|

Register or Log In To remove these advertisements. |

|

|

|

|||||||

|

|

|

Thread Tools | Display Modes |

|

|

#1 |

|

Registered User

Join Date: Sep 2018

Location: Blissfield MI

Posts: 252

|

Advice needed pls. Setting engine/trans

Ok so Im trying to set my engine and trans in my 56 GMC. Engine is sbc 350 and trans is 700r4. I bought an after market tubular mounting kit for both the engine and trans. I have a ton of questions but Iíll try to keep it to a minimum. Just interested in knowing what yaíll did or had to do to make it work.

1) did you use an electric fan? 2) did you move rad support out towards the front in where I think it would be if it had a straight 6. 3) whatís considered level for the engine? Is that a thing? The intake or valve covers or ? 4) did you have to cut anything to make it fit right? Like the original trans crossmember? 5) when I replaced the rearend we put it at 4 degrees because thats what I kept reading it should be. What degree should the trans be? Rear is out of a 76 trans am. Not that it matters in reference to the question. The truck was barely together when I got it. Some of it was literally held together with wire and lots of things missing. It sat for 20 yrs in a field in Montana. Iíll try to attach some photos Thanks in advance for any help you can give Posted via Mobile Device |

|

|

|

|

|

#2 | |

|

Registered User

Join Date: Sep 2018

Location: Blissfield MI

Posts: 252

|

Quote:

Last edited by Rickysnickers; 05-03-2022 at 10:01 AM. |

|

|

|

|

|

|

#3 |

|

Registered User

Join Date: Jan 2012

Location: Motown

Posts: 7,680

|

Re: Advice needed pls. Setting engine/trans

55-59 gm trucks came with sbc, so going back with sbc is easy peasy. my 58 truk has the motor in the same spot as it came from the factory, but the 700r4 required minor floor cover mods to bring the tail shaft up. 55-57 is a little different than the 58-9 but i have a lot of room between the fan and pulley.

i also built a structural trans mount to replace the stock trans xmember. if you cut out the stock trans mount you need to build a substantial xmember to support the cab and spring mounts. orrieg has a 350/350 and kept the trans xmember. as for angles, it's gonna be what's it's gonna be. chances are the angles will match, typically the diff angle matches the motor angle, cuz the motor angle is fixed. read orrieg's build, my build, other builds, etc...

__________________

cool, an ogre smiley  Ogre's 58 Truk build Ogre's 58 Truk buildhow to put your truck year and build thread into your signature shop air compressor timer |

|

|

|

|

|

#4 | |

|

Registered User

Join Date: Sep 2018

Location: Blissfield MI

Posts: 252

|

Quote:

Posted via Mobile Device |

|

|

|

|

|

|

#5 |

|

Registered User

Join Date: Jul 2007

Location: Toppenish, WA

Posts: 15,815

|

Re: Advice needed pls. Setting engine/trans

The good and the bad, a six cylinder radiator mounts a few inches (the TF guys will have to say how many) in front of where the V8 radiator sat. I'm thinking that there is a stamped sheet metal spacer that moves the V8 radiator back. At any rate that gives you all the room you want for just about as big a fan as you want and plenty of room for a clutch fan. It also gives you a little wiggle room in your favor to mount the engine and trans. I'd figure in enough room to clear the HEI if you are running an HEI, If memory serves right with the engine in the stock V8 position there isn't much room for an HEI in front of the firewall. My 57 panel was a V8 swap into a six cylinder truck using the cast iron V8 bellhousing and 3 speed from the six.

__________________

Founding member of the too many projects, too little time and money club. My ongoing truck projects: 48 Chev 3100 that will run a 292 Six. 71 GMC 2500 that is getting a Cad 500 transplant. 77 C 30 dualie, 454, 4 speed with a 10 foot flatbed and hoist. It does the heavy work and hauls the projects around. |

|

|

|

|

|

#6 |

|

Senior Member

Join Date: Apr 2017

Location: Suwanee GA

Posts: 276

|

Re: Advice needed pls. Setting engine/trans

Couple of thoughts you may want consider. I did this in our 56.

