|

|

|

#1 |

|

Registered User

Join Date: Nov 2013

Location: Show Low, Arizona

Posts: 778

|

49 GMC Five Window

1949 GMC Build Thread

The Obligatory Background Story I bought this truck a couple of years ago in Quartzite, Arizona, a wide spot in the road near the Arizona-California border along I10. Itíd spent most of its life in Blythe California, a desert town. The cab and the hood were sitting on the ground in a yard. The seller had disassembled the truck and had modified the chassis to accept the front and rear suspension from a C10 when he decided to move and the project stalled.   I had the cab and sheet metal blasted to see what I had to work with. I knew the heater leaked and took out the floor on the passenger side, but after the cab was blasted there were holes in both the door pillars and one of the cab corners. Despite coming from a very dry place, there was a lot of dust and dirt accumulated in the pockets and it held moisture in and allowed rust.  I painted the sheet metal as quickly as I could with Southern Polyurethane epoxy to keep it from rusting This truck was a basket case when I bought it and I had this nostalgic idea of a hot rod pickup like Iíd seen in high school fifty years ago. Iíd learned to drive in an Advanced Design truck too. The C10 suspension seemed like it was going to be too wide without narrowing the cross member, so I sold all the C10 suspension components. Iíve always been attracted to British cars, and I has just sold my Jaguar XJS with a LS motor for the seed money to start the truck project. I had read of folks using the Jag IFS on old trucks and it had the right width. A local chassis shop, Industrial Chassis, had done Buick with a Jag IRS and IFS and raved about the ride. I knew a little about rebuilding the Jag suspensions and after talking to Steve at Industrial Chassis, I decided to go that way. Iíd transplanted a 5.3 LS motor into my Jag along with a 4L60 and decided Iíd do it again for the truck. I was scheming on how to get a manual transmission in the XJS before I sold it, and decided to go with a manual transmission. I debated whether I wanted a patina truck or a nice paint job, and came down on the side of the fully restored look after looking at the trucks at the Goodguy shows in Scottsdale. I was ok with either, but after going to the Goodguy show in Scottsdale with my wife, she felt strongly that we should go with a restomod with a new paintjob. I wanted to have her on board with the project, so thatís the way we went. Iíve been driving GM trucks for the last 45 years and frankly Iím tired of pickup truck ride quality. For this project I wanted a very plush ride, something very luxury car like, so I decided to go with airbags. The Jag front suspension was very easy to modify to accept airbags, but the Jag IRS was more of a challenge. Next - the bodywork |

|

|

|

|

|

#2 |

|

Registered User

Join Date: Aug 2012

Location: West Side of the valley, CA

Posts: 878

|

Re: 49 GMC Five Window

sounds like a solid platform and a straight forward plan. Looking forward to it.

|

|

|

|

|

|

#3 |

|

Registered User

Join Date: Feb 2014

Location: Sunnyvale, CA

Posts: 605

|

Re: 49 GMC Five Window

Looking forward to following along.

__________________

1950 3100 5 window |

|

|

|

|

|

#4 |

|

Senior Member

Join Date: Mar 2011

Location: West Plains, Missouri

Posts: 7,559

|

Re: 49 GMC Five Window

I'll tag along for the build...Jim

__________________

my build thread: http://67-72chevytrucks.com/vboard/s...d.php?t=459839 Jimbo's long bed step build:http://67-72chevytrucks.com/vboard/s...t=464626<br /> |

|

|

|

|

|

#5 |

|

Registered User

Join Date: Feb 2013

Location: Fallbrook California

Posts: 250

|

Re: 49 GMC Five Window

I'm looking forward to the progress on your truck.

