|

|

|

|

|

#1 |

|

Registered User

Join Date: Sep 2012

Location: Midway, NC

Posts: 3,275

|

Re: Project TN 20

Cool truck. Funny about the windshield wipers. Years ago I was headed up to Wytheville VA for a dirt race. Was dark as crap and raining to beat the band. We got into the mountains and the windshield wiper on the passenger side took a dump and left. Used an old sock and some tape to keep it from scratching up the windshield. Crazy times. That was jus the beginning.

__________________

http://67-72chevytrucks.com/vboard/s...d.php?t=581873 The low buck build threads. Check'em out! http://67-72chevytrucks.com/vboard/s...d.php?t=666022 My build thread Crossmembers CC |

|

|

|

|

|

#2 |

|

Registered User

Join Date: May 2005

Location: Hendersonville, TN

Posts: 134

|

Re: Project TN 20

Thanks!

Wytheville is just another section of God's Country, I love it up that way. |

|

|

|

|

|

#3 |

|

Registered User

Join Date: May 2005

Location: Hendersonville, TN

Posts: 134

|

Tighten up the steering

Steering has been sloppy with about 30 degrees of slop since I've had her. So I set out to right that a few weeks ago. When one of the wee ones was jerking about on the steering wheel I notice the pitman arm was shot. I assumed that would fix it. Not so much. So I decided to work on tightening down on the steering box, no luck. Then I checked the rag joint. The nut wasn't tightened down and it was just slipping til it caught.

Could have easily ended up wrapped around a tree...  I decided to also replace the steering box, as it was leaking. It took a lot of searching, but the replacement part I found was at O'Reilly's, part # 27-7501. Now she is nice and tight. |

|

|

|

|

|

#4 |

|

Registered User

Join Date: May 2005

Location: Hendersonville, TN

Posts: 134

|

And Time for Heat

A bit past chilly these days in Tennessee, and don't want DHS called with me taking the little ones to school with no heat...Heat exchanger was leaking, and motor blown. Hoses were not even attached. So time for a rebuild.

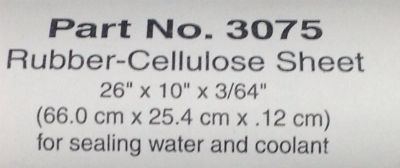

I did the vinegar soak in a big Walmart tub, took 5 days and nicely ate the rust off the heater box. Don't put the middle piece in, or not in for long...don't ask me how I know, but it's not all steel and vinegar will eat more than the rust away. So I had to contact Tony at 4-5-6 trucks and he shipped me a replacement for $45, and in a rush so I had it for Thanksgiving weekend to rebuild. Here are the parts soaked, cleaned, primed, and painted:  Used some gasket material I bought at Autozone for the gaskets:   Oldest boy helped me put it together.  Replacement motor and fan from LMC. |

|

|

|

|

|

#5 |

|

Registered User

Join Date: May 2005

Location: Hendersonville, TN

Posts: 134

|

Way underwhelmed with the quality of the blower fan...

Look at the warp. It was so bad it rubbed either on top or bottom depending on how I centered it. I had to trim the fins on the the top to get it to stop. |

|

|

|

|

|

#6 |

|

Registered User

Join Date: May 2005

Location: Hendersonville, TN

Posts: 134

|

Flush and All Together

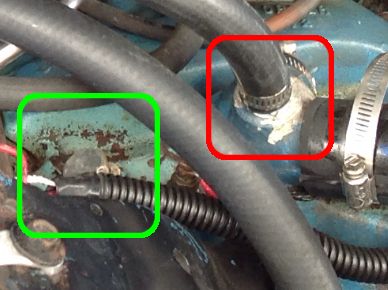

I flushed the system and put in a new 185 F thermostat. For the lower heater hose, the hose specified for a '66 fit, though I did have to cut about 6" off of it. It is a Gates part 20345, a good American based company. For the upper I had to use a Gates 18" flexi. One hose was made in USA the other in Mexico.

Tridon brand hose clamps, made here in Tennessee, were available at Home Depot. Stainless Steel no less.  This thread helps with hose routing: http://www.67-72chevytrucks.com/vboa...r+hose+routing I got it all together and....no heat. I'll save the full dialog, as that was discussed in this thread: http://www.67-72chevytrucks.com/vboa...d.php?t=608492 But the punchline is I routed the input hose off of the top of the thermostat housing, not the intake.  Once I got the input hose to the right place, I burped the core by loosening the intake hose at the core and pulled it almost all the way back. Started the engine (cold so as not to spill hot coolant) pulled the hose off for a second until there was a steady flow, and popped it back on. If you do this hot you can get burned. Now the heat is smoking hot. I remember now why back in high school I never bothered to fix the broken fan motor on my first truck... |

|

|

|

|

|

#7 | |

|

Registered User

Join Date: Sep 2012

Location: Midway, NC

Posts: 3,275

|

Re: Project TN 20

Quote:

Yeah that's a beautiful place. Great progress on the truck.!

__________________

http://67-72chevytrucks.com/vboard/s...d.php?t=581873 The low buck build threads. Check'em out! http://67-72chevytrucks.com/vboard/s...d.php?t=666022 My build thread Crossmembers CC |

|

|

|

|

|

|

#8 |

|

Registered User

Join Date: May 2005

Location: Hendersonville, TN

Posts: 134

|

Time for a glove box

My ultimate idea for a glove box is to build a metal one like Rian, but I got tired of waiting for myself to do it. So I thought I would try my hand at a cardboard reproduction, seeing that the wife had bought herself something nice in a box, I thought the box could be a glove box for me so I could get my money's worth....

I started with what was left of the one that came with it  Then I traced it  A box cutter and a hot glue gun  I picked up some rugged fabric at W*lm*rt and some spray tac. Good old duct tape to re-inforce around the attachment points, and I began to glue pieces in  This part is a lot harder than I expected, I began to tac in a small section, then peel back the fabric and spray once it was in place. The final product is not bad at all, the pic makes it look wrinkled, though it only has a few "not perfect" bits. I think if I did a second one it would be more close to professional, but it is quite usable and up to most folks standards. The light on the left is an LED board that we make at my work, I'll have to find a circuit to tie it in to so it lights up at an appropriate time. I also poked a hole for an iP*d wire to go through

|

|

|

|

|

|

#9 |

|

Registered User

Join Date: May 2005

Location: Hendersonville, TN

Posts: 134

|

Brakes...again

Been a while. Mostly for the last two years I've been driving the truck, no projects. Then a few weeks ago on the way down the (steep) driveway, I realized my front brakes were out completely, and my rear brakes couldn't hold the truck. Oh - and I hadn't hooked up that e-brake thing yet. One has to keep calm, so I managed to get her to a stop after getting down the drive and onto the flat.

Here is what I found when I got her on the lift, the proportioning valve had been mounted at the frame below the master cylinder. Unfortunately the PO mounted it where one of the front lines was laying on the frame, and with time it rubbed through: |

|

|

|

|

| Bookmarks |

| Tags |

| driver, project, tn 20 |

|

|