|

Register or Log In To remove these advertisements. |

|

|

|

|||||||

|

|

|

Thread Tools | Display Modes |

|

|

#26 |

|

Registered User

Join Date: Jan 2012

Location: Washington,Il

Posts: 632

|

Re: At my wits end, motor getting hot. Input please

Unless you can verify the coolant is boiling out of the radiator, I'd say a okay. if the coolant system is working.210 in Texas in the summer?? Both my monte's won't even turn on both fans 'till 220!!!!

__________________

It builds on my intelligence when I make a mistake, Boy am I building on it! '67 C-10,'70 Nova SS

|

|

|

|

|

|

#27 | |

|

Registered User

Join Date: Oct 2009

Location: Denton, Texas

Posts: 1,735

|

Re: At my wits end, motor getting hot. Input please

Quote:

I installed the new 160 degree thermostat with drilled holes after verifying first that it is working out of the box. Fully opened up in a pot of boiling water @ 180 degrees. I checked the second installed 180 degree thermostat in a pot of boiling water and it wasn't fully opened until 210 degrees. It started to open up around 195 degrees. I put in a bottle of Prestone radiator flush+cleaner and let the motor sit running and driving for 40 minutes. The temperature on the temp gauge never went over 180 degrees. The motor, however, was idling really low. I poured some water on the stock mechanical fuel pump and it started to pump more fuel and the RPMs went back to normal. Is there some kind of heat insulating spacer I can install between the fuel pump and motor? Thank you for all of the replies. I really appreciate everyone input as this issue has had me pulling my hair out trying to figure this out on my own. Keith |

|

|

|

|

|

|

#28 |

|

Registered User

Join Date: Mar 2001

Location: Moore, Ok

Posts: 1,149

|

Re: At my wits end, motor getting hot. Input please

I think clutch fan is a good upgrade even if it doesn't solve the problem problem. Lean condition can definitely make it run hot. Might try a little richer metering rods since it relatively low cost and easy to try. Is it possible you are not overheating and the temp sender is just off?

__________________

72 SWB parts and pieces Oklahoma |

|

|

|

|

|

#29 |

|

Cantankerous Geezer

Join Date: Aug 2002

Location: Bel Aire, KS

Posts: 6,264

|

Re: At my wits end, motor getting hot. Input please

You have a flex fan on your truck, which is not stock. Do NOT use a fan clutch with the flex fan. The clutch is used with a rigid blade fan, which was original equipment on your truck. The flex fan blades flatten at speed, allowing air from the vehicle moving at speed to provide the cooling. The clutch disengages the fan from the engine at speed, doing the same4 thing as the flex fan.

Check your coolant temp with a meat thermometer, cost is about $5. Check the thermometer for accuracy in boiling water, should be 212*, depending on elevation. I am assuming this is your problem, since the coolant hasn't boiled over. The only effect the pressure on the coolant is to increase the boiling point, which increases the temp of the boiling point of water.

__________________

Fred There is no such thing as too much cam...just not enough engine.

|

|

|

|

|

|

#30 |

|

Registered User

Join Date: Dec 2009

Location: bisbee, arizona

Posts: 1,529

|

Re: At my wits end, motor getting hot. Input please

what carb? what altitude? what fuel?

can you richen up the mixture abit with larger jets? Note that there is so much alcohol in fuel it can cause a lean condition and cause it to overheat. At altitude you can get away with leaner fuel air ratio's without overheating but as air density increases more fuel is required and if its not that lean condition may contribute to overheating. fuel and alcohol makes the problem worse because just in the initial mix of fuel and alcohol all other things being equal a lean condition is predisposed. try incrementally increasing jet size . Then go back and adjust plug gap, timing. expect a loss of fuel economy. a quick test would be to use some av gas and see if the problem goes away, if it goes away your problem, at least one of them,is fuel quality. if you dont want to mess with jets then experiment with fuel/alcohol/avgas ratios to bring the problem managebly back under control. mixing fuels and using avgas is messy too and not a long term solution. eventually, if its a fuel problem, jet experimentation will get you there. share your success! |

|

|

|

|

|

#31 | |

|

20' Daredevil (Ret)

Join Date: May 2003

Location: Jefferson State

Posts: 13,728

|

Re: At my wits end, motor getting hot. Input please

Quote:

OP: there are many horror stories of flex fans disintegrating with devastating results. My only flex fan experience wasn't that serious, but it was the only time my truck ran hot. After going back to a clutch fan, it never overheated again. Also, as posted above, check if the lower hose has the spring inside it.