|

|

|

|

|

|

#6 |

|

Registered User

Join Date: Nov 2013

Location: Show Low, Arizona

Posts: 778

|

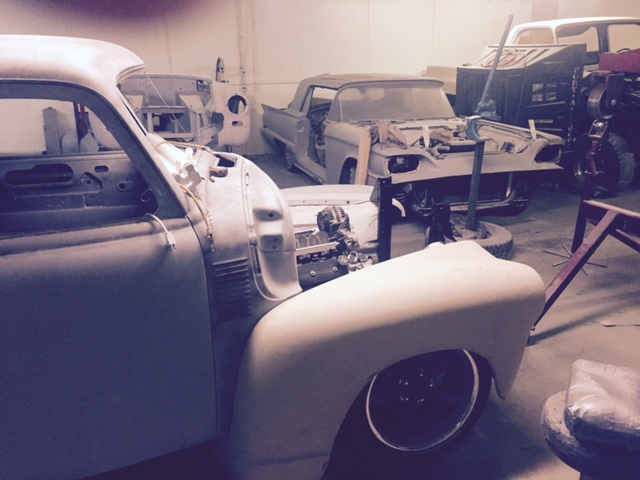

Re: 49 GMC Five Window

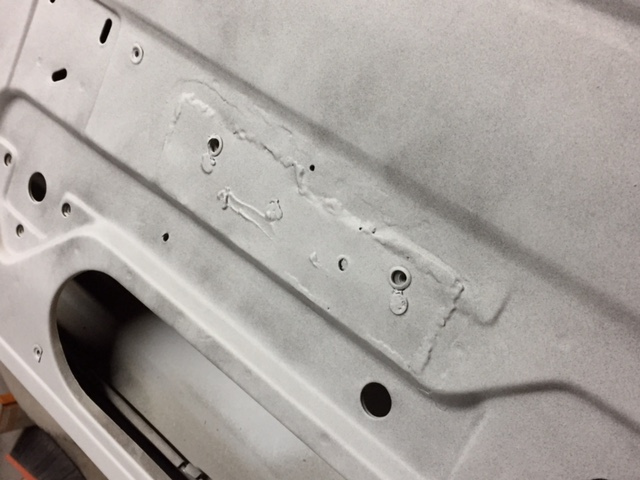

The Bodywork

After trailering the disassembled truck to Phoenix, I took all the sheet metal to a local blaster that did a lot of work for car restoration projects to do as little damage as possible to the steel. I tried having the doors and running boards chemically dipped, but didnít like the idea of residual chemical in the seams and corners, and had the dipped parts blasted too. Here's the cab in Southern Poly epoxy primer just after blasting-  The results of the blasting showed just what condition the cab and doors were in. The bottoms of the door pillars were rusted out, the drivers and passenger side floor was pretty much gone and one of the cab corners needed replacing. There were holes in the bottom of the doors on the inside panel. Previous owners had punched holes in various places in the cab, including what must have been an antenna in the roof and a big hole in the dash where theyíd shoved a tach or something into. I like to do paint and bodywork, but this truck was going to take a lot of time. I still work full time and was remodeling/selling my house, so I decided that Iíd hire the metal work done, or this project was going to take a long time to finish. The sandblast shop recommended I talk to Wyattís Rod Shop in Mesa and when I got there a mid-40ís GMC COE sitting on a custom chassis with a Corvette suspension with ĎWyattís Rod Shopí painted on the door was sitting outside.  I found Wyatt making a rear fender for a Chevy sedan delivery on an English wheel and knew Iíd probably come to the right place. We struck a deal to do all the sheet metal work on the í49. All the following work is Wyatt Tichenorís, done at his shop, Tichenor Coach Works- Replacing and repairing sheet metal is pretty standard on this site, so I wonít bore you with more, but hereís a picture of the dirt that came out of the door pillar that no doubt held the moisture in and caused it to rust, even in the desert.  The gas tank filler hole was closed off since I plan on relocating the tank to behind the differential.  Gas tank filler patched finished  The dents, welds, and imperfections were bumped out with a hammer and dolly and the metal finished to a degree where it didnít require any filler, only Feather-fill high build primer. There were a couple of areas that required a skim coat of bondo to level the surface, but only sparingly. I rebuilt the door hinges, but had heard too many stories about doors popping open using the original latch and striker plate. After showing Wyatt the Altman bear claw latches for the AD trucks, he said that he could make it a lot more pleasing to look at with a custom bear claw latch. Hereís how it ended up-   The stock door handle no longer engaged the lock mechanism so I had to fabricate some linkage to get from the door handle, around the glass channel and into the new bear claw.  I wanted to replace the stock cardboard door cards with aluminum ones with a pattern on them from the bead roller. Wyatt convinced me that I should upholster the panel instead of running bare aluminum, but to get the panel to lay flush to the door, I either had to bump out the panel for the arm rest or shave it off and figure out how to put the angle back in the armrest. I made the arm rest mount flush with the door panel.  I got sidetracked for a while figuring out how to motorize my bead roller so I could make my aluminum door cards by myself. Hereís a foto of it Ė it has a 40 amp 12VDC electric scooter motor with a 8:1 speed reduction through some sprockets that use a #25 chain. A 20 amp LED power supply is modulated with a PWM to vary the rollerís speed with a potentiometer. A junk guitar Cry Baby foot pedal houses the pot that allows me to use both hands to guide the metal through the dies and control the speed with my foot. So far Iíve not used it.  I wanted to move the LS engine as far back as I could in the engine bay, and Wyatt suggested that while he was replacing the floors, we should think about a custom firewall that would let the engine come back another couple of inches. The labor to build a new firewall wasnít all that much more than fixing all holes in the old one and smoothing it out. I wanted a finished firewall with nothing on it so he drilled all spot welds out of the inner panel and made a new one from sheet stock using a bead roller to mimic the old factory panel, but with an indent for a V8 instead of an inline 6. To get to the bolts on the bell housing to allow changing the clutch without pulling the motor and accommodate a modern manual transmission, Wyatt made a removable cover for the inside of the cab Ė one for the trans and the other for the bell housing. My plan is to put the ECU in the cab and Iíll run the wires through the top access cover and mount the ECU under the dash. Borrowed a dummy Vintage Air evap housing/blower to make sure it would still fit after the firewall modification Ė it did.    This is the mockup phase with the engine installed. The engine pushed back like this gives me room to run cheap truck accessories Hereís the nearly finished V8 firewall.  Currently, the cab is nearing completion.The bottom half is in urethane primer and Iím doing the final block-out with 400 grit (adult supervision from Wyatt)  I want a clean engine compartment, free of hoses and electrical wiring to the greatest extent possible. At one time this truck had the battery moved into the engine bay and they hacked the battery tray into the inner fender with welds that looked like petrified bubblegum. They were beyond economical repair, so I bought some reproductions. They looked pretty decent when they came out of the box, but when I started blocking them out, they had a lot of ripples and dents. Wyatt filled all the extra holes with weld and I skinned them with bondo to smooth them out. Here they are waiting for a coat of feather-fill to block them out again for primer. Planning on painting them body color  The truck came without a bed or rear fenders when I bought it. Joe (Mother Trucker) in Tucson had a nice set of rear fenders and I bought them from him. A trial fit of the fenders with the wheels I wanted to use showed the fenders wouldnít accommodate the width of the wheel, so I had to either widen the fenders, narrow the rear end or install tubs. Since I wanted to keep the stock appearance as much as possible, I nixed widening the fenders in favor of mini tubs and narrowing the Jag IRS. I sliced some trailer fenders in half and tigíd on a skirt and Wyatt fabed some L-section on a stretcher/shrinker so the mini-tubs could be spot welded to the new MarK bed sides. Wyatt put a flange on the tubs so they would fit tight to the bed wood for a factory look.  Hereís what the truck looked like at the first mock-up of the body panels after the metal work was done and in Feather-fill  With the bed on the chassis at home-  I jumped the gun a little bit and had Wyatt paint the rear fenders when he had some slack time at his shop. Heís since stopped painting top coats at his shop to focus on just metalwork. Hereís the fenders sitting in my living room at home. The color is a sage green from the latest Fiat 500s, of all things Ė itís the first color that my wife and I could agree on.  Iím shooting for a final fit of the chassis to the cab/fenders/hood at Wyattís shop in the next month. Heís already shut down his paint booth, so Rob at Drew Brothers Customs in Chandler has agreed to do the work. The truck with cab, fenders, hood grill will be trailered to his shop, disassembled, painted, then reassembled and back on the chassis. Iíll put the bed and rear fenders on at home. |

