|

|

|

#376 |

|

Senior Member

Join Date: Jun 2002

Location: Murray, Kentucky

Posts: 3,595

|

Re: "Midnight Rider" 1970 C10 SWB Fleetside

Nice work throughout the whole build. I can appreciate how long it takes to get some of these things done! Rg

__________________

Roger '68 Short step - https://67-72chevytrucks.com/vboard/...d.php?t=849675 '69 ('70?) 2wd Blazer '70 GMC Jimmy 2wd '73 Firebird - https://67-72chevytrucks.com/vboard/...d.php?t=853203 |

|

|

|

|

|

#377 |

|

Senior Member

Join Date: Jul 2010

Location: Race City U.S.A.

Posts: 1,029

|

Re: "Midnight Rider" 1970 C10 SWB Fleetside

I was organizing some parts related to the windshield washer/wiper system. I realized during this, that the hole in firewall for the washer hoses was accidentally deleted. Fortunately, it is still very apparent where the hole is suppose to be. A one inch hole saw made quick work of it. I'm glad to not be in a rush and have extra time to find things like this.

__________________

Board Member #87725 My build thread... http://67-72chevytrucks.com/vboard/s...d.php?t=813848 Last edited by omodified; 05-04-2024 at 03:53 PM. |

|

|

|

|

|

#378 |

|

Senior Member

Join Date: Jul 2010

Location: Race City U.S.A.

Posts: 1,029

|

Re: "Midnight Rider" 1970 C10 SWB Fleetside

I noticed the first time the cab was on the rotisserie that there were a few areas that were going to be hard to prep for paint. One of the areas is where the floor pans meet the weather-strip. There is a pretty good recess there that makes it hard to get anything in there to prep the surface. The other area is on the underside in the back where the rear crossmember meets the back panel. Again, this area is recessed and it's hard to get anything in there to prep the surface. What could be reached, got sanded and a wire wheel was used to get the rest. Also, sanded some factory undercoating off of the front side of the rear crossmember.

To protect these surfaces, we sprayed a rust encapsulator from Eastwood.

__________________

Board Member #87725 My build thread... http://67-72chevytrucks.com/vboard/s...d.php?t=813848 Last edited by omodified; 05-04-2024 at 03:53 PM. |

|

|

|

|

|

#379 |

|

Senior Member

Join Date: Jul 2010

Location: Race City U.S.A.

Posts: 1,029

|

Re: "Midnight Rider" 1970 C10 SWB Fleetside

Working on the inside of the cab. Found some areas that needed a little massaging. Final sanding other areas, getting ready for paint. Soooo close now...

__________________

Board Member #87725 My build thread... http://67-72chevytrucks.com/vboard/s...d.php?t=813848 Last edited by omodified; 05-04-2024 at 03:54 PM. |

|

|

|

|

|

#380 |

|

Senior Member

Join Date: Jul 2010

Location: Race City U.S.A.

Posts: 1,029

|

Re: "Midnight Rider" 1970 C10 SWB Fleetside

Some more progress photos for documentation of the last few weeks. A little more sanding going on. Also, decided to prime the eye level interior stuff to check details.

I also noticed during this process that there is a number stamped on the cab, behind where the mirror gets mounted. I guess this is generally hidden by the mirror and the the windshield weatherstrip. Well, I had always kind of questioned if my hood was original or not, despite the original spot welds and other factory looking markings. This stamping confirms it for me as the hood has a similar stamping on the back drivers side. Does anybody know what these numbers mean or what the factory used them for? I can't find any info about it.

__________________

Board Member #87725 My build thread... http://67-72chevytrucks.com/vboard/s...d.php?t=813848 Last edited by omodified; 05-04-2024 at 03:55 PM. |

|

|

|

|

|

#381 |

|

Paint, Body & Metalworker

Join Date: Jan 2008

Location: Airville, PA

Posts: 35

|

Re: "Midnight Rider" 1970 C10 SWB Fleetside

Looks to be turning out well. Seems you've found a shop receptive to what you want and are willing to do the work it takes.

|

|

|

|

|

|

#382 | |

|

Senior Member

Join Date: Jul 2010

Location: Race City U.S.A.

