|

|

|

#76 |

|

Senior Member

Join Date: Mar 2011

Location: West Plains, Missouri

Posts: 7,559

|

Re: 49 GMC Five Window

Sorry but I can't see any of the pics you posted in your update...Jim

__________________

my build thread: http://67-72chevytrucks.com/vboard/s...d.php?t=459839 Jimbo's long bed step build:http://67-72chevytrucks.com/vboard/s...t=464626<br /> |

|

|

|

|

|

#77 |

|

Registered User

Join Date: Nov 2013

Location: Show Low, Arizona

Posts: 776

|

Re: 49 GMC Five Window

Really looking forward to my first drive up the neighborhood. Plan is to drive it up the hill so if it quits it won't be so hard to push home!

My big 4 seat long travel car got sold last month - I traded my car for cash and a two seat turbo Subaru. I was sad to see it go - my son and I built it when we weren't the best of friends and it kind of bonded us together again. Nobody wants to go to the dunes anymore and it wasn't getting used. The good news is, I got enough out of it to fund the completion of my '49 and probably the MGTD too. Here's a picture of it- LS1 with forged internals, stock cam, single turbo - dynod 525 at the wheels. About 24" of wheel travel.  With my BIL from France - he didn't puke and had a hell of a good time!  Out sitting in the dunes  Wow! I wished my MGTD looked that nice. Wife's car a late Series 2 1953. Bought as a basket case and have just finished making new doors and all the metalwork. Should start assembly in the next month or two. |

|

|

|

|

|

#78 |

|

Registered User

Join Date: Oct 2014

Location: Kitchener, Ontario, Canada

Posts: 3,254

|

Re: 49 GMC Five Window

Your rail is awesome I would love to have one of them some day, but there is nowhere to drive them around here. I helped my dad rebuild the MG 25 years ago, he drove it all over. Good plan on driving up the hill first lol.

__________________

http://67-72chevytrucks.com/vboard/s...d.php?t=648459 https://67-72chevytrucks.com/vboard/...d.php?t=769441 1951 MG TD 1967 Jeep CJ5 1.9L TDI 33X13.5X15 Mud Grapplers. 1952 GMC 9700 p/u 7.3L diesel on air, dually |

|

|

|

|

|

#79 |

|

Registered User

Join Date: May 2014

Location: lagrange georgia

Posts: 9

|

Re: 49 GMC Five Window

Can we get some new pics of the truck please.

|

|

|

|

|

|

#80 |

|

Registered User

Join Date: Nov 2013

Location: Show Low, Arizona

Posts: 776

|

Re: 49 GMC Five Window

Sure, but there has not been much progress lately. Finished the paint job almost a year ago and I've just been piddling along