|

|

|

|

|

#7 |

|

Registered User

Join Date: Nov 2013

Location: Show Low, Arizona

Posts: 778

|

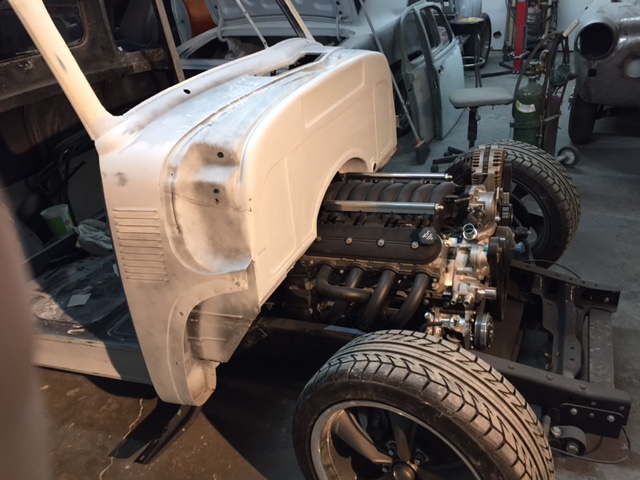

Re: 49 GMC Five Window

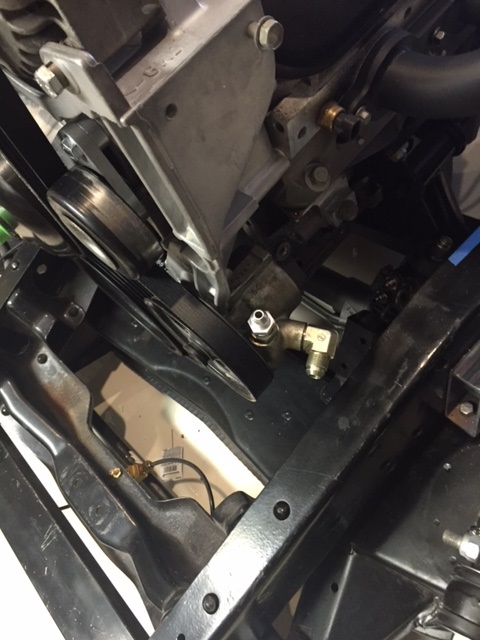

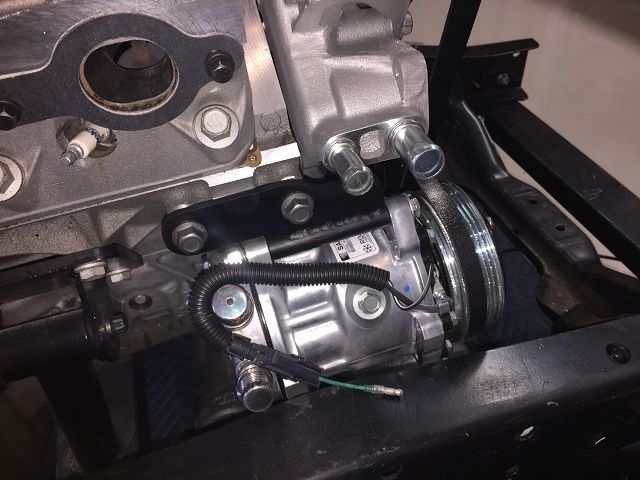

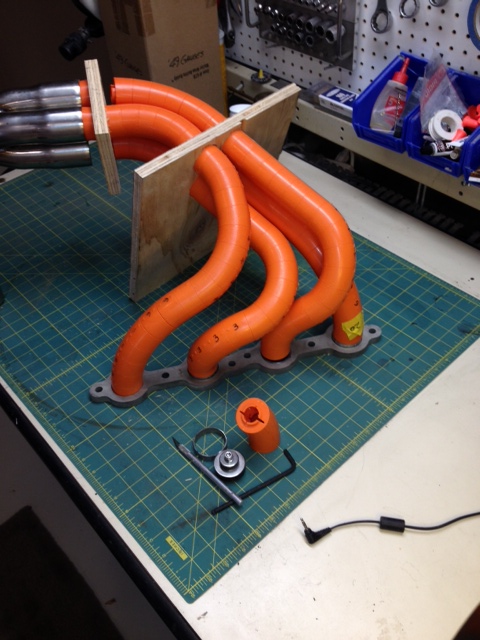

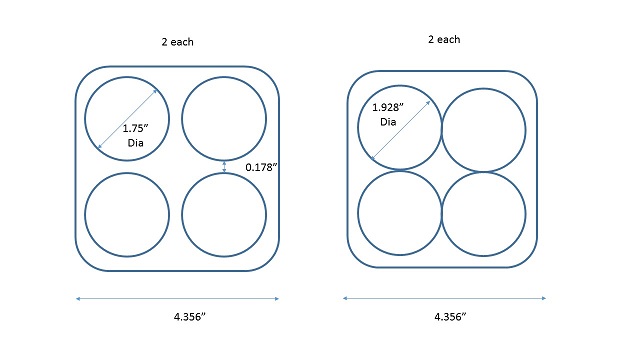

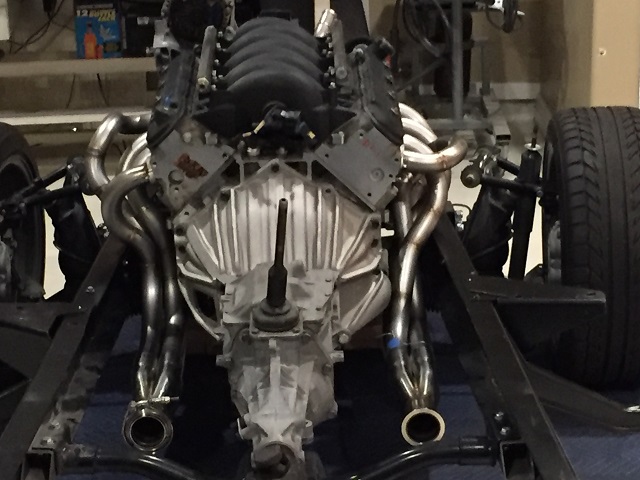

The Engine

Iím not making any new friends over at the HAMB with this decision (and maybe some on this board too) but I really like the LS Chevy motors with fuel injection. Iíve done a couple of other projects where I used LS engines and was comfortable with making the fuel injection work. I shopped Craigslist and the local junkyards for a 5.3 truck motor, and finally found an aluminum 5.3 with 95K miles out of a Trailblazer for $650 at a local junkyard. The truck accessories and a wiring harness and ECU from a drive by cable throttle from a Suburban set me back another $100. I cleaned it up and installed a Corvette intake and shaved the valve covers of the coil mount bosses Ė I plan to remote mount the coil packs to clean up the engine bay Ė still havenít figured out exactly how Iím going to do this.  Without buying an expensive aftermarket accessory drive, I didnít see how anything but the truck accessory layout would work in the í49. All the truck accessories cleared in the mockup stage, but since the truck pulley and accessories protrude more than the f-body or Corvette, I moved the engine further back into the firewall to give more room up from for the accessories and cooling fans. This also gave me a little more room for headers and a low mount ac compressor by taking advantage of the taper in the frame rails. This is the near-final accessory drive Iím using-  The Corvette intake positions the throttle body such that he throttle lever hits the water neck of the truck pump. I tried heating the truckís stainless water neck to see if I could move it in the housing, but gave up when it looked like all I was going to do was crush it. A water pump from a 2009 Trailblazer solved the problem with a different location of the discharge tube. After I put on the Corvette intake with the Suburban throttle body, the belt routing for the accessory drive hit the throttle body. A cheap idler relocation bracket from ebay fixed that problem. (If youíre really paying attention, you might notice the belt routing is incorrect in this photo) I know this sounds ridiculous, but the plastic power steering reservoir mounted on the pump looks entirely too modern for the engine bay. I took it off and put on a AN-8 fitting on the suction side of the power steering pump so I could fit a remote reservoir. For other projects, Iíve made reservoirs out of two round halves of aluminum AC driers welded together, so thatís what Iíll do for this truck too.  I was too cheap to spring for the $175 air conditioner bracket that Alan Grove sells so I fabricated my own. I had to shave two of the ears off the Sanborn compressor to get it to clear the frame rails, but it does clear.  I used the truck belt tensioner on my bracket.  Headers were my biggest challenge. Iíd used Corvette sheet-metal headers on my LS Jag conversion but I couldnít make them clear both the motor mount and the steering rack on the driver side on the truck. I didnít want cast manifolds either. Pacesetter is here in Phoenix and makes long tube headers and shortys for the LS motors and I went there and bought a pair of shorty Camaro headers. They fit, but the collector interfered with the stock pedal arm (wanted the original pedal setup for the nostalgic look) so I took them back. The Pacesetter sales manager offered to let me try a pair of Camaro long tubes Ė they fit too but the collector on the driverís side hit the brake booster bracket on the chassis. Back again, and he gave me some GTO headers to try, but the collector was wrong and wouldnít fit. With any of these solutions, Iíd need to snake the steering shaft around with a lot of u-joints too. Too many compromises. Iíd built headers before for turbo systems, aircraft and sand rails, but nothing with as many constraints as the LS motor in an old GMC truck with narrow frame rails, an archaic pedal setup and a Jaguar rack and pinion, but decided to give it a shot. I