__________________

- Mike - 1972 K20 LWB 350/350/205 RIP El Jay |

|

|

|

|

|

|

#32 |

|

Registered User

Join Date: Oct 2009

Location: Denton, Texas

Posts: 1,735

|

Re: At my wits end, motor getting hot. Input please

As an update.

After I installed the 160 degree thermstat with holes, I put in the Prestone radiator flush+cleaner. I let it idle for awhile then road tested it. The temp got up to 180 degrees and seemed to stay there. I replaced the fan belt today and had to change a few brackets in the process. Took it for another spin today for about 30 minutes and the temp held at 180. Crossing my fingers and toes that I am on the right path. I plan on flushing out the cooling system tomorrow. Any ideas on a good way to do this? Keith |

|

|

|

|

|

#33 |

|

Senior Member

Join Date: Jul 2012

Location: Oblong, Illinois

Posts: 7,028

|

Re: At my wits end, motor getting hot. Input please

Sounds like you may have nailed it. If the higher temperatures return don't discount the water pump. It may flow well at idle and the impeller may spin on the shaft at higher rpm with more force applied, reducing the amount of coolant it is able to move.

|

|

|

|

|

|

#34 |

|

Registered User

Join Date: May 2008

Location: S.W. Chicago, IL.

Posts: 317

|

Re: At my wits end, motor getting hot. Input please

What's the status of the lower hose?

Did you replace it with the radiator swap? How about the angle of the rad outlet? Could be pinching or collapsing, restricting the coolant flow. Is there a spring inside the hose? Check it before the flush. Had a parts counter guy say "new hoses reinforced, so no spring", went to another store that had the spring inside the lower hose. |

|

|

|

|

|

#35 |

|

Registered User

Join Date: Jul 2015

Location: 2nd left past the stump on a dirt road.

Posts: 2,629

|

Re: At my wits end, motor getting hot. Input please

Check this out too! Flush your motor with Oxalic Acid, otherwise known as Wood Bleach. This is what they use to market as cooling system flush but now can't due to EPA regulations. Safe on brass, copper, and cast blocks. May not be good on gaskets, paint, some types of chrome, and rubber!

You will have to follow with Arm and Hammer Washing Soda to neutralize it! Very Important! Also when your done with the Oxalic acid, Drain your block from the bottom 2 plugs (ON THE ENGINE BLOCK YOU WILL SEE A BUNCH OF KRUD COME OUT!), flush with clean water, then flush again with Soda wash which is Sodium carbonate. Now here is the good part, Napa carries a cooling system product which restores the corrosion inhibitors called Napa Kool, read here: http://www.thedieselstop.com/forums/...a-kool-128789/ Now to finish once the system is completely cleaned, fill with Prestone, distilled water, making sure you get the proper concentration levels. Too much coolant and not enough water will actually hurt rather than help. Flex-a-Lite makes a Zinc anode to assist with corrosion. Here: https://www.flex-a-lite.com/catalogs...esult/?q=32060 Finalize the entire system by cleaning, replacing, and/or adding a ground wire or 2. Your cooling system needs this to protect it. Correct electrolysis to make the coolant work, chemically. Not to mention you will notice your electronic system will respond to this also and be a bit perkier! |

|

|

|

|

|

#36 | ||

|

Registered User

Join Date: May 2008

Location: Mesa, AZ

Posts: 281

|

Re: At my wits end, motor getting hot. Input please

Quote:

What concerns me is that the OP feels the "engine is hot". I added emphasis. Quote:

Water at 120F will cause 2nd degree burns after 8 minutes of exposure. Water at 124F will take 2 minutes. Water at 131F will take 17 seconds. Water at 140F will take 3 seconds to cause 2nd degree burns. http://www.antiscald.com/prevention/...info/table.php Your engine will "feel" hot! Here's some more perspective: My 350, when I'm warming it for tuning purposes, the air around it will "feel" "cool" until the thermostat opens. Once the thermostat opens, a lot of hot coolant will flow into the radiator. The radiator's job is to radiate the heat from the coolant into the surrounding air around the engine. Suddenly, I can assure you, I'm no longer having fun tuning anymore. I live in the AZ desert! If I were in your situation, I would try to find a way to verify the calibration of that thermometer. Your "fleshmometer" is not calibrated in degrees F, and it'll be destroyed before you can take an accurate reading anyway. (Would you use a thermometer that's destroyed at 150F to check something hotter than 180F?) One good way to do it is to buy a (non-cheapie) infrared thermometer, and point it right at the thermostat outlet as the engine warms up. It should read about what your thermostat is set for, when it opens. But remember, a thermostat does not snap open or shut, the rated temperature is "about" half way open. Regards, Mike

__________________

I own 3 classic vehicles. 1971 LWB C10 Deluxe. 1974 VW Super Beetle. 1971 VW Fastback. The C10 and the Super Beetle run, the Fastback is just not there yet! Please visit my Super Beetle and Fastback profile on TheSamba. |

||

|

|

|

|

|

#37 |

|

Old member

Join Date: Jan 2002

Location: Liberty, & Garden City S.C. , U.S.

Posts: 19,945

|

I suggest recovery tank. Good mix of water and antifreeze and check the temp with a heat gun. I bet my pay check the temp gauge is 20-40 * off.

Best money is the recovery tank. You can buy cheap ones at parts stores are go to the local yard and get one.

__________________

1971 LWB Custom, 6.0LS & 4L80E, Speedhut.com GPS speedometer & gauges with A/C. 20" Boss 338's Grey wheels 4 wheel disc brakes. My Driver Seeing the USA in a 71  Upstate SC GM Truck Club 2013,14 and 2016 Hot Rod Pour Tour http://upstategmtrucks.com/ Get out and drive the truck this summer and have some fun! It sucks not being able to hear! LWB trucks rule, if you don't think so measure your SWB! After talking to tech support at Air Lift I have found out that the kit I need is 60811. Per the measurements I gave them. Ride height of truck inside spring and inside diameter of springs. |

|

|

|

|

|

#38 |

|

Senior Member

Join Date: Feb 2010

Location: Falls City, Nebraska "100 Miles From Nowhere"

Posts: 2,219

|

Re: At my wits end, motor getting hot. Input please

Need to quit using whatever water source you've been using and invest in distilled water for your cooling system. Acid flushes are good as long you remember topull the radiator to flush out all the calcium that gets busted loose within the block. After viewing the pics of calcium build up on the rubber components, you can bet money that crap is twice as thick in the block and in the radiator. I have to agree with Andy as well, these temp gauges are good for extreme indications but are seldom spot on...~Ghostrider~

__________________

Michael of the clan Hill, "Two Seventy Two's" 71 1-ton Dually 350 4-Speed 71 C/50 Grain Truck, 350 Split-Axle 4-Speed 02 3/4 ton Express 14 Indian Chief Vintage 1952 Ford 8N, "Only Ford Allowed On The Property"  "Be American, Buy American"

|

|

|

|

|

|

#39 |

|

Senior Member

Join Date: Nov 2012

Location: BY THE CAROLINA SEA

Posts: 922

|

Re: At my wits end, motor getting hot. Input please

I did not notice if this was suggested or not, but I once heard someone say that a coolant called LIQUID ICE made a big difference in engine temperature.