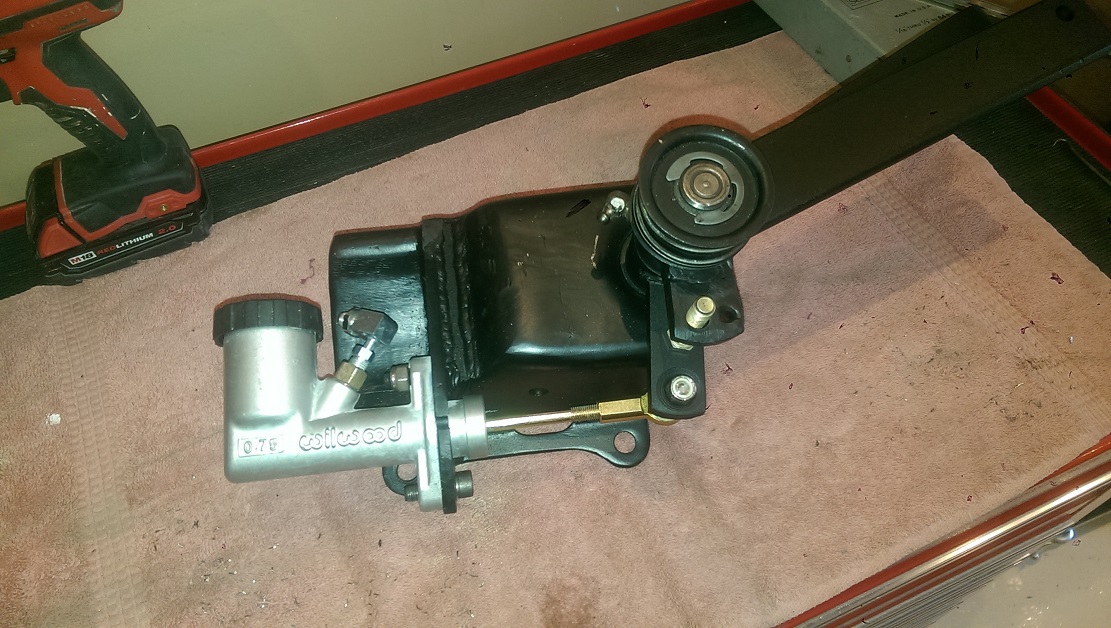

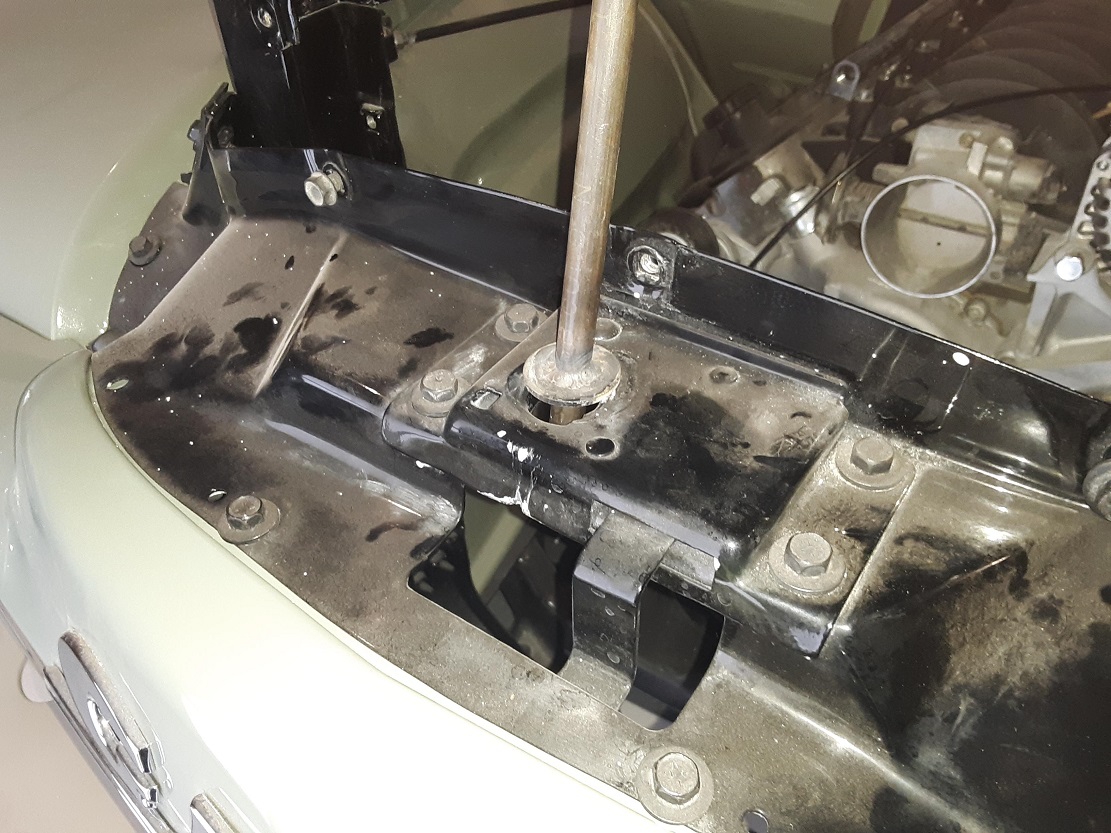

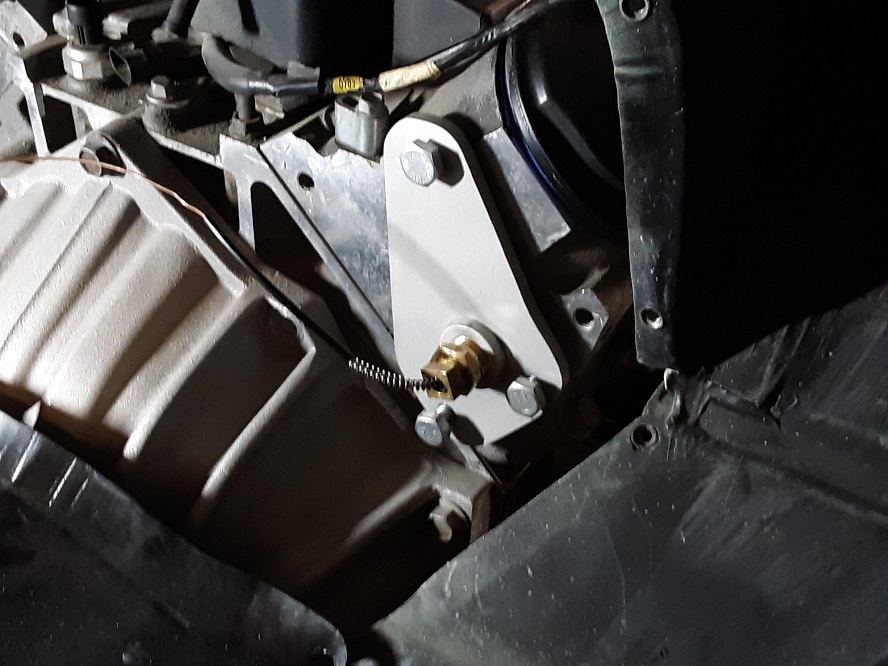

Was not happy with the clearance of the hydroboost to the header collector, so I moved the booster and master back about fifteen inches on the inner frame rail. Here is the pedal assembly with the clutch master and the pedal ratios correct for a hydroboost  The bracket for the remote hydroboost. Filling the master will now have to be under the driver seat  The relocated hydroboost now occupies the space where the pickup for the trailing arm mounted for the Jag IRS. Will have to redesign and weld up a new crossmember. Not looking forward to working under the truck. My bear claw latches are in and working well. Had clevis ends on all the control rods, but was not happy with the door action, so I replaced them all with miniature rod ends. Can now open the door with one finger and it shuts with just a gentle push (no rubber in the door yet though) Bought a radiator for the GMC, but had to return it for incorrect mounts and filler neck in the wrong location. Not quite sure what to do for a radiator. Someone suggested the Ron Davis radiator, but the price is about 2x. Maybe the 'pay it and just cry once' adage applies here. Nice looking radiator, but it just didnt fit. I was part Chevy and part GMC  Truck has been jacked up in the shop for most of the year waiting to have the brake master installed and the lines plumbed   I bought a lot of parts last year getting ready to plumb the fuel, air and brakes - most of it is sitting in the bed of the truck. Having some second thoughts about the airbag suspension. A company in Portland is making a coil over setup for the front and rear of the Jag suspension and I'm temped to change directions  Since I retired, there seems to be less time to work on the truck. I talked to the shop that helped me with the metal work and paint, and he said to bring it back to the shop and he would help me finish it. I spent about eight months last year working in his shop, mostly on the truck, and it was a fun learning experience. I told him I would bring it back in January and take him up on his offer. I think that is the only way it is going to get done. I need the discipline of showing up at the shop four or five days a week to work on the truck and keep me away from the other projects I have at home, surfing the net, talking with the wife, drinking beer and taking naps. I never understood people who told me 'Since I've retired I don't know how I had time to work', but I am beginning to see what they meant. |

|

|

|

|

|

#81 |

|

Registered User

Join Date: Nov 2013

Location: Show Low, Arizona

Posts: 776

|

Re: 49 GMC Five Window

The picture of the bear claw linkage didn't show up. so here it is. You can see in this picture where I laid the arm rest bump out on the inner door flat. Looking for ideas for a custom armrest