started with some stainless flanges, cheap ebay merge collectors and a header Ďlegoí kit from ICEngineworks in Texas. With the engine and the front suspension in the truck for mock-up I tried numerous configurations to get the primary lengths to be all around 28 or so inches and have a single steering shaft to the rack from the column with just two u joints. Hereís one of my first attempts with a design that would have gone through the inner fender well-  And another configuration in legos on the bench-  I got tired of getting up and down from the floor to trial fit header tubes in the truck, so when I got a configuration that was close, I built a wooden fixture on my workbench to do the final fit from the comfort of a chair. Once I got the legos to all fit, I transferred the dimensions onto 304 stainless mandrel bends, cut them on my Portaband mounted in my Swag base and then sanded them on a belt sander to get a perfect fit for welding with the TIG.   I had a hell of a time getting the tubes to fit together for tacking. Mandrel tube isnít perfectly round, and when you mate a straight section to a cut through a curved section, the fit-up of the tubes is always a Ďbest fití compromise. I bit the bullet for these clamps and it helped immensely.  Hereís the finished driverís side headers in the chassis Ė tacked but not welded Ė (the small tube in the middle is where the steering shaft goes)  I was going to run bare stainless headers and simply glass bead them and polish them up with a Scotch-brite, but when the final welds were done, there was an Ďaw ****í moment when I realized Iíd somehow picked up a piece of mild steel mandrel and used that for one of the bends. Rather than ordering another mandrel bend, cutting it out and welding in the correct stainless one, I was so darned tired of screwing with headers I had them ceramic coated black. They still look good and will last forever, but that mistake was a rookie move. I had planned on using slip on collectors, but was too cheap to spring for $600 for a pair of good ones from Burns Stainless. The Chinese ones from ebay looked ok, but where the primary tubes slide inside them was a sloppy fit to the headers and I didnít see how Iíd ever get them to seal up, even with a barrel full of red RTV. A local ATV shop has a plasma table and cut these clover-leafs out of 3/16Ē plate so I could weld the cheap slip-on merge collectors to the header primaries.  Added some O2 sensor bungs and they were done. Hereís a picture of the final headers in the chassis.  The final coated header- driverís side  The transmission is a T5 from a 1980s V8 Camaro with a S10 tail-shaft support to move the shifter to a more forward location for a truck. This transmission is rated a 300 ft-lbs and is probably not the optimum choice for the LS motorís torque and horsepower. But thereís some method in my madness. Iím old and just want to put-put around Ė my clutch side-stepping stoplight launches are far behind me. The clutch, hydraulic TO and bell housing will work with a T56 or a TKO transmission too, so when Iím ready to change it I wonít have to buy those too. If I donít trash the T5, I can sell it to someone that wants if for their six cylinder truck - it has much better ratios than the S10 T5s. The bell housing is a reproduction GM 621 that I got from Kiesler, a Sachs 1050 flywheel for an LS truck and a big block Chevy clutch. The big block clutch on the LS flywheel is a bit of a compromise because the big blockís clutch disk overlaps the LS flywheel area only about 80%. With the torque the 5.3L motor puts out vs the big block, I donít think it will be a problem. The truck came with a small diameter under cab brake booster, but I had some misgivings on how that was going to work with four wheel disc brakes. I harvested a Hydroboost from an Astrovan at a local junkyard and fabíd the linkage to use with the truckís pedal setup. For the master, I used a 1.125Ē diameter Corvette from about 1980. Hereís a pic of the Hydroboost and master cylinder installed in the chassis- you might notice the Hydroboost is installed upside down, but thatís so the accumulator can clear the clutch master cylinder. The guys on Pirate 4x4 say it doesnít make any difference and works equally well either way   Next up - the suspension |

