|

Register or Log In To remove these advertisements. |

|

|

|

|||||||

|

|

|

Thread Tools | Display Modes |

|

|

#1 |

|

Senior Member

Join Date: Nov 2008

Location: Glendora, CA

Posts: 6,344

|

I'm A Welder Now! Not Really, But Trying.

I finally stopped procrastinating and tried my hand at MIG welding - practice that is.

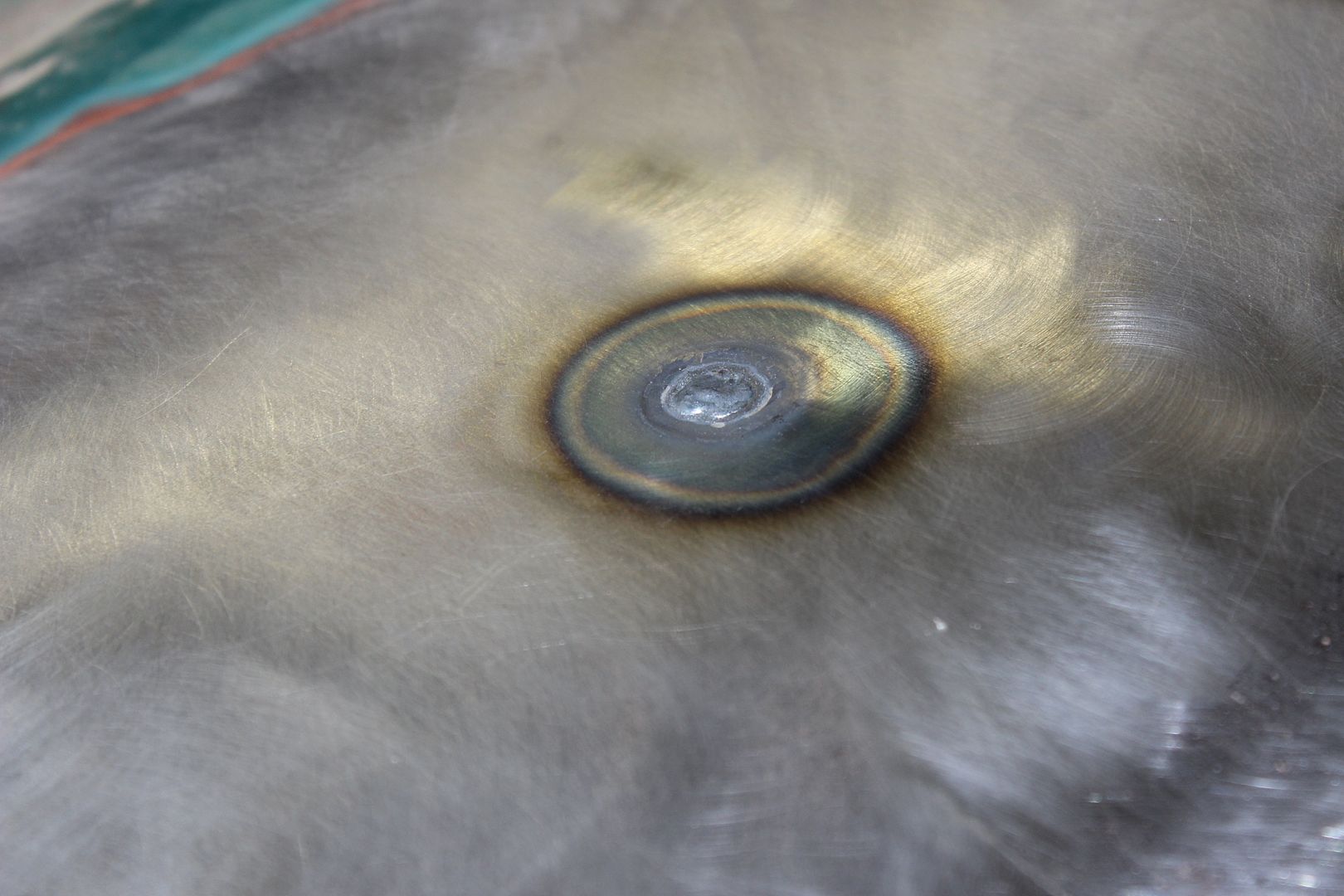

I've got a Hobart Handler 140 with .023" wire and ArC02 gas set at 20psi. I set the wire speed by varying the speed dial while running continuously on the spare door I show below until I got the continuous "bacon frying" sounds everyone talks about. I got this door to repair FOUR giant speaker holes the PO cut in my truck's doors and for metal for various rust repairs.  - As you can see, there were three 1/8" holes near the factory mirror holes, and a larger hole for mounting the door handle. I decided to practice by closing them off. Close-ups here after I flap disked the rust off:   Feel free to criticize, I can take it....I think