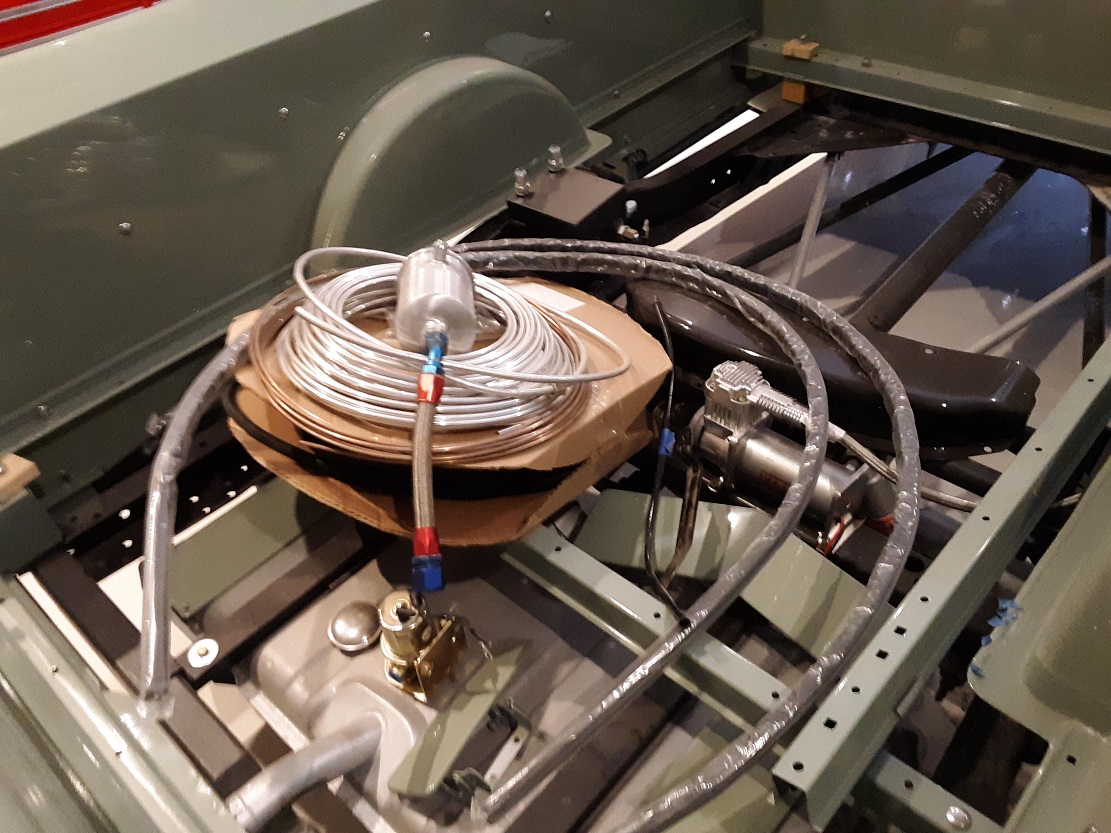

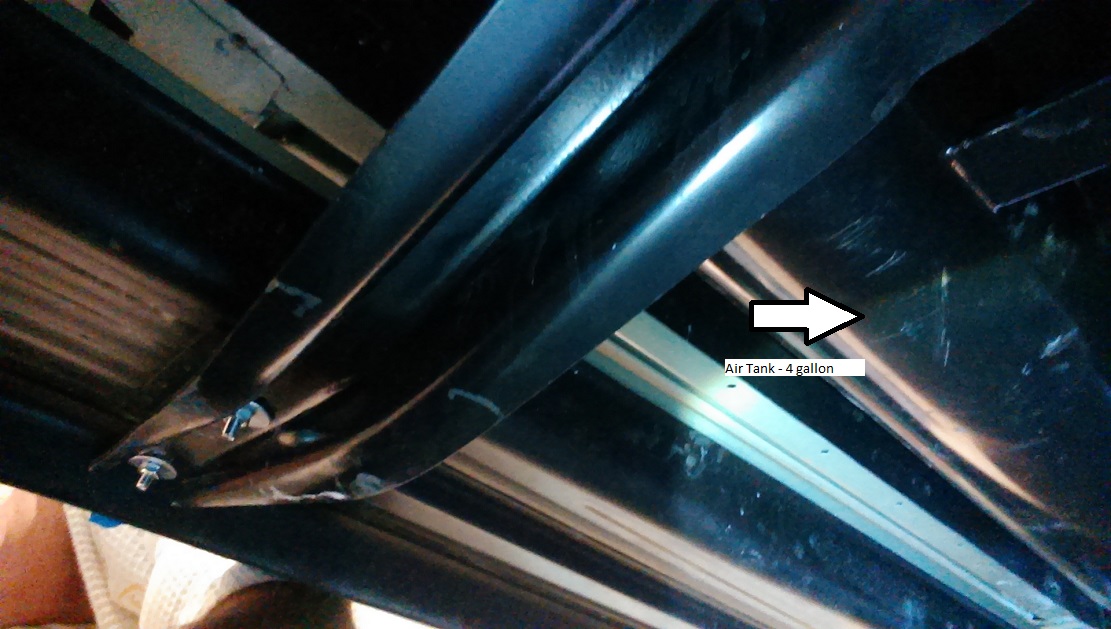

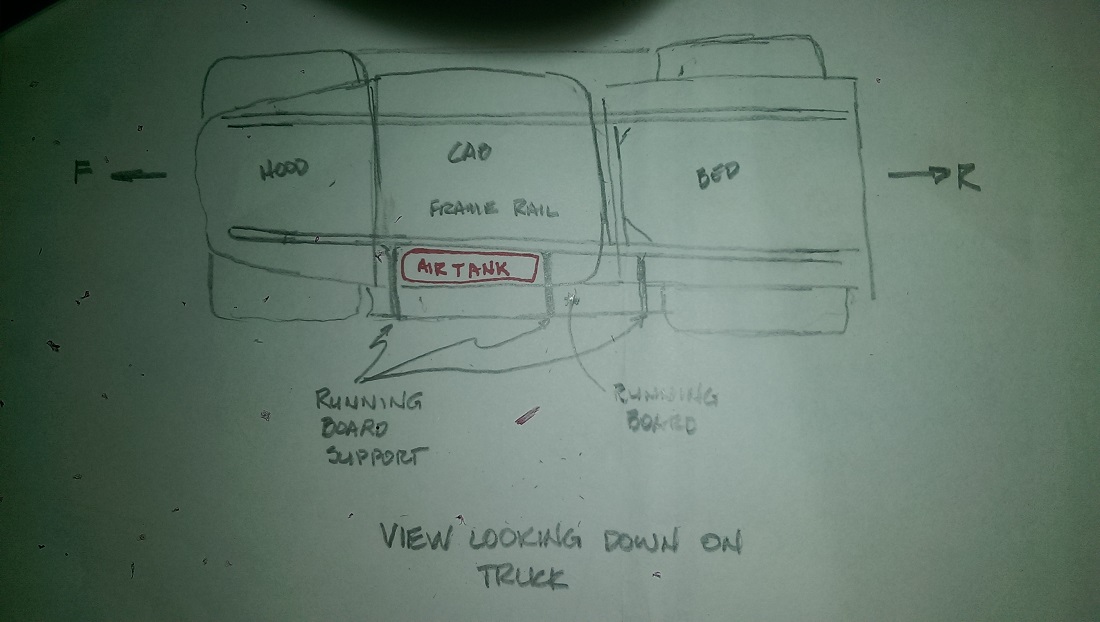

ed ed Also mounted a four gallon air bag tank between the running board and the frame rail. Here's a pic of it but it is kind of hard to see  To make a little more sense of where it is mounted, here's a drawing of the location  Still trying to figure out how to lock the doors with the bear claw. I put linear actuators to the bearclaw latches, but I really don't like the setup. Thinking about a retractable bolt in the door jamb instead. Here is the lock/unlock key setup using two microswitches to lock and unlock

|

|

|

|

|

|

#82 |

|

Registered User

Join Date: May 2014

Location: lagrange georgia

Posts: 9

|

Re: 49 GMC Five Window

This is the most beautiful truck I believe I've seen. I'm saving for a GMC but life gets in the way all the time but I will have one one day God willing. I have built the truck in my head for twenty years and seeing your truck is what I dream my finish product will resemble. I think you have great taste and excellent craftsmanship.

|

|

|

|

|

|

#83 |

|

Registered User

Join Date: Nov 2013

Location: Show Low, Arizona

Posts: 776

|

Re: 49 GMC Five Window

Thanks for the nice words.

Keep at it, you'll get one. |

|

|

|

|

|

#84 |

|

Senior Member

Join Date: May 2007

Location: Doodah Kansas

Posts: 7,774

|

Re: 49 GMC Five Window

easily one of the best GMCs ever. I am staggered by the work on this truck.

