|

Register or Log In To remove these advertisements. |

|

|

|

|||||||

|

|

|

Thread Tools | Display Modes |

|

|

#1 |

|

Restoring a 68 SWB

Join Date: Jan 2008

Location: Nashville, TN

Posts: 1,068

|

Has this, or can this be done?

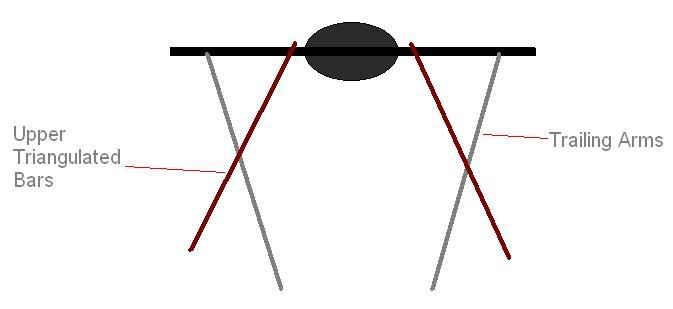

Forgive my ignorance and the lame drawing. For certain reasons I don't wanna use a panhard bar, and don't wanna spend the money to install a watts link. I was wondering if the concept in the picture has been done or if it would even work using the stock trailing arms. Thanks

__________________

My Build Thread: Lucy - My 1968 SWB - Shop Truck Style North Nashville Concrete Contractor |

|

|

|

|

|

#2 |

|

Registered User

Join Date: Sep 2006

Location: Covington, WA

Posts: 770

|

Re: Has this, or can this be done?

I don't see why it wouldn't work. So long as the uppers are a large enough angle to be able to block the back axle from going side to side.

|

|

|

|

|

|

#3 |

|

Restoring a 68 SWB

Join Date: Jan 2008

Location: Nashville, TN

Posts: 1,068

|

Re: Has this, or can this be done?

Ok, if it can be done can someone give me an idea of how far apart the bars need to be mounted on top of the axle, and how long they would need to be?

The longer the bars the less the angle will be. What is an optimal/acceptable angle?

__________________

My Build Thread: Lucy - My 1968 SWB - Shop Truck Style North Nashville Concrete Contractor |

|

|

|

|

|

#4 |

|

Registered User

Join Date: Jan 2008

Location: Johnson City, TN

Posts: 264

|

Re: Has this, or can this be done?

Your basically looking at a double triabulated 4 link, done very often in off-roading. The only problem I see is with the stock trailing arms you have no pivot point at the axle end. It would need a bushing or heim type attachment, something that would allow the trailing arm to pivot at the axle to prevent binding as the suspension cycles up and down. You'd be better off replaceing the trailing arms with links also then it would work fine. You can do single triangulated or double trianulated either way. For a lowered 2WD truck a single triangulation is all that is needed. In off-roading where susupension travel is measured in double digits, single triangulatiion can cause some rear steering when one side is full droop and the other is at full compression. Double triangulation basically eliminates rear steer all together in these full articulation moments, but you'll never see that condition in a lowered truck.

Angle for the triangulated links needs to be about 40 degrees or greater measuring angle between the two links (so each link would angle in about 20 degrees from perpendicular to the axle)

__________________

66 Chevy Stepside tandem project My junk: http://67-72chevytrucks.com/vboard/s...d.php?t=480902 Last edited by HotRodYJ; 08-07-2008 at 07:01 AM. |

|

|

|

|

|

#5 |

|

Surviving, one day at a time!

Join Date: Jan 2008

Location: Turlock,CA

Posts: 295

|

Re: Has this, or can this be done?

You might be better off using a wishbone 3 link set up so the axle can articulate.

__________________

79 Burb,350,tremic 5 spd, 4 wheel disc, daily driver 74 swb,350,350,driver & future project "There's no such thing as a finished project" |

|

|

|

|

|

#6 |

|

Registered User

Join Date: Feb 2007

Location: Allen,TX

Posts: 170

|

Re: Has this, or can this be done?

If you make a 4 link with AT LEAST a 40 degree angle between the frame and link, you don't need a panhard.

I can't draw (on the computer anyway) but I think you know what I mean. |

|

|

|

|

|

#7 | |

|

Restoring a 68 SWB

Join Date: Jan 2008

Location: Nashville, TN

Posts: 1,068

|

Re: Has this, or can this be done?