Posts: 1,029

|

Re: "Midnight Rider" 1970 C10 SWB Fleetside

Quote:

__________________

Board Member #87725 My build thread... http://67-72chevytrucks.com/vboard/s...d.php?t=813848 |

|

|

|

|

|

|

#383 |

|

Registered User

Join Date: Jun 2014

Location: Mocksville, NC

Posts: 1,761

|

Re: "Midnight Rider" 1970 C10 SWB Fleetside

Looking awesome Mr. O. I agree, the pinch welds are very noticeable on these trucks so they need to be straight on a build of your quality.

__________________

Builds: Green Gus the 68 C10 | Bluey the 72 1500 | Lowly the 70 C10 - Instagram: @dr.hewitt - C10 Concept/Development Photos: Master Thread |

|

|

|

|

|

#384 |

|

Paint, Body & Metalworker

Join Date: Jan 2008

Location: Airville, PA

Posts: 35

|

Re: "Midnight Rider" 1970 C10 SWB Fleetside

Pinch welds are often overlooked. I personally like to, after the vehicle is painted. Tape them off separately from the vehicle, scuff and shoot in a satin black. The pinch weld is still there but from 20+ ft you're eye isn't drawn to it and you get a better body profile. Beings the satin black is ontop of the paint, as it chips over it's life. You can just remask and spray a fresh coat.

|

|

|

|

|

|

#385 |

|

Senior Member

Join Date: Jul 2010

Location: Race City U.S.A.

Posts: 1,029

|

Re: "Midnight Rider" 1970 C10 SWB Fleetside

I know paint is coming just around the corner. So, I'm thinking about assembly coming just after. In the last few years, I have acquired some more parts/hardware that will be part of the build, but need nickel plated to match everything else. The issue is, the place I used has gone out of business and there aren't any options around anymore. I found an electroless nickel kit made by Caswell that actually looked like I could use in my kitchen. It seemed easy enough to work with and the kit comes with almost everything I would need. So, I ordered a kit to try it out. In hindsight, I should have done a better job estimating the size of the kit I needed to order....

To start, I rounded up all of the parts I could find. Mostly it was just random hardware. Specifically, I recently purchased several sets of 12 point hood latch bolts in order to find a matched set. I also threw in some radio mounting brackets and an early takeoff ball bearing ashtray.    Preparing to plate, you have to get two solutions ready. One is a detergent bath for degreasing and the other is the plating bath. The plating kit came with two - two gallon glass lined tanks. For the detergent bath, I mixed a 1/2 pound of detergent with one gallon of distilled water and warmed it to 190°. For the plating bath, I mixed one quart of solution with 1.35 gallons of distilled water and warmed it to 185°. The kit came with a thermometer so keeping track of temps was easy.       Once the temps became stable, it was time to prepare the parts for plating. The first thing to do was strip the first batch of parts in muriatic acid. Since this is toxic and smells really bad, I did this in the garage sink, with the doors open. I let the parts soak for three minutes, then rinsed with water. I immediately transferred the parts to the degreaser bath so there was no flash rust.   Next was plating. Caswell, has a very specific formula for you to understand how much solution you need for your project. They refer to it as credits. The numbers of credits you use is calculated as time in bath x surface area (inē). They would also have you measure each part to be plated. I refused to spend that kind of time on this so I just grouped everything into 5"x5" batches. Caswell says once your credits reach 80% of your starting credits, you have to replenish with 4oz of solution to bring your credits back to the original number or the bath will crash. Using 5x5 batches in the formula, I would need to replenish 4oz every 14 minutes. One batch would be finished after 28 minutes. Based on this, I would only have enough solution to complete two batches. I organized the batches by priority, in case I didn't have enough to do everything. Well, I followed Caswell's instructions and replenished when I was suppose to. I had enough to start the third batch as planned. I decided to let this batch sit the entire 28 minutes to see how it would turn out. It actually turned out fine. So good, that I decided to take a chance on the last batch, which was the ash tray. I'm glad I took the chance because it turned out nice too. I'm not sure how much further I could have gone or how many more parts I could have put in each batch, but I'm glad I didn't have to push it any more than I did. This stuff actually turned out better than any of the stuff I paid for in the past. This is a little expensive for what I actually got, but it was way worth it seeing how it turned out. Not afraid to do this again if I have to!!!

