|

Register or Log In To remove these advertisements. |

|

|

|

|||||||

|

|

|

Thread Tools | Display Modes |

|

|

#1 |

|

Registered User

Join Date: Jan 2014

Location: Kitchener,ontario

Posts: 29

|

Commonwealth '58 Apache shop truck

Hey guys, been here a little while just lurking around and reading builds. Never really commented on much. My names Jay and I'm 23 and work as a robotic weld technician as well as working on starting up my own business selling air suspension parts and custom metal fab/welding/parts. I've got a shop located in London, Ontario where I'm working on my '58 Apache. If you want to check out my website http://www.commonwealthmotoring.com that'd be cool, or "like" our facebook page https://www.facebook.com/commonwealthmotoring?_rdr=p

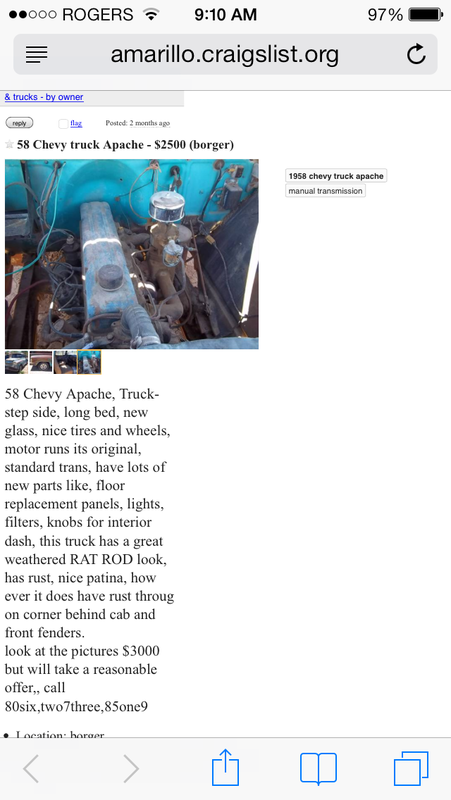

Anyways onto the truck build. I've had this truck for a little over a year now. Bought it out of Texas in January of 2014 and had it sent to Detroit in October 2014. Most of the stuff I'm posting is from an existing build thread on another forum so it may be a little out of place until I get up to date. Plans for the build: Bagged obviously 5.3 vortec with cam, intake, head work, and holley efi (enough for 400ish HP) T56 4-link Mustang II front end Original patina I've messed around with quite a few cars over the years from my first car which was a 79 Jeep Cherokee, to a couple Subarus, Volkswagens, an old rare Mercedes, and even a $500 Honda Civic. I`ve always been into old trucks and have passed up opportunities to buy something old too many times before. My dad`s first vintage truck was a 1950 Chevy 3100 that we pulled out Kentucky when I was about 12. It was the typical shop truck look. Flat black, red wheels, white walls and some leafs removed to bring it down. I always had a thing for that truck and have wanted something like it ever since. Here's the truck that started it all  When I was in my final semester of college (January 2014) I decided that I wanted to get a new project since I`d soon have the income to start a major build. Being from Canada there`s not much good old steel that`s affordable so I turned to Craigslist to find a good candidate. I spent weeks scouring listings in the southern states where rust is not common and amazing patina is on mostly everything. I was in the market for a 58-59 Apache. Preferable all there, original paint with sun baked patina, long bed step side and not completely molested. I emailed and texted everybody with a truck that met the criteria, but everything was either too expensive, too rotted, or they didn`t wanna work with helping me ship it to the Detroit border. Finally one day I stumbled upon the ONE.  All there, original patinaed paint, step side long bed, unmolested orignal 235 inline 6 and 4 speed trans. The only issue was it was in northern Texas and only had a phone number to call. I said screw the long distance charges and gave the guy a call. We talked and negotiated price and logistics and he sent me some more pics of the truck. From what I know he was the second owner and only had it for a couple years. The owner before him died in the late 90's and I believe the truck had been sitting since 1974 since that's the year the plates are dated that came on the truck. The price was right where I wanted it to be so a deal was struck. I sent money via paypal for a truck I had never seen in person to a guy I never met in hopes of owning my dream truck. This was in January 2014. A couple weeks later I had recieved the title in the mail and I was one step closer to owning the piece of old metal. The pics I recieved from the previous owner        The months after that were filled with finishing school, on again off again with a girl and finding a career. Getting the truck home was on the bottom of my priority list, but never left my mind. I landed a job as a robotic weld technician for a company that makes brakes pedal assemblies for the big three shortly after finishing school. The money was finally coming in and it was finally time to get the old girl home. After a month and half of getting the run around from shipping companies I finally had the truck delivered in Detroit on October 31st. Exporting the truck from the US was a bit of a b**** as the policies had changed since I did it last. Importing to Canada was a breeze. Pics from the day I saw it in person for the first time. Happiest ever!    So now youve probably read all this crap and you want to see some pictures of a badass bagged truck. Well sorry youre out of lucky. I moved from home to a different city an hour away from my old shop to be closer to work. This resulted in me not having much time for the truck, but finally the time has come. Just this weekend my buddies and I moved all our junk to a new shop that is 5 minutes from my apartment. This means I can finally spend some time on the truck. The plan 4-link rear and Mustang ii front end 5.3 lm7 mated to a tremec t-56 6 speed Ford 8.8 out of a Ford exploder Steelies and bias ply tires (possibly astro supremes at some point) Stockish interior (bench seat, original gauges, nothin flashy) Bagged Keep the body how it is Do burnouts Drag frame I recently purchased a big boy welder after my old 110v lincoln was stolen from the old shop. All the fab work I will be doing myself using my new to me Lincoln cv400 mig welder. Its a big sum ***** and I'm thrilled to start using it. I figured I'd start this build thread today as I spent most of the day ordering parts. The list of parts I have or have coming are Heidts Mustang II front crossmember All tabs and rod ends for 4-link Jim Weimer air bag control arms Jim Weimer 2" drop spindles Jim Weimer big brake kit Anyways on to some current pics Unloading into the new shop. You might be able to notice that I pulled most of the leafs out of the leaf packs just to get a vision of it being lower. Shoutout to my buddies Brandon and Madison killin it on the move  With my Yamaha XS400 cafe project that I hope to finish soon  When it was still at the old shop I cut out the rot in the floor and tacked in replacement panels. Then my welder was stolen and I couldnt finish the other side   So that's my story. I hope I haven't bored you guys and girls too much. I'm planning to have frequent updates to keep you guys filled in. Also check out my IG as I post a lot on there too. @jaymarshall |

