|

Register or Log In To remove these advertisements. |

|

|

|

|||||||

|

|

|

Thread Tools | Display Modes |

|

|

#1 |

|

Registered User

Join Date: Sep 2013

Location: Evansville, IN

Posts: 1,774

|

Air Compressor setup in my garage help

I purchased a 60-gallon air compressor a couple of years ago from a buddy. I'm finally getting around to actually plumbing up my entire garage with drops. I did my research and decided to use the RapidAir Maxline kit. I read a lot of good reviews and so far its pretty easy to assemble.

Given my garage is a 32'x40' and I wanted a minimum of 5 drops, I ended up going with a loop type system around the perimeter of the garage. I'm running 3/4" piping all the way around including my drops. Each drop has a threaded 1/2" outlet and a drain. My drops are going to be: at my workbench near my vise, at my workbench near my small HF sandblast cabinet, one on the side wall for my truck workspace, one on the side wall primary for painting and handheld sandblaster, and one between the two overhead doors on a hose real for outside stuff/tire filling/etc. This is just for a one-man hobby-type configuration. Here's where I need help: If I come off the compressor with a flexible hose to a nice 3/4" regulator/filter combo then to a "T" for my loop and then a 3/8" filter for my drop for painting, would that be a decent setup? Would I need a dedicated filter for my sandblast cabinet? It is located almost caddy-corner from the compressor. What size fittings does everyone use? I see 1/4", 3/8", and 1/2" but 1/4" appears to be more common. Do I need dedicated drops for each size? The local air tool supplier recommended this stating I'd need more volume for 1/2" impacts and such. I'm thinking 3/8" for hose reel (it had a 3/8" male input), 3/8" or 1/2" for my truck workspace drop, 1/4" for vice area?, and whatever I'd need for sandblast cabinet. I'm also considering a retractable hose reel on the ceiling if need be.

__________________

Ryan 1967 Red Stepside..."Laymond" http://67-72chevytrucks.com/vboard/s...40#post6441840 1972 Medium Olive SWB-Chester http://67-72chevytrucks.com/vboard/s...d.php?t=759628 1967/71 Blue SWB C10..SOLD 1977 SWB K10..my grandpa's.....never should have sold |

|

|

|

|

|

#2 |

|

Registered User

Join Date: Jun 2013

Location: Somewhere

Posts: 3,066

|

Re: Air Compressor setup in my garage help

With plastic pipe you're gonna wind up w/ hot, wet air. What are the plans to cool it and remove water?

What diameter tube will you use? That determines initial fitting size, and you can always reduce from there. Hmm, their website says the ID of the RapidAir tube is .375". http://www.rapidairproducts.com/flowrate.asp which seems off since pipe is usually measured by ID. |

|

|

|

|

|

#3 |

|

Registered User

Join Date: Sep 2013

Location: Evansville, IN

Posts: 1,774

|

Re: Air Compressor setup in my garage help

I have the 3/4" Maxline kit. The piping is the 3/4 Duratec/Maxline with a ID of .80.

I'm not planning on running any type of cooler at this time. Want to get it up and running and go from there. I can always add one if I need it. This is primarily for a weekend/hobby type of setup. I stated in my OP that I'm currently planning on running a 3/4" regulator/filter at the tank and then a 3/8" filter at my painting drop. Each outlet block also has a drain. The Outlets have a 1/2" threaded output. I can setup that down to whatever size I need.

__________________

Ryan 1967 Red Stepside..."Laymond" http://67-72chevytrucks.com/vboard/s...40#post6441840 1972 Medium Olive SWB-Chester http://67-72chevytrucks.com/vboard/s...d.php?t=759628 1967/71 Blue SWB C10..SOLD 1977 SWB K10..my grandpa's.....never should have sold |

|

|

|

|

|

#4 | |

|

Registered User

Join Date: Aug 2009

Location: S.C.

Posts: 1,593

|

Re: Air Compressor setup in my garage help

Quote:

Most of what I use for line size is 3/8" hose and 1/4" fittings, seems to be the most common for replacement parts, extra hose... I also have a 1/4" line at work that gets used as a "whip", very flexible and easy to move around. That line will slow down my 1/2" gun, just pull the 3/8" line out and all is good. Blast cabinet, don't know about a filter, but I would suggest some sort of water separator. I don't have a dedicated system, hopefully someone with more experience can chime in.