__________________

Board Member #87725 My build thread... http://67-72chevytrucks.com/vboard/s...d.php?t=813848 Last edited by omodified; 05-14-2024 at 10:06 AM. |

|

|

|

|

|

#386 |

|

Senior Member

Join Date: Jul 2010

Location: Race City U.S.A.

Posts: 1,029

|

Re: "Midnight Rider" 1970 C10 SWB Fleetside

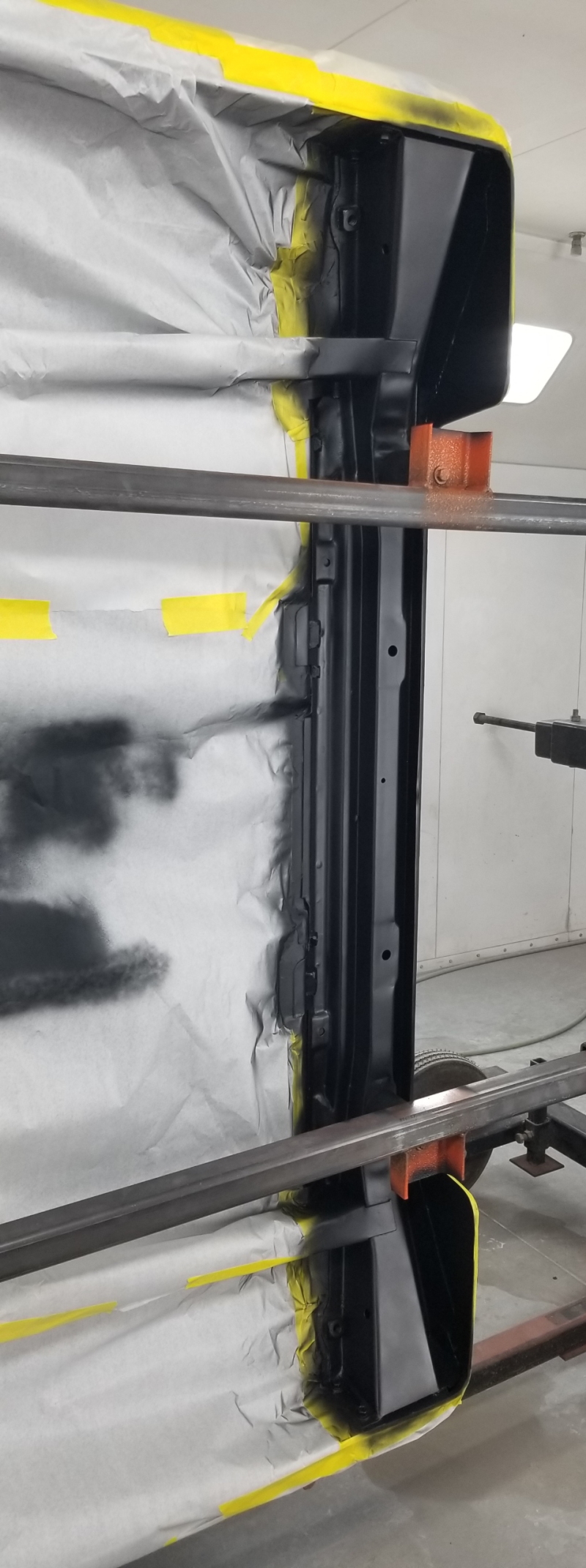

Body shop update with a few more details...

__________________

Board Member #87725 My build thread... http://67-72chevytrucks.com/vboard/s...d.php?t=813848 |

|

|

|

|

|

#387 |

|

Registered User

Join Date: Dec 2014

Location: Tucson, AZ

Posts: 731

|

Re: "Midnight Rider" 1970 C10 SWB Fleetside

"Science bi*&hes"!

__________________

1987 V20 farm-hand rescue 1998 C2500 lot-rot rescue |

|

|

|

|

|

#388 |

|

Senior Member

Join Date: Jul 2010

Location: Race City U.S.A.