__________________

FRANKENTRUCK 1981 Chevrolet C10 Shortbed Stepside GRANDTRUCK 1968 Chevrolet C10 Stepside Longbed http://67-72chevytrucks.com/vboard/s...d.php?t=584617 PROJECT JIGSAW 1967 GMC C3500 GREAT WHITE 1986 Blazer M1009 454 engine w/700R4 transmission gas conversion |

|

|

|

|

|

#40 |

|

Registered User

Join Date: Aug 2012

Location: Midland, TX

Posts: 1,267

|

Re: At my wits end, motor getting hot. Input please

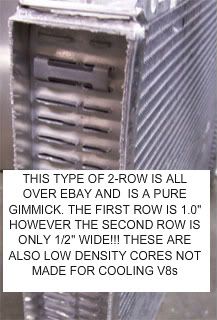

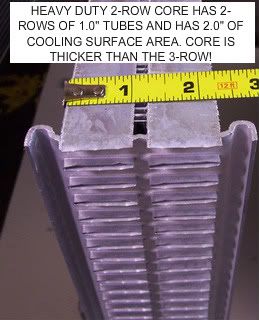

Maybe I missed it, did you confirm you have a spring inside the lower hose?

Also, Here's a primer that I found helpful, long but informative. Also, you might look at a 2 core radiator sized properly. I'm using this out here in good old hot West Texas and have never seen more than 195, most of the time it's rock solid on 185. http://www.speedcooling.com/1967-197...r/prod_38.html     There is considerable misinformation regarding what makes a radiator transfer heat (so take what you read with a grain of salt). Ill try to make a short radiator and heat transfer for dummies post Heat is transferred from the coolant to the radiator mass, and from the radiator mass to the airflow. The temperature difference at each transfer junction (coolant to metal, and metal to air) drives the quantity of heat transferred. Aluminum weighs less, and the lower mass allows it to transfer heat more quickly than brass. The steady state heat transfer between the two materials (aluminum and brass) is very similar, but aluminum reacts quicker to a change in the temperature difference of the coolant fluid (like when you are on the throttle) because the heat transfer takes less time heating up the mass of the radiator itself before establishing the temperature difference between the radiator and the airflow. The fact the aluminum experiences an elevated surface temperature quicker allows it to reject the heat into the airflow quicker. When the radiator is underdesigned (to reduce weight or fit a poor location) this rapid thermal response provided by aluminum can make a difference in overheating (or not) after a brief period of WFO travel (like in racing). When the load is steady state (a fixed industrial engine or a long crawl up a grade towing), the response time benefit is insignificant because while the brass takes longer to respond, having the proper area for heat transfer is more important (both radiators eventually reach the same steady state temperatures and the same heat transfer rate). Sizing the face area of a radiator core to have one square inch for every cubic inch of displacement has been around for a long time (400 ci. engine matched to a 20"x20" radiator). This rule of thumb does not work everywhere (dry deserts need more face area) so some add 10% or more extra face area. Core thickness is an airflow restriction on the air side (bad for heat transfer), and more tubes (one tube per core) increases surface area (good for heat transfer) on the coolant side. Multicore radiators are great for getting the radiator metal hot, but not always great for getting that extra heat into the air, and the hot air away from the radiator. The coolant to metal transfer is fairly efficient, because both materials (coolant and metal) have significant mass to store the heat being transferred. The heat transfer junction, the required wetted area of the tubes inside the radiator core, can be calculated with fairly good accuracy. The surface area can be accomplished with more small oval tubes (1/2" and 5/8" typical of brass radiators) or with fewer larger tubes (typical aluminum 1" and 1 1/4" tubes). Go with the most tubes (cores) for the greater surface area, if the fan drive can handle the airflow restriction. The aluminum radiator core manufacturers already take any credit for the more rapid thermal response of aluminum when calculating the tube surface area, they use the minimum surface area they can design, so further reducing the face area of the core (to try and squeeze even more efficiency from the aluminum construction) is risky unless the design can be tested and adjusted (if the budget allows doitagain engineering). I advise against reducing the face area of the core, and any thinking that the material choice allows a discount factor to the heat transfer potential, unless you are racing to shave weight and the load is transient. The coolant side of each core tube sees the same temperature coolant flow and the same rate of heat transfer from the coolant to the radiator core metal. The result is the radiator metal is almost always the same temperature with minimal gradient front to back. The coolant to metal heat transfer is the same for each core (what heats the radiator metal is the same), and the coolant temperature leaving each core (to be delivered to the engine) is nearly the same, but the air side of the radiator is not so simple. The discount factor for heat transfer on subsequent cores is only on the airflow side. The face cores experience unheated air, and subsequent cores experience air at a higher temperature. The best heat transfer occurs where the greatest difference between the air temperature and the radiator metal is found, the face or entering side of the radiator. If you want the best heat transfer, increasing the face area of the radiator metal that sees cool air will gain you the most impact for your effort (a larger radiator face will beat more cores nearly every time). The construction of the radiator fin design is important to the increase in temperature through subsequent cores in series, and is related to a "bypass factor" that models how much air bypasses heat transfer from direct contact to the surface area of the fins. The mass of air that can squeeze between (bypass) the fins without picking up heat mixes with the mass of heated air that does make contact, and the result raises the air temperature of the downstream cores. In reality, without getting into math or fin designs, the elevation of air temperature between