|

Register or Log In To remove these advertisements. |

|

|

|

|||||||

|

|

|

Thread Tools | Display Modes |

|

|

#1 |

|

Registered User

Join Date: Mar 2007

Location: Behind the Taco Bell dumpster

Posts: 296

|

Who wants to check my gear pattern? :)

These look good? Need a seasoned builder to give me a thumbs up, it's been about 10yrs since I rebuilt a rear. Backlash is at .007, .040 shims on pinion, 3.73 fat gear in a 3 series. Thanks.

Drive:  Coast:

Last edited by superhondaz50; 12-31-2017 at 02:16 PM. |

|

|

|

|

|

#2 |

|

Registered User

Join Date: Mar 2007

Location: Behind the Taco Bell dumpster

Posts: 296

|

Re: Check my gear pattern :)

Anybody?

|

|

|

|

|

|

#3 |

|

Registered User

Join Date: Apr 2017

Location: Knoxville, Tennessee

Posts: 892

|

Re: Check my gear pattern :)

Never built a rear end, but I understand it to require some major skills. Which rear end?

__________________

1969 GMC K25 2007 Chevy 2500HD Classic Duramax 1999 Tahoe 2DR 4WD Base Model 5.7l |

|

|

|

|

|

#4 |

|

Registered User

Join Date: Mar 2007

Location: Behind the Taco Bell dumpster

Posts: 296

|

Re: Check my gear pattern :)

12 bolt

|

|

|

|

|

|

#5 |

|

Registered User

Join Date: Oct 2005

Location: Overland Park, Ks.

Posts: 5,228

|

Re: Check my gear pattern :)

It looks a little too deep. Try moving the ring gear away from the pinion a little & retest.

George |

|

|

|

|

|

#6 |

|

Registered User

Join Date: Feb 2015

Location: TX Hill Country

Posts: 150

|

Re: Check my gear pattern :)

For whatever it is worth I did my first GM 12 bolt truck this summer and changed all the bearings, seals, ring 3.73, pinion, and added a Truetrac. So far it has been silent, running cool, and everything works so far. I think it looks just slightly too deep as well. Your backlash measurement is very good but when you change any of the shims on the carrier or pinion it all goes back out the window to try again. I had to fit and refit mine many times to get it the best I could in all directions with the shim set I had. I don't remember using so much on the pinion. I recall mine was around .026-.028 but each one is an individual and yours will vary. I admire your efforts, best of luck to you and you are getting close.

|

|

|

|

|

|

#7 |

|

Registered User

Join Date: Nov 2009

Location: Michigan

Posts: 474

|

Re: Check my gear pattern :)

Maybe a little deep but not too bad in my opinion.

__________________

Brad handshoe |

|

|

|

|

|

#8 |

|

Registered User

Join Date: Mar 2007

Location: Behind the Taco Bell dumpster

Posts: 296

|

Re: Check my gear pattern :)

Ok cool, too deep as the markings are darker towards the bottom correct? Shim in it is at .042, the next size down I could make was .040 which moved the marking alot closer to the top if that makes sense. Will I have a catastrophic failure running it as is?

|

|

|

|

|

|

#9 |

|

Registered User

Join Date: Mar 2007

Location: Behind the Taco Bell dumpster

Posts: 296

|

Re: Check my gear pattern :)

|

|

|

|

|

|

#10 |

|

Registered User

Join Date: Feb 2015

Location: TX Hill Country

Posts: 150

|

Re: Check my gear pattern :)

My no answer answer. Hard to tell by pictures alone but you are very close. If it is too close it will run hot and bind.

Is this a gear ratio change or not? If it is the same ratio then the original shim thickness on the carrier and pinion is a good place to start as a baseline but rarely do they every end up being exactly the same when finished. Use as many shims as you can on the carrier sides using a gentle tap of a hammer to get them in. When using your marking paint make sure to give the carrier some resistance when turning. Also with it all assembled when you spin the pinion/driveshaft yoke by hand the resistance should be even and smooth to the feel through the full rotation of the ring gear. If there are any tight spots or something does not sound right I would then go with a thinner pinion shim but then your backlash will probably grow but if it stays under .010 you are good. |

|

|

|

|

|

#11 |

|

Registered User

Join Date: Feb 2015

Location: TX Hill Country

Posts: 150

|

Re: Check my gear pattern :)

Yes, I like that much better in my opinion.

|

|

|

|

|

|

#12 |

|

Registered User

Join Date: Mar 2007

Location: Behind the Taco Bell dumpster

Posts: 296

|

Re: Check my gear pattern :)

I think I'm on it with these, they have a more football shape on the bottom. Backlash was still at .007.

|

|

|

|

|

|

#13 |

|

Registered User

Join Date: Mar 2007

Location: Behind the Taco Bell dumpster

Posts: 296

|

Re: Check my gear pattern :)

Yes, gear change from 3.08 to 3.73

|

|

|

|

|

|

#14 |

|

Registered User

Join Date: Mar 2007

Location: Behind the Taco Bell dumpster

Posts: 296

|

Re: Check my gear pattern :)