__________________

the mass of men live lives of quiet desperation if there is a problem, I can have it. new project WAYNE http://67-72chevytrucks.com/vboard/s...d.php?t=844393 |

|

|

|

|

|

#85 |

|

Registered User

Join Date: Nov 2013

Location: Show Low, Arizona

Posts: 776

|

Re: 49 GMC Five Window

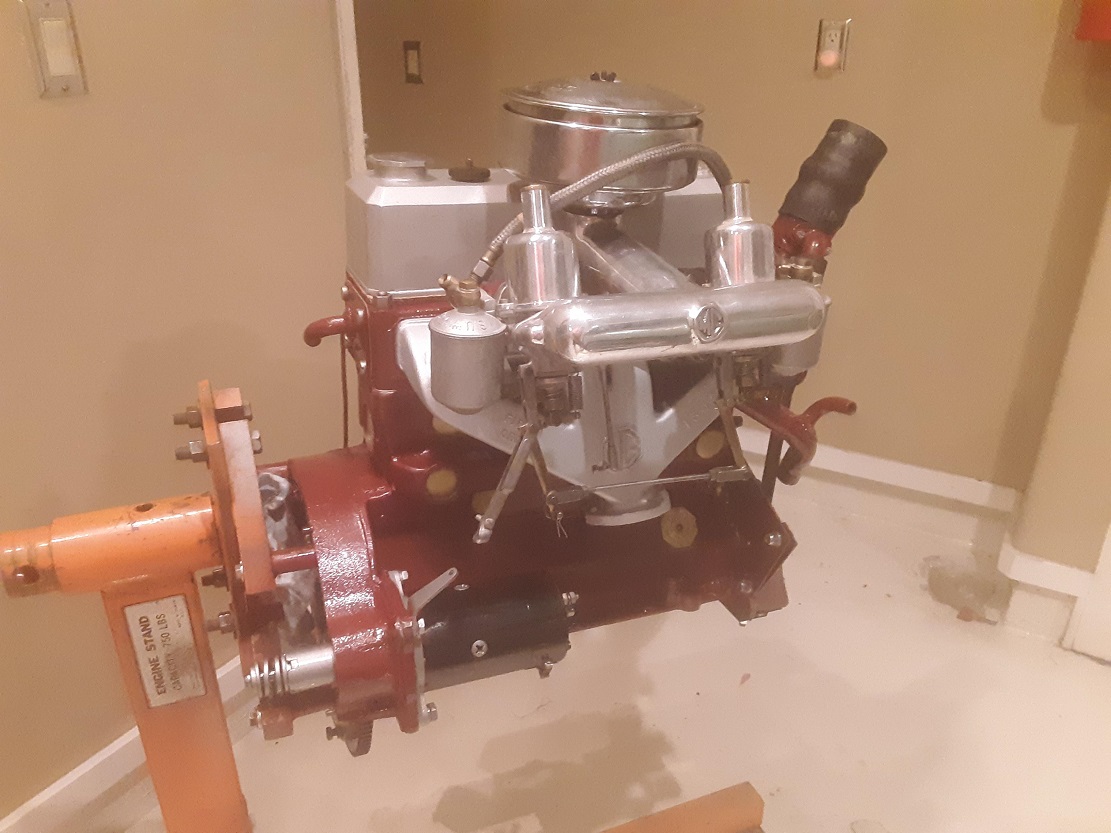

Thanks for the kind words Joe and Bobby

Here's something for you Joe - a hood prop, unlike a broomstick, that cant inadvertently pop out if it's hit. Here's the top of it with a cup that the spring goes into to hold it.  Here's the bottom, with a fender washer welded on to it to keep it from falling into the hole for the latch pin  I'm finally getting close to getting the pedals how I want them. I shortened both the clutch and the brake about 4" to bring the foot pedal to about 4-5" from the floorboard. The clutch pedal is on the floor when the actuator rod on the clutch master is at the bottom of the bore. I re-welded the short arm on the brake pedal to get the leverage ratio correct for the hydroboost too. Here's a shot of the pedal setup.  I made a actuator lever for the gas pedal so I can actuate the throttle (using a bicycle brake cable) I tried having a lever at the bottom of the gas pedal that would actuate the cable, but it hit the bellhousing (because my engine sits so far back), so I had to have the linkage visible in the cab. Oh well, it looks mostly stock. The pedal rides on a ball bearing roller wheel for a sliding-glass door I bought at ACE hardware.  The access panels for the clutch master and the hydroboost linkage are under these access covers, secured with Dzus fasteners  I had to modify the trailing arm for my iRS to clear the master cylinder. While I was under the truck, I also set my pinion angle at 3.5 deg up, and adjusted the engine angle down 3.5 deg so the pinion angle and engine angle are parallel. When I got them to withing 0.1 degree of each other I called it good. Here's a pick of the reworked trailing arm support (still need to clean it up a little and paint it) and the Corvette master and Astrovan hydroboost in the background.  I ordered a emergency brake cable from Control Cables for the Jag IRS. Here's a shot of the cable installed-  I was planning on using the brake handle off of a Jag XJS I'd bought at the self serve junkyard, but it is so big and clunky, I don't see how it is going to fit in nicely in the cab. I got a handle off of a forklift in the forklift junkyard (didn't even know there was such a thing till I started to look) The fork lift parking brake was kinda cool because it had a handle that could turn and take up slack/wear in the cable. Here's both handles.  I really don't like either solution. I was using a friend's Mazda a couple months ago and it had an electric parking brake, and I wondered if they were available in the aftermarket. And they are, but are a little spendy at around $450. YouTube shows a couple of DIY electric parking brakes, and it convinced me I should build one myself. Going to use an actuator like this one - 330 pounds force and a 4" stroke - about $50.  Need to put an inconspicuous DPDT switch in the cab to actuate it. It might even become part of the truck's security system My steering column is out of a 59 or 60 Cadillac. I took it apart and had the shaft cut for a double D at the end and put in a thrust bearing. The hole in the floorboard is about twice as big as it needs to be for the Cadillac column so there's a gaping hole in the firewall to fill. I'm planning on having a leather boot (kinda like a shifter boot) to seal the cab around the column Here's a bezel I cut out of 304 stainless that will hold the boot in place against the firewall and the support to hold the column for the floorboards made from a piece of slit schedule 40 pipe and some tabs First the mock up in cardboard of the bezel-  The bracket and trim bezel- (the bezel will get bent to conform to the firewall contour)  Other posters tell me I'm out of step with the best technology if I don't have an in-tank fuel pump. They are probably right, but I'm going to do it the way I've always done it and spend the same on a half a dozen parts for an external system as I would have for the in-tank pump setup. Here's the components I plan to use - boost pump, swirl pot and Corvette regulator/filter. The 255 Walbro I had squirreled sway for this truck got used on the sandbuggy (which could have set the house on fire when I started the buggy and left it to warm up in the garage. Ethanol in the gas had eaten the pump housing and it dumped a gallon or two of gas on the floor next to a running engine while I went into the house- maybe there's a lesson there on ethanol,external pumps and fire hazard), so I'll need to buy another pump. I plan on running all AN-6 hard line for the fuel system so I bought a Parker flaring tool too.  The gas tank is out of a second gen Camaro. The big block Camaro's had a fuel pickup with a suction line and a vent line, and my plan is to use the vent line as a fuel return from the swirl pot to the tank. Here's the fuel tank with the sender's 3/8" line fitted with a swagelok fitting, but I still need a swagelok for the 1/4" line. I tried just flaring the tube with the Parker tool, but the stainless line cracks so easily that the swagelok will be safer.  Well, that's about it for this update. I putz away at working on the truck several days a week, but decided that I was never going to get it done at this rate. The metal fabricator that did all my sheetmetal work and painted the truck said he'd come over on Saturdays to help. His best guess is that we can finish the truck in about three months. The to-do list is about 3 1/2 pages of single spaced typed task - I'm not so sure about three months, but it sure as hell will be faster than doing it myself. I've been working on my wife's MG TD too. Not AD truck related but here's a pic of the engine I built for it - 1250cc and a whopping 54 HP.  Bought this car with engine assembled but the rest of the car in boxes. On of the boxes had all the parts you'd normally replace in an engine overhaul and the seller didn't know for sure but thought the motor was fresh. It wasn't and $1500 later, here I am. At least I know what I've got now. Last edited by e015475; 11-14-2018 at 09:01 PM. |