cores is less than 15%. If the airflow temperature is raised from 70dF to 170dF through a four core radiator, a 100 degree increase, 45 degrees (~45%) of the temperature rise (and heat transfer) is in the air to metal contact in the first core, and a lower percent from subsequent cores (something like ~30%/17%/8%). The aluminum radiator guy's are right that two cores are more efficient (nearly 80% of the cooling is from the two front cores), but if the total surface area of the coolant to metal, and metal to air, contact is less ... the net result is not so great of a design (just like ricers 100 ci 4-banger @ 3 hp/ci is good, but nothing like a 302 @ 1 hp/ci: there is no substitute for more surface area in a radiator unless you want to spend a lot). The actual area of the core face that experiences the high air to metal temperature difference is more important than the calculated face area. People tend to forget that the radiator face is not working to transfer heat, unless it's moving air. What makes air flow through a radiator core (through a restriction)? Pressure drop (static pressure) or the momentum of the air mass (velocity pressure) through the core establishes the airflow, and the resulting heat transfer. Most people with a cooling problem try to increase the mass of air blowing through the radiator by increasing the velocity pressure acting on the core. They add a round fan (usually electric) in front of the radiator (a pusher fan). When an unshrouded fan is used, a puller with no shroud or a pusher, the core area experiencing the airflow (and temperature difference) is limited to only that is the direct path of the high velocity air. A 20x20 (400 sq.in.) radiator face with a 16" diameter fan blade, without a shroud, is little better at heat transfer than a radiator with a 16" round (201 sq.in.) face area. Adding a 16" pusher in front of this radiator, with the unshrouded 16" puller, gains almost nothing in air side heat transfer effect. How do you get the entire entering face of the radiator to work transfering heat? You try to get airflow across the entire face of the radiator core. Try many small fans (fit lots of round high velocity airstreams in a square area)? It can work, but it's looks complicated (and is probably expensive). It's easier to make a static pressure difference across the radiator core work to move air through the entire face of the radiator, by using a puller fan and fitting a shroud on the suction side of the core. You only need one fan, and it can motivate airflow across the entire face area of the radiator core, just by adding a shroud to contain an area of negative pressure on the leaving air side of the core. The problem with using static pressure to draw airflow through a radiator is that it takes a significant increase in power to generate pressure (research fan laws). Using a multicore radiator core that is thick and restrictive on the air side requires that it be matched with a fan and shroud that can generate a static pressure difference great enough to overcome the restriction. Replacing a two core with a more airflow restrictive four core can sometimes work against you if the fan clutch is weak, or it is combined with a swap to an electric fan. Most electric fans cannot develop significant airflow at higher static pressures, because the power draw must be limited to protect the wiring. Compare an electric fan to a high flow (and pressure) mechanical fan. The blades of the electric are narrow, and the blade pitch is shallow (compared to the mechanical fan), both design aspects limit the potential of an over-amp condition. Yes, electric fans are great to gain power on the end of the crankshaft, because to generate a significant negative pressure behind the radiator sometimes takes three to five horsepower (the gains we read in the electric fan advertisements). Use electric fans when you can, when the radiator is overdesigned for the power and transient heat transfer required, and use a shroud. Just do not expect a 1/4 hp electric to pull the same airflow and pressure drop of a fan drawing 3 hp off the front of the engine. I read that fans have little effect to gain airflow at speed ("airflow is going through the radiator on the highway because you are going faster, so adding a fan or shroud to cool the engine on the highway is not going to solve the problem.") We read it all the time. It's BS. What is difficult to understand is that most vehicles generate a high pressure area under the chassis at speed (the air above and to the sides of the vehicle is high velocity/low pressure, but underneath it's low velocity and high pressure). Yes, the pressure in front of the radiator can be higher (conversion of the velocity pressure to static pressure) but the pressure behind the radiator can increase with speed as well. Betting that the converted high velocity air in front of the vehicle radiator can overcome the pressure under the vehicle (the pressure on the leaving side of most unaided radiator cores), to motivate airflow, is almost like betting that you can piss up the inside of the airhose of your compressor with 20 psi streaming out the end. You still need a fan and shroud to eliminate most radiator airflow problems at highway speeds, because you still need to establish a pressure drop across the radiator core (and sometimes it's more difficult at 60 mph, than when parked at the curb). Crossflow vs. downflow design is not as important as where the radiator cap pressure relief is located. The cap should be on the low pressure side of the water pump, something that is easier to package and service with a crossflow core. I hope this helps (I have had enough internet tech for the week)? In summary: if the budget demands a choice between a high dollar aluminum radiator, or a brass radiator and a well fitting shroud, get the system with the shroud (and use a mechanical fan drive with a fan blade that has some pitch angle to the blades, and a clutch to save power when it's not needed). Happy Trails!