|

|

|

|

|

|

#2 |

|

Senior Member

Join Date: Nov 2008

Location: Glendora, CA

Posts: 6,344

|

Re: I'm A Welder Now! Not Really, But Trying.

|

|

|

|

|

|

#3 |

|

Registered User

Join Date: Jul 2011

Location: Auburn ca.

Posts: 2,886

|

Re: I'm A Welder Now! Not Really, But Trying.

Looking good Dan. Sheet metal takes a bit of getting used to.

|

|

|

|

|

|

#4 |

|

MOVE OVER

Join Date: Jun 2002

Location: Warrensburg, MO

Posts: 5,470

|

Re: I'm A Welder Now! Not Really, But Trying.

I need to do this,, one thing I am lacking, among other things.. LOL is welding skills

__________________

No matter where you are..... There you are... Buckaroo Banzi |

|

|

|

|

|

#5 |

|

Senior Member

Join Date: Nov 2008

Location: Glendora, CA

Posts: 6,344

|

Re: I'm A Welder Now! Not Really, But Trying.

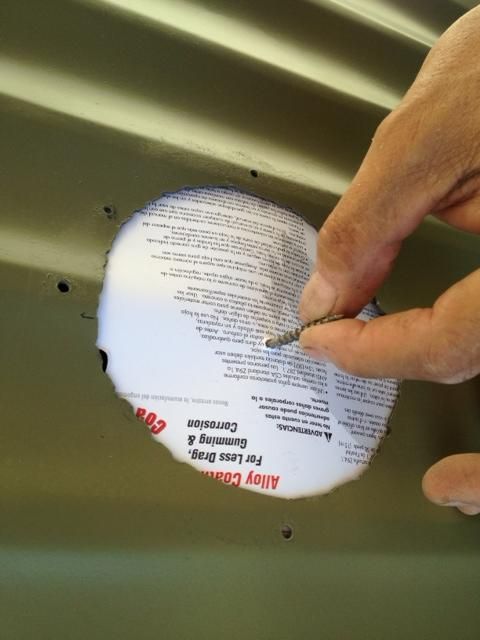

Of course I couldn't leave it at this and immediately started thinking about those speaker holes in my doors. I cut a blank big enough for two repairs:

Made a pattern from lightweight cardboard using a screw to hold it against the door's interior and traced with a Sharpie, then cut it out and started grinding for a "perfect" fit - yeah, well that didn't happen....but I already "know" how to fill small holes, right?!    Yes, I know to spot weld and jump around to keep from warping. |

|

|

|

|

|

#6 |

|

Registered User

Join Date: Nov 2011

Location: Lebanon, TN

Posts: 311

|

Re: I'm A Welder Now! Not Really, But Trying.

X2

Hey rambler I've started a club for us non welders. We have meetings and everything. lol.

__________________

J'aimi 54 Chevy 3100 5.3/4L60E (Plan to make summer daily driver) 54 Chevy 3600 "Destiny" future project (Plan to build for my daughter) 72 C10 current daily driver 74 Nova Son's DD (His 1st car, we had to start him off right) 00 F*rd Expedition wife's DD (She's the trader in the house and doesn't drive a GM  ) )

|

|

|

|

|

|

#7 |

|

Square

Join Date: Feb 2011

Location: Phoenix Arizona

Posts: 1,568

|

Re: I'm A Welder Now! Not Really, But Trying.

good job dan!!

__________________

Squarebody Syndicate |

|

|

|

|

|

#8 |

|

Senior Member

Join Date: Nov 2008

Location: Glendora, CA

Posts: 6,344

|

Re: I'm A Welder Now! Not Really, But Trying.