|

|

|

|

|

#86 |

|

Senior Member

Join Date: May 2007

Location: Doodah Kansas

Posts: 7,774

|

Re: 49 GMC Five Window

thanks for the prop tip but I dont even have a latch plate installed yet haha.

nothing wrong with an external pump setup, if you know what you are doing, and it seems like you do. i get a little mixed up when guys use tanks with an in tank pump and switch it to external. but if you dont have an in tank pump to begin with it makes plenty of sense. it looks like you cleaned your camera lens! the artifacts I always look for in your pictures are not there any more haha

__________________

the mass of men live lives of quiet desperation if there is a problem, I can have it. new project WAYNE http://67-72chevytrucks.com/vboard/s...d.php?t=844393 |

|

|

|

|

|

#87 |

|

Registered User

Join Date: Nov 2013

Location: Show Low, Arizona

Posts: 776

|

Re: 49 GMC Five Window

No more artifacts!

Kicked our kids off my phone plan, and with the money I saved I bought a new phone! |

|

|

|

|

|

#88 |

|

Registered User

Join Date: Oct 2014

Location: Kitchener, Ontario, Canada

Posts: 3,254

|

Re: 49 GMC Five Window

Wow looking good. I would suggest using a motorcycle brake cable as it is a little thicker and stronger. As for the linear actuator for your e brake that is a great idea and self holding.

__________________

http://67-72chevytrucks.com/vboard/s...d.php?t=648459 https://67-72chevytrucks.com/vboard/...d.php?t=769441 1951 MG TD 1967 Jeep CJ5 1.9L TDI 33X13.5X15 Mud Grapplers. 1952 GMC 9700 p/u 7.3L diesel on air, dually |

|

|

|

|

|

#89 |

|

Registered User

Join Date: Nov 2013

Location: Show Low, Arizona

Posts: 776

|

Re: 49 GMC Five Window

Been slacking off and took a week off and took the family to Flagstaff for Thanksgiving, But here's a little progress on the truck-

If you've ever thought about adapting a non-truck steering wheel instead of one of those fancy Ididit or Flaming River columns, here's what I did- I started with a 57-58 Cadillac column from CL and cut the end of the tube off, extracted the tube that went down to the automatic transmission and discarded it. I took the shaft down to a machinist and had the diameter turned to .75" and had him mill two flats in it to accept a double-D u-joint. I bought a "column saver" which has a bronze bushing and thrust bearings to replace the bearing I cut off the Cadillac column- Here's the column saver mounted onto the Cadillac steering shaft.  Here's the column saver installed in the bottom of the Cadillac column. I searched high and low for the brush that is used for the horn and finally gave up and made one of my own out of a piece of brass  I shaved the steering column collar where the gear shift lever went through the pot metal. I rebuilt the turn signal mechanism and contacts by just cleaning and lubing them up. Replaced all the wires leading to the turn signal contacts. The pot metal collar that held the gear shift lever was no longer supported by the tube within the column that went down to actuate the transmission gear shift, so I JB welded the shift collar to the turn signal collar. It probably looked ok on the Cadillac when the collars were separate, but now that they're together I'll need to skim with a little bondo, and Featherfill before I paint it.  In the Cadillac, the column sits in a recess in the dash, but for the truck I needed some sort of transition so it didn't end abruptly and looked finished. I found a stainless measuring cup in the kitchen, and cut the bottom out of it so it would slip over the column and be a little more aesthetically pleasing. Here's the JB welded collars and the measuring cup transition on the column  Here's the completed column almost ready for paint. When I got the column and wheel, the wheel had about a hundred cracks around the rim. I used a hack saw blade and opened the cracks and filled them with epoxy. That was 18 months ago, and a couple of cracks have reappeared on the rim. I'm not going to fuss with them anymore and will wrap the steering wheel in leather to cover them (Horn ring isn't fastened on in this pic)  The 57-58 Cadillac horn ring has the Cadillac swan emblem in the middle. There's one on ebay for $100 but I can't bring myself to pay that much for a little piece of plastic, Looking for any ideas on what to put in the hole to finish the wheel.  All in, I have about $300 in the column but a lot of labor. If I paid myself $10 and hour, I could have had an Ididit or FR column. |

|

|

|

|

|

#90 |

|

A320 Pilot/USAF Retired

Join Date: Mar 2009

Location: Charleston, SC

Posts: 2,629

|

Re: 49 GMC Five Window

Nice work!

__________________

JJ My 1957 build: http://67-72chevytrucks.com/vboard/s...d.php?t=334552 http://www.trifive.com/forums/showthread.php?t=22037 Instagram - Chuckdriver57 |

|

|

|

|

|

#91 |

|

Post Whore

Join Date: May 2015

Location: Alabama

Posts: 14,663

|

Re: 49 GMC Five Window

Column looks great...whered you get the column saver from?

__________________

Mongo...aka Greg RIP Dad RIP Jesse 1981 C30 LQ9 NV4500..http://67-72chevytrucks.com/vboard/s...d.php?t=753598 Mongos AD- LS3 TR6060...http://67-72chevytrucks.com/vboard/s...34#post8522334 Columbus..the 1957 IH 4x4...http://67-72chevytrucks.com/vboard/s...63#post8082563 2023 Chevy Z71..daily driver |

|

|

|

|

|

#92 |

|

Registered User

Join Date: Nov 2013

Location: Show Low, Arizona

Posts: 776

|

Re: 49 GMC Five Window

Greg-

I ordered mine from Ecklers. A quick Google shows Brothers, Summit and other sells it too - at lower price than I paid! I think they are all made by Classic Performance. |

|

|

|

|

|

#93 |

|

Registered User

Join Date: Nov 2013

Location: Show Low, Arizona

Posts: 776

|

Re: 49 GMC Five Window

Been picking away at a few things and thought I'd give a little update.