__________________

1969 RS/SS Z10 Camaro Pace coupe 1972 GMC Short Step buildhttp://67-72chevytrucks.com/vboard/s...=1#post6356218 1979 Mazda RX7 1979 Pontiac Trans Am WS6 & 1979 Pontiac Trans Am 10th Anniversary 1999 Honda Valkyrie 2006 Corvette Z06 2010 BMW 650i Last edited by Z10; 08-29-2015 at 01:06 PM. |

|

|

|

|

|

#41 |

|

Registered User

Join Date: Oct 2009

Location: Denton, Texas

Posts: 1,735

|

Re: At my wits end, motor getting hot. Input please

Status update.

First I want to thank everyone who has contributed to this thread. Lots of great info and input. A few things to clarify, there isn't a spring in the lower radiator hose. Have never had one in any of the hoses that I have replaced though I do understand why they maybe present. Apparently sometimes the lower radiator hose could "collapse" from the suction of the water pump. The spring was to prevent the walls of the hose from closing off. Forunately, this hasn't been one of my issues. I have driven the truck now for the past week and the temp pretty much sticks to the 160 - 170 degree range. I had done of few more things since the last posting. Replaced the radiator fan belt. Old one was showing some severe wear. I also got a little more aggressive with the flushing and used a product called Glisten from WallyMart. It is a dishwasher machine cleaning product to remove lime, scale, and rust. As an added bonus, if used correctly it is an effective disinfectant against E-coli and Salmonella! LOL  I dumped the contents in the cooling system. Ran it up to temp for about 10 minutes, then let it sit for about an hour. Then drained and flushed cooling system with lots of water via a garden hose. For what its worth, I didn't have much faith in the Prestone treatment. There was still some crud around the thermostate flange on the intake-manifold after the Prestone treatment. After the Glisten treatment all crud was gone. I dumped the contents in the cooling system. Ran it up to temp for about 10 minutes, then let it sit for about an hour. Then drained and flushed cooling system with lots of water via a garden hose. For what its worth, I didn't have much faith in the Prestone treatment. There was still some crud around the thermostate flange on the intake-manifold after the Prestone treatment. After the Glisten treatment all crud was gone.After flush, I added anti-freeze, distilled water, and Royal Purple's "Royal Ice+" I am very satisfied with the current engine temps of 160 -170. Big temperature difference from the 200 - 210 degrees. Engine is definetly not radiating extreme heat outward anymore. I believe that there were several issues going on at the same time causing the problem. 1. Cooling system was basically neglected. Old radiator had several pin-holes and I was adding tap water and anti-freeze weekly to replinish loss of fluids. The tap water is likely chockfull of impurities and evidenced by the photos of the lower radiator hose outlet on the old radiator. I believe Ironangel hit that mark dead on. 2. Previous thermostats weren't working correctly. The ones rated at 180 weren't even opening up until 195 and fully opened untile reaching 215 degrees. 3. Radiator fan fanbelt was in need of replacing. So, a good clean/flush of the cooling system coupled with a known good thermostat has really turned this around. I won't be using tap water anymore as mine just has too many impurites in it. |