Ok, that's it for today. I'm gonna cut and fit all four patches first so when I begin spot welding I can jump from door to door and keep the heat down. I'll probably still need a small amount (I hope) of filler.

I DID have a couple holes "blow out" while practicing on the old door. I THINK it may have happened because the metal was thin on the backside due to existing rust(?). I still need to practice more, obviously but at some point I know I'm going to get impatient and just jump in. All advice appreciated. - Dan |

|

|

|

|

|

#9 |

|

Registered User

Join Date: Jul 2011

Location: Las Vegas - Nev. aka Sin City

Posts: 1,835

|

Re: I'm A Welder Now! Not Really, But Trying.

good job!!!!!

|

|

|

|

|

|

#10 |

|

Senior Member

Join Date: Nov 2008

Location: Glendora, CA

Posts: 6,344

|

Re: I'm A Welder Now! Not Really, But Trying.

Thanks. I'm sure it's not too interesting to a lot of guys here - they've demonstrated killer fab abilities - which of course is what got me thinking, "I can do that". Hundreds of dollars later (ha ha) I have the basics to do my rust repair and I'm even going to try my hand at closing off my bed tube ends, and possibly the stake holes.

|

|

|

|

|

|

#11 |

|

MOVE OVER

Join Date: Jun 2002

Location: Warrensburg, MO

Posts: 5,470

|

Re: I'm A Welder Now! Not Really, But Trying.

LOL let me know when the next meeting is !

__________________

No matter where you are..... There you are... Buckaroo Banzi |

|

|

|

|

|

#12 |

|

Senior Member

Join Date: Jul 2009

Location: Tomball, Texas

Posts: 1,592

|

Re: I'm A Welder Now! Not Really, But Trying.

Hey Dan - I've only got a bit of a head-start on you, but I've learned you have to take it pretty easy grinding/flap disking the welds before you go back and start filling gaps between previous welds. Take too much and you thin the metal and burn holes bigger than you are welding up!

__________________

Rick 78 GMC K15 SWB, 350/NV4500/NP205/4.10s Project Hazel 71 GMC C25 350/TH400 - Project Angie 59 Chevy SWB Stepside (next in line? Not sure now  ) )2001 GMC Sierra K2500 |

|

|

|

|

|

#13 |

|

Senior Member

Join Date: Nov 2008

Location: Glendora, CA

Posts: 6,344

|

Re: I'm A Welder Now! Not Really, But Trying.

Thanks.

Yeah I immediately wanted to flap disk the weld down flush with the surrounding metal. But obviously if I do that more than once I am thinning the metal out - not a good thing. On the larger hole I built up too much weld and then ground it down all at once. Too much heat. |

|

|

|

|

|

#14 |

|

Registered User

Join Date: Aug 2007

Location: Corona, California

Posts: 7,998

|

Re: I'm A Welder Now! Not Really, But Trying.

Looking good.

We all have to start some where. You'll get the hang of it in no time. Kim |

|

|

|

|

|

#15 |

|

Registered User

Join Date: Apr 2010

Location: Morristown TN.

Posts: 355

|

Re: I'm A Welder Now! Not Really, But Trying.

Looks good...

|

|

|

|

|

|

#16 |

|

Senior Member

Join Date: May 2011

Location: Cypress, Tx.

Posts: 1,504

|

Re: I'm A Welder Now! Not Really, But Trying.

Way to go Dan! Looking good!

__________________

'72 Ford Bronco project(July 17 2021-?) https://67-72chevytrucks.com/vboard/...d.php?t=828015 59 Apache (sold 6-25-2021) 67 Ford Mustang (re-restored after Harvey) 1968 Jeep Cj5 (2-8-2020 to present) 1992 Jeep Yj (8-17-20 to present) (Jurassic build) www.Classiccarsandtools.com |

|

|

|

|

|

#17 |

|

Registered User

Join Date: Jul 2011

Location: Auburn ca.

Posts: 2,886

|

Re: I'm A Welder Now! Not Really, But Trying.

Quote:

|

|

|

|

|

|

#18 |

|

Senior Member

Join Date: Nov 2008

Location: Glendora, CA

Posts: 6,344

|

Re: I'm A Welder Now! Not Really, But Trying.

Good point, although I don't know how I could do that? My 4" grinding disc wouldn't fit in there very well...hmm...I'll have to think about how to do that.

