! Like the bead roller and shrinker too.

|

|

|

|

|

|

#215 |

|

Registered User

Join Date: Apr 2011

Location: .

Posts: 3,104

|

Re: 55 Wagon Progress

Seeing your work keeps me on target.

You make it look like there was never any repair at all. Top Notch |

|

|

|

|

|

#216 |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,648

|

Re: 55 Wagon Progress

Thanks for the comments guys!

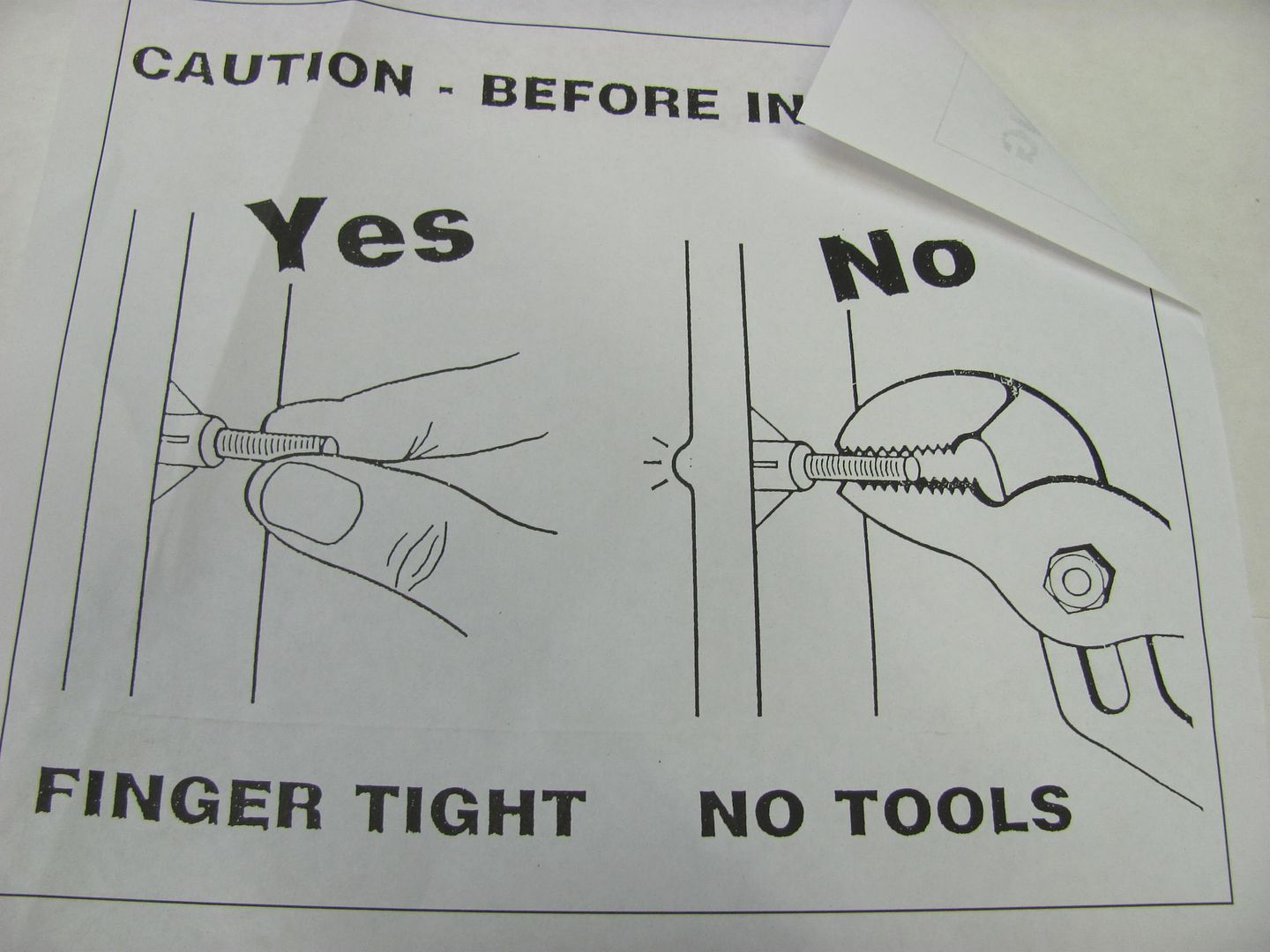

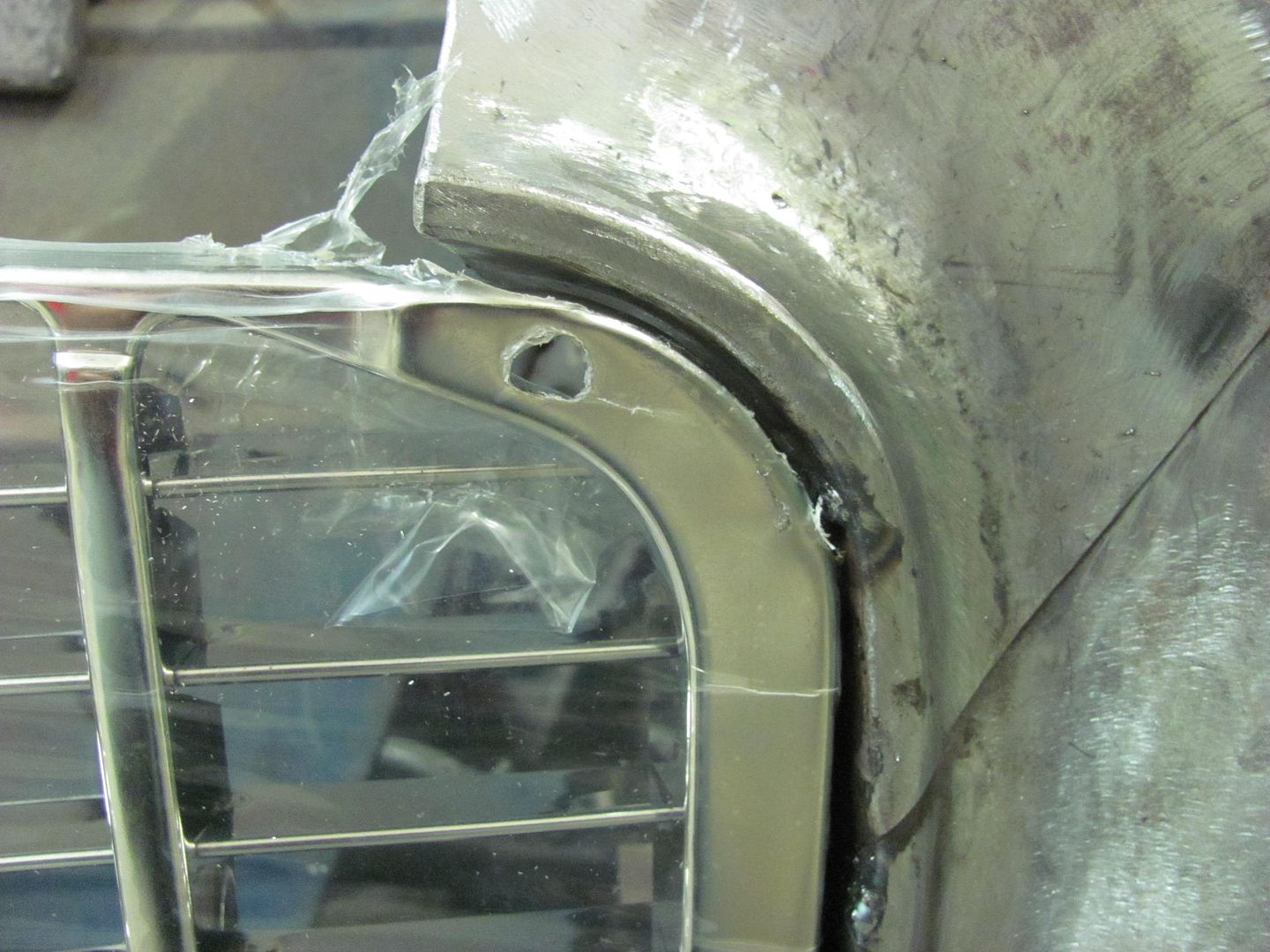

Tonight we worked on fitting the new Gene Smith grille components. It started with the mandatory instructions...  To insure the studs didn't move once hand tightened, some thread lock stuff was used... We did find the qty of hardware was short by two each, and after a quick call to Gene Smith, Fred has some on the way for us..   The new grille fits just like the old one, it is VERY tight in the top corners..   To eliminate the paint rub syndrome and other possible front end squeaks from metal on metal, some templates were made so we can do some hammering on the new grille... and keep a consistent distance between.  Initial fitment:    Where the passenger side fit fairly well initially, the drivers side showed some rocking and gap issue.    I initially thought the driver's side piece was mis-shapen, but in placing them side by side they were pretty much a mirror image. Checking the front edge of the opening with a straight edge, the passenger side showed to be good and straight, the driver's side had a depressed area. This likely occurred when some fender shaving and rust repairs were performed, without the luxury of the chrome pieces for fitment. So some relief cuts were made to bring out the low area of the opening...   ....for a drastic improvement in the fitment.    The surround trim studs did have some alignment issues with the grille. One of these "tweaking" devices is highly recommended to fine tune the fitment..

__________________

Robert |

|

|

|

|

|

#217 |

|

Registered User

Join Date: Jan 2012

Location: Eastern Ontario, Canada

Posts: 1,041

|

Re: 55 Wagon Progress

Great work!