|

|

|

|

|

#2 |

|

Registered User

Join Date: Jan 2014

Location: Kitchener,ontario

Posts: 29

|

Re: Commonwealth '58 Apache shop truck

April 17, 2015

Got some work done on the truck last night. Was at the shop till 4am. Got about 3 hours work in. Lifting a bed off a frame by yourself is not something I recommend, but it worked out. Best thing about patina is not worrying about scratches. Picked up parts from UPS and the post office in the morning. Heim joints, bushings, tons of tabs and frame brackets. Enough to get started on the 4 link  Pulled all the rotten original wood out of the bed. Plan to use incorporate the bigger pieces into the build just not sure what yet. Didnt get any before pics of the wood in the bed, but it was in pretty rough shape  Then since I was already there and I was on a high i figured why not hack the back of the frame off  Then had some fun with setting the bed over the wheels to see how she'll look. Will be lower after I notch the bed sides

|

|

|

|

|

|

#3 |

|

Registered User

Join Date: Jan 2014

Location: Kitchener,ontario

Posts: 29

|

Re: Commonwealth '58 Apache shop truck

April 27, 2015

Parts came in last week for the front end. Narrowed air bag control arms, 2" drop spindles and "big" brake kit. Heading out to the shop after work tonight to try and pull the front end off and maybe get the motor out of it so I can start getting the crossmember fit and start mock up.  May 12, 2015 Well got about 7 hours in on the truck last week. the first night I pulled the front fenders, hood, axle and all that stuff off the frame. Second night I pulled the motor and while doing that it was easier for me to get it out by removing the cab as well. Now it's ready to start fitting the mustang 2 crossmember and get the front rolling while I wait for the frame rails to be laser cut for the rear. Sorry for the crap Iphone pics. Need to get a decent camera one day Front end off  Probably what ride height will be. couple inches to the "rocker"   The mess of collective parts  My buddies 280 in the back that he NEEDS to finish  [/QUOTE] [/QUOTE]