|

|

|

|

|

#8 |

|

Registered User

Join Date: Aug 2012

Location: West Side of the valley, CA

Posts: 878

|

Re: 49 GMC Five Window

Wow.

Nice job! I don't think you'll get any dissenters on this site about the drive train choice. How did your wife ever let you store parts in the living room? Mine would have had a fit! Looking good, keep it up. |

|

|

|

|

|

#9 |

|

Senior Member

Join Date: Mar 2011

Location: West Plains, Missouri

Posts: 7,559

|

Re: 49 GMC Five Window

Nice job on everything, LS engines are the way to go...Jim

__________________

my build thread: http://67-72chevytrucks.com/vboard/s...d.php?t=459839 Jimbo's long bed step build:http://67-72chevytrucks.com/vboard/s...t=464626<br /> |

|

|

|

|

|

#10 |

|

Senior Member

Join Date: Jul 2012

Location: Oblong, Illinois

Posts: 7,028

|

Re: 49 GMC Five Window

That is some really great work e015475! LS swap? Big fans here with three AD Suburban and countless truck builds using them.

Tagging along for the rest. |

|

|

|

|

|

#11 |

|

Post Whore

Join Date: May 2015

Location: Alabama

Posts: 14,670

|

Re: 49 GMC Five Window

Man those headers are slick...

|

|

|

|

|

|

#12 |

|

Registered User

Join Date: Oct 2015

Location: Goldsboro, N.C.

Posts: 63

|

Re: 49 GMC Five Window

Enjoying your build, looking forward to more.

__________________

http://67-72chevytrucks.com/vboard/s...d.php?t=698665 |

|

|

|

|

|

#13 |

|

A320 Pilot/USAF Retired

Join Date: Mar 2009

Location: Charleston, SC

Posts: 2,629

|

Re: 49 GMC Five Window

Great build!

__________________

JJ My 1957 build: http://67-72chevytrucks.com/vboard/s...d.php?t=334552 http://www.trifive.com/forums/showthread.php?t=22037 Instagram - Chuckdriver57 |

|

|

|

|

|

#14 |

|

Man of Mini-Talents

Join Date: Sep 2009

Location: Oklahoma City, OK

Posts: 4,295

|

Re: 49 GMC Five Window

I'm quite familiar with that Fiat color. I was looking at one just the other day thinking it was cool. I can't blame you for the LS choice either. I truly do not understand all the dissing they get, but haters gonna hate.

__________________

Steve Project - Ruth 66 Skylark Project - Lola 60 Biscayne Project - Iron Ox 54 GMC 100 Project - Darth 69 Camaro |

|

|

|

|

|

#15 |

|

Registered User

Join Date: Aug 2012

Location: West Side of the valley, CA

Posts: 878

|

Re: 49 GMC Five Window

aww geez, i forgot my tagline for GMCs. ugh...

Gotta love them  I have someone at work that has that fiat color, even the wheels. It stands out which is why its in my memory. So what do you have planned for the interior? |

|

|

|

|

|

#16 |

|

Registered User

Join Date: Feb 2014

Location: Sunnyvale, CA

Posts: 605

|

Re: 49 GMC Five Window

Wow, looking nice and killer build on the headers.