__________________

1952 Canadian Chevy 1300 C4 IFS & D44 IRS 5.3 HO L33 My Build: http://67-72chevytrucks.com/vboard/s...d.php?t=632938

|

|

|

|

|

|

#218 |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,648

|

Re: 55 Wagon Progress

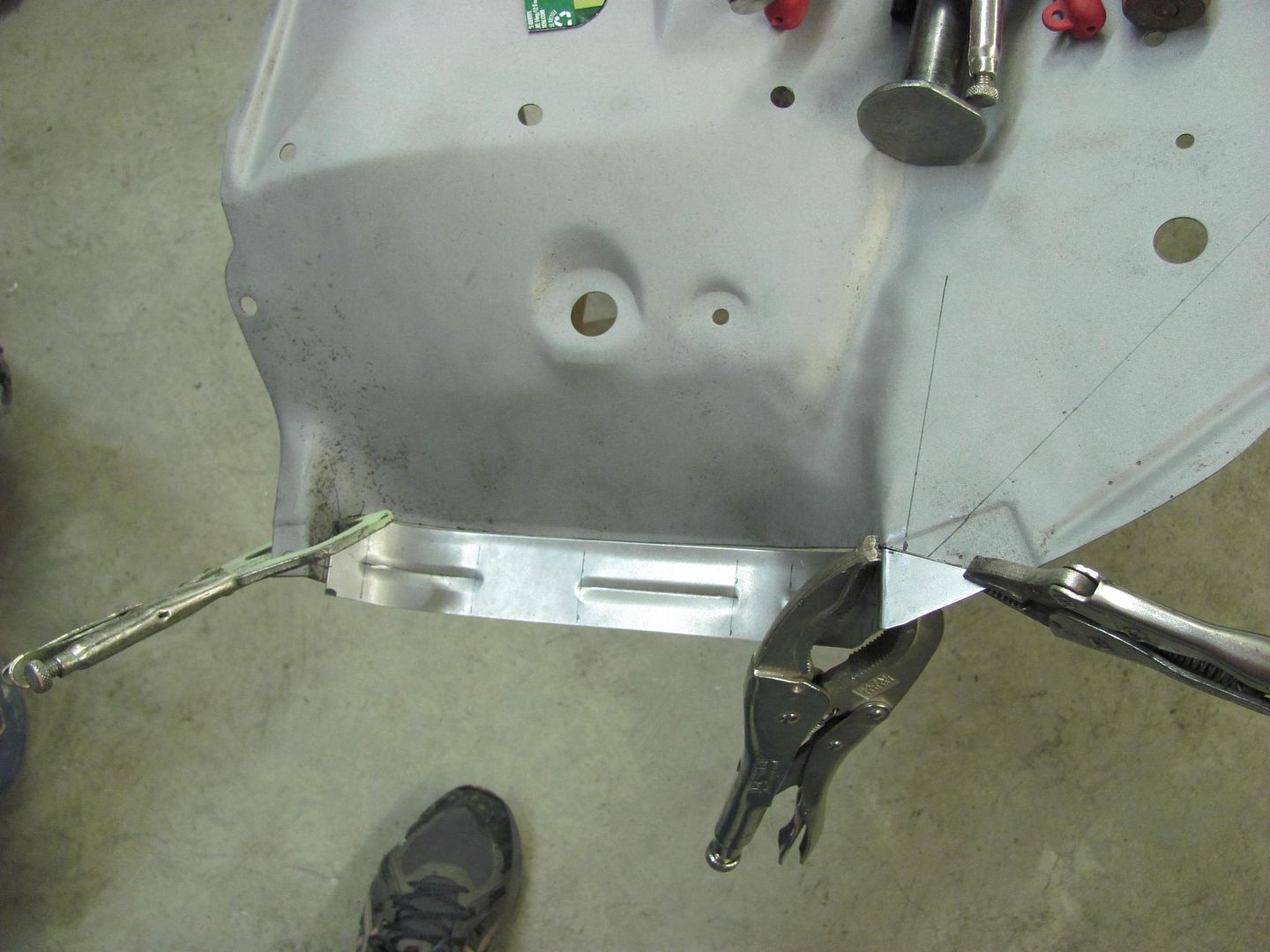

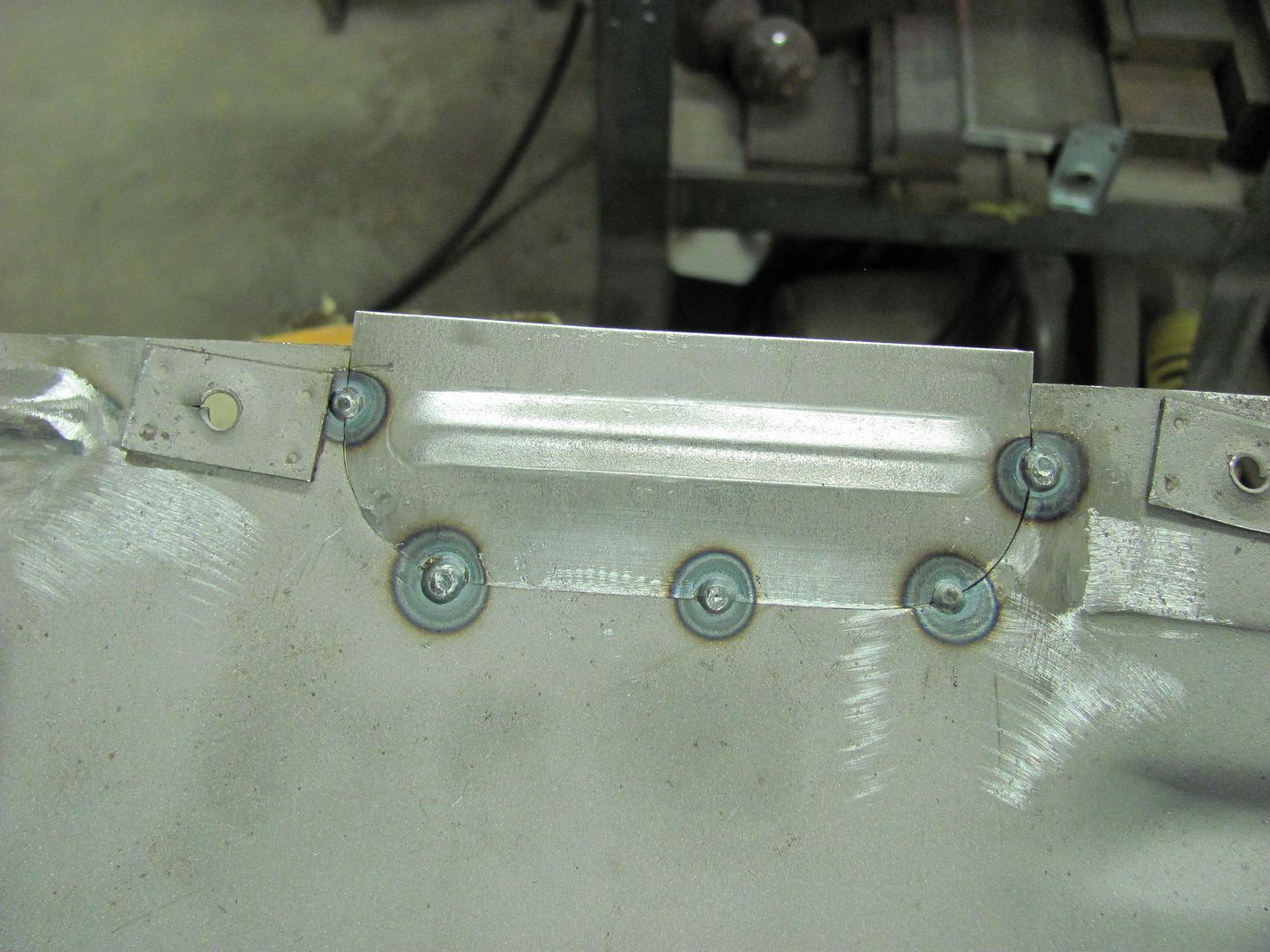

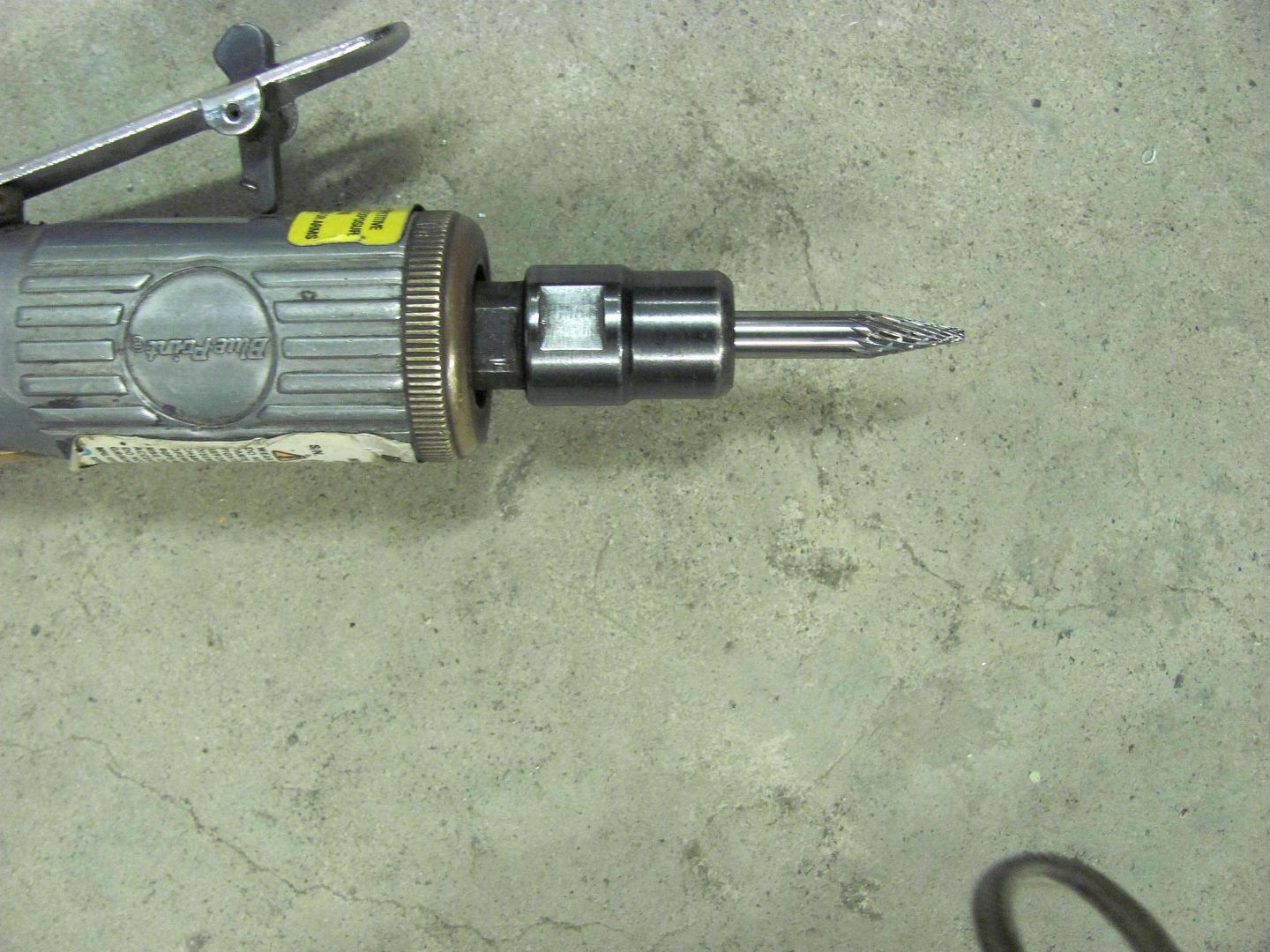

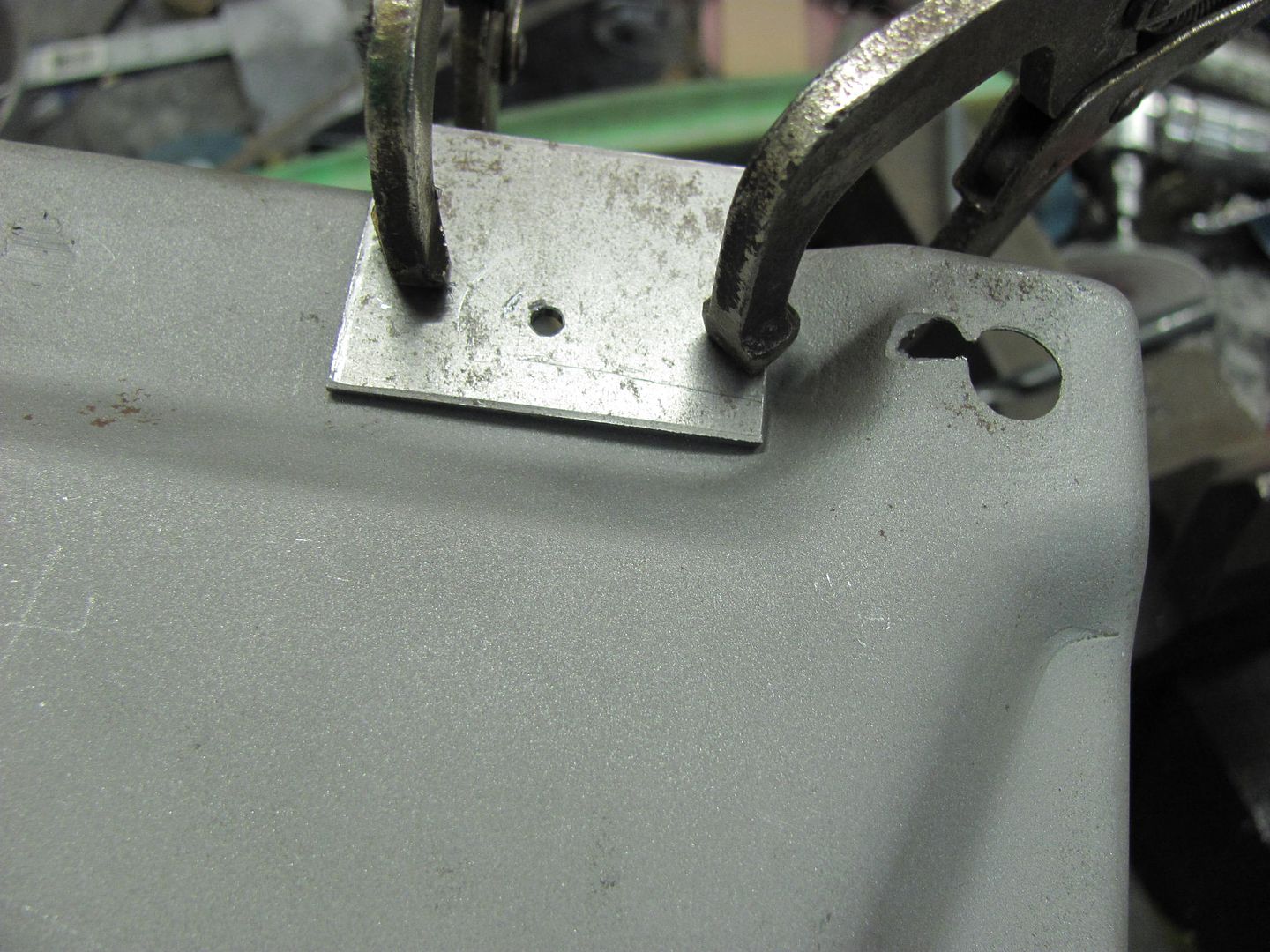

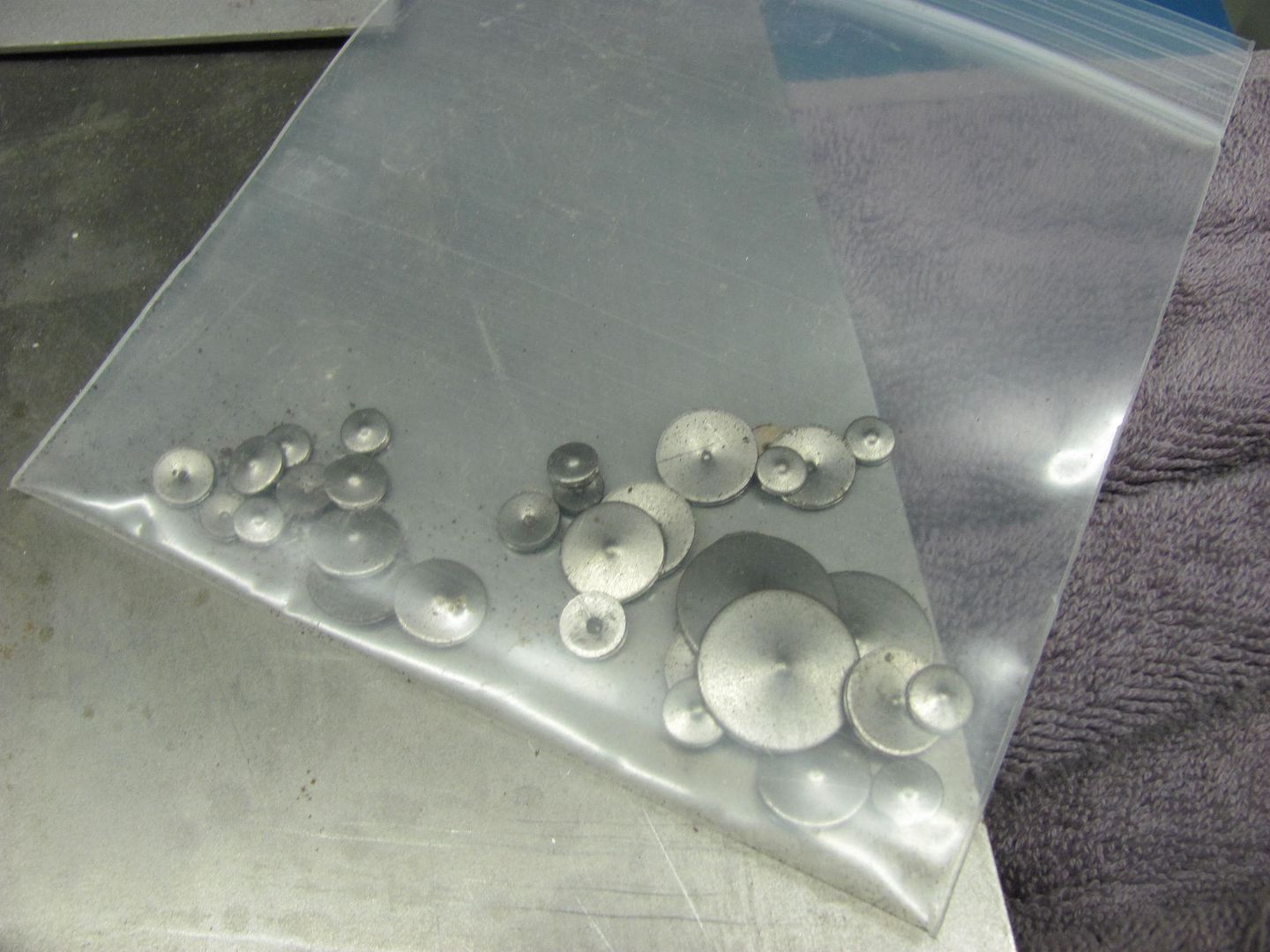

Today we worked on filling some holes in the battery trays so we could finish the inner fender mock up. Hard to drill out a slot, so we clamped on a plate with a pilot hole to use with the Blue Point sheet metal hole cutter:

Plugs.....   We tried this same repair in the corners, but the pitting was too far along and did a good job of blowing holes. So, time to back up an punt, let's make some new corners..      Shrinking the tuck....    New corners welded in....   Some of the lines from forming were left to duplicate those from the factory...  Gusset bracket added to core support....  Holes located on inner fender....  Stiffener brace and angle bracket bolted in....   Tray bolted to the gusset, and plug welded to the angle bracket....  Battery hold down brackets added....   Got a couple plug welds to grind, media blasting, and these parts are ready for powder coating!

__________________

Robert |

|

|

|

|

|

#219 |

|

Senior Member

Join Date: Jul 2012

Location: Oblong, Illinois

Posts: 7,028

|

Re: 55 Wagon Progress

Great ideas, nice work! Did you make the plugs?

|

|

|

|

|

|

#220 |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,648

|

Re: 55 Wagon Progress

A buddy of mine has a turret punch, and I punched out a variety to have some for such repairs....