Posts: 1,029

|

Re: "Midnight Rider" 1970 C10 SWB Fleetside

Been gathering ideas for the exhaust. Due to my motor being rated at 550hp, I decided a few months ago that 3 inch exhaust was in order. You may have seen in an earlier post where I polished out 3 inch inlet/outlet mufflers. Well, the struggle I reached recently was that the headers I currently have installed are 2.5 inch at the collector. It's too bad because I really like the look of these and the clearance they offer. I looked into using a 2.5" to 3" adapter, but I also read where 550hp+ engines should have 1.75" primary tubes or bigger. These shorties are 1.625" so it's time to find something different.

I tried to find a manufacturer that makes a set of shorty headers that meet my specs. Unfortunately, there isn't anything out there with a 3" collector. So, I started looking at long tubes. A few members on this board have used Doug's D3348 headers with pretty good results. So, I decided to start there. I went with the model specifically for 67-72. I like the idea that these are already coated. I was going to have to coat my old short headers anyways, but I wont have to worry about that with these. I got the right side installed, and the clearance was very tight to the frame rail, 0.005" at the closest point. I need at least 0.375" to feel comfortable. I didn't really want to remove this much material from the frame and I also didn't want to dent the headers. So, I decided to send these back. I wasn't very happy with the welds on these anyway.         Since I really liked the TIG welds that the Speed Engineering short headers have (way nicer than Doug's partial MIG welds) I decided to try a set of their 25-1066 mid length headers. They don't offer anything specific for 67-72 C10, so I went with universals. They are for LS engines so I assumed the fit would be close. Well, I was wrong. They look really nice, but the collectors are aimed toward the transmission. In fact, they hit where I have already removed the transmission ears. I can't take anymore material away from there, so these will get sent back too.   Next, I decided on a pair of Speed Engineering 25-1025 long tube headers. These have a ton of clearance to the frame on the driver side. They do hit the corner of the block ever so slightly. I will need to clearance the block there about 0.00625".     The passenger side is a little closer. I have 0.080" of clearance to the frame. Better than Doug's but I will still have to remove some of the frame to get enough clearance. I really do like the looks of these headers, so I think I will keep and use them. I used a large metal file to attack the frame. Using a grinder might blister the paint on the frame and make it harder to touch up later. After filing for what seemed like a day, I ended up with 0.400" clearance and some damn good looking headers.

__________________

Board Member #87725 My build thread... http://67-72chevytrucks.com/vboard/s...d.php?t=813848 |

|

|

|

|

|

#389 |

|

Registered User

Join Date: Sep 2016

Location: Ozark, MO

Posts: 568

|

Re: "Midnight Rider" 1970 C10 SWB Fleetside

Thanks for the details on header fitment. I personally have never had a set that didn't have to be bent somewhere or other parts removed to make them work. Now, please put the plug wires on and check for spots that will get burned thru (ie requiring more modification)

|

|

|

|

|

|

#390 | |

|

Senior Member

Join Date: Jul 2010

Location: Race City U.S.A.

Posts: 1,029

|

Re: "Midnight Rider" 1970 C10 SWB Fleetside

Quote:

__________________

Board Member #87725 My build thread... http://67-72chevytrucks.com/vboard/s...d.php?t=813848 |

|

|

|

|

|

|

#391 |

|

Senior Member

Join Date: Jul 2010

Location: Race City U.S.A.

Posts: 1,029

|

Re: "Midnight Rider" 1970 C10 SWB Fleetside

Once I fit the new headers, I hit another snag with my exhaust plan. I realized the CPP transmission crossmember is directly in the path of the collectors. I will have to route the exhaust up and over. With it being 3", I wasn't sure if there would be enough room to do this. So, I ordered the perfect solution. Here is the Dirty Dingo DD-C10-TRANS crossmember. This will allow me to run the exhaust along the same plane as the collectors. This will work so much better!

This crossmember is nice because of the clearance it offers but also the transmission adjustability. However, I had already matched up the pinion angle to the previous transmission location. So, to make installation easier, I documented the angle of the transmission before I removed the old crossmember and I used a laser to paint a line back to the pinion. This will ensure the transmission gets centered correctly.   Installation turned out great. Will swap out for nickel plated hardware at a later date. Look at all the room for activities!!!

__________________

Board Member #87725 My build thread... http://67-72chevytrucks.com/vboard/s...d.php?t=813848 |

|

|

|

|

|

#392 |

|

Senior Member

Join Date: Jul 2010

Location: Race City U.S.A.