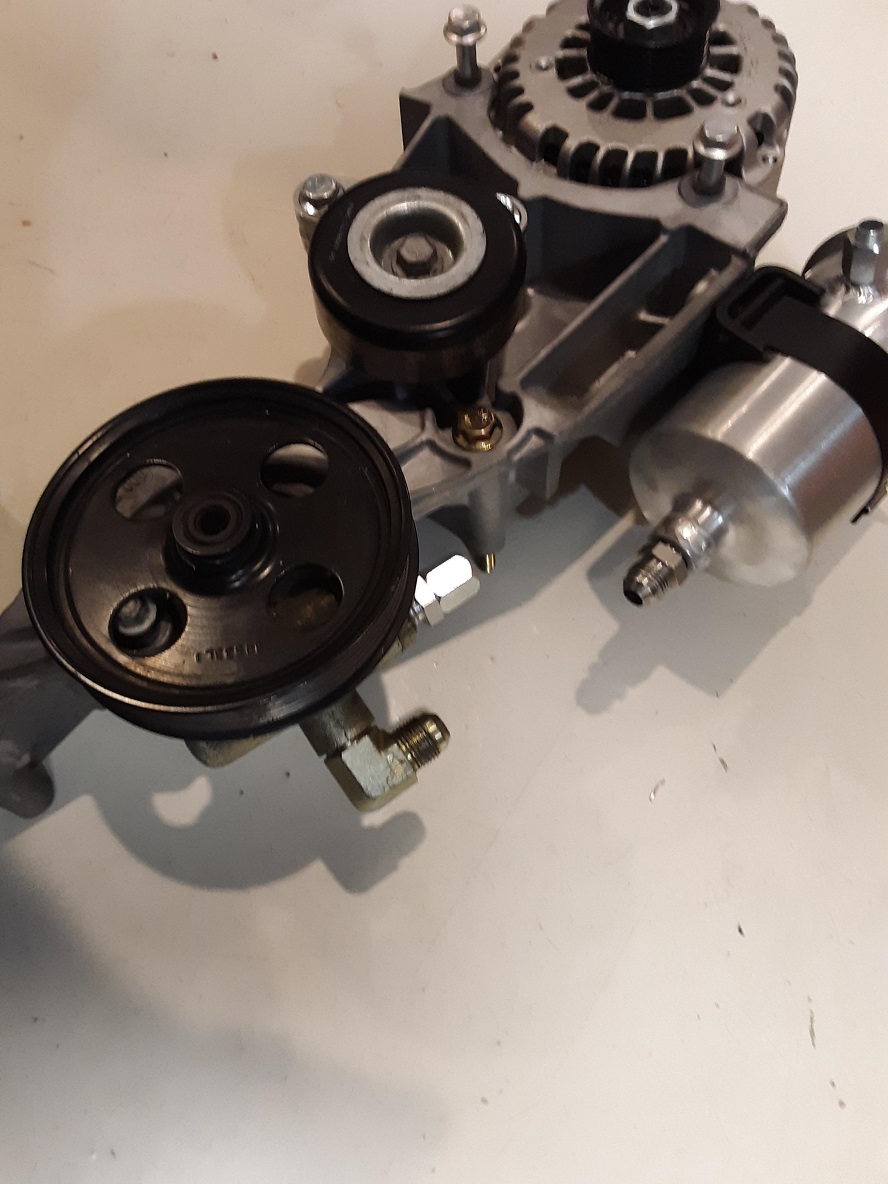

It has been a little nippy here in Arizona - close to freezing every night for about the last week (I can just see the crocodile tears now). This is the best 'tool' investment I've ever made for my shop-  Been out in the shop working on the truck till 10PM the last couple of nights with the heat pump on. Wife is getting a little pissed that I'm not spending more time inside. Aiming to get my engine bay assembled for what I hope is the last time. I ditched the Chinese billet aluminum fuel rails and installed a Corvette fuel spider. It isn't as flashy, but I was nervous about the aftermarket rails and all the ORB connectors. Replaced all the manifold and valve cover seals and cleaned up all the overspray on the motor from the paint job.  I'm going to run my heater hose through -8 AN hose and want to use fittings instead of hose clamps, so I pulled the steel tube inserts out of the water pump and tapped the holes with NPT threads. Here it is with the AN adapters installed-  I was at Copperstate Electric (highly recommended if you're in AZ) having a starter and generator rebuilt for my MG TD, and decided it'd be a good idea to have a newly built alternator for the truck - here it is nice and new looking sitting on the truck accessory drive I'm using.  The power steering reservoir on the truck looks a little too 'modern' and plasticy for me, so I bought this aluminum reservoir for cheap on ebay and mad a bracket for it to fit on the accessory bracket. It had a -10 AN male fitting on the bottom of it that was swagged to the tank, and I didn't trust it to not leak, so I cut it off and TIG'd a bung on it. Will plumb it in rubber AN hose. The idler pulley has been moved so that the drive belt will clear the car-style intake using a kit from ebay. I bought a TC Type 2 power steering pump for a Corvette to use on my '49, mostly because I wanted the bearing style pump out of the Vette and Tuff Stuff sold one with an AN fitting on the suction side. However, when I installed the Vette pump in the truck bracket, the inlet pointed right into the fenderwell and I couldn't get a hose on it and the pulley was about another 1.5" in diameter. Not going to work and the new pump is now in the swap meet pile and I put the old truck pump back on. Oh well. Here's the 90 degree suction side fitting for the truck pump. It is a slip fit into the pump housing and there's no oring seal like there was with the original plastic tank, so the plan is to JB weld it in. If it leaks, I'll TIG it or braze it in. Fingers crossed it doesn't leak.  Another view of the tank. It attaches with a over-center Southco clasp I bought on ebay. Why anybody would want a quick release on their power steering tank is beyond me, but I thought it looked cool. (I should probably weld another -6AN fitting on for a dedicated hydroboost return so maybe that quick release will be handy)  It has come to my attention that LS motors are very "HAMB unfriendly", but I'm so far into it now about the only thing I can do to even have the slightest resemblance to a politically correct SBC is to hide the coils-on-plugs. Maybe I can fool a few people. Here's my coil relocation bracket. I'm thinking about mounting them under the radiator on the core support or on top of the front cross member. Under the dash in the cabin is a possibility too, but whatever I do, I need them on brackets so I can get a 'footprint'. Scrap aluminum, some all thread and aluminum tube from Aircraft Spruce.  The Trailblazer engine I bought was drive by wire. I've done conversions with both cable and wire, and for this truck I wanted to avoid that ugly DBW foot pedal in favor of an original-looking pedal with a cable. I pulled the harness, computer, throttle body and MAF off of an earlier Suburban with a cable throttle to use. I stripped all the wires out for the 4L60e and anything else I didn't need. In the past, I've always done my own rework on engine harnesses, but there was an ad in CL for a guy who said he'd do one for $200 and he'd pick up and deliver, so I took a chance. It came back with a fuse block, relays and all the connections nicely labeled. I asked that he leave it uncovered so I could check all the pinouts and put the loom I want on it as well as give me access to extend the PCM if I needed. He didn't change the connectors to the EV1 type from the truck and I see a lead marked "TCC" (he was to pull all the wires related to the automatic transmission out of the loom, including the torque converter lockup) Here's the harness ready for a trial fit on the '49  I'll need to install the EV1 injector connectors first though.....about $12 on ebay for a set. I'd really like the wiring harness to 'disappear' on the engine (I think kids these days call it 'tucking' the wiring harness) I'm not a fan of the corrugated plastic loom, and for the visible parts of the harness I want use a woven black covering with RayChem shrink tube. I'm willing to de-pin the harness connectors to make this happen. I'm a glutton for punishment, I know.  