Last edited by Jay92; 12-07-2015 at 10:30 PM. |

|

|

|

|

|

#4 |

|

Registered User

Join Date: Jan 2014

Location: Kitchener,ontario

Posts: 29

|

Re: Commonwealth '58 Apache shop truck

June 14, 2015

Got the mustang 2 front crossmember welded im and mocked up Friday night. Pretty straight forward. Couple measurements some welds and done.   Some "weldporn". Picked up a Lincoln cv400 for really cheap. It's the biggest mig welder Lincoln offers so I'm no longer limited by my welder. Finally got it set up last week and got it pretty dialed. Programming welding robots at work makes me appreciate and love manual welding so much more.  The lowest part on the frame is that middle tranny crossmember. With that on the ground it leaves about 2 inches at the rockers and about 3 inches at the mustang 2 crossmember. I'm gunna make a new tranny brace that will allow it to lay out fully with the stock engine/tranny  June 22, 2015 Picked up some Cragar SS's for cheap on Friday. Unsure if I'll use em yet. I'll decide once I get the body back on. I more or less got them as roller wheels, if I don't like em they'll go on my dad's 57 Bel-Air wagon. Not bad for $80 tho  I started preping the rear end last week as well. Got the leaf spring mounts ground off and the lower link mounts welded on. New frame rails should be ready this week. I'm on vacation next week so I'm going to attempt to have the rear rails welded, 4-link done and the body back on to see how she looks. Should be an exciting couple of weeks July 2, 2015 Was on vacation this week so got a decent amount of work done. not quite as much as I had wanted, but that's just how things go. Picked up the laser cut rear frame rails friday and promptly got started boxing them in. This was probably one of the harder things I've had to do. A lot of checking to make sure they were square and didn't warp when welding 72 feet of butt joint. Basically tacked the 2" flat bar on the plates then continued bending and tacking to get the curve down.   I didn't get any pics of them final welded yet. I got them tacked onto the frame and in position. The passenger side rail needs some straightening from a bit too much heat when welding, but I've got a plan. After I got them tacked on I positioned the rear end and got the lower 4link bars in position. Mounted them as high up on the frame as possible to keep them parallel to the ground at ride height. I've changed my mind on how I'm going to do the upper bars so more to come

Last edited by Jay92; 12-07-2015 at 10:31 PM. |

|

|

|

|

|

#5 |

|

Registered User

Join Date: Jan 2014

Location: Kitchener,ontario

Posts: 29

|

Re: Commonwealth '58 Apache shop truck

July 21, 2015

Took a couple weeks to take a break from the truck. The upper four link crossmember was driving me nuts and caused me to loose some motivation. Threw the cab and fenders back on and set the wheel on to see if it looked cool. It does and I found my motivation. I couldn't come up with a good idea that would look somewhat OK. First idea was to build a truss over the pumpkin and mount the arms in the center of the diff and at the frame. That wouldn't work to get the right length and angle in the upper arms. Then I thought to bend a hoop and mount the arms on the axle tubes and the center of the crossmember/hoop. That wouldn't really flow with the rest of the chassis (cuz that matters apparently). Then I came up with this 3/16" x 2" x 4" rectangle tubing, welded together and smoothed out. still need to finish the curved portion at the top and sides to give it some flow. Anyways got it all tacked up, upper and lower arms are parallel with eachother which is nice and plenty of adjustment in the heim joints for pinion angle and the axle cycles smooth through its stroke. Now that that's done time to mount bags and fully weld everything then smooth all my welds out and radius the edges.  Threw some roller wheels on from my buddies old ls400. Needs tall bias ply tires for sure.  July 25, 2015 Threw the body back on and rolled the ol' girl outside today. It's set pretty much at my desired right height. So happy with it right now.

