|

Register or Log In To remove these advertisements. |

|

|

|

|||||||

|

|

|

Thread Tools | Display Modes |

|

|

|

|

#1 |

|

Registered User

Join Date: May 2007

Location: Deale Md

Posts: 4,663

|

Re: '55 International Metal/Body/Paint Work

That's going to look so good when color on it.

__________________

James 63 GMC V6 4speed carryall 65 chevy swb bbw V8 auto 68 K20 327/4 speed, buddy buckets 2002 GMC CC Dually Duramax 64 GMC lwb 3/4 V6 4speed SOLD 66 GMC swb bbw buddy buckets SOLD IG duallyjams The only thing that stays the same is constant change! |

|

|

|

|

|

#2 |

|

Registered User

Join Date: May 2011

Location: Anderson SC

Posts: 3,912

|

Re: '55 International Metal/Body/Paint Work

I can't wait!! I'm getting the front header panel welded in tomorrow then I can start the panel straightening since all the metal replacement will be done and it'll hold it's own shape. The inside of the bed and the top rails will be shot with color matched Line-X so there will only be minimal bodywork to do there- that stuff hides minor waves/ripples. There won't be much area to block sand that way so bodywork won't take all that long. Still not sure what we'll do about a tailgate. Can't find one so I may end up making it.

When this one is finished I get to start body/paint on a '58 VW Bug Ragtop. Supposed to be rust free and straight, stored in a dry garage for years... I won't know how to act with no rust to fix!!

__________________

Project Goldilocks '66 C10 Short Fleet BBW Build '65 C10 Highly Detailed Stock Restoration Thread '78 Camaro Targa Roof Build '55 International Metal/Body/Paint Work '66 F100 Full Rotisserie Restoration '40 Packard 120 Convertible Coupe Restoration How To Restore and Detail an Original Gauge Cluster How To Detail Sand Body Panels, Edges, Corners, Etc |