Posted via Mobile Device |

|

|

|

|

|

#19 |

|

Registered User

Join Date: Jul 2007

Location: Toppenish, WA

Posts: 15,718

|

Re: I'm A Welder Now! Not Really, But Trying.

It looks like you have a pretty good fit on the filler piece. The welds don't look bad for mig welds on sheet metal either.

I watched Gene Winfield do this with a torch Sunday at a class he put on.   Then he leaded the panel  And spread the lead around  And then let us try our hand at spreading it around. Here's Chris from the HAMB giving it a go.

__________________

Founding member of the too many projects, too little time and money club. My ongoing truck projects: 48 Chev 3100 that will run a 292 Six. 71 GMC 2500 that is getting a Cad 500 transplant. 77 C 30 dualie, 454, 4 speed with a 10 foot flatbed and hoist. It does the heavy work and hauls the projects around. |

|

|

|

|

|

#20 |

|

Senior Member

Join Date: Nov 2008

Location: Glendora, CA

Posts: 6,344

|

Re: I'm A Welder Now! Not Really, But Trying.

NIICE.

Posted via Mobile Device |

|

|

|

|

|

#21 |

|

Registered User

Join Date: Jul 2011

Location: Auburn ca.

Posts: 2,886

|

Re: I'm A Welder Now! Not Really, But Trying.

[QUOTE=Dan in Pasadena;6045297]Good point, although I don't know how I could do that? My 4" grinding disc wouldn't fit in there very well...hmm...I'll have to think about how to do that.

Posted via Mobile Device[/QUOTE Our local tool store sells drum sander arbors like this. I have 2" and 3/4" diameters. http://www.highlandwoodworking.com/r...2diameter.aspx I use them quite a bit. sometimes I chuck them in the drill press and hold the part by hand. I use them in a 3/8 drill motor most of the time though. Last edited by mknittle; 05-01-2013 at 07:17 PM. |

|

|

|

|

|

#22 |

|

Senior Member

Join Date: Nov 2008

Location: Glendora, CA

Posts: 6,344

|

Re: I'm A Welder Now! Not Really, But Trying.

I thought about something like that but on my Dremel. Bigger ones would obviously be much better, much faster. BUT, can you easily get replacement sanding drums made for sanding metal?

By the way, IF I can smooth those holes out, I'll recut my patches. I need these repairs to go as smoothly as possible since I'm a true rookie. |

|

|

|

|

|

#23 |

|

Registered User

Join Date: Jul 2007

Location: Toppenish, WA

Posts: 15,718

|

Re: I'm A Welder Now! Not Really, But Trying.

I was thinking rotary file or just a half round file. It looks like you already have the fit pretty good though.

__________________

Founding member of the too many projects, too little time and money club. My ongoing truck projects: 48 Chev 3100 that will run a 292 Six. 71 GMC 2500 that is getting a Cad 500 transplant. 77 C 30 dualie, 454, 4 speed with a 10 foot flatbed and hoist. It does the heavy work and hauls the projects around. |

|

|

|

|

|

#24 |

|

Senior Member

Join Date: Nov 2008

Location: Glendora, CA

Posts: 6,344

|

Re: I'm A Welder Now! Not Really, But Trying.

Eh... if I use them they'd require more work to fit closer. But I'm leaning toward trying to sand the holes smoother. The PO drilled small holes around the perimeter then used SOMETHING; no idea what, to connect them do they're kinda "notchy" in person |

|

|

|

|

|

#25 |

|

Registered User

Join Date: Jul 2007

Location: Toppenish, WA

Posts: 15,718

|

Re: I'm A Welder Now! Not Really, But Trying.

Real "old Skool" tech there. That was common back in the day when guys didn't have power tools that they could cut a decent hole with and used a drill to make a ring of small holes that they cut the webs between them with a hack saw blade or tin snips.

__________________

Founding member of the too many projects, too little time and money club. My ongoing truck projects: 48 Chev 3100 that will run a 292 Six. 71 GMC 2500 that is getting a Cad 500 transplant. 77 C 30 dualie, 454, 4 speed with a 10 foot flatbed and hoist. It does the heavy work and hauls the projects around. |

|

|

|

|

| Bookmarks |

|

|