|

|

|

|

|

|

#6 |

|

Registered User

Join Date: Jan 2014

Location: Kitchener,ontario

Posts: 29

|

Re: Commonwealth '58 Apache shop truck

November 11, 2015

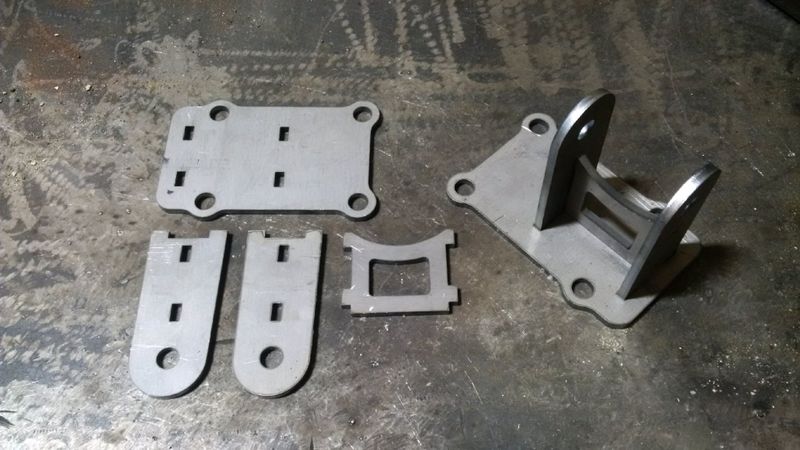

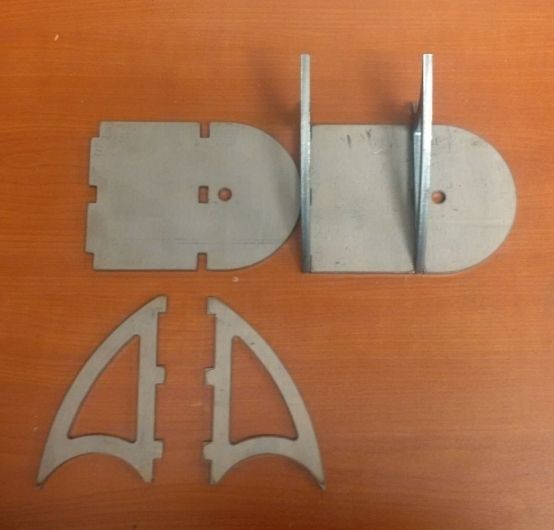

It's been a couple months since I updated this build. Been busy with life and haven't had much time to get into the shop, but I think things have slowed down a bit and I've got some parts collected to get more done. So in the past couple months I sold my broken STi swapped Impreza that's been taking up space for a couple years now  Also did a good clean of the shop after the subie went and been helping my buddy with his 280z. Just a chevy 305/T5 combo to shred some tires with. It's actually pretty close to running now so watch for that.   Took some scrap metal back and loaded up the beer fridge with some adult pops  And the last few weeks I've been helping another buddy with his Forester XT. Manual swap, bagged and Work Euroline DH. Still needs some adjusting to go lower, but it's almost there. Sorry for the ****ty pic.  And recently I`ve also been working on designing some parts and getting them laser cut for the truck. Have the upper and lower rear bag mounts cut out and ready to weld and just finished off these LS motor mounts I`m working on These will be going up for sale on my webstore that I`m working on. They`ll be sold with a bushing and brackets to be used as a universal weld in kit, as well as the bag mounts.    Had a chance to TIG weld the rear lower bag mounts tonight. Interlocking the parts like lego really makes it easy to get everything in position   And some amateur weld porn

|

|

|

|

|

|

#7 |

|

Registered User

Join Date: Jan 2014

Location: Kitchener,ontario

Posts: 29

|

Re: Commonwealth '58 Apache shop truck

December 3, 2015

Small update til I get a bunch done on the weekend. Finally got the rear portion of the frame straightened out that tweaked when I welded it. That had been bugging me for a while and stopping me from progressing. Got the rear crossmember welded in as well. No pics of this yet. Also cut out the stock tranny crossmember and notched the control arms where they where hitting the mustang 2 crossmember. This brought the truck down a good 2-3" and now lays body.  Made some front upper bag plates and got the front bags in place. Had to cut the upper strut mount out to make way for the bag plate. Tacked em in and got them to the same angle as the lower control arms when slammed out. Also made some mock up bag blocks out of some aluminum. That way I can set the height of the bag brackets so that the bag isn't fully deflated when aired out and able to have some pressure to roll as low as possible. More on those later.   Planning to get the rear bag mounts in place this weekend and possibly start getting the engine in place. As well as roll it outside to get one last good look at it before winter hits. AND WE'RE UP TO DATE December 4, 2015 Got the rear bags in on friday night and pushed the truck outside. Then rearranged the shop and cleaned up so I can start getting the engine in. Rear crossmember for the upper bag mounts is 3/16"x2" DOM tube. Should be enough to hold the weight. Here you can see the mock up bag blocks. 3.5" blocks of aluminum. Set the chassis at the lowest it will sit at and the axle to 15.5" to account for the 31" tall bias ply tires. If my math is correct there will be .8" left before the bags fully bottom out when the truck is aired out. This way I can have some air in the bag and still roll as low as possible.   Got all that tacked on and installed the bags to test it out. Hooked up some fittings and air line to cycle it with a little compressor.    And a short vid of the rear working. Front works as well, but need to get ss-6 bags as the air house 1's I had laying around are too short. https://www.facebook.com/video.php?v=773958122710596 |