Will also need to extend the wiring for the coil packs, so I bought 3' extensions for the coil sub-harness. The corrugated loom will be hidden in the frame rail  All I need now is a willing visitor to my shop to help me get the water pump and accessory bracket back on without screwing up any paint work, then I can start trial fitting the harness. Few more progress items in the cab. I pulled the Camaro shifter I had on the T5 and took it apart to graft a new shift rod. The Camaro shift lever needed to be about 8-10" longer and it hit the seat too. Here's a pic of the new American Shifter lever mated to the Camaro part. (sorry it is a little hard to see through the steering wheel)  The boot is an EMPI item off of a VW Beetle. I welded the Camaro stick to a rod extender bolt that had the same threads as the American Shifter shift rod. American Shifter is one of the Hoffman companies and I'm not especially thrilled by the quality, but it's passable. The Lokar ones for 2X the price didn't look any better.  Underneath the boot  The local SoCal speed shop is a Vintage Air dealer and recommend the largest size VA air box for the truck. It was pretty spendy at about $750. I met a guy with an AD who'd installed the VA unit in his truck, and his recommendation was to use the smaller air box from VA and that the bigger air box was overkill for the cab of a truck. It was a little more than half the price of the bigger unit too, which was a bonus. Here's the smaller unit he recommends, well the trial fit dummy anyway - it sure packges up nicer under the dash too. Anybody have any experience with this size air unit?  The AD owner recommending the smaller VA unit also had his ac vents set up to blow through the radio grill. I'm going to do this too. He turned some knobs and made his own ac controls too - pretty slick.  I've been screwing around with my bear claw latches for what seems like forever. I've finally got everything working the way I want it (doors can be locked from the inside while driving, the key will open the passenger door and there's provisions for an electric door lock actuated from a key fob). I'm not as smart as those Altman guys, so my latches rely on rods going down to a bellcrank to connect the door handle to the bearclaw and clear the door glass. Everything worked great, but the outside door handle did not want to return to level after the door was opened. I'd hoped the spring in the bear claw would be sufficient to overcome the friction in the linkage, but it was a little too weak. Here's a picture of the bear claw installed.  I'd already replaced all the clevis joints with rod ends, bushed the door handle and took all the slop I could out of the bell crank, but no luck, so here's the helper spring that assists the spring in the bear claw now. It is about the same diameter as the ones I remember on screen doors when I was a kid but about half as long. The stainless clip at the end comes up through the weep hole in the bottom of the door to hold the spring, and the top clips into the bell crank.  Everything works now, but instead of a satisfying 'clunk' when the door closes, there's a 'clunk/boing' sound of the spring resonating. I just can't win. That's about it for now. Expecting my US Radiator order any day. Have a big Spal fan for it already and I'd scheming on what I want to do for a fan shroud. Thinking about something using the bead roller to give the shroud some detail. Once I get the radiator, shroud and fan in, I can think about how I'm going to fit the MAF and air filter. |

|

|

|

|

|

#94 |

|

Senior Member

Join Date: Mar 2011

Location: West Plains, Missouri

Posts: 7,559

|

Re: 49 GMC Five Window

Nice update, and everything looking good...Jim

__________________

my build thread: http://67-72chevytrucks.com/vboard/s...d.php?t=459839 Jimbo's long bed step build:http://67-72chevytrucks.com/vboard/s...t=464626<br /> |

|

|

|

|

|

#95 |

|

Registered User

Join Date: Jan 2017

Location: Larkspur, Colorado

Posts: 916

|

Re: 49 GMC Five Window

Noticed the EMPI VW boot that you used for the shifter. Looks like that could be perfect for a stock look with my SM465 4 speed and cut down noise and fumes. Does it fasten to the floor somehow? Thanks for the tip,

Steve weim55 Colorado |

|

|

|

|

|

#96 |

|

Senior Member

Join Date: May 2007

Location: Doodah Kansas

Posts: 7,774

|

Re: 49 GMC Five Window

beautiful work! I love this truck.

poor you about getting chilly.

__________________

the mass of men live lives of quiet desperation if there is a problem, I can have it. new project WAYNE http://67-72chevytrucks.com/vboard/s...d.php?t=844393 |

|

|

|

|

|

#97 |

|

Registered User

Join Date: Nov 2013

Location: Show Low, Arizona

Posts: 776

|

Re: 49 GMC Five Window

Jim - Nice to see your truck up and running again. Best wishes for the new year.

"Does it fasten to the floor somehow?" I don't recall ever seeing a bezel to hold the boot to the tunnel on the old VWs. I was planning to make one out of a piece of stainless sheet stock when the time came for the interior. "beautiful work! I love this truck." Thanks. Pretty envious of yours though. You're driving. Got to ride in an AD truck with an LS motor and 5spd a few weeks ago. Nice. I really want to stop fabbing and start driving. "poor you about getting chilly" I know! I installed it before I retired so I could work out there in the summers when it is 115F. It is a bonus to be able to walk out to the shop on chilly mornings in your slippers and bathrobe an putter around! |

|

|

|

|

|

#98 |

|

Registered User

Join Date: Nov 2013

Location: Show Low, Arizona

Posts: 776

|

Re: 49 GMC Five Window

Seems like progress is slow and there is a million little things to do. But the 'to-do' list is down from over 4 pages to about 3 1/2, so I guess that's progress.