Quote:

__________________

My Build Thread: Lucy - My 1968 SWB - Shop Truck Style North Nashville Concrete Contractor |

|

|

|

|

|

|

#8 |

|

Registered User

Join Date: Apr 2008

Location: Imperial Beach, CA

Posts: 1,040

|

Re: Has this, or can this be done?

Why not just go with a simple Panhard bar? so easy. What you are doing is really making more problems for later. If you want to just do something diffrent go with a 3 link and just get the center bar. this is almost as simple as a panhard bar.

Something like this is what you need. you can make one yourself if you can weld. http://www.jegs.com/p/Competition+En...10002/-1/11319

__________________

69 c-10 BBC  462ci, forged crank, H-beam rods, 10.5-1 KB forged pistons, Dart Iron Eagle 308cc, Straub Cam, Comp Cams chrome moly full rollers, Weiand Team G, Prosystems 950, TH400/3500 Dalenzie stall, Currie 9+ Detroit Locker w/31spline axles.  3.5/6in drop. My Build. 3.5/6in drop. My Build.

|

|

|

|

|

|

#9 | |

|

just can't cover up my redneck

Join Date: May 2004

Location: Columbus OH

Posts: 11,414

|

Re: Has this, or can this be done?

Quote:

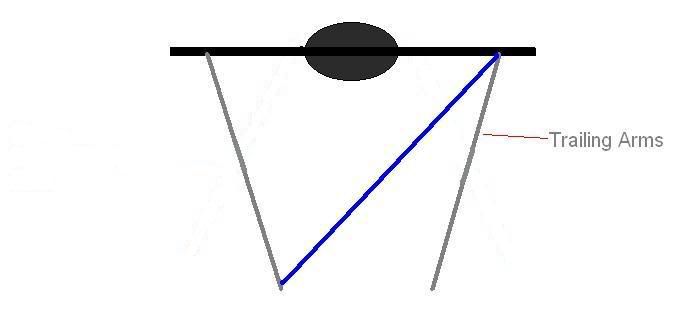

Yes, that is how they function with a Panhard bar... The stock trailing arms don't "fight" with the Panhard bar. If you tried to use "upper" bars (like in a 4-link) they would cause a bind because they would travel in a different path. This different path cannot follow the arc of the original trailing arms unless it had a way to "adjust" its length to match...and if it did "slip", the centering effect that you are trying to achieve is lost. The simplest way to attain this goal is a "Sliding Wishbone". It will keep the axle centered and not fight with the stock trailing arms. It can adjust it's length to compensate. |

|

|

|

|

|

|

#10 | |

|

Registered User

Join Date: Sep 2006

Location: Covington, WA

Posts: 770

|

Re: Has this, or can this be done?

Quote:

|

|

|

|

|

|

|

#11 | |

|

Registered User

Join Date: Jan 2008

Location: Johnson City, TN

Posts: 264

|

Re: Has this, or can this be done?

Quote:

__________________

66 Chevy Stepside tandem project My junk: http://67-72chevytrucks.com/vboard/s...d.php?t=480902 |

|

|

|

|

|

|

#12 |

|

3DrDwn--the 'burb not the band

Join Date: Jan 2007

Location: missoula, mt

Posts: 598

|

Re: Has this, or can this be done?

I don't have all the answers on this so I hope someone with more knowledge than I will chime in and fill in as I may be creating more questions than answers...

I have begun to see 2 links in service where they have run a link from the front pivot of one arm to the rear or axle mount area of the opposite arm. MY question is how well does this work and would it be a suitable solution for Tdave? Josh

__________________

Slo and Lo that is the tempo. '72 burb build page here: http://67-72chevytrucks.com/vboard/s...d.php?t=259256 '89 GMC Dually crew build page coming soon. 88  4x4 crew DD 4x4 crew DDduallys past/present pics here: http://67-72chevytrucks.com/vboard/s...46#post4001246 89 1 ton Dually rear flip kit install here: http://67-72chevytrucks.com/vboard/s...d.php?t=354327 |

|

|

|

|

|

#13 |

|

Registered User

Join Date: Sep 2006

Location: Covington, WA

Posts: 770

|

Re: Has this, or can this be done?

Thats a good idea. I wonder if the factory trailing arms are strong enough to be pulled like that. Otherwise I could see that being somewhat ok for the time being type of deal. Only worry is how close they are at the pivot point on the frame.

|

|

|

|

|

|

#14 | |

|

Restoring a 68 SWB

Join Date: Jan 2008

Location: Nashville, TN

Posts: 1,068

|

Re: Has this, or can this be done?