|

|

|

|

|

#8 |

|

Registered User

Join Date: Jan 2014

Location: Kitchener,ontario

Posts: 29

|

Re: Commonwealth '58 Apache shop truck

Now that we're up to date I'm planning on getting the engine in place this week as well as designing a new 4-link crossmember and hacking out the one that's in there right now. I want to get one laser cut like how the frame rails are done so everything kinda flows with eachother.

__________________

Commonwealth Shop truck build, bagged, 4-link, LS 58 Apache Commonwealth http://www.commonwealthmotoring.com/ Air ride and custom parts IG - Commonwealth_mf FB - https://facebook.com/commonwealthmotoring |

|

|

|

|

|

#9 |

|

Registered User

Join Date: Oct 2009

Location: Marysville KS

Posts: 105

|

Re: Commonwealth '58 Apache shop truck

Looks good, Subscribed

|

|

|

|

|

|

#10 |

|

Registered User

Join Date: Aug 2007

Location: Corona, California

Posts: 7,998

|

Re: Commonwealth '58 Apache shop truck

Very nice looking build.

Kim |

|

|

|

|

|

#11 |

|

Registered User

Join Date: Jan 2014

Location: Kitchener,ontario

Posts: 29

|

Re: Commonwealth '58 Apache shop truck

Thanks guys!

__________________

Commonwealth Shop truck build, bagged, 4-link, LS 58 Apache Commonwealth http://www.commonwealthmotoring.com/ Air ride and custom parts IG - Commonwealth_mf FB - https://facebook.com/commonwealthmotoring |

|

|

|

|

|

#12 |

|

Registered User

Join Date: Jan 2014

Location: Kitchener,ontario

Posts: 29

|

Re: Commonwealth '58 Apache shop truck

__________________

Commonwealth Shop truck build, bagged, 4-link, LS 58 Apache Commonwealth http://www.commonwealthmotoring.com/ Air ride and custom parts IG - Commonwealth_mf FB - https://facebook.com/commonwealthmotoring |

|

|

|

|

|

#13 |

|

A320 Pilot/USAF Retired

Join Date: Mar 2009

Location: Charleston, SC

Posts: 2,629

|

Re: Commonwealth '58 Apache shop truck

Cool build!

__________________

JJ My 1957 build: http://67-72chevytrucks.com/vboard/s...d.php?t=334552 http://www.trifive.com/forums/showthread.php?t=22037 Instagram - Chuckdriver57 |

|

|

|

|

|

#14 |

|

Registered User

Join Date: Oct 2014

Location: Kitchener, Ontario, Canada

Posts: 3,254

|

Re: Commonwealth '58 Apache shop truck

Welcome neighbor. Sounds fun. Nice work on the frame and suspension.

__________________

http://67-72chevytrucks.com/vboard/s...d.php?t=648459 https://67-72chevytrucks.com/vboard/...d.php?t=769441 1951 MG TD 1967 Jeep CJ5 1.9L TDI 33X13.5X15 Mud Grapplers. 1952 GMC 9700 p/u 7.3L diesel on air, dually |

|

|

|

|

|

#15 | |

|

Registered User

Join Date: Jan 2014

Location: Kitchener,ontario

Posts: 29

|

Re: Commonwealth '58 Apache shop truck

Quote:

Engine mounts are done and tacked in place. 3/16"x1" DOM tube to a 2" tube with a rubber bushing inserted and bolted to the engine side motor mounts. Pretty simple design and I'll add some gusseting between the tubes. The drivers side will need some room for the steering shaft to go through.   The truck intake wont be staying and will be getting swapped out when the engine is built  Good amount of clearance at the firewall. Tons of room for the engine, but the floor will need some work to fit the T56.  Been busy with the holidays so haven't had much time to work on the truck lately. Plus it's finally starting to get cold so hopefully once we get heat in the shop I'll have more drive to go work on it for more than an hour. I got my bias ply tire mounted on the cragars and they look so much better than the previous radials. I'm thinking I'll get two more cragars for the front and run those for a while.  A really good friend of mine finally purchased an old vehicle after months of searching and figuring out what he wants. He picked up a 1966 Chevy C10, that came with a 6.0l vortec and 4l60e for a steal. He came to me to build the truck for him and wants it on the road come spring. It'll be getting a full back half 4-link much like mine, air ride, LS and being converted to short bed. We'll start up a build thread for that once we really start getting into it.  My brother was down from Thunder Bay for the holidays and took some shots of the truck that aren't Iphone quality. Enjoy!