So would y'all say I'm good to go? Gonna install the bearings and button it up today.

|

|

|

|

|

|

#15 |

|

Registered User

Join Date: Aug 2014

Location: Dallas, Texas

Posts: 54

|

Re: Check my gear pattern :)

Um, pinion still looks a little deep into the ring .....

|

|

|

|

|

|

#16 |

|

Registered User

Join Date: Mar 2007

Location: Behind the Taco Bell dumpster

Posts: 296

|

Re: Check my gear pattern :)

|

|

|

|

|

|

#17 |

|

Registered User

Join Date: Mar 2007

Location: Behind the Taco Bell dumpster

Posts: 296

|

Re: Check my gear pattern :)

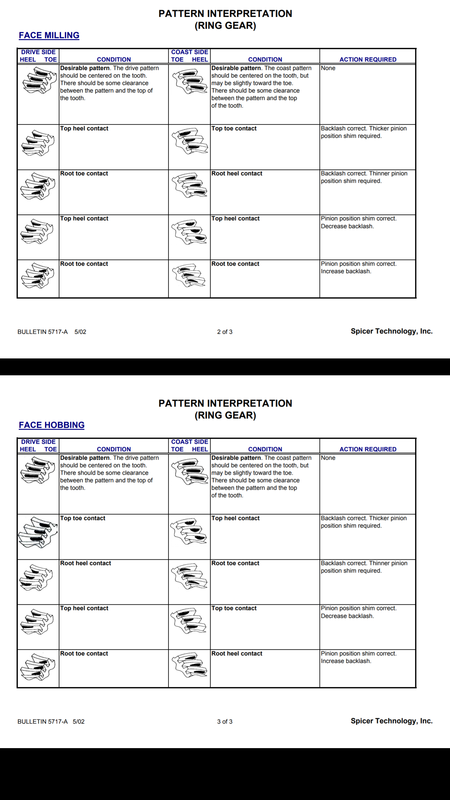

So I was looking at this PDF, under face hobbing I can see the the pattern for coast, decrease shim, looks similar to mine, although my pattern is more centered. My drive side I think looks ok correct? Am I like .001-.002 off? I also see for the correct pattern, it says my coast pattern can be closer to the toe, what y'all think? |

|

|

|

|

|

#18 |

|

Registered User

Join Date: Aug 2014

Location: Dallas, Texas

Posts: 54

|

Re: Check my gear pattern :)

In the second pic the contact pattern is still too far "in" the pattern should be more centered on the face of the gear tooth. Like someone mentioned before, be sure to apply pressure in the opposite direction of the force you are applying to get your pattern.

|

|

|

|

|

|

#19 |

|

Registered User

Join Date: Mar 2007

Location: Behind the Taco Bell dumpster

Posts: 296

|

Re: Check my gear pattern :)

Sounds good, I clamp a 2x4 to the pinion and use wrench on the carrier to get good leverage on the two. You think about .002 off the shim stack should get me closer or go thinner?

|

|

|

|

|

|

#20 |

|

Registered User

Join Date: Aug 2014

Location: Dallas, Texas

Posts: 54

|

Re: Check my gear pattern :)

That might be enough - you're really close. Make sure to abide by your manual specs on lash. Be particular because you don't want a rear end lockup - especially if your girl or a younger person is driving and doesn't heed the warning signs of differential problems

Don't mean to insult but the crush sleeve is very important and changing the shim(s) a lot can damage the tension qualities of the sleeve. Be careful with that. Last edited by OBS454; 01-02-2018 at 09:33 PM. Reason: Forgot to add |

|

|

|

|

|

#21 | |

|

Registered User

Join Date: Mar 2007

Location: Behind the Taco Bell dumpster

Posts: 296

|

Re: Check my gear pattern :)

Quote:

|

|

|

|

|

|

|

#22 |

|

Registered User

Join Date: Mar 2007

Location: Behind the Taco Bell dumpster

Posts: 296

|

Re: Check my gear pattern :)

Ok, got two shim packs built, current was a .039, I have a .037, and .035. hopefully .037 does it, hopefully backlash will still be good. I'll find out Friday.

|

|

|

|

|

|

#23 |

|

Registered User

Join Date: Mar 2007

Location: Behind the Taco Bell dumpster

Posts: 296

|

Re: Check my gear pattern :)

|

|

|

|

|

|

#24 |

|

Senior Member

Join Date: Nov 2013

Location: East Tennessee

Posts: 2,186

|

Re: Check my gear pattern :)

That pattern will run just fine....just make sure the backlash is in tolerance..

__________________

1967 C10 Step side 1968 C10 Step side 1970 Chevrolet K/5 Blazer 1972 Chevrolet K/5 Blazer .............

|

|

|

|

|

|

#25 |

|

Registered User

Join Date: Mar 2007

Location: Behind the Taco Bell dumpster

Posts: 296

|

Re: Check my gear pattern :)

|

|

|

|

|

| Bookmarks |

|

|