__________________

1950 3100 5 window |

|

|

|

|

|

#17 |

|

Registered User

Join Date: Nov 2013

Location: Show Low, Arizona

Posts: 778

|

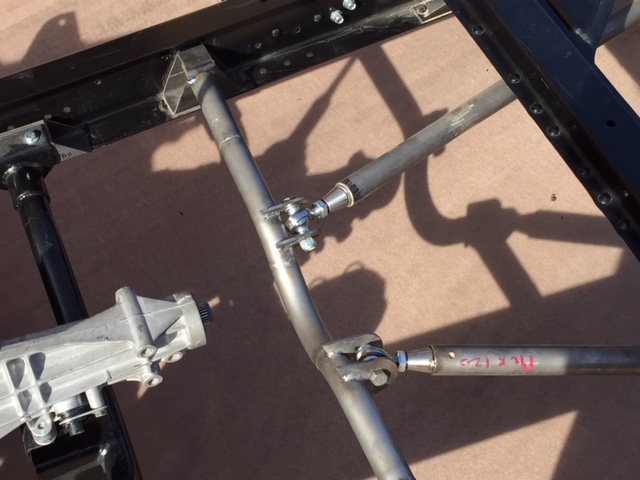

Re: 49 GMC Five Window

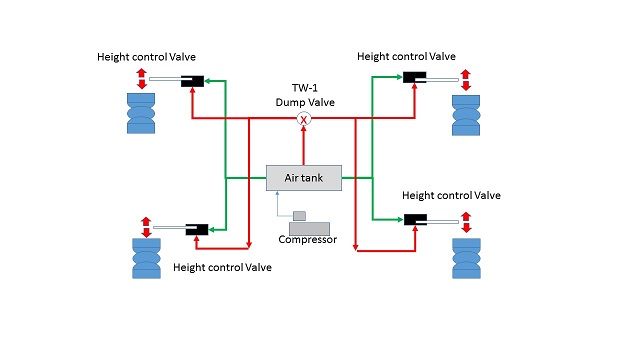

The Suspension

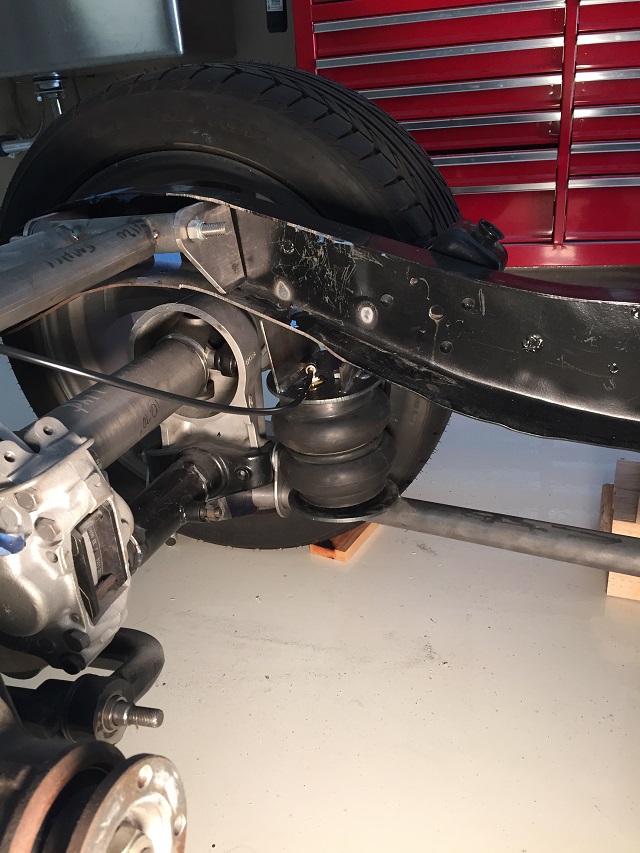

This is where it kinda gets weird and I really start to wander off the AD restorod reservation. I started this project knowing that the C10 front cross-member it came with was going to be too wide a track for a low truck, and the last thing I wanted was something that was going to ride like a truck anyway. So I sold it on Craigslist and wanted to use the Dakota front end that Industrial Chassis sells. But when I called them, they said it wasnít currently in production (but it is now I think). Iíd recently rebuilt the suspension on my old Jag XJS, and when I was researching truck IFS suspensions, the Jag came up a lot, especially in hotrods in Europe, Australia and New Zealand. It was kinda like the M2 is here. The track width was right, uses a Chevy bolt pattern, has big Girling brakes, they were cheap, I knew how to rebuild them, and they had the additional bonus of being very easy to adapt to use airbags. Whatís not to like? Having rationalized my way into the Jag IFS, I began to wonder if the traditional Jag IRS could work too. The track width seemed right (came to regret this later), lots of Cobra kit cars use them with a fair amount of HP, there a quite a few ratios available, most have positraction, can use Dana 44 carrier/ring/pinion, bolt pattern is good, uses standard ujoints, it is a modular bolt-in unit, and finally, thereís the nostalgic/cool factor. There are better IRS setups than the Jag, but as a kid growing up in the 60ís and 70ís, I thought hotrods with the Jag rear suspension were the tits. Rationalization complete. Never mind that I could only find a couple of guys that has succeeded in putting one on airbags and you had to drop out the whole rear end to change the rear brake pads on the inboard brakes. How often do you change rear brake pads anyway? First the front suspension. This is a junkyard Jag IFS  The Jag IFS is mounted on rubber isolators, and since I was looking for as posh a ride as I could get, I decided that Iíd use those isolators on my truck instead of welding the Jag cross member to the frame rails. Hereís the front bracket that the jag isolator bolts to - the isolatorís bolt location in the bracket set the caster of the front end at about 3.5 degrees-  A bracket attached to the truckís frame picks up the Jagís rear rubber isolator  The Ďhatí the centers the spring in the upper pocket of the cross member was removed to provide a flat base for the 6Ē SLAM airbag Ė  The pan that bolts to the lower Jag control arm was modified to accept the SLAM airbag by cutting out the spring Ďhatí and welding in a round plate that would be drilled to the airbagís mount pattern-  Another view without the bag in the way-  The Jag suspension doesnít have its own upper shock mount, so I bought a universal shock tower mount from Suicide Doors and modified it for my truck. It will be welded to the Jag cross member.  Had the steering rack rebuilt at Arizona Rack and Axle, which is very near my work. $150 and a lifetime guarantee. They may come to regret this. Hereís the complete Jag IFS in the truck with the airbags. Takes about 75 psi to bring it to ride height.  I was a little concerned about how close the front tire was to the fender when the truck was sitting low. I noticed that the mounting flange on the staggered Boss wheels Iím using were much thicker on the narrower front wheel than the rear. I wondered if I could pick up a little extra clearance by having the mounting flange machined on the front wheels to match the thickness of the rear wheels. A local custom wheel store told me that they sometimes do this to fine-tune offset for fender clearance on wide wheels. I found a machine shop here that specializes in machining offsets on wheels in a CNC machine. For $150, they welded the holes closed, machined the back face about .500Ē to correct the offset and re-machined the bolt pattern on the CNC. Hereís a shot of the final product- it needs to be repainted, but that was a good deal.  On to the IRS. I wanted to rubber mount the IRS too, but there was no way to use the factory mounts that I liked, so I built a truss that would bolt to the IRS to the frame rails of the truck. To isolate it, I used Jeep spring eye bushings in 1.5Ē diameter tube. The Jag IRS is tilted up 4 degrees and the engine is tilted down 4 degrees for driveshaft balance.  A couple of adjustable rods mounted at the bottom of the diff and connected to the frame will keep engine torque and braking forces from moving the diff and truss too much in the frame as well as keep the diff angle planted to avoid any driveshaft vibration.  Somewhat impulsively, I bought a set of Boss wheels for the truck before I really should have. I have 18Ē wheels about 8Ē wide in the front and 10Ē in the rear. When I mocked up the new bed and fenders to the chassis, I couldnít get a finger between the fender lip and the tire. Not only that, the tires were wider than the fender. The tire width issue was easily solved by mini-tubbing the bed side, but to solve the close tire and fender situation, I would either have to widen the fender or narrow the Jag IRS. I decided to narrow the Jag IRS by shortening the lower control arms and half shafts. The lower control arm was shortened, sleeved and re-welded-  The Jagís half-shafts are a forged solid shaft, and the idea of cutting that apart, sleeving it, and welding it didnít seem likely to be successful. They look like this-  The XKE driveshaft length would have worked, but they are expensive. Since they are a standard u joint, I could buy Spicer yokes and make them like a Corvette half shaft. Hereís the IRS with the shortened lower control arms and new tube half shafts-  The Dana 44 diff I got out of the junkyard with the IRS had a ratio of 2.77. I found a Jag diff from a six cylinder XJS on Craigslist with a 3.54 ratio, so I picked it up. Cool finned cover was a bonus. The rear airbag was a bit of a challenge. I suppose I could have used an integrated shock-airbag, but that would put a moment load on the lower control arm and those shockwaves are expensive. What I did was add a trailing arm kind of like a C10 has that moves in the same plane as the lower control arm, so when I put a bag on the arm, thereís no moment load, just a straight force. It uses a 5Ē slam airbag Ė  This is the tie-in to the Jag lower control arm Ė looking up from the floor (not welded yet either)  The front of the IRS radius arm for the airbag mounts in the same pivot line as the lower control arm-  Hereís the chassis ready to go have the MIG welds done next week Ė this is about normal ride height  With the bags on the bump stops, hereís the ground clearance. Since I narrowed the IRS, the outboard hub carriers rub against the side of the frame rail now. A little clearancing of the aluminum carrier will allow the truck to drop another inch or so. At this point my truck oil pan will be about 2Ē off the pavement.  Iím on the fence about how to control the airbag ride height. Manual valves would be pretty simple, but the idea of having all that tube in the cab isnít appealing. A traditional electrical valve and switch box is a little better but still a little clunky for my taste. I like the idea of the Accuair system, but not the cost. Iím contemplating doing something like this for a set-and-forget type system.  Any feedback from any old coots like me with airbag suspensions would be appreciated. Not into the 'aired out' thing, the truck probably will never haul anything more than lawnchairs and a beer cooler so I just want a really cushy ride |