Move the engine forward a little this give more clearance for transmission and did not have do do any firewall or transmission cover changes. 6.0 with 6l90 trans. nice this as said before that this truck had a small block option so your rad, front clip should not have to move. Move the engine to the passenger side a 3/4 to a inch. Modified the mount with extra holes This gave me a lot more clearance to work with manifolds and power steering( or manual) steering box inside the frame rail in stock location. its all about pinion angles and clearance. once its in its not moving. So mock in all you stuff your planning to do before full mounting. The motor should already be the correct angle but you have some room to work with in a few degrees with your trans mount if needed. same for rear with shim adjustments. |

|

|

|

|

|

#7 |

|

Registered User

Join Date: Nov 2010

Location: calgary alberta

Posts: 8,486

|

Re: Advice needed pls. Setting engine/trans

like ogre said, they came with a small block so the mount part is easy for the engine.

mock up the engine angle and fab a cross member. make it a tad low so if anything you will need to shim the trans mount to get the right angle. if the cross member is too high then you gotta re-do that if the angle needs to change. remember the mount will squish a bit with the trans weight added. leave room for the exhaust and any other stuff you may want under there. |

|

|

|

|

|

#8 | |

|

Registered User

Join Date: Jan 2012

Location: Motown

Posts: 7,680

|

Re: Advice needed pls. Setting engine/trans

Quote:

the shroud is maybe an inch thick. you can see the trans cooler lines here coming straight down the oil pan. no flex lines needed this way vs going to the frame like a lot of guys do. i have the fan temp sensor in the lower radiator hose.

__________________

cool, an ogre smiley  Ogre's 58 Truk build Ogre's 58 Truk buildhow to put your truck year and build thread into your signature shop air compressor timer |

|

|

|

|

|

|

#9 | |

|

Registered User

Join Date: Sep 2018

Location: Blissfield MI

Posts: 252

|

Quote:

So you are saying I should be able to leave the rad support in the V8 spot and not have to move it forward to the 6 cyl position? My biggest question is can these trucks have a 700r4 in them and not have to get out a cutting wheel? We are trying to get it to fit around the original trans crossmember without cutting into it. My frame is completely stock (my preference). It has already been cleaned, painted and all wearable parts replaced. Cab is set. Im hoping I dont have to fab up a different crossmember. Ppl have got to have put 700r4s in these trucks and would know if itís possible without cutting stuff Posted via Mobile Device |

|

|

|

|

|

|

#10 |

|

Registered User

Join Date: Jan 2012

Location: Motown

Posts: 7,680

|

Re: Advice needed pls. Setting engine/trans

technically gmc trucks did not come with sbc, but you get the idea

__________________

cool, an ogre smiley  Ogre's 58 Truk build Ogre's 58 Truk buildhow to put your truck year and build thread into your signature shop air compressor timer |

|

|

|

|

|

#11 |

|

Registered User

Join Date: Jul 2007

Location: Toppenish, WA

Posts: 15,815

|

Re: Advice needed pls. Setting engine/trans

In truth the 55-1/2 though 59 frames have a lot more room in the engine area than the 48/55.1 or the 60/87 frames do.