__________________

'86 C-30 dually, 454/tbh400 '73 K-20 350/350/205 (sold  ) )I'm kinda like duct tape- no real purpose, but handy to have around. |

|

|

|

|

|

|

#5 |

|

Senior Member

Join Date: Jan 2011

Location: Hayes Va

Posts: 4,569

|

Re: Air Compressor setup in my garage help

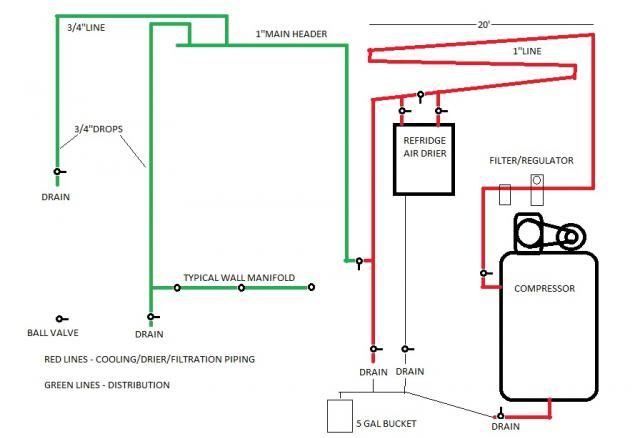

For a painting drop get a far away from the compressor as you can. You can build a stand pipe system to help get rid of the water. Couple of ways to do it and here is a picture of one of them.

Jimmy

__________________

60 to 66 Chevy and GMC window decals http://67-72chevytrucks.com/vboard/s...d.php?t=661131 Good friends, good food and a hotrod what else do you need? 1966 BBW long fleet Daily driver 1965 BBW short fleet Sold and going to a good home 1965 Suburban 2003 3500 Duramax 2005 Ultra Classic |

|

|

|

|

|

#6 |

|

Registered User

Join Date: Jul 2009

Location: San Jose Ca

Posts: 2,871

|

Re: Air Compressor setup in my garage help

^^^that is the way I am going to do mine when I get a better compressor set up

__________________

David Used parts build: http://67-72chevytrucks.com/vboard/s...d.php?t=638991 My brother's Nova: http://www.67-72chevytrucks.com/vboa...d.php?t=727985 Rear suspension rework: http://www.67-72chevytrucks.com/vboa...d.php?t=750557 Instagram: myfabguy |

|

|

|

|

|

#7 |

|

Registered User

Join Date: Jun 2013

Location: Somewhere

Posts: 3,066

|

Re: Air Compressor setup in my garage help

To me it makes no sense to force water to settle in (in this drawing) 4 places, which forces me to drain those 3 places, plus the tanks anytime the compressor is used.

|

|

|

|

|

|

#8 |

|

Registered User

Join Date: Sep 2013

Location: Evansville, IN

Posts: 1,774

|

Re: Air Compressor setup in my garage help

I'm back out in the garage tonight back on this. Looking at the wall behind my air compressor and doing something like the drawing looks very possible and not a big deal to do. Raises a couple new questions

I assume black pipe will work well for this? 3-4' high be sufficient? Then should I go from the pipe to my 3/4" filter/regulator then to my "t" to my loop? I believe the filter has a drain fwiw. Filters then be necessary for my sandblast cabinet and paint drop?