|

|

|

|

|

#18 |

|

Registered User

Join Date: Nov 2013

Location: Show Low, Arizona

Posts: 778

|

Re: 49 GMC Five Window

A little more progress to report-

The rear shocks came in. I bought KYB gasadjust shocks with about a 5" stroke. I'll mount them at about a 30 degree angle. This whole shock-airbag thing is kind of a crap-shoot. All the airbag sites out there seem to be pimping shocks for airbags, but I can't seem to put my finger on just what is different on a airbag shock versus a regular shock. These are gas charged and were originally designed for a Dodge Durango  My younger brother is a first-class welder and a pretty talented fabricator. I wanted some nice welds for the brackets for the rear suspension (and for him to hide my fit-up sins) so I loaded the chassis on the car trailer and drove to his place in southern Arizona. He backed my trailer and chassis into his shop fired up his Millermatic. Major shop envy here - note the wood stove in the shop that kept the temp at 72F (he lives at 6000' or so - too cold for a Phoenix guy)  His knees still bend and he knows what he's doing with a welder - he's burning in the Jag rear suspension mounts- [IMG]  [/IMG] [/IMG]I modified some upper shock mounts I got from Suicide Doors (think they call themselves Thorbros now) and he burned them in.  I trailered the chassis back to Wyatt's shop in Mesa and unloaded it there. Next step will be putting the cab on the chassis and doing the final prime and fit of the fenders, hood and doors. A bit of a aw-sh*t moment when I unloaded it from the trailer and saw that the header collector just kisses the bottom of the hydroboost unit. Looks like I need to tilt the engine down another half degree to get the headers to clear, and it looks like I'll have to wrap about 4" of the collector and fab a heat shield. |

|

|

|

|

|

#19 |

|

Senior Member

Join Date: May 2007

Location: Doodah Kansas

Posts: 7,774

|

Re: 49 GMC Five Window

there isnt an "airbag shock", just a gas charged shock. if you have really big bags in the back and dont lift it very high you will probably want a monotube high quality shock, because the low pressure big bag will really want to oscillate the shock and a lesser shock will foam. I see you are using 5" slams in direct actuation (not an advantage/lever setup) so those shocks you got will be fine in the sense that they are gas charged.

is 5" stop to stop? that may not be enough, the slam bag lifts about 6 and if you are shooting to lay out you will need a 1/2" on the bottom to allow the truck to lay down without resting on the shock mounts, so that means 4.5" of lift, minus the 30 degrees, so a little under 4" of lift.. and at 4" of lift the shock will be topped out, which will ride like a square wheel. you will probably want a longer shock. If it were mine, which its not, I would get a shock with about 7-8 inches of travel and set ride height in the meat of that travel so there is travel up and down. Lots of airbag guys can get disappointed in the ride when its really just the shock. On my last bagged truck I used 10.5 travel gas charged shocks from a jeep rubicon. rode like a pillow even a half inch off the ground. such amazing fab work, thanks for all the great pictures!