__________________

Robert |

|

|

|

|

|

#221 |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,648

|

Re: 55 Wagon Progress

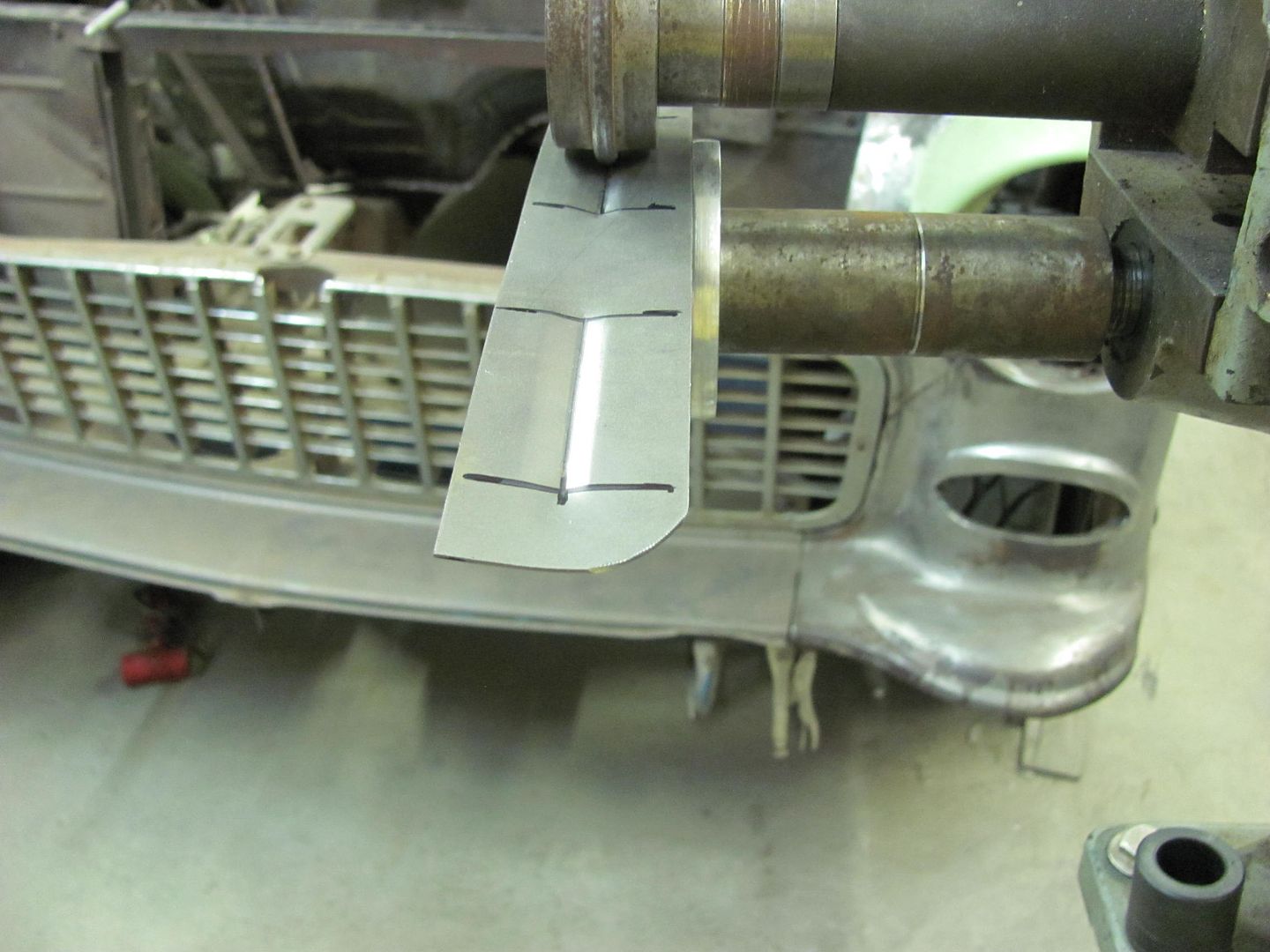

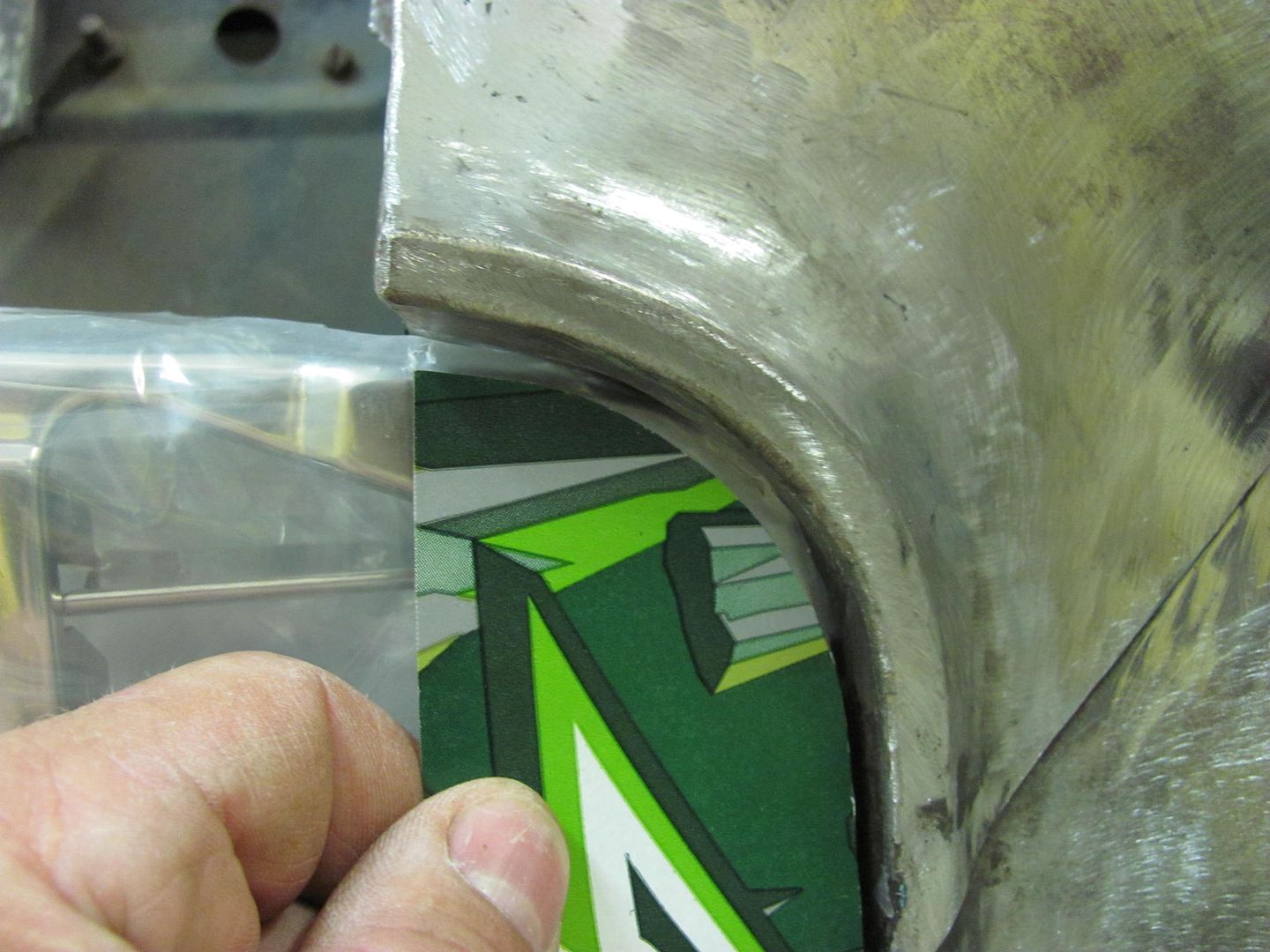

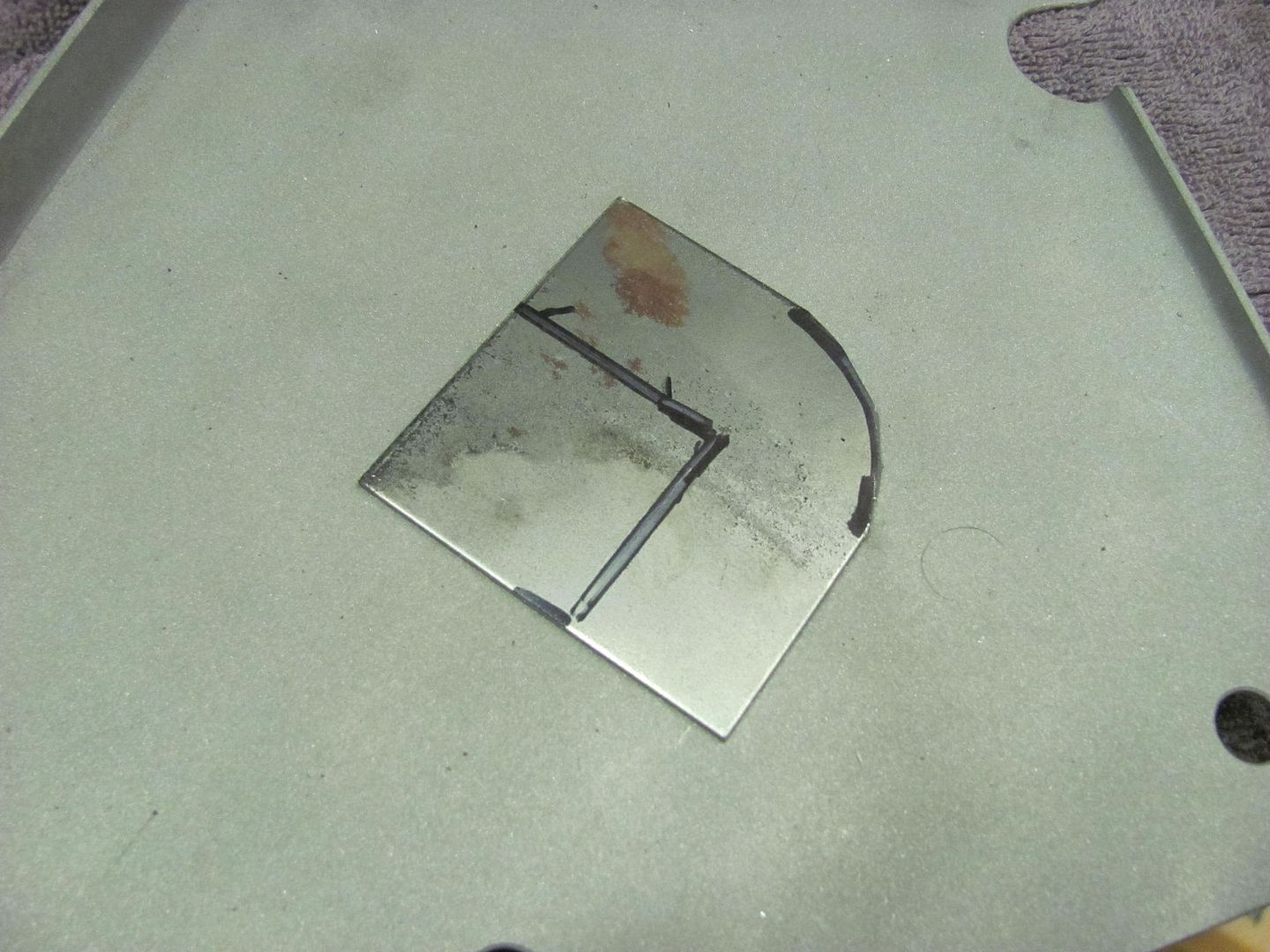