|

|

|

|

|

#3 |

|

Registered User

Join Date: May 2011

Location: Anderson SC

Posts: 3,912

|

Re: '55 International Metal/Body/Paint Work

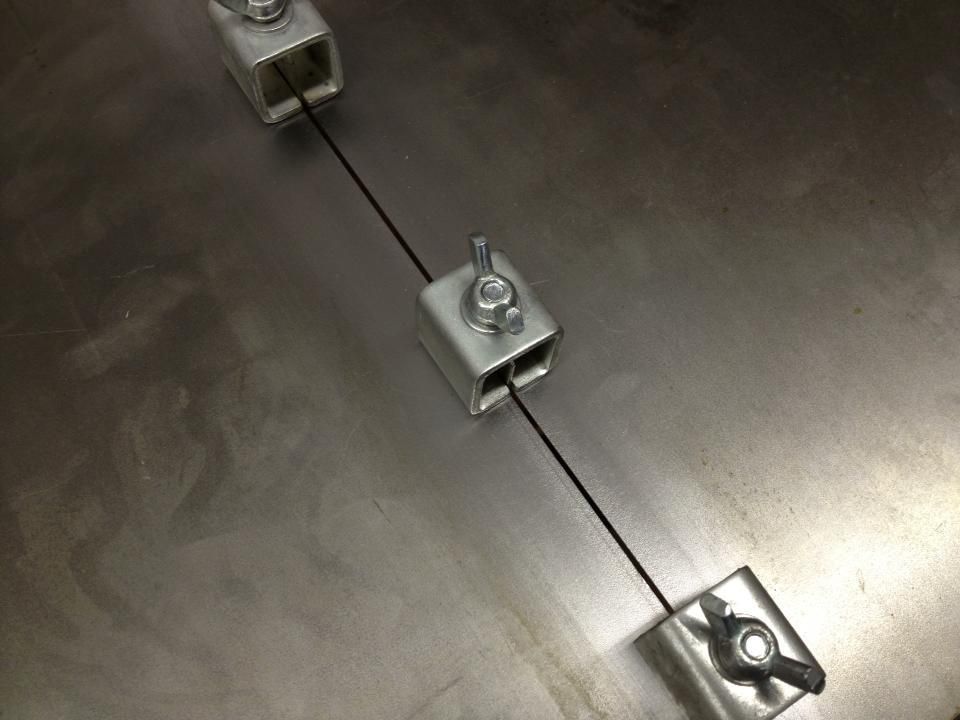

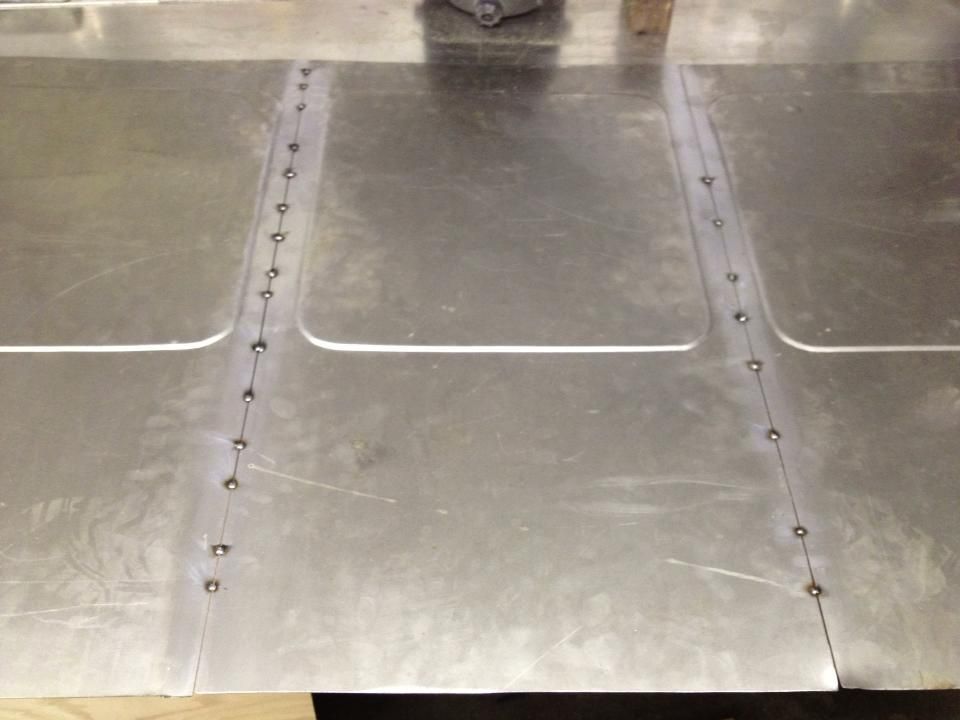

Here's the process of making the header panel. I used 18g and made it in three sections since it wouldn't fit in our bead roller in one piece. Making it in three pieces also allowed me to work out any distortion around the rolled bead in the shrinker/stretcher.

The bottom part of the original header was completely rusted off and stayed with the lower cross brace, that's why its much shorter than the new pieces.  Laid out the stamping pattern for rolling using 1/4" offset dies.  First of three panels rolled. I only rolled the depth of the bead 1/8" to minimize warping. The bead roller has a 20 gauge limit so I also didn't want to push the roller to do something it wasn't designed to do.   Aligned for welding.

__________________

Project Goldilocks '66 C10 Short Fleet BBW Build '65 C10 Highly Detailed Stock Restoration Thread '78 Camaro Targa Roof Build '55 International Metal/Body/Paint Work '66 F100 Full Rotisserie Restoration '40 Packard 120 Convertible Coupe Restoration How To Restore and Detail an Original Gauge Cluster How To Detail Sand Body Panels, Edges, Corners, Etc |

|

|

|

|

| Bookmarks |

|

|