__________________

the mass of men live lives of quiet desperation if there is a problem, I can have it. new project WAYNE http://67-72chevytrucks.com/vboard/s...d.php?t=844393 Last edited by joedoh; 12-22-2016 at 01:58 PM. |

|

|

|

|

|

#20 |

|

Registered User

Join Date: Nov 2013

Location: Show Low, Arizona

Posts: 778

|

Re: 49 GMC Five Window

Great advice - thanks. That's the kind of info I need and the best reason to post a build thread is to tap into the great experience here.

Sized the shock/suspension so that the shock was the droop limit and the airbag was the compressed limit. A Jag OE coilover shock is only about 3" of travel and I have about 5.5" in these shocks. At my normal ride height, about a beer can height off the running board, I should be about in the middle of the shock's travel range. Like you said, I realize if I run the suspension up high it will be at the shock's limit and ride like crap. Will run the ones I've got, but if I have to, I can still build a little tower for the top mount and still clear the bed wood for a longer shock, as you suggest. |

|

|

|

|

|

#21 |

|

Senior Member

Join Date: May 2007

Location: Doodah Kansas

Posts: 7,774

|

Re: 49 GMC Five Window

sounds like you put the right amount of thought into it!

another common mistake is guys think they can drive lower than they actually can, not because it hits things or bottoms out but its just a psychological thing that says "I am too low!", and they start adjusting things up. ground clearance is a state of mind! there is an old ford that shows up at shows here with a 3" ride height, and no adjustment! I think he is from Arkansas, drives it for the shows. your bottomed out height is close to that, it will look very tough and wholly proper, I cant wait to see it

__________________

the mass of men live lives of quiet desperation if there is a problem, I can have it. new project WAYNE http://67-72chevytrucks.com/vboard/s...d.php?t=844393 |

|

|

|

|

|

#22 |

|

Registered User

Join Date: Nov 2013

Location: Show Low, Arizona

Posts: 778

|

Re: 49 GMC Five Window

The cab went on the chassis today. This should be the final time before paint.

Put the driveshaft in. Mounted a running board to show ground clearance.  Iowaboy - still on the fence on what to do with the interior. I had the seat done before we decided on a paint color. I was told I exceeded my authority in the color and style, so I sold them on Craigslist (I wasn't that impressed with the quality either) I'm back to considering using the factory frame and an all foam seat and backrest. For a steering wheel, I picked on up from a 59 Cadillac and planned to paint it the same color as the truck. Here's what I have-  Here's what one looks like when finished (It is in a Cadillac, but you get the idea)  I modified the Cadillac steering column to fit the truck and put a column saver at the bottom. The Cadillac steering wheel was pretty cracked when I got it. I filled all the cracks with epoxy and sanded it down, then put a couple of coats of feather-fill on it- it is still waiting for a final sand. I don't know if I'll ever be able to make it look acceptable. It is another 'science project' and my hands are full trying to get the body to paint. Another science project is the gauges. My transmission doesn't have a mechanical output for the speedometer, so my preference is aftermarket gauges. I had a CAD file made of a new gauge face and then had them laser etched into plastic sign material. I used a Speedhut speedometer and peeled off the gaugeface and needle and installed it in the GM housing.  Here's the tach and the speedometer together-  I backlit them with a LED RGB and a dimmer. Here's the blue one-  For fuel, oil pressure, water temp and voltage, I'd planned on mounting some miniature gauges in the lower part of the dash by putting them in cans drilled into the lower dropdown at the bottom of the dash. I'm really nervous about cutting the dash for the additional gauges, and I'll probably just buy some Dakota Digital's gauges and be done with it. So I'm pretty much all over the map on what to do with the interior. The only thing I'm certain about is that I'm going to paint the interior the body color. |

|

|

|

|

|

#23 |

|

Registered User

Join Date: Nov 2013

Location: Show Low, Arizona

Posts: 778

|

Re: 49 GMC Five Window

A progress update..............

Checking the inner fender clearance to the headers. Needed a little massaging to clear. Everything is dusty in the metal shop - note the paint stick shims on the radiator support.  Details on the passenger side. Looking for about an inch clearance between the header and the inner fender. Dimples in the inner fender are pretty subtle and made to look like an extension of the factory contours.  Little planishing and skim coat of filler needed to finish the inner fender bump-outs. Too cold to spray primer this week - maybe it will warm up this weekend. Will definitely need the rear discharge ports for the Sanborn compressor and to tap the water pump heater lines so I can fit a 90 deg turn downs to clear the inner fender. Fit up of the front fenders. Very happy with the wheel to fender clearance I got with re-machining the wheel face. Wife is saying she wants to see the truck in steel wheels, whitewalls and GMC hub caps........oh well.  Found a painter who's work I really liked. Trick will be getting the truck out of the metal shop in the condition the painter will accept without wanting to reprime it and block it again. I'm shooting for having it so he'll guide coat it one more time and block it with 600 grit without doing anymore prep. That's the plan anyway. Back to the grindstone............ |

|

|

|

|

|

#24 |

|

Formerly- 1972SuperCheyenne

Join Date: Oct 2008

Location: Wake Forest NC

Posts: 5,782

|

Re: 49 GMC Five Window

Looking great man, keep at it!

__________________

--Josh My Build Thread:http://67-72chevytrucks.com/vboard/s...d.php?t=799218 A good crossthread is better than Loctite any day. Life is not about what you have, but who you have to share it with. |

|

|

|

|

|

#25 |

|

Senior Member

Join Date: May 2007

Location: Doodah Kansas

Posts: 7,774

|

Re: 49 GMC Five Window

you are a painters wet dream, but I doubt they will tell you (or price it that way). if all they have to do is show up, block it, tack it, spray it, and clean their gun, those are the jobs they pray to the paint gods for. most of the time the painter has to do at least a little filler work and all the disassembly for taping and still gets blamed for poor results.

looks amazing all together!

__________________

the mass of men live lives of quiet desperation if there is a problem, I can have it. new project WAYNE http://67-72chevytrucks.com/vboard/s...d.php?t=844393 |

|

|

|

|

| Bookmarks |

|

|