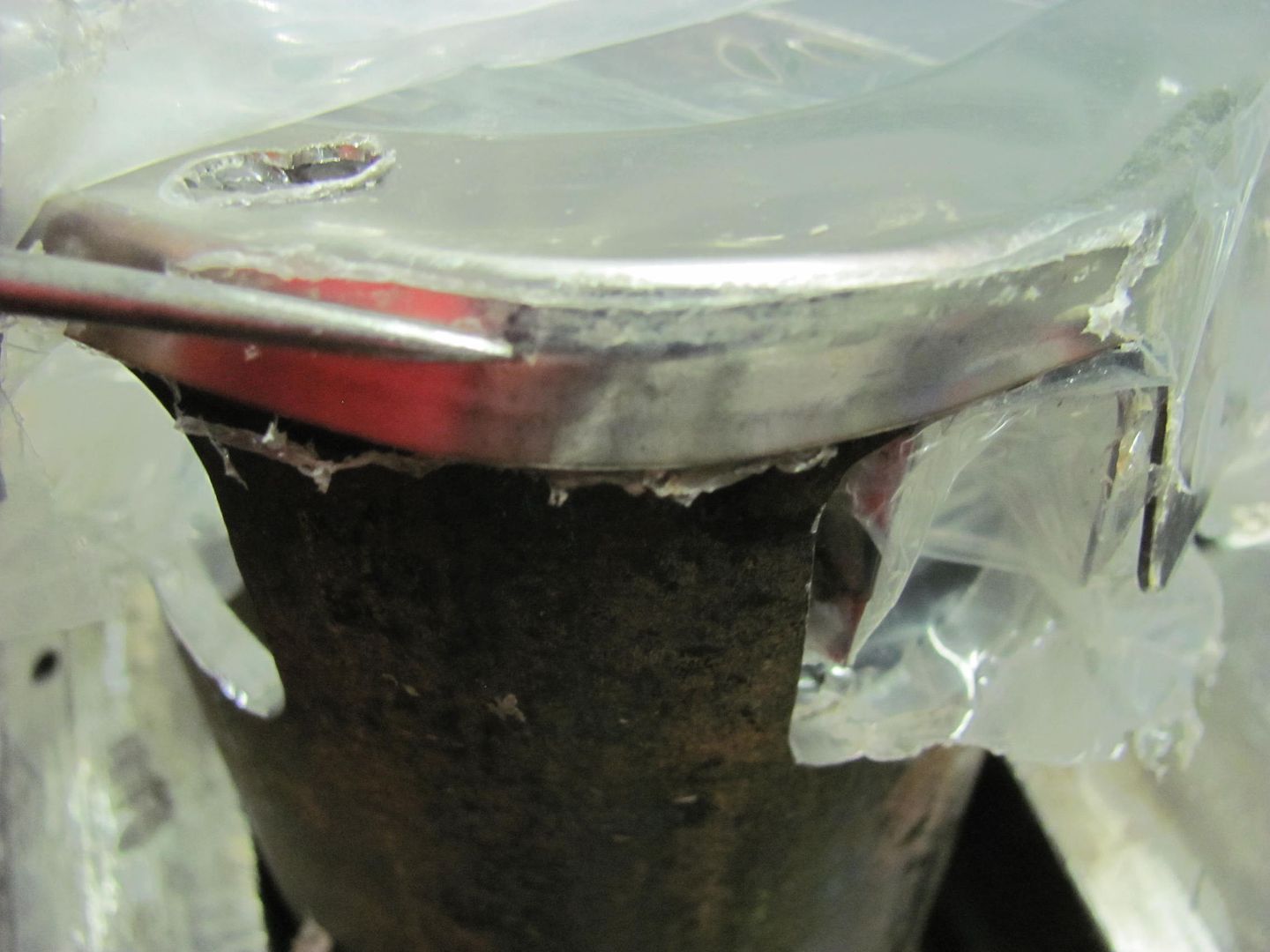

As Kyle media blasted and otherwise prepped parts for powder coating, I turned my attention to the new grille. This looked to be a very accurate reproduction as it fit tightly in the corners exactly as the original did..