__________________

Commonwealth Shop truck build, bagged, 4-link, LS 58 Apache Commonwealth http://www.commonwealthmotoring.com/ Air ride and custom parts IG - Commonwealth_mf FB - https://facebook.com/commonwealthmotoring |

|

|

|

|

|

|

#16 |

|

Registered User

Join Date: Aug 2007

Location: Corona, California

Posts: 7,998

|

Re: Commonwealth '58 Apache shop truck

Nice progress.

Looks good. Kim |

|

|

|

|

|

#17 |

|

Registered User

Join Date: Oct 2014

Location: Kitchener, Ontario, Canada

Posts: 3,254

|

Re: Commonwealth '58 Apache shop truck

That's going to be a wicked truck. Your friend is getting you to build his truck does that mean yours is on hold?

__________________

http://67-72chevytrucks.com/vboard/s...d.php?t=648459 https://67-72chevytrucks.com/vboard/...d.php?t=769441 1951 MG TD 1967 Jeep CJ5 1.9L TDI 33X13.5X15 Mud Grapplers. 1952 GMC 9700 p/u 7.3L diesel on air, dually |

|

|

|

|

|

#18 | |

|

Registered User

Join Date: Jan 2014

Location: Kitchener,ontario

Posts: 29

|

Re: Commonwealth '58 Apache shop truck

Quote:

I finally put a deposit down on a T56 so I have to go pick that up in the states soon. Once I have that I can get the trans member done and that will be the last main piece needed for the chassis. Then everything will be sent for powder coat

__________________

Commonwealth Shop truck build, bagged, 4-link, LS 58 Apache Commonwealth http://www.commonwealthmotoring.com/ Air ride and custom parts IG - Commonwealth_mf FB - https://facebook.com/commonwealthmotoring |

|

|

|

|

|

|

#19 |

|

Registered User

Join Date: Jan 2014

Location: Kitchener,ontario

Posts: 29

|

Re: Commonwealth '58 Apache shop truck

Been a while since an update, but I've been working on the truck almost every night after work. I'm getting it ready for the Speed and Custom show later this weekend in London. It wont be running for the show, but It'll be mostly assembled. After the show I'll be tearing it all down for final welding then paint/powder coat and working to get it running for Eurokracy in June.

At the start of Feb I finally went to Rochester, New York to pick up a T56. Had some rad BBQ and a couple cold ones   Unfortunately the bellhousing I had order and sent to Buffalo was on back order and didn't arrive until the week after. So another quick trip to the boarder to pick it up and then back to getting the trans in to get a look of where it'll sit in the frame.   Somewhere in that time I had also tackled the rust in the passenger side floor. Cut my patch panel a little short, but that`s what welders are for  And a shot of the truck and the Z together  Then a lost a week of work to go relax in St. Lucia for my birthday in late February. Saw some pretty cool cars down there that you don`t see in Canada  Would definitely roll around in one of these as a daily  Back home and back to work. I decided on boxing the frame to give it some more strength. On top of that the original trans crossmember and leaf spring mounts had to be removed from the frame. This is no easy task when everything is riveted in place. After a couple of hours, plenty of zip disks and a couple broken drill bits I was left with this mess.  To box the frame I used 3/16" sheet and got it cut to just fit into the frame. Forgot to get pics of this but it's pretty self explanatory. Next was getting the new trans crossmember fit up. I had my machinist at work make up some slugs to be welded into the frame for the crossmember to bolt to. This way the frame wont distort when tightening the bolts. The slugs were 1" OD and 1/2" ID. Took some time to cut out the 1" holes for the slugs with a hole saw, but it got done. Made some plates for the ends and a bracket for the trans to sit on and welded it to a piece of 2" DOM tubing and it's done.   Tossed the cab back on to see what parts of the floor needed to be cut to fit the t56. Only needed to take some off the front of the trans tunnel and some off the rear. And you can see the finished product of the passenger side floor patch   The floor will still need some clearancing for the driveshaft as you can see it's pretty close at the input. I'm toying with the idea of a 2 piece drive shaft to make life a little easier  This brings us to the last week or so of work on the truck and the last of the stock crossmembers to be removed. Once again another hour or so went into getting the stock engine crossmember out to make room for the new steering rack. Cut that ***** in half and throw it in the scrap pile  With the new steering rack going in, the frame had to be notched so the tie rods have clearance when it's aired out. Drilled some holes  Cut some ****  Fit up of the notches wasn't great, but it can be filled in with weld  And final product  While I was working on that portion of the truck I made some gussets to go between the upper control arm mounts and the bag brackets  Since I wanted to retain the stock location of the master cylinder (under the drivers floor), yet wanted to upgrade to power brakes I had to make up a bracket for the assembly. I could have bought a bracket, but it would have needed some work to get it to work with the boxed frame. Also we make brake pedal assemblies at my work so it seemed fitting that I make it myself. Using the stock pedal arm I made the bracket to weld to the frame and hold the arm in position. Along with a machined pivot pin and clevis, cuz theres no point buying a clevis when you can just machine one.     That brings us to today and the truck nowhere near completion and 4 more days until it`s first show.