__________________

Ryan 1967 Red Stepside..."Laymond" http://67-72chevytrucks.com/vboard/s...40#post6441840 1972 Medium Olive SWB-Chester http://67-72chevytrucks.com/vboard/s...d.php?t=759628 1967/71 Blue SWB C10..SOLD 1977 SWB K10..my grandpa's.....never should have sold |

|

|

|

|

|

#9 | |

|

Registered User

Join Date: Jul 2009

Location: San Jose Ca

Posts: 2,871

|

Re: Air Compressor setup in my garage help

Quote:

__________________

David Used parts build: http://67-72chevytrucks.com/vboard/s...d.php?t=638991 My brother's Nova: http://www.67-72chevytrucks.com/vboa...d.php?t=727985 Rear suspension rework: http://www.67-72chevytrucks.com/vboa...d.php?t=750557 Instagram: myfabguy |

|

|

|

|

|

|

#10 |

|

Senior Member

Join Date: Jan 2011

Location: Hayes Va

Posts: 4,569

|

Re: Air Compressor setup in my garage help

Filters never hurt. Also if you google home made air driers you will find a system that uses a condenser coil after the pump and before the tank to cool the air and seperate out the water into a small tank. This also works good. A combination of both could give you very dry air.

Jimmy

__________________

60 to 66 Chevy and GMC window decals http://67-72chevytrucks.com/vboard/s...d.php?t=661131 Good friends, good food and a hotrod what else do you need? 1966 BBW long fleet Daily driver 1965 BBW short fleet Sold and going to a good home 1965 Suburban 2003 3500 Duramax 2005 Ultra Classic |

|

|

|

|

|

#11 |

|

Registered User

Join Date: Oct 2012

Location: Cache, OK

Posts: 458

|

Re: Air Compressor setup in my garage help

I did the pipe run on mine. Black pipe is fine from what I can tell. Some of the experts say to only use copper, but I had never worked with copper before. Don't use galvanized or PVC. I would go with 3/4". I used 1/2" because I got it cheap from Lowe's since it was installed and returned and marked down. I don't have a current pic here at work, but at the end of the drop there I have a T fitting with 1 drop on the end for use with my air tools. The other T feeds into a Motorgard filter (toilet paper like filter) and a Devilbiss QC3 desiccant dryer/regulator just for my paint gun. That way I don't use up all my filtering media to run an air ratchet or impact, etc. I do not use the filter when I run my blasting cabinet. I also mounted a hose reel above there. It is handy so I would recommend it.

__________________

1969 Chevy C10 SWB Fleet - Build thread > http://67-72chevytrucks.com/vboard/s...d.php?t=593554 2008 GMC Sierra Denali - 6.2L AWD - my daily 2011 Ford Flex Limited - Ecoboost AWD - wife's daily 1987 Buick Regal Turbo T - 63K miles - Strip/Street car 1965 Ford Mustang Coupe - 289, c4, 53K miles |

|

|

|

|

|

#12 |

|

Registered User

Join Date: Apr 2012

Location: san diego ca

Posts: 618

|

Re: Air Compressor setup in my garage help

Ive done them in black pipe and copper. Galvanized pipe flakes. Copper is faster to install. I believe you need the thicker walll pipe on copper (type L). We always loop our air line supply n return then branch out from there. I like a regulator and water seperator at point of use.

|

|

|

|

|

|

#13 |

|

Registered User

Join Date: Jan 2012

Location: Motown

Posts: 7,677

|

Re: Air Compressor setup in my garage help

if you turn this air cooler 90* and hook the compressor to the top you can get away with using one drain at the bottom

copper will cool better than black pipe and go together quicker, but black pipe will cool well too unless your doing a commercial shop, 3/4 anything is big enough, my shop is all 1/2'' copper the drops should come out of the top of the header. ''T'' up and 2 90*s to turn down a ''T'' down will allow dirt and moisture to run down your drops here is how i ran our commercial shop; 3 lifts, paint booth, cnc plasma table and 6 guys using air tools 1'' black pipe for the main header, 3/4'' copper for the drops the cooling loop is 30 ft of 1'' black pipe anchored directly to a block wall, we also run a air dryer

__________________

cool, an ogre smiley  Ogre's 58 Truk build Ogre's 58 Truk buildhow to put your truck year and build thread into your signature shop air compressor timer |

|

|

|

|

|

#14 |

|

Registered User

Join Date: Jul 2012

Location: Moseley, VA

Posts: 164

|

Re: Air Compressor setup in my garage help

if you go on tptools.com you can find some useful info (or get the catalog, better info). Check out the pic at

http://www.tptools.com/Modular-Metal....html?b=d*8092 This is how I set up my system. Vertical up from compressor to main line and then drops go vertical up and 180 down.