Quote:

BTW...after thinking about what you guys are saying about the panhard not fighting with the trailing arms I think I understand. If I tried to use a triangulated 4 link up top I can see where that would inhibit the natural path that the trailing arms are supposed to go and create binding. I see what you mean now HodRodYJ about the trailing arms needing some type of heim joint in that scenario. Still learning. Thanks for the education guys.

__________________

My Build Thread: Lucy - My 1968 SWB - Shop Truck Style North Nashville Concrete Contractor |

|

|

|

|

|

|

#15 |

|

Restoring a 68 SWB

Join Date: Jan 2008

Location: Nashville, TN

Posts: 1,068

|

Re: Has this, or can this be done?

Sorry, internet was acting up. Double post.

__________________

My Build Thread: Lucy - My 1968 SWB - Shop Truck Style North Nashville Concrete Contractor Last edited by tdave00; 08-07-2008 at 11:32 PM. Reason: Double post |

|

|

|

|

|

#16 |

|

3DrDwn--the 'burb not the band

Join Date: Jan 2007

Location: missoula, mt

Posts: 598

|

Re: Has this, or can this be done?

Exactly like that. I talked to a few guys about 2-link ing my '66 conti and that was suggested to me and I've seen more than a few using this just not sure why.

Josh

__________________

Slo and Lo that is the tempo. '72 burb build page here: http://67-72chevytrucks.com/vboard/s...d.php?t=259256 '89 GMC Dually crew build page coming soon. 88  4x4 crew DD 4x4 crew DDduallys past/present pics here: http://67-72chevytrucks.com/vboard/s...46#post4001246 89 1 ton Dually rear flip kit install here: http://67-72chevytrucks.com/vboard/s...d.php?t=354327 |

|

|

|

|

|

#17 | |

|

Registered User

Join Date: Sep 2006

Location: Covington, WA

Posts: 770

|

Re: Has this, or can this be done?

Quote:

Check out this thread. He used that style of 2 link w/ the bar across the back in his build.Bedsled71 |

|

|

|

|

|

|

#18 |

|

Registered User

Join Date: Jan 2008

Location: Johnson City, TN

Posts: 264

|

Re: Has this, or can this be done?

Pro Street and drag cars are set-up this way. Not sure it provides enough lateral support for hard corning on the street but yes the concept is sound and should work.

__________________

66 Chevy Stepside tandem project My junk: http://67-72chevytrucks.com/vboard/s...d.php?t=480902 |

|

|

|

|

|

#19 |

|

just can't cover up my redneck

Join Date: May 2004

Location: Columbus OH

Posts: 11,414

|

Re: Has this, or can this be done?

This would work if the front mounts were farther apart, like in a "parallel" link. It the case of the stock position, I would say no.

The only other issue is with the driveshaft. If you have a lot of suspension travel, it can become a problem... (airbags) With more of a stock travel situation, it should be ok. |

|

|

|

|

|

#20 |

|

Registered User

Join Date: Jun 2002

Location: Tri Valley California

Posts: 792

|

Re: Has this, or can this be done?

Look underneath a 65-72 chevelle. They run a rear trailing arm. Also Chris Alston Chassisworks sells a backhalf kit that is that.

|

|

|

|

|

|

#21 | |

|

just can't cover up my redneck

Join Date: May 2004

Location: Columbus OH

Posts: 11,414

|

Re: Has this, or can this be done?

Quote:

Yes they do.....but all of the arms pivot on both ends. The problem here is that you cannot add "upper arms" to the non pivoting lowers, it would cause a bind. |

|

|

|

|

|

|

#22 |

|

Registered User

Join Date: Jun 2002

Location: Tri Valley California

Posts: 792

|

Re: Has this, or can this be done?

Sorry I did not read that he wanted to use the stock arms. My bad. No you can not use upper bars but you can you a wishbone. You will need to weld a tube to your axle tubes to go underneath your rear end and fasten the one end of the wishbone to it. The other 2 ends to the front. I can maybe take pics of mine.

|

|

|

|

|

|

#23 |

|

Account Suspended

Join Date: Jun 2000

Location: over yonder

Posts: 14,270

|

Re: Has this, or can this be done?

why reinvent the wheel? use what's proven and you'll be fine.

|

|

|

|

|

|

#24 |

|

Registered User

Join Date: May 2004

Location: Lubbock, Texas

Posts: 2,121

|

Re: Has this, or can this be done?

Even on the Chevelles the arms bind...

__________________

'96 Nissan Pathfinder '02 Firebird Trans Am. '88 K5 Blazer |

|

|

|

|

| Bookmarks |

|

|