Posts: 1,029

|

Re: "Midnight Rider" 1970 C10 SWB Fleetside

One thing I realized when I had the short headers installed was that I wanted all of my exhaust to use v-band connections. The long tube headers did not come with any type of flange on the collector. I bought v-bands with clamps from Speed Engineering which need to be welded on. I had a friend from work help me with the TIG welding cause I knew he would easily be able to match the quality already found on theses headers.

Once everything was welded in place, I took a barrel sander to the inside and smoothed everything out. I even smoothed out the welds inside the primary tubes. Now, off to Jet-Hot for some coating!!!

__________________

Board Member #87725 My build thread... http://67-72chevytrucks.com/vboard/s...d.php?t=813848 |

|

|

|

|

|

#393 |

|

Senior Member

Join Date: Oct 2012

Location: Phx, AZ

Posts: 292

|

Re: "Midnight Rider" 1970 C10 SWB Fleetside

That is a nice x-member.

__________________

Scott 1970 C10 LWB-->SWB Under Construction https://67-72chevytrucks.com/vboard/...d.php?t=847605 2014 2500HD DirtyMax|Daily Driver|Stock 2003 Tahoe Stock 1985 K5 5.3LS/4L60E|8Lug 4:56|3/4 Ton Front|14BFF Rear|Roll Cage|Dove-tailed & Bobbed |

|

|

|

|

|

#394 |

|

Senior Member

Join Date: Jul 2010

Location: Race City U.S.A.

Posts: 1,029

|

Re: "Midnight Rider" 1970 C10 SWB Fleetside

I received the headers back from Jet-Hot. Initially, I was pretty impressed with how the finish turned out. Then I started digging in a little closer and realized that many of the tight areas between the primary tubes did not get polished. I did reach out to Jet-Hot about it and they explained that the headers are indeed 100% coated. However, because the area is so tight, it doesn't allow for 100% polishing to be achieved during their process. They recommended that I polish myself with a non-abrasive metal polish cream. I found a video that shows the Jet-Hot process. I suppose I can understand why polishing cannot be achieved in the tight places. Disappointing, but at least I can have the final say on how these things turn out. For polishing, I used a Dremel with the tiniest polishing pads I could find. Once I hit all of the really tight spots with the Dremel, I polished the entire piece by hand. It actually turned out really nice. Passenger side is finished and installed. I used new exhaust gaskets and torqued one pass to 132 lb/in and then again to 216 lb/in. Last, I blocked off the O2 sensor hole, for now.

__________________

Board Member #87725 My build thread... http://67-72chevytrucks.com/vboard/s...d.php?t=813848 Last edited by omodified; 08-11-2024 at 09:47 PM. |

|

|

|

|

|

#395 |

|

Senior Member

Join Date: Jul 2010

Location: Race City U.S.A.

Posts: 1,029

|

Re: "Midnight Rider" 1970 C10 SWB Fleetside

Getting really close to painting. Really just waiting on the temp and humidity to drop off for the year. One of the last prep items is replacing the seam sealer. A lot of the old sealer had already been removed but there was still some hanging around. One spot in particular was on the front side of the rockers. The passenger side looked good underneath. The driver side ended up having a small rust hole, unfortunately.

Poked around the area to see just how bad the area is. Opened it up to get all good metal surrounding.   Repaired and ready to go. Thankfully, this is the last of the rust. Applying the seam sealer is next.

__________________

Board Member #87725 My build thread... http://67-72chevytrucks.com/vboard/s...d.php?t=813848 |

|

|

|

|

|

#396 |

|

Senior Member

Join Date: Jul 2010

Location: Race City U.S.A.

