|

|

|

#1 |

|

Senior Member

Join Date: May 2004

Location: johnstown, NY

Posts: 2,393

|

What did I screw up??

I was welding on my lower control arm today. Before I started, the crossshaft turned freely. After I finished welding, I froze it up. I can barely turn it with a pair of pipe plyers. I thought maybe it temporarily expanded by the heat, but after it cooled down, I still cant move it. What happened? Should I replace the whole shaft or can I just replace the bushings?

josh |

|

|

|

|

|

#2 |

|

senior member

Join Date: Feb 2003

Location: fort macleod alberta

Posts: 2,770

|

Re: What did I screw up??

is it possible the bushings just got too hot and have melted around the shaft? just a guess?

__________________

69 GMC bagged |

|

|

|

|

|

#3 |

|

Senior Member

Join Date: May 2004

Location: johnstown, NY

Posts: 2,393

|

Re: What did I screw up??

I don't know, maybe. From the outside they look normal.

|

|

|

|

|

|

#4 |

|

senior member

Join Date: Feb 2003

Location: fort macleod alberta

Posts: 2,770

|

Re: What did I screw up??

probly wouldnt hurt to change them anyways

__________________

69 GMC bagged |

|

|

|

|

|

#5 |

|

Registered User

Join Date: Apr 2001

Location: DALLAS,TX

Posts: 22,071

|

Re: What did I screw up??

How much heat did you generate? What/where were you welding?

__________________

67SWB-B.B.RetroRod 64SWB-Recycle 89CCDually-Driver/Tow Truck 99CCSWB Driver All Fleetsides @rattlecankustoms in IG Building a small, high rpm engine with the perfect bore, stroke and rod ratio is very impressive. It's like a highly skilled Morrocan sword fighter with a Damascus Steel Scimitar..... Cubic inches is like Indiana Jones with a cheap pistol. Last edited by SCOTI; 04-18-2007 at 11:29 PM. |

|

|

|

|

|

#6 |

|

Senior Member

Join Date: May 2004

Location: johnstown, NY

Posts: 2,393

|

Re: What did I screw up??

|

|

|

|

|

|

#7 |

|

Registered User

Join Date: Apr 2001

Location: DALLAS,TX

Posts: 22,071

|

Re: What did I screw up??

Sounds like you may have warped the arm vs. what is was before welding. Try putting it in a press if it looks bowed one way or another (might not be able to tell though).

__________________

67SWB-B.B.RetroRod 64SWB-Recycle 89CCDually-Driver/Tow Truck 99CCSWB Driver All Fleetsides @rattlecankustoms in IG Building a small, high rpm engine with the perfect bore, stroke and rod ratio is very impressive. It's like a highly skilled Morrocan sword fighter with a Damascus Steel Scimitar..... Cubic inches is like Indiana Jones with a cheap pistol. |

|

|

|

|

|

#8 | |

|

Senior Member

Join Date: May 2004

Location: johnstown, NY

Posts: 2,393

|

Re: What did I screw up??

Quote:

Think I can fix this? Last edited by jlaird; 04-19-2007 at 11:20 AM. |

|

|

|

|

|

|

#9 |

|

Seņor Member

Join Date: May 2002

Location: Edge of the world

Posts: 5,367

|

Re: What did I screw up??

I vote the latter. The shape of the a-arm stamping sure looks strong. I can see the old, nasty rubber bushings melting on the inside (where they're pressed up against the overheated metal).

__________________

|

|

|

|

|

|

#10 |

|

Senior Member

Join Date: May 2004

Location: johnstown, NY

Posts: 2,393

|

Re: What did I screw up??

I took the cross shafts out and reassembled them. The bushings didn't melt. I think after I cut the spring pocket out, the arm slightly tweaked because I didn't have enough bracing on it. I put the shaft back in and it seems to be ok. One thing I have learned from welding is you can never use enough bracing. On the other control arm, I braced it in three spots around the shaft area. I'll post some pics tomorrow of my masterpiece!

|

|

|

|

|

|

#11 |

|

Seņor Member

Join Date: May 2002

Location: Edge of the world

Posts: 5,367

|

Re: What did I screw up??

__________________

|

|

|

|

|

|

#12 | |

|

Registered User

Join Date: Apr 2001

Location: DALLAS,TX

Posts: 22,071

|

Re: What did I screw up??

Quote:

Try to only weld 1" @ a time & allow the material time to completely cool if you can't brace what needs welding.

__________________

67SWB-B.B.RetroRod 64SWB-Recycle 89CCDually-Driver/Tow Truck 99CCSWB Driver All Fleetsides @rattlecankustoms in IG Building a small, high rpm engine with the perfect bore, stroke and rod ratio is very impressive. It's like a highly skilled Morrocan sword fighter with a Damascus Steel Scimitar..... Cubic inches is like Indiana Jones with a cheap pistol. |

|

|

|

|

|

|

#13 | |

|

Seņor Member

Join Date: May 2002

Location: Edge of the world

Posts: 5,367

|

Re: What did I screw up??

Quote:

__________________

|

|

|

|

|

|

|

#14 | |

|

Registered User

Join Date: Aug 2006

Location: Florida

Posts: 1,684

|

Re: What did I screw up??

Quote:

lol

__________________

1986 C10 SWB 6.0/6l90e Miami...Flee it like a native |

|

|

|

|

|

|

#15 |

|

Registered User

Join Date: Apr 2001

Location: DALLAS,TX

Posts: 22,071

|

Re: What did I screw up??

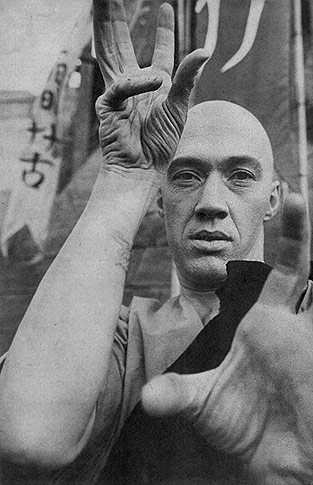

Young grasshopper. . ..... If you can take the ......

__________________

67SWB-B.B.RetroRod 64SWB-Recycle 89CCDually-Driver/Tow Truck 99CCSWB Driver All Fleetsides @rattlecankustoms in IG Building a small, high rpm engine with the perfect bore, stroke and rod ratio is very impressive. It's like a highly skilled Morrocan sword fighter with a Damascus Steel Scimitar..... Cubic inches is like Indiana Jones with a cheap pistol. |

|

|

|

|

| Bookmarks |

|

|