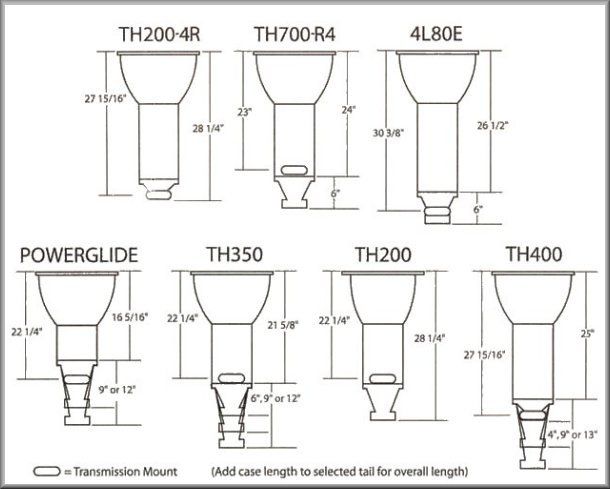

The six cylinder radiator placement lets you mount the V8 just enough ahead of the stock V8 location when you are running an automatic so you can have clearance without mods. One thought is that if you are running the stock rear axle and drive shaft swap yokes to fit the transmission and set your engine and trans in to get that fit correct and go from there. That would save the hassle and expense of getting a new driveshaft. This chart compares most GM automatics that a Chevy/GMC pickup builder might use and should help a bunch. http://www.crateenginedepot.com/pdfs...Dimensions.pdf While I was at it I found these charts. This one for guys running a GM overdrive trans .png?width=960&height=720&fit=bounds) This one is a ball park measurement comparison that gives a quick idea of the differences in length and size. It's been around for years

__________________

Founding member of the too many projects, too little time and money club. My ongoing truck projects: 48 Chev 3100 that will run a 292 Six. 71 GMC 2500 that is getting a Cad 500 transplant. 77 C 30 dualie, 454, 4 speed with a 10 foot flatbed and hoist. It does the heavy work and hauls the projects around. |

|

|

|

|

|

#12 |

|

Senior Member

Join Date: Oct 2014

Location: Eagle, ID

Posts: 3,137

|

Re: Advice needed pls. Setting engine/trans

Short answer. Yes, a 700r4 can be put in your truck w/o any cutting, unless you want a floor shifter.

|

|

|

|

|

|

#13 | |

|

Registered User

Join Date: Sep 2018

Location: Blissfield MI

Posts: 252

|

Quote:

As far as the rear end, I switched it to one that came out of a 76 trans am. Wheel spacing was above 1/2Ē different I think from bavking plate to backing plate. Thanks again Posted via Mobile Device |

|

|

|

|

|

|

#14 | |

|

Registered User

Join Date: Sep 2018

Location: Blissfield MI

Posts: 252

|

Quote:

Thank you! Posted via Mobile Device |

|

|

|

|

|

|

#15 |

|

Registered User

Join Date: Jul 2007

Location: Toppenish, WA

Posts: 15,815

|

Re: Advice needed pls. Setting engine/trans

It takes a bit of jockeying and you might have to set the crank centerline a few frog hairs lower than the crank centerline of the six was to get the trans to clear without mods but it can be done. Or you may just have to modify the trans cover a bit and not the floor or firewall if you work it right.

I'd consider working from the trans mount to the front rather than trying to get the motor mounts set and then figure out the transmission mount. You might want to mock up a transmission crossmember by clamping a board or piece of channel or what ever angle or tubing you have available that is long enough to use and set the engine and trans in and mock up where you want the trans to be. You might have to use something as a spacer to lower the mockup crossmember a bit. you really aren't gong to set a lot of weight on it but it need to be somewhat solid so you can figure out how high you want the engine in the front. Then it is either draw up the plans to fab a crossmember or shop though the universal transmission crossmember listings to find one that has the right drop aka right height for the trans mount to bolt to..

__________________

Founding member of the too many projects, too little time and money club. My ongoing truck projects: 48 Chev 3100 that will run a 292 Six. 71 GMC 2500 that is getting a Cad 500 transplant. 77 C 30 dualie, 454, 4 speed with a 10 foot flatbed and hoist. It does the heavy work and hauls the projects around. |

|

|

|

|

|

#16 | ||

|

Registered User

Join Date: Jan 2012

Location: Motown

Posts: 7,680

|

Re: Advice needed pls. Setting engine/trans

Quote:

Quote:

the truck is a I6 truck unless the vin starts with a V, chevy vin anyway the 6cyl core support is already in the forward position i'm not that familiar with 56 gmc, so correct me if i'm wrong