Posts: 1,029

|

Re: "Midnight Rider" 1970 C10 SWB Fleetside

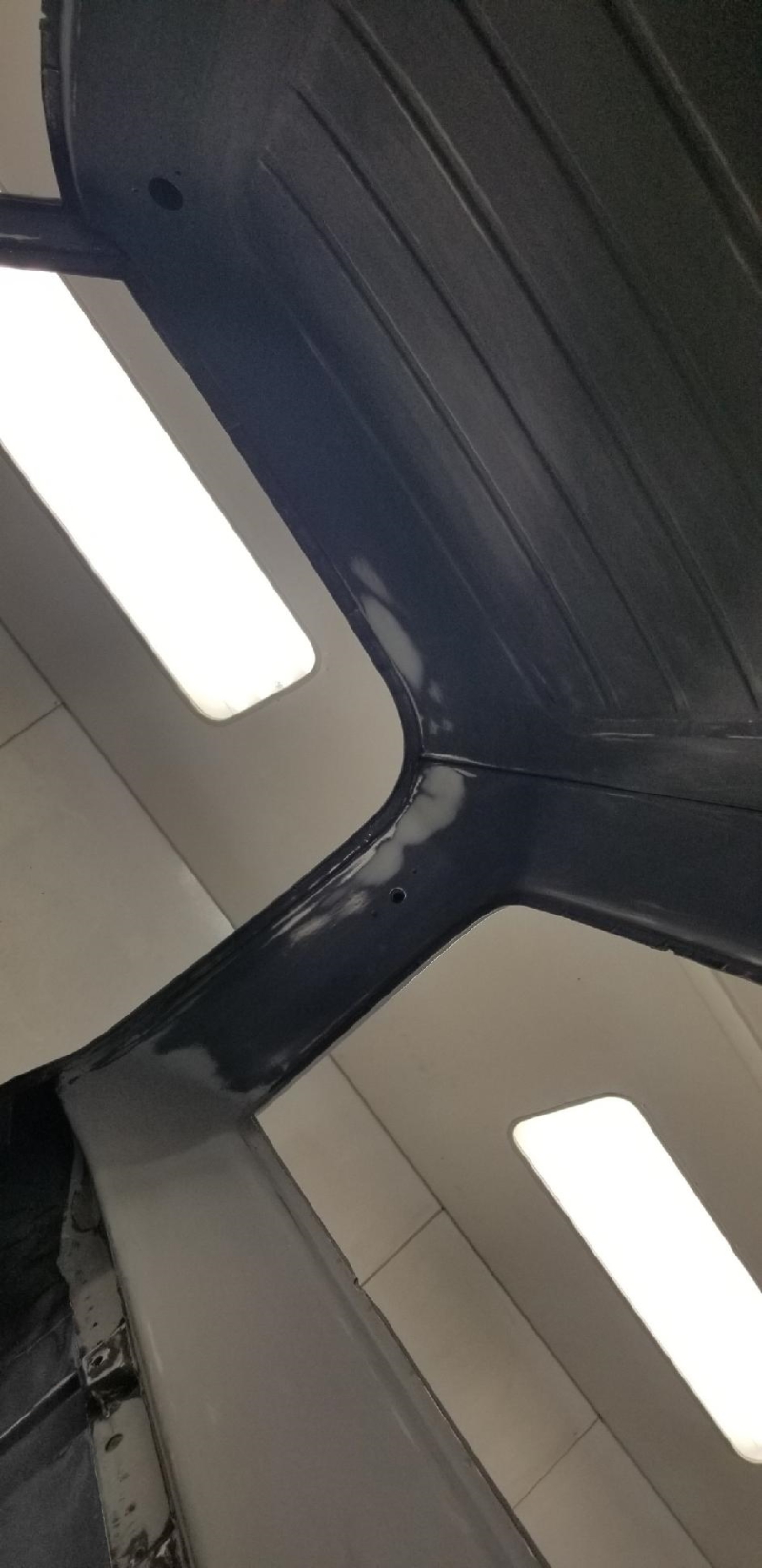

Seam sealer applied. Next up, black primer sealer.

__________________

Board Member #87725 My build thread... http://67-72chevytrucks.com/vboard/s...d.php?t=813848 |

|

|

|

|

|

#397 |

|

Senior Member

Join Date: Jul 2010

Location: Race City U.S.A.

Posts: 1,029

|

Re: "Midnight Rider" 1970 C10 SWB Fleetside

Decided on my base coat color. Going with Axalta Nason 99 black. It is the modern equivalent of 1970 Chevrolet 500 Black. Here it is sprayed out. The truck will have much more clear!

__________________

Board Member #87725 My build thread... http://67-72chevytrucks.com/vboard/s...d.php?t=813848 |

|

|

|

|

| Bookmarks |

|

|