__________________

1967 C10 SWB Fleetside Duramax/Allison 1966 Chevelle Malibu, EFI BBC, pro touring starter kit |

|

|

|

|

|

#15 |

|

Senior Member

Join Date: Jan 2011

Location: Hayes Va

Posts: 4,569

|

Re: Air Compressor setup in my garage help

Take a look at the pic I posted and the location of the drains. It is important to do them that way and not in the bottom of the run like yous is done. This allows the water to settle out at the bottom of the drop and not in the flow path of the air.

Jimmy

__________________

60 to 66 Chevy and GMC window decals http://67-72chevytrucks.com/vboard/s...d.php?t=661131 Good friends, good food and a hotrod what else do you need? 1966 BBW long fleet Daily driver 1965 BBW short fleet Sold and going to a good home 1965 Suburban 2003 3500 Duramax 2005 Ultra Classic |

|

|

|

|

|

#16 |

|

Registered User

Join Date: Sep 2013

Location: Evansville, IN

Posts: 1,774

|

Re: Air Compressor setup in my garage help

Well this project has spiraled out of control, much like anything else I do. I'm going on a full month and still not done. However I'm real close now. All the drops are done so all I need is to connect to the compressor. If I would have gone with a simple 30-gallon portable setup, I could've almost ordered my dropmember with what I've got in this setup. Should be nice when completed though.

Again, it's the Maxline 3/4" setup configured in a full loop. I have (5) drops with (1) designated for painting, sand blast cabinet, a 30' hose real between the overhead doors, a drop by my vise and another at my work station on the other side of the garage. All drops have a drain before going to the hose. Paint drop has another 1/2" filter. I went to Lowe's today and picked up some black pipe and supplies. Figures I lay it out in the aisle, get home and I already want to change some things. For starters I have to shorten it up 10" in width. Not a big deal. I also want to exchange the last 5' pipe with a 4' to get the regulator up close to eye level. This whole setup is 3/4". I'm planning using a 90 off the regulator/filter and up to my loop. Does anybody see any huge mistakes or simple changes? I've just got it mocked up for right now so alterations should be easy.

__________________

Ryan 1967 Red Stepside..."Laymond" http://67-72chevytrucks.com/vboard/s...40#post6441840 1972 Medium Olive SWB-Chester http://67-72chevytrucks.com/vboard/s...d.php?t=759628 1967/71 Blue SWB C10..SOLD 1977 SWB K10..my grandpa's.....never should have sold |

|

|

|

|

|

#17 |

|

Registered User

Join Date: Jun 2013

Location: Somewhere

Posts: 3,066

|

Re: Air Compressor setup in my garage help

Clean your threads good, or they'll tend to leak.

You'll need to open those 3 valves after every use, or water will collect and when you drain nasty black water will come out. If under pressure it'll spray out and get on the wall. I'd get rid of the valves and mount it on the wall perpendicular to how it's in the the pic and angle the pipe a bit so water has to drain to the tank, or out the filter, where there should be a water separator. You may want to put a valve before the regulator. I also used a union after the valve so I can remove the various filters and regulator. |

|

|

|

|

|

#18 |

|

Registered User

Join Date: Jan 2012

Location: Motown

Posts: 7,677

|

Re: Air Compressor setup in my garage help

check all threaded joints under pressure with soapy water, leaks can make your compressor run more often

your up pipe from the compressor will always be full of water unless you gravity drain to the tank if your shop has block or concrete walls, bolt it directly to the wall for a heat sink i agree with franken rotate it 90* and plumb the lowest drain into a bucket with a lid or through the wall buying all those fittings and valves in black pipe got pretty expensive as mentioned above you can make a better cooler from copper with one drain valve copper will dissipate heat better and goes together a lot quicker with fewer chances of leaking i ran my whole piping system in copper, my compressor never gets turned off except in the winter this is from another thread