|

|

|

|

|

#42 |

|

Registered User

Join Date: Jan 2012

Location: Washington,Il

Posts: 632

|

Re: At my wits end, motor getting hot. Input please

Score!!!!

__________________

It builds on my intelligence when I make a mistake, Boy am I building on it! '67 C-10,'70 Nova SS

|

|

|

|

|

|

#43 |

|

Registered User

Join Date: Oct 2009

Location: Denton, Texas

Posts: 1,735

|

Re: At my wits end, motor getting hot. Input please

I also purchased a new heater-core from OldAir Products out of Fort Worth, Texas. Mine is for the non AC. It is not like the original cores in that it does have the bulkier ends. However it does have plates with attatchment points to replace the old metal "straps". Have not installed it yet as most who know this job can get quite involved due to several attachments posts on the lower portion of the heater fan box.

Curious to find out if re-intallation of the heater core will help lower the engine temp. I likely will flush the cooling system yet again as colder temps arrive here in North Texas and re-install a known good 180 degree thermostat with a 50/50 mix of antifreeze and distalled water. |

|

|

|

|

|

#44 |

|

Registered User

Join Date: Mar 2012

Location: Boulder, CO

Posts: 350

|

Re: At my wits end, motor getting hot. Input please

I've been using 'Shout' laundry additive for flushing cooling systems. It works great, flushed out easily and leaves everything all nice and shiny. It is safe for all systems, I work on a variety of marques, so I need versatility. Oxalic acid is a great rust remover,but it's pretty caustic and can do more damage than good if improperly utilised. The problem tap water is the inconsistency in mineral content from place to place. Distiller water eliminates that variable.

Posted via Mobile Device |

|

|

|

|

|

#45 |

|

Registered User

Join Date: Apr 2009

Location: houston texas

Posts: 1,438

|

Re: At my wits end, motor getting hot. Input please

I live in southeast tx. I put a 160 thermostat in my 72. it made a big difference. the gauge stay at around 1/4 from the left consistently .

|

|

|

|

|

|

#46 |

|

Registered User

Join Date: Apr 2009

Location: houston texas

Posts: 1,438

|

Re: At my wits end, motor getting hot. Input please

|

|

|

|

|

|

#47 | |

|

Registered User

Join Date: Oct 2009

Location: Denton, Texas

Posts: 1,735

|

Re: At my wits end, motor getting hot. Input please

Quote:

Thank you for the tip of using the "Shout" laudry additive as a flusher. Will try that next time. The Glisten has 25% of Citric Acid. I only flushed with lots of tap water via a garden hose. Removed the thermostat and flushed out the engine with the lower radiator hose removed. Flushed out the radiator through the top radiator hose. Lots and lots of water. I didn't use any kind of "neutralizer" afterwards. Not too sure how safe the Citric Acid is on seals and cylinder head gaskets. I hope this doesn't come back and bite me on the rear end down the road. Wondering if I should reflush the system. Keith |

|

|

|

|

|

|

#48 | |

|

Senior Member

Join Date: Feb 2009

Location: Northern Nevada

Posts: 7,329

|

Re: At my wits end, motor getting hot. Input please

Quote:

__________________

Tony 71 Custom Deluxe, SWB, 2WD, 402, A/C. I developed an assembly kit for restoring the (a) truck from the ground up. My build thread, and more on the assembly kit https://67-72chevytrucks.com/vboard/...d.php?t=730025 |

|

|

|

|

|

| Bookmarks |

|

|