__________________

Commonwealth Shop truck build, bagged, 4-link, LS 58 Apache Commonwealth http://www.commonwealthmotoring.com/ Air ride and custom parts IG - Commonwealth_mf FB - https://facebook.com/commonwealthmotoring |

|

|

|

|

|

#20 |

|

Registered User

Join Date: Oct 2014

Location: Kitchener, Ontario, Canada

Posts: 3,254

|

Re: Commonwealth '58 Apache shop truck

Good luck at the show.

__________________

http://67-72chevytrucks.com/vboard/s...d.php?t=648459 https://67-72chevytrucks.com/vboard/...d.php?t=769441 1951 MG TD 1967 Jeep CJ5 1.9L TDI 33X13.5X15 Mud Grapplers. 1952 GMC 9700 p/u 7.3L diesel on air, dually |

|

|

|

|

|

#21 |

|

Registered User

Join Date: Aug 2007

Location: Corona, California

Posts: 7,998

|

Re: Commonwealth '58 Apache shop truck

Making good progress.

Looks good. Hope you make it. Kim |

|

|

|

|

|

#22 |

|

Registered User

Join Date: Jan 2014

Location: Kitchener,ontario

Posts: 29

|

Re: Commonwealth '58 Apache shop truck

Thanks guys!

__________________

Commonwealth Shop truck build, bagged, 4-link, LS 58 Apache Commonwealth http://www.commonwealthmotoring.com/ Air ride and custom parts IG - Commonwealth_mf FB - https://facebook.com/commonwealthmotoring |

|

|

|

|

|

#23 |

|

Registered User

Join Date: Dec 2010

Location: NH or WY

Posts: 33

|

Re: Commonwealth '58 Apache shop truck

Are you planning on moving the T56 shifter forward? There's kit's made to relocate it to the inspection plate, which would be a much better position for the truck. That way you won't be whacking your elbow on the back wall of the cab when shifting gears!

http://www.performancetrucks.net/for...nstall-485277/ |

|

|

|

|

|

#24 |

|

Registered User

Join Date: Mar 2015

Location: Morada, CA --- (Near Lodi)

Posts: 1,443

|

Re: Commonwealth '58 Apache shop truck

Thats coming along real nice - like all the custom bracket work and stuff you are doing to it, thats what makes things "special"!

On your shifter, you may save yourself a whole lot of 'retrofit headache' and just make up some kind of cool custom bent shifter arm.... this guys got it down!!! http://youtu.be/8lEYaTvvq4g

__________________

My Build: 57 Chevy Pro-Street |

|

|

|

|

|

#25 |

|

Registered User

Join Date: Jan 2014

Location: Kitchener,ontario

Posts: 29

|

Re: Commonwealth '58 Apache shop truck

I've been thinking of ways to move the shifter forward. Thought about the mid shift kit, but I may attempt to come up with my own idea first. Something that bolts to where the mid shift would go with a cup and ball, then a shaft that runs to the stock shifter.

__________________

Commonwealth Shop truck build, bagged, 4-link, LS 58 Apache Commonwealth http://www.commonwealthmotoring.com/ Air ride and custom parts IG - Commonwealth_mf FB - https://facebook.com/commonwealthmotoring |

|

|

|

|

| Bookmarks |

|

|