In order to do some metal bumping on the grille corners and provide some clearance, which should help eliminate future front end squeaks and paint rubs, we'll need to make an anvil. This piece of pipe looks close to our templates..  Unfortunately our grille shows some interference, so unless we plan on disassembly of a new grille, the anvil will need a specialized shape..  After some drilling, band saw and sanding action, here are the results:  This may just work...  Working the corners.... Luckily any markings that may occur here will be covered by the surround chrome..  Test fitment shows a nice consistent gap:

__________________

Robert |

|

|

|

|

|

#222 |

|

Registered User

Join Date: May 2007

Location: Deale Md

Posts: 4,663

|

Re: 55 Wagon Progress

Went to fall Carlisle today while in the car corral I looked at all the tri five and did not see one out of at least a dozen that the grill fit correctly or that the fenders, hood gaps align up and they all were in the 30,000 asking price range and even some were by professional restoration shops.

major props to your work

__________________

James 63 GMC V6 4speed carryall 65 chevy swb bbw V8 auto 68 K20 327/4 speed, buddy buckets 2002 GMC CC Dually Duramax 64 GMC lwb 3/4 V6 4speed SOLD 66 GMC swb bbw buddy buckets SOLD IG duallyjams The only thing that stays the same is constant change! |

|

|

|

|

|

#223 |

|

6>8 Plugless........

Join Date: Sep 2007

Location: Prairie City, Ia

Posts: 17,142

|

Re: 55 Wagon Progress

You do such an amazing job and thanks for taking the time to document all this and post it!

__________________

Ryan 1972 Chevy Longhorn K30 Cheyenne Super, 359 Inline 6 cylinder, Auto Trans, Tilt, Diesel Tach/Vach, Buckets, Rare Rear 4-link and air ride option Build Thread 1972 GMC Sierra Grande Longhorn 4x4 1972 Chevy Cheyenne Super K20 Long Step side tilt, tach, tow hooks, AC, 350 4 speed 1972 C10 Suburban Custom Deluxe 1969 Chevy milk truck 1971 Camaro RS 5.3 BTR STG3 Cam Super T10 1940 Ford 354 Hemi 46RH Ford 9" on air ride huge project Tired of spark plugs? Check this out. |

|

|

|

|

|

#224 |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,648

|

Re: 55 Wagon Progress

Thanks for the comments guys. James, I'm surprised some of the car owners didn't run you off, picking their car apart like that

__________________

Robert |

|

|

|

|

|

#225 |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,648

|

Re: 55 Wagon Progress

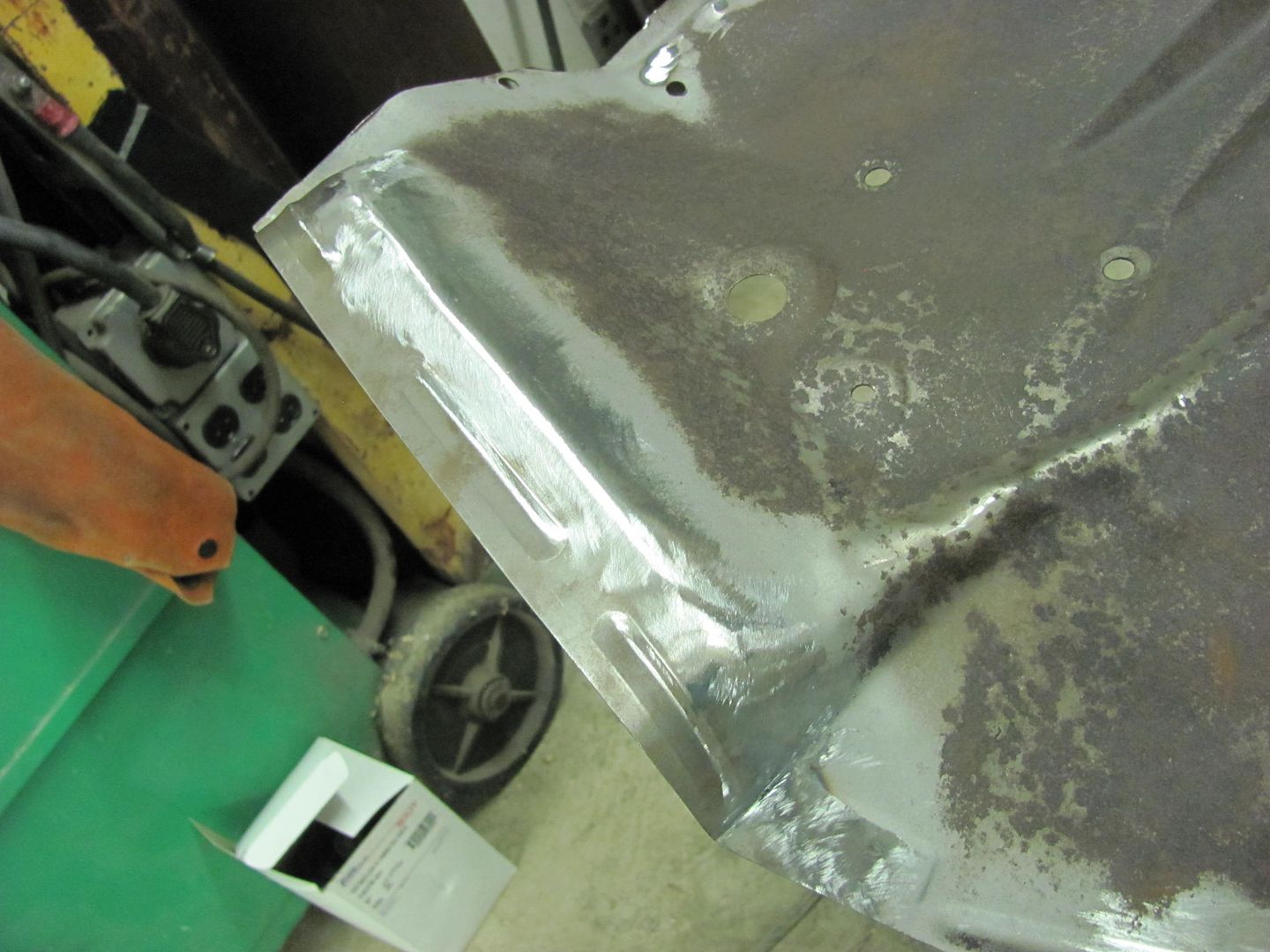

Today we worked on hood and gap alignment at the front of the car, the passenger side is all but done, so we started around to the driver's side. The windshield cowl showed a high spot behind the fender and door, that was bulged about 3/16. Good ol' factory fit!

So we made a vertical slice behind the fender and door, bumped the high spot down, and welded the joint. We had a blowout near the leaded seam due to some rust that had collected on the back side.. Forgot to take a picture before slicing and dicing, but here's the culprit. Also had some porosity in the vertical weld that got cleaned out and re-welded later...  Fitted, tacked, and finished     Gaps...   Much better

__________________

Robert |

|

|

|

|

| Bookmarks |

|

|