__________________

cool, an ogre smiley  Ogre's 58 Truk build Ogre's 58 Truk buildhow to put your truck year and build thread into your signature shop air compressor timer |

||

|

|

|

|

|

#17 |

|

Registered User

Join Date: Nov 2010

Location: calgary alberta

Posts: 8,486

|

Re: Advice needed pls. Setting engine/trans

I see in a previous pic, post 2, that you have a tubular cross member under the engine with the mounts attached to that. if that is movable, without the fear of the solid axle crushing things when the truck goes over a bump, maybe drop the engine enough to have clearance for the trans on the firewall/floor transition area. keep an eye on the engine angle so you can get the angle you need. a lot of guys use the 2-3 deg down at the rear angle, especially if you have a carbed engine (maybe stick a level on the carb mount area of the intake manifold with the truck sitting on it's wheels at ride height etc), so the carb stays level at ride height. mock it up and see how it looks. otherwise maybe a different set of engine mounts is possible instead of the tube under the engine type or maybe the tube could be modified so it doesn't hang so low? it does make a decent oil pan protector.....

|

|

|

|

|

|

#18 |

|

Registered User

Join Date: Nov 2010

Location: calgary alberta

Posts: 8,486

|

Re: Advice needed pls. Setting engine/trans

modifying the trans cover on the floor is a relatively simple task and something that can easily be replaced with a stock cover later should the need arise. they are just flat on the AD trucks, correct?

|

|

|

|

|

|

#19 | |

|

Registered User

Join Date: Sep 2018

Location: Blissfield MI

Posts: 252

|

Quote:

Posted via Mobile Device |

|

|

|

|

|

|

#20 | |

|

Registered User

Join Date: Sep 2018

Location: Blissfield MI

Posts: 252

|

Quote:

Posted via Mobile Device |

|

|

|

|

|

|

#21 | |

|

Registered User

Join Date: Sep 2018

Location: Blissfield MI

Posts: 252

|

Quote:

Posted via Mobile Device |

|

|

|

|

|

|

#22 | |

|

Registered User

Join Date: Sep 2018

Location: Blissfield MI

Posts: 252

|

Quote:

Posted via Mobile Device |

|

|

|

|

|

|

#23 |

|

Registered User

Join Date: Jan 2012

Location: Motown

Posts: 7,680

|

Re: Advice needed pls. Setting engine/trans

as much cutting, measuring and welding that's required for those $$$ kits

they're often chosen for convenience, but it's better and easier to build your own most of them leave a lot to be desired in the strength department

__________________

cool, an ogre smiley  Ogre's 58 Truk build Ogre's 58 Truk buildhow to put your truck year and build thread into your signature shop air compressor timer |

|

|

|

|

|

#24 |

|

Registered User

Join Date: Oct 2018

Location: DeKalb, IL

Posts: 163

|

Re: Advice needed pls. Setting engine/trans

as far as drivetrain angle is concerned, it somewhat depends if you are carbureted or fuel injected. 3 degrees down angle on the crank should bring the carburetor flange on the manifold level. that is what was expected in the original mounting. if you are fuel injected it really doesn't matter but 3 degrees is a good starting point.

|

|

|

|

|

|

#25 |

|

Registered User

Join Date: Nov 2010

Location: calgary alberta

Posts: 8,486

|

Re: Advice needed pls. Setting engine/trans

yeah, thats what I was thinking too, about the fuel injection part angle not as critical. looks like a 350 carbed engine is going in so the 3 deg down at the rear would be good. carb will be level as long as the rake angle is also level. it's why I always recommend to put the truck on stands high enough off the ground so you can work under it, level side to side and at the rake angle desired, place the stands or blocks where they will be strong to hold the weight of the unit without a teeter totter effect but not in the way for the jobs needed, then build around that. when done the suspension may need to be tweaked once the unit is put back on the ground. I use some modified jack stands with good sized threaded rod in place of the movable part of the stand. at the end of the rod I have welded on a 3/8 bolt which can usually be placed up through an existing hole in the frame and then bolted down. a jam nut on the stand end of the threaded rod keeps the rod from self adjusting.

attached a pic you can sorta see the stand in the background. the flat tabs on the frame are for the engine mounting supports. I used a set of 2000 camaro clamshell mounts and exhaust manifolds and built connector parts from flat plate to connect the dots. they are easily unbloted for a quick engine removal without a bunch of stuff in the way, or replaced with different connector plates should the engine choice change. one pic shows the plates bolted to the frame, the white tube is where the steering shaft fits through. maybe help somebody lurking here if nothing else. not trying to jack your thread |

|

|

|

|

| Bookmarks |

|

|