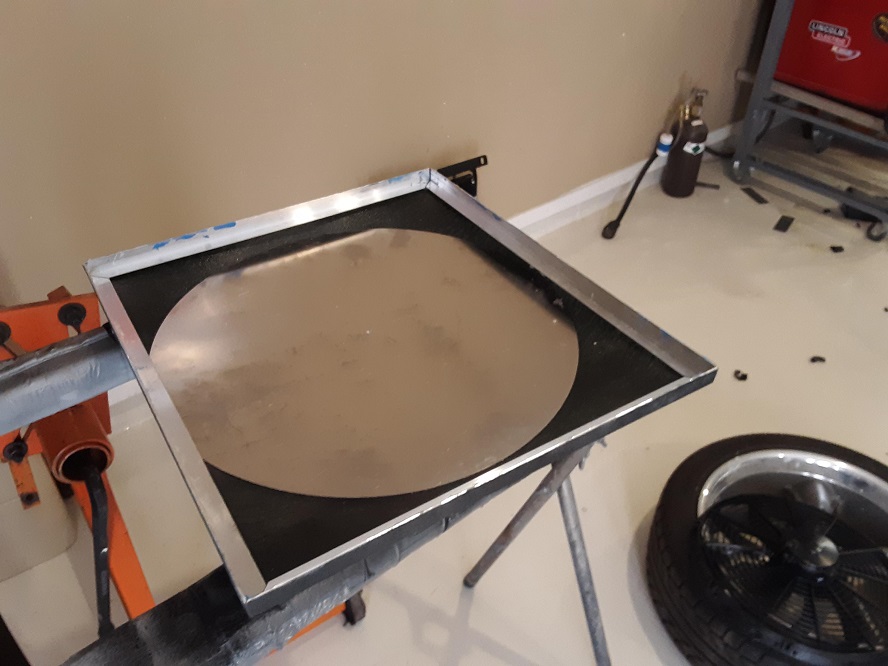

The US Radiator for my truck arrived undamaged and it looks pretty good. The bolt holes to mount it into the truck's radiator support were off by an inch and I had to redrill them, but other than that it is a nice piece. I put the Vintage Air condenser on it to see how it was going to fit - it didn't. The brackets on the condenser are about 1 1/2" short.  I managed to get to work in the kitchen by telling my wife that the fins on the radiator and condenser were very delicate and might get damaged in the shop. That worked for about a day. The VA part number for the condenser kit for the AD Chevy is the same as for the GMC. But the GMC has the radiator pushed forward about 1 1/2" for the longer GMC I6 engine. I bought it from my local SoCal shop, and to their credit they went to bat for me with VA, but VA said that they'd supplied the correct part number for my GMC. They offered to send me a 'universal' bracket I could modify. SoCal said they'd refund my money if I wanted to bring it back. Looks like I'll have to fab my brackets and I'm pretty disappointed in Vintage Air's customer service. Well onward and upward, I guess. I needed a fan shroud and was just going to build one out of aluminum when I had this brainfart of making one with a 3D shape for a little more 'factory' look. Shaping it out of metal on the english wheel and welding it together looked pretty time consuming and frankly above my skill level so I began to think about something in fiberglass. I've seen DIY speaker boxes made from fiberglass and an MDF form and decided I try to use that technique to make a fan shroud. I cut a piece of 3/4" MDF the same size as the core or my radiator to use as the base for the 'plug' of my mold. I reinforced the edges with some aluminum angle. Next I went to the local craft store and bought some styrofoam to use as a spacer, then topped that with a 18" aluminum disk (that I will eventually use as the mount flange for the electric fan) Here's the 'sandwich' of MDF, styrofoam and aluminum  To form the shroud, I took an old cotton t shirt and stretched it over the plug. The front had too many welding burn holes and a sewn in pocket, so I used the back. I stapled the t shirt to the MDF board and saturated it with epoxy resin to form a 3D shape  I ground the back side of the shroud down to the aluminum angle braces then I pried the MDF and styrofoam plug away from the shroud. Here's what it looks like from the back-  I will fiberglass the inside of the fan shroud with about three layers of 1.5 oz mat to stiffen it up for durability. I'll use a router to cut the aluminum for the fan once I get it stiffened up with mat. Here's what the whole thing will look like with a 1900 CFM Spal fan. I'd like to do something with a variable speed controller for the Spal fan. Going to look for some sort of PWM controller with a temp input.  For the outside, I'll skim it with bondo then spray it with Featherfill. Top coat will be a semi-gloss black trim paint to give a 'factory' look. Note the burn hole in the tshirt. I've never made anything out of fiberglass, so if anybody has any comments or suggestions, I'm all ears. On to other problems......... Almost ready to string my harness so I can shorten/lengthen wires and loom up the harness, but before I can do that, I needed to decide where the coil packd are going to be located. The AD frame is pretty narrow and the headers run close to the frame rail, so mounting them there was out. I didn't like the idea of mounting them on the firewall or inner fenders (they are kind of ugly) and mounting them in the cab meant 8 high tension leads had to get into the engine bay, which wasn't very appealing. Finally decided that I mount them under the engine on the front cross member. I built a steel 'shoe' to support the coils and drilled and tapped the cross member to attach it. It will be almost invisible in the engine bay.  I might build a little shield/cover out of stainless for it if I get ambitious. Here's the rack of coils ready to bolt to the adapter shoe on top of the cross member-  I isolated all of the sensor leads by un-pinning/re-pinning them from the PCM connectors and wrapping them individually in loops. My plan is to mount the PCM and fuse box in the cab and then run the wires to each sensor individually. This will tell me where I need to lengthen or shorten wires and how I can loom the harness to have as little as possible showing as you look into the engine bay,  I'm going to weld up some stainless mandrel bends to use for radiator hoses and once they're welded, take them to Wyatt's shop and polish them up. I used the ICE header legos to mock up the hose before start hacking up expensive madrel bends in 304 (the legos are the wrong diameter, but this gives me the general idea)  The truck was already painted with the engine in it when I decided I wanted to use original gauges, so I couldn't machine the cylinder head for the temp sensor bulb. I pried out a core plug on the back of the head and made this adapter plate to mount the temp bulb. Bonus that there is no bulb capillary tube in the engine bay to clutter it up.  Just in case you were wondering, 66F and clear last week in Phoenix. Shorts and fiip flops and working with the shop door open and heat off. Come June, I'll have to pay the piper for my weather smugness, but for now......

|

|

|

|

|

|

#99 |

|

Post Whore

Join Date: May 2015

Location: Alabama

Posts: 14,663

|

Re: 49 GMC Five Window

Interesting temp sender location....I assume you have it sealed off good...

__________________

Mongo...aka Greg RIP Dad RIP Jesse 1981 C30 LQ9 NV4500..http://67-72chevytrucks.com/vboard/s...d.php?t=753598 Mongos AD- LS3 TR6060...http://67-72chevytrucks.com/vboard/s...34#post8522334 Columbus..the 1957 IH 4x4...http://67-72chevytrucks.com/vboard/s...63#post8082563 2023 Chevy Z71..daily driver Last edited by mongocanfly; 01-20-2019 at 10:05 PM. |

|

|

|

|

|

#100 |

|

Registered User

Join Date: Nov 2013

Location: Show Low, Arizona

Posts: 776

|

Re: 49 GMC Five Window

The thermostat location is in the stock location in the water pump. This is only the bulb for the temperature gauge. I plan on sealing it with a bead of RTV. If that doesn't work I'll need to find a CNC mill or router and put an oring groove in the face of it.

|

|

|

|

|

| Bookmarks |

|

|