|

Register or Log In To remove these advertisements. |

|

|

|

|||||||

|

|

|

Thread Tools | Display Modes |

|

|

#1 |

|

Registered User

Join Date: Jun 2016

Location: Medicine Lodge, Kansas

Posts: 20

|

87 Sierra Conversion to R-134

I inherited an 87' R1500 a few years ago with very low miles on it and good body condition. Dad had it converted to R-134 some time before he passed his truck to his son. The a/c worked 'pretty good' but was prone to evaporator freeze-over. I've put up with it for about 7 years but the compressor went south and I set out to replace it.

Reading up on GM R-134 systems, I noticed that many vehicles replaced the simply low-pressure cut-out switch with a pressure cycle switch. It served the same purpose as low-pressure cut-out but added hysteresis to open at about 20 psig and re-close at at 35 psig. This had the effect of cycling the compressor to limit the evaporator's lowest excursion. The switch is field adjustable so that the technician can tweak the setting for max-cool without freezing. The new, smarter switch looks just like the older low-pressure cutout. However, the newer switch has a larger thread on the order of 12mm and wont thread onto the 1/4" port on stock R-12 receiver dryer. Is anyone aware of an adapter for this application? Or, perhaps, there is an alternative receiver drier with the larger port to fit the R-134 switch. I'm not adverse to getting on the lathe and making my own adapter but I'd rather purchase the parts for an elegant trade-out. |

|

|

|

|

|

#2 |

|

Registered User

Join Date: May 2007

Location: New Hampshire

Posts: 349

|

Re: 87 Sierra Conversion to R-134

The evaporator pressure control switch (or compressor cut-off switch, low side control switch, etc.) that was supplied as factory equipment in trucks equipped with air conditioning, is a true pressure cycling type switch. While the differential is fixed (i.e. non-adjustable) and set at about 20 psi, the range is adjustable. The "off the shelf" range (i.e. the cut-in/cut-out set points) is about 45/25 psi.

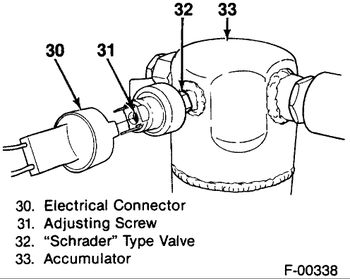

The Cycling Clutch Orifice Tube (CCOT ) refrigeration system is designed to cycle a compressor on and off to maintain desired cooling and to prevent evaporator freeze-up. Passenger compartment comfort is maintained by the temperature select bar on the controller. Control of the refrigeration cycle (on and off operation of the compressor) is done with a switch that senses low side pressure as an indicator of evaporator pressure. During air temperatures of 60-80°F, the equalized pressures within the charged air conditioning system will close contacts of the pressure switch. When an air conditioning mode is selected, voltage is supplied to the compressor clutch coil. As the compressor reduces the evaporator pressure to approximately 25 psi , the pressure switch will open, de-energizing the compressor clutch. As system equalizes and the pressure reaches approximately 46 psi , the pressure switch contacts close, re-energizing the clutch coil. Going by the book, when a 134a retrofit is done, best performance is achieved by adjusting the range of the compressor cycling switch down a bit - from where it was with R-12 in the system:  The head of the a range adjusting screw is accessed between the two harness connector terminals. CCW to lower the range and CW to raise it:  It doesn't take much, just about a 1/4 turn will lower the cut-out point from 24 psi (used with R-12) to somewhere between 19-21 psi on a cool day. Don't be temped to pull it down any lower, any colder and you'll risk icing the evap coil. |

|

|

|

|

|

#3 |

|

Registered User

Join Date: Jan 2014

Location: Swaledale, IA

Posts: 485

|

Re: 87 Sierra Conversion to R-134

I am going to get my A/C system going soon - I tried once last year with one of the do-it-yourself cans and it would cycle on/off/on/off all the time and the pressure gauge would have big swings. I thought I was doing it wrong and stopped so I wouldn't hurt something - from the above it almost sounds like that is what Its supposed to do?

|

|

|

|

|

|

#4 |

|

Registered User

Join Date: Jun 2016

Location: Medicine Lodge, Kansas

Posts: 20

|

Re: 87 Sierra Conversion to R-134

Thank you sir. You have confirmed what I have been reading.

My sticking point arose from the fact that switch on the truck was not adjustable. A replacement after market switch was also not adjustable. I've poked around and discovered replacement switches for r-12 systems that ARE adjustable. This is the obvious solution. I have a couple of switches marked as "r-134 compatible" that do adjust and exhibit about 18 psi differential. They just wouldn't plumb into my R-12 equipment without adaption. I will renew my quest for an ADJUSTABLE switch with the r-12 port. As soon as I get the refrigeration back up, I need to pull of the dash pad and refurbish all the hoses, etc to the various control-doors so that I can get air to come out of the right holes . . . but for now, getting cool air out of ANY holes will be most welcome. It's supposed to be 105 today . . . Thanks for the nudge in the right direction. |

|

|

|

|

|

#5 |

|

Registered User

Join Date: Jun 2016

Location: Medicine Lodge, Kansas

Posts: 20

|

Re: 87 Sierra Conversion to R-134

Mattchu60. Yes, assuming your vehicle does use the fixed-orifice, pressure-cycle form of refrigerant control. Some vehicles use a 'smarter' temperature controlled expansion valve more like most home a/c systems. In this case, the compressor runs all the time and refrigerant flow is controlled by the TXV.

Our ol' trucks used the fixed orifice at the inlet to the evaporator. Hence, the amount of refrigerant delivered to the evaporator must be controlled by cycling the compressor. There are pressure-cycle and temperature cycle switches used for this purpose with pressure-cycle being the simplest and least expensive. But is IS handy if the switch is adjustable so that you fix evaporator freeze-over problems and/or do a conversion from R-12 to R-134. I'm going to add an LED indicator lamp to show when the pressure switch is closed. By noticing the duty-cycle (on-off ratio) for the compressor, you can keep a heads-up on the general health of the system. To be sure, having the light on all the time (compressor never cycles) is not a good thing. On a really hot day, you'd like to see the compressor on most of the time but it should always cycle. |

|

|

|

|

|

#6 |

|

Registered User

Join Date: Oct 2012

Location: Eldon, MO

Posts: 1,753

|

Re: 87 Sierra Conversion to R-134

I was just reading up on this in my 86 FSM and as I recall one of the trouble shooting charts mentioned no more than 8 cycles per minute. What effect does adjusting the pressure have on the compressor cycling? IE, lower=more cycling or less?

|

|

|

|

|

| Bookmarks |

| Tags |

| 1987 sierra, r134 conversion |

|

|