__________________

cool, an ogre smiley  Ogre's 58 Truk build Ogre's 58 Truk buildhow to put your truck year and build thread into your signature shop air compressor timer |

|

|

|

|

|

#19 |

|

Registered User

Join Date: Sep 2013

Location: Evansville, IN

Posts: 1,774

|

Re: Air Compressor setup in my garage help

Thanks for all the advice. As if I didn't need more options

I hadn't thought about draining the water under pressure. I started adding valves before each drop so I can shut them off when not in use and not to make a huge mess. I'm pretty accident prone. If I keep the above setup I will be adding another valve before or after the regulator for draining purposes. I've never dealt with copper before so I didn't consider that as an option. I'm all for rotating everything 90 degrees but the layout with the regulator and accessibility concerns me. The compressor is mounted in the corner of my garage between the overhead door and man door. My electrical panel, light switch, and (2) outlets are on one wall and the other is only 56" wide. If I go vertical the location of the regulator and drains are easy to get to. Horizontal I'm afraid the regulator would either be 6-7' in the air or behind the compressor. I'm mounting this to 1/2" OSB on a insulated wood-studded wall. I'm still thinking. Need to finish so I can finally start tearing the truck apart

__________________

Ryan 1967 Red Stepside..."Laymond" http://67-72chevytrucks.com/vboard/s...40#post6441840 1972 Medium Olive SWB-Chester http://67-72chevytrucks.com/vboard/s...d.php?t=759628 1967/71 Blue SWB C10..SOLD 1977 SWB K10..my grandpa's.....never should have sold |

|

|

|

|

|

#20 |

|

Registered User

Join Date: Jun 2012

Location: cleawater florida

Posts: 246

|

Re: Air Compressor setup in my garage help

I did my air lines in galvanized pipe. 1 1/4 off the compressor with drain at bottom. up the wall to 1 inch across roof line. every drop goes up 3" and u turns into 1/2 pipe. from there it goes down to t with fitting for line.from t goes down to valve and drain at bottom of pipe. at my water separate line I have a separator regulator at t with drain valve below it.Ive been told you can run coiled copper pipe thru a drum sitting outside full of water. supposed to drain off water and cool air. my set up dosent get water at regulator. furthest from compressor. approx. 25ft

|

|

|

|

|

|

#21 |

|

Registered User

Join Date: Apr 2014

Location: Birmingham, AL

Posts: 560

|

Re: Air Compressor setup in my garage help

Why not just use an auto-drain valve kit that is either mechanical or electric. HF sells the mechanical auto drain and it works fine.

|

|

|

|

|

|

#22 |

|

Senior Member

Join Date: Apr 2013

Location: Danvers Minnesota

Posts: 967

|

Re: Air Compressor setup in my garage help

I just installed the Maxline rapid air system in my shop it went together pretty slick. Did a loop all the around on ceiling with four drops each drop has drain. Made a zig zag coming out of compressor to water separater them up to ceiling.

__________________

1972 K10 SWB wife's driver 1967 Pontiac GTO Big Bird - 1972 Longhorn K30 http://67-72chevytrucks.com/vboard/s...d.php?t=753294 |

|

|

|

|

|

#23 | |

|

Registered User

Join Date: Oct 2007

Location: Spanaway

Posts: 8,451

|

Re: Air Compressor setup in my garage help

Quote:

__________________

Mike. Swamp Rat build thread : http://67-72chevytrucks.com/vboard/s...d.php?t=595019 72 3/4T 4X4 4" BDS Lift 33" BFG's |

|

|

|

|

|

|

#24 |

|

Senior Member

Join Date: Apr 2013

Location: Danvers Minnesota

Posts: 967

|

Re: Air Compressor setup in my garage help

I got my jump house from Northern Tool I think it was around thirty dollars

__________________

1972 K10 SWB wife's driver 1967 Pontiac GTO Big Bird - 1972 Longhorn K30 http://67-72chevytrucks.com/vboard/s...d.php?t=753294 |

|

|

|

|

|

#25 |

|

Registered User

Join Date: Oct 2007

Location: Spanaway

Posts: 8,451

|

Re: Air Compressor setup in my garage help

Thanks!

__________________

Mike. Swamp Rat build thread : http://67-72chevytrucks.com/vboard/s...d.php?t=595019 72 3/4T 4X4 4" BDS Lift 33" BFG's |

|

|

|

